Black Masterbatches Market Report

Published Date: 02 February 2026 | Report Code: black-masterbatches

Black Masterbatches Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the Black Masterbatches market, examining market size, growth trends, segment performance, and regional insights. It covers forecasts from 2023 to 2033, offering valuable data for stakeholders and industry players.

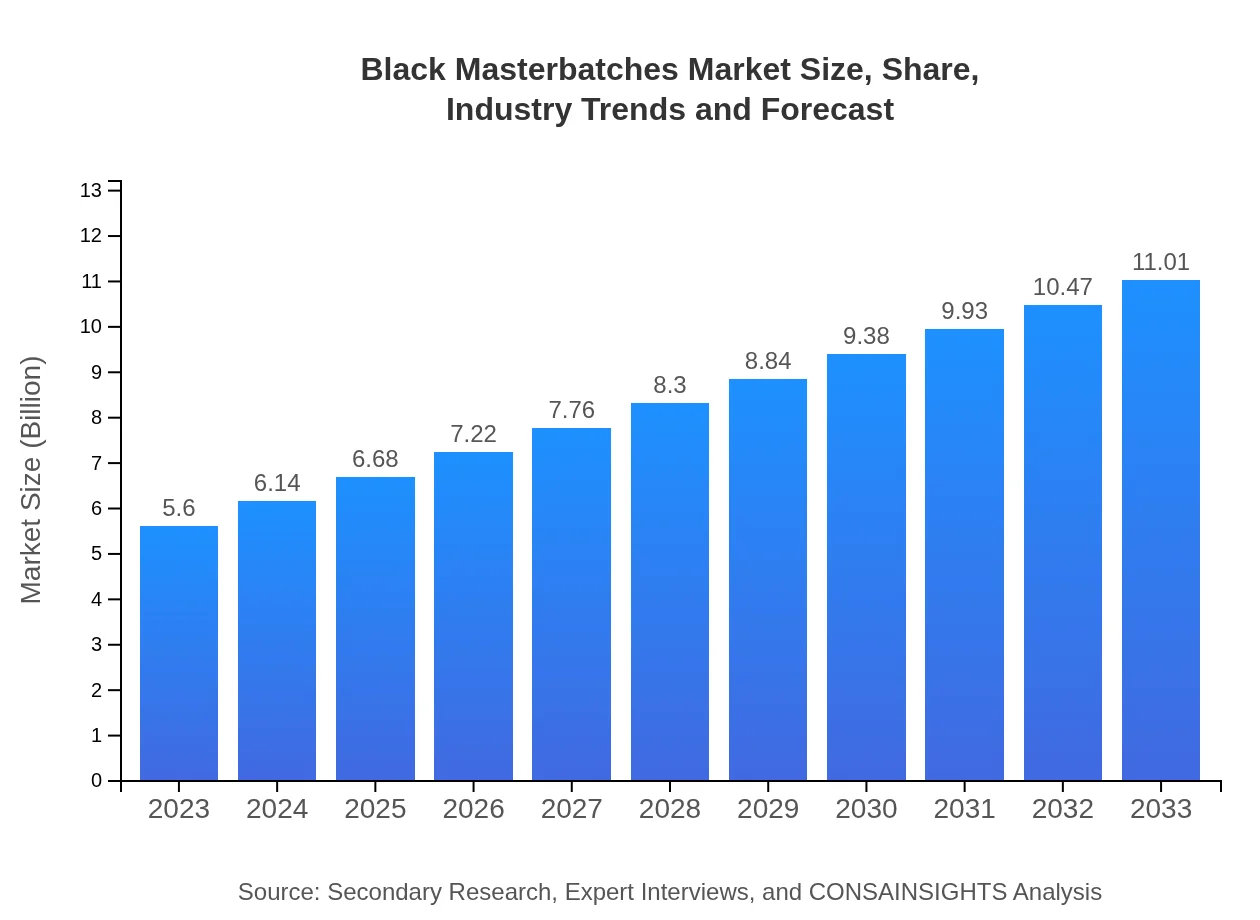

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $5.60 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $11.01 Billion |

| Top Companies | Cabot Corporation, Clariant AG, A. Schulman, Inc., BASF SE, Tosaf Compounds Ltd. |

| Last Modified Date | 02 February 2026 |

Black Masterbatches Market Overview

Customize Black Masterbatches Market Report market research report

- ✔ Get in-depth analysis of Black Masterbatches market size, growth, and forecasts.

