Chemical Injection Skids Market Report

Published Date: 02 February 2026 | Report Code: chemical-injection-skids

Chemical Injection Skids Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Chemical Injection Skids market from 2023 to 2033, highlighting key trends, market size, segmentation, and competitive landscape while offering insights into future growth prospects and challenges.