- ✔ Understand Black Masterbatches's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Black Masterbatches

What is the Market Size & CAGR of Black Masterbatches market in 2023?

Black Masterbatches Industry Analysis

Black Masterbatches Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Black Masterbatches Market Analysis Report by Region

Europe Black Masterbatches Market Report:

Europe’s market is expected to rise from $1.42 billion in 2023 to $2.80 billion by 2033, as regulations promoting the use of high-quality and sustainable materials continue to gain traction.Asia Pacific Black Masterbatches Market Report:

In the Asia Pacific region, the Black Masterbatches market is anticipated to grow from $1.10 billion in 2023 to approximately $2.17 billion by 2033, fueled by rapid industrialization, urbanization, and rising automotive production.North America Black Masterbatches Market Report:

North America exhibits robust growth, with projections of increasing from $1.92 billion in 2023 to $3.76 billion by 2033, primarily due to a significant rise in consumer goods and automotive applications.South America Black Masterbatches Market Report:

The South American market is expected to expand from $0.55 billion in 2023 to $1.09 billion by 2033, driven by growth in the construction industry and increased adoption of sustainable packaging.Middle East & Africa Black Masterbatches Market Report:

The Middle East and Africa’s market is projected to grow from $0.60 billion in 2023 to $1.19 billion by 2033, supported by increasing investments in construction and manufacturing sectors.Tell us your focus area and get a customized research report.

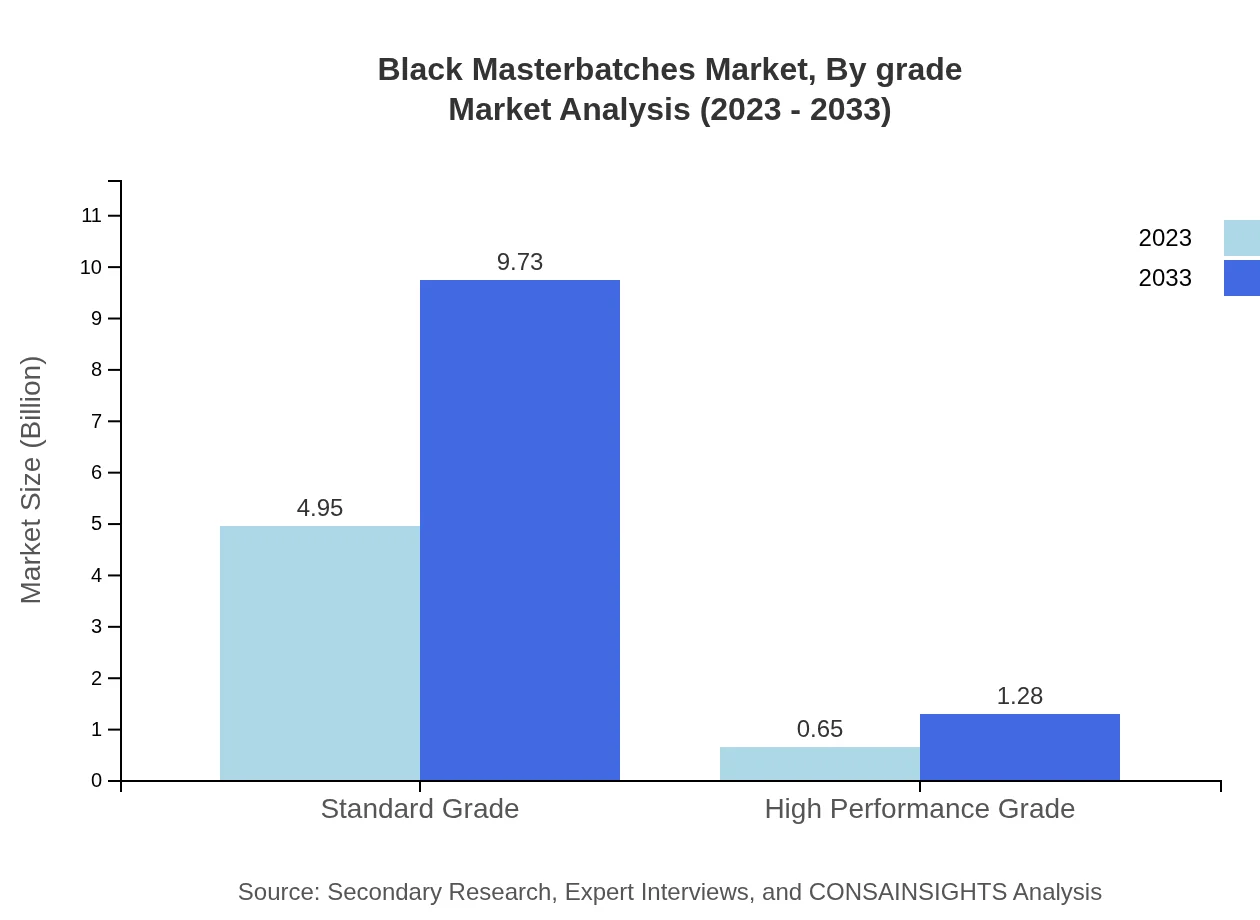

Black Masterbatches Market Analysis By Grade

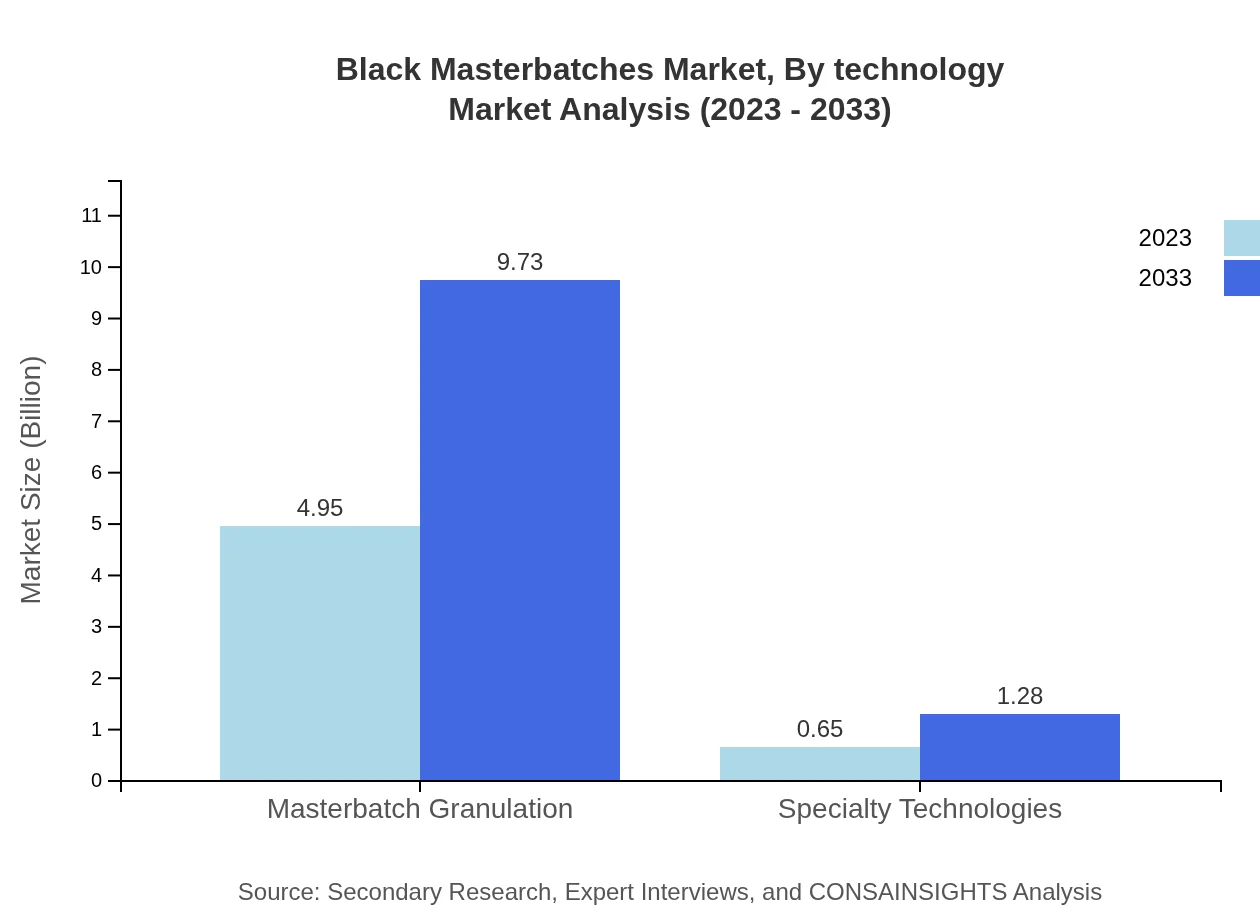

The Black Masterbatches Market is primarily divided into Standard and High-Performance Grades. Standard Grade is projected to dominate, growing from $4.95 billion in 2023 to $9.73 billion by 2033, holding 88.41% of the market share. In contrast, High-Performance Grade, while smaller, is expected to increase from $0.65 billion to $1.28 billion, retaining an 11.59% share.

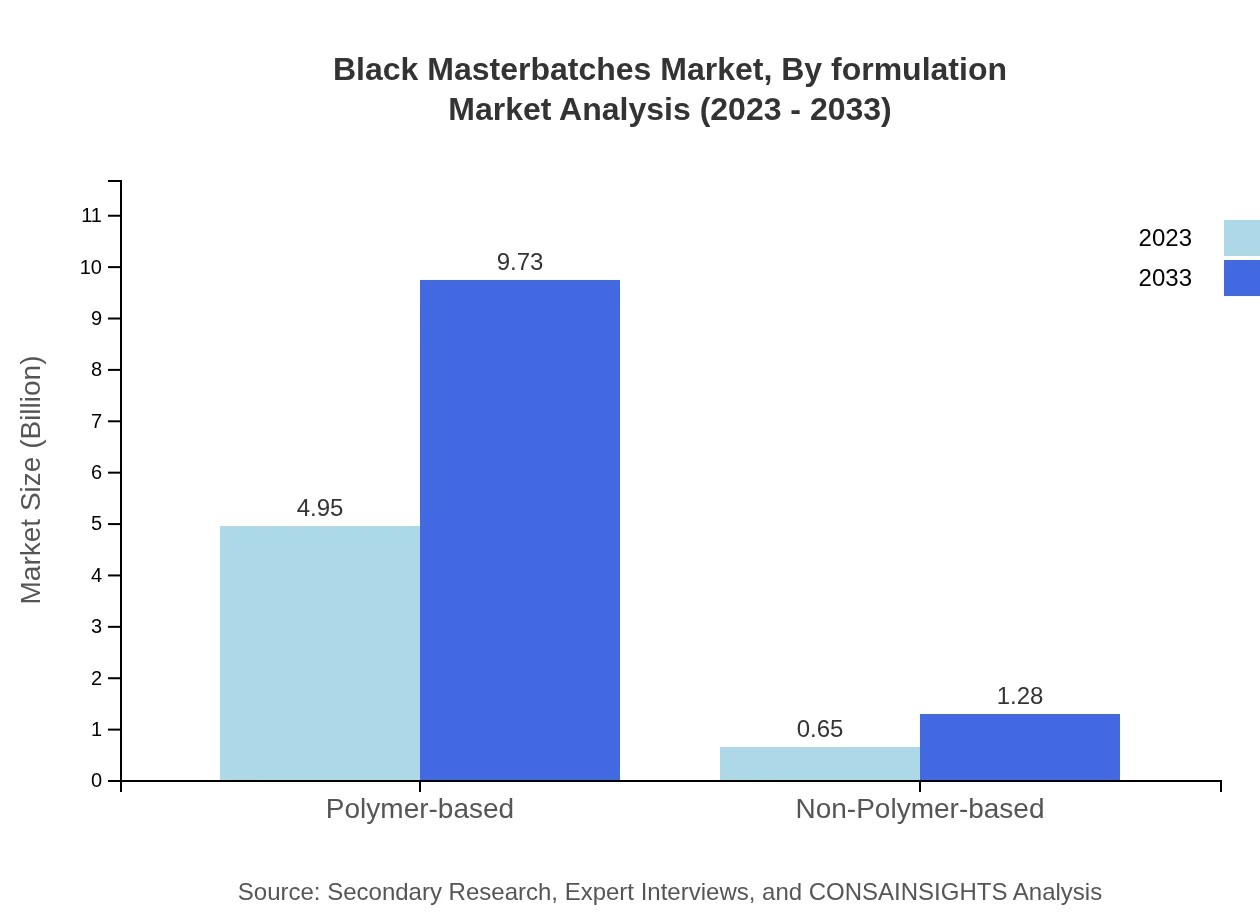

Black Masterbatches Market Analysis By Formulation

The market is also segmented by formulation types such as polymer-based and non-polymer-based black masterbatches. Polymer-based masterbatches dominate, with a projected market size of $4.95 billion growing to $9.73 billion, making up 88.41% of the share, while non-polymer-based products will grow to $1.28 billion for an 11.59% share.

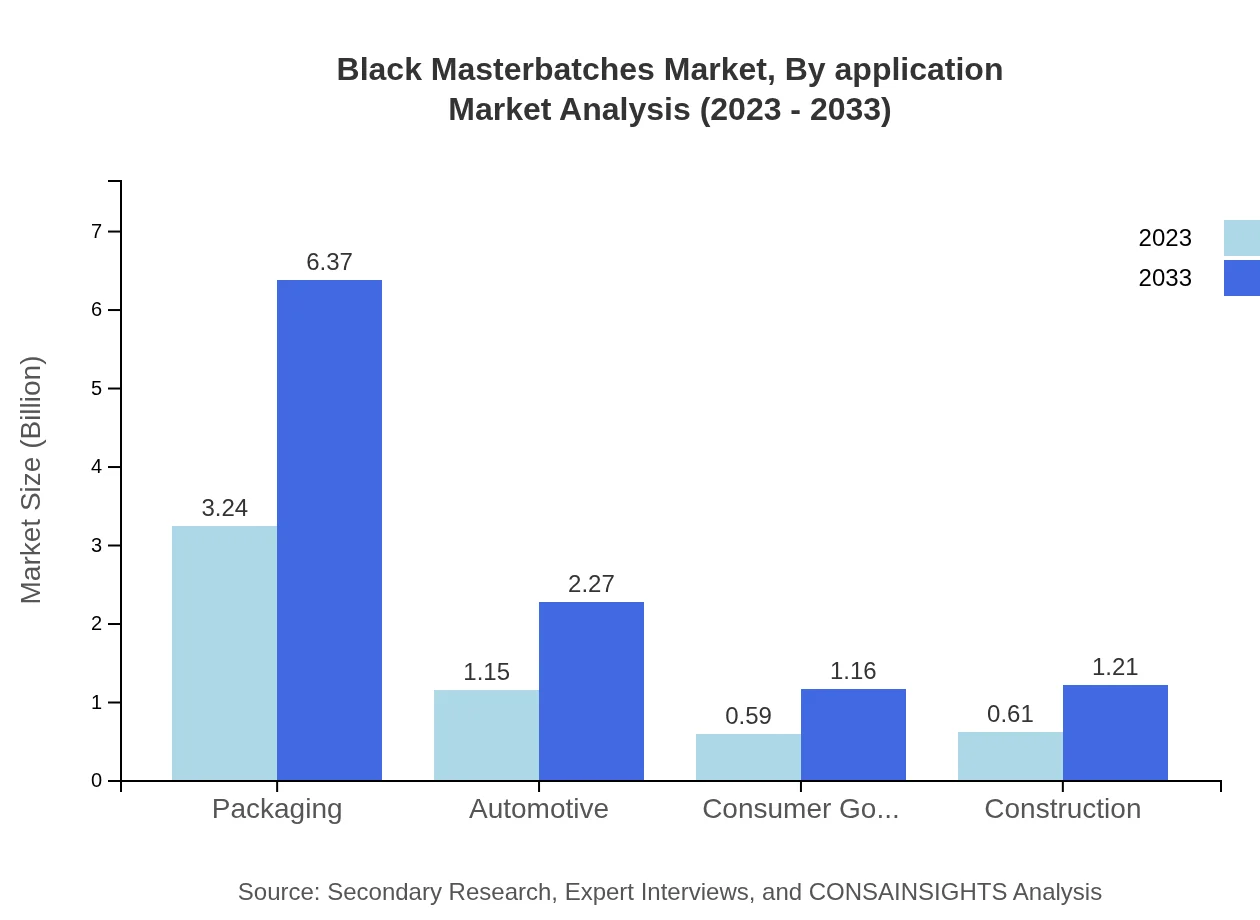

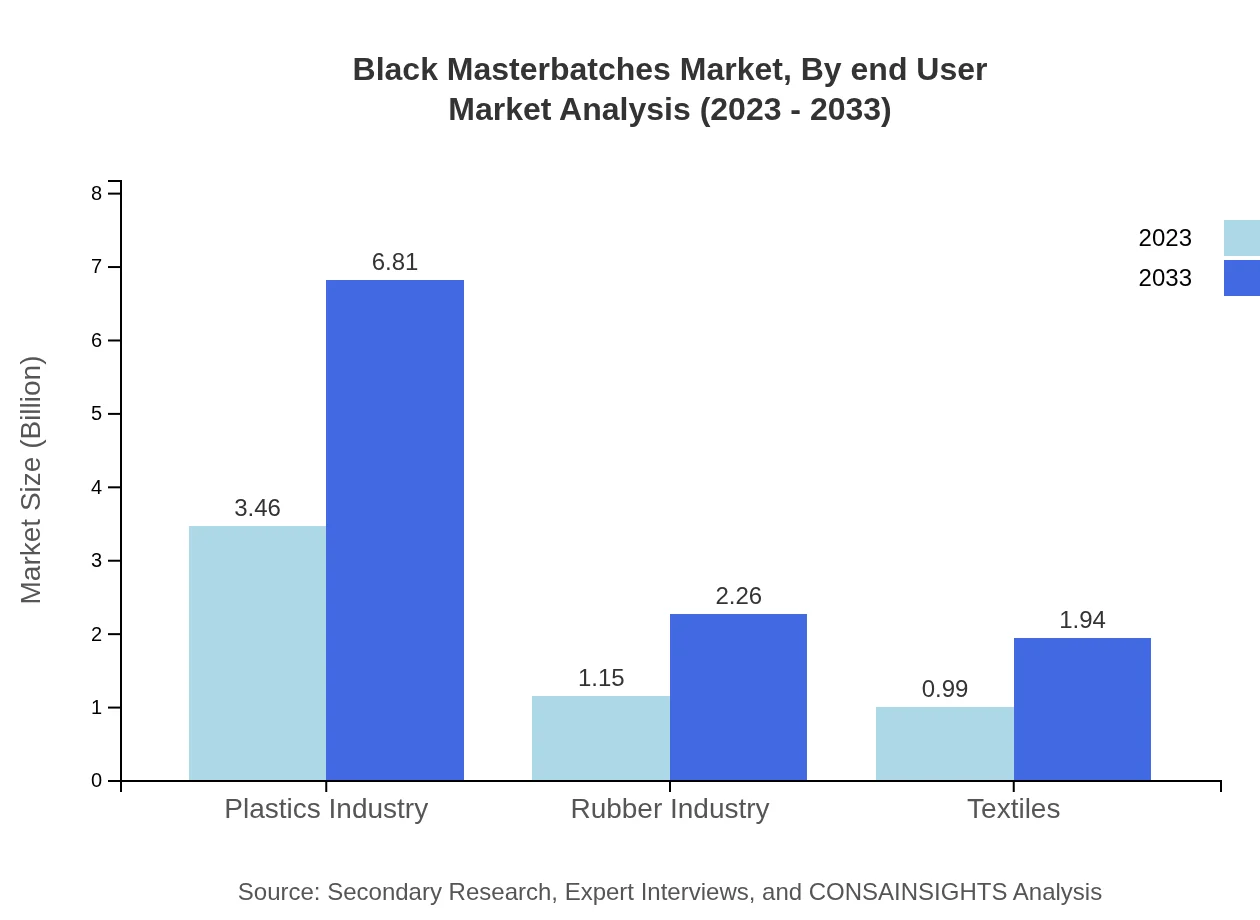

Black Masterbatches Market Analysis By Application

Key applications include Plastics, Rubber, Textiles, and others such as packaging and automotive. Plastics account for the majority share, rising from $3.46 billion to $6.81 billion, representing 61.87% of the market, while other segments like Automotive show growth from $1.15 billion to $2.27 billion.

Black Masterbatches Market Analysis By End User

The Consumer Goods and Construction sectors significantly contribute to market growth, with market sizes of $0.59 billion and $0.61 billion in 2023, respectively. Innovative applications in consumer electronics and durable goods will drive demand.

Black Masterbatches Market Analysis By Technology

Technological advancements, particularly in specialty technologies, are revolutionizing the market. Innovations such as improved granulation techniques result in higher efficiency and application flexibility, fostering growth in high-performance applications.

Black Masterbatches Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Black Masterbatches Industry

Cabot Corporation:

Cabot Corporation is a leading producer of specialty chemicals and performance materials, whose innovations in carbon black and masterbatch technology have positioned it as a key player in the industry.Clariant AG:

Clariant AG specializes in chemical innovation, offering high-quality black masterbatches that enhance product performance across various applications in plastics.A. Schulman, Inc.:

A. Schulman is a prominent manufacturer of plastic compounds, masterbatches, and resins, known for its commitment to sustainability and material efficiency.BASF SE:

BASF is a global leader in the chemical industry, contributing to the black masterbatches market with a diverse range of high-performance solution offerings.Tosaf Compounds Ltd.:

Tosaf is noted for its innovative approach to masterbatch production, focusing on environmentally friendly formulations and new technology applications.We're grateful to work with incredible clients.

FAQs

What is the market size of black masterbatches?

The global black masterbatches market is projected to reach approximately $5.6 billion by 2033, growing at a CAGR of 6.8% from a base market size of $5.6 billion in 2023. This growth indicates a robust demand across various applications.

What are the key market players or companies in the black masterbatches industry?

Key players in the black masterbatches industry include major manufacturers like Clariant, AMPACET Corporation, and Cabot Corporation, who dominate through innovative product offerings and robust distribution networks to enhance their market presence.

What are the primary factors driving the growth in the black masterbatches industry?

Growth in the black masterbatches market is driven by increasing demand in packaging, automotive, and consumer goods industries, along with the need for enhanced product performance, environmentally friendly solutions, and advancements in polymer materials.

Which region is the fastest Growing in the black masterbatches?

The Asia Pacific region is projected to be the fastest-growing market for black masterbatches, expanding from a market size of $1.10 billion in 2023 to an estimated $2.17 billion by 2033, fueled by industrial growth and urbanization.

Does ConsaInsights provide customized market report data for the black masterbatches industry?

Yes, ConsaInsights offers customized market report data tailored to the specific needs of clients in the black masterbatches industry, including detailed analysis and insights to facilitate informed business decisions.

What deliverables can I expect from this black masterbatches market research project?

Deliverables from the black masterbatches market research project include comprehensive reports, market forecasts, competitive landscape analysis, insights on trends, and strategic recommendations tailored to enhance decision-making processes.

What are the market trends of black masterbatches?

Current market trends for black masterbatches include a surge in sustainable production methods, increased demand for high-performance grades in diverse applications, and technological advancements aimed at improving processing efficiency.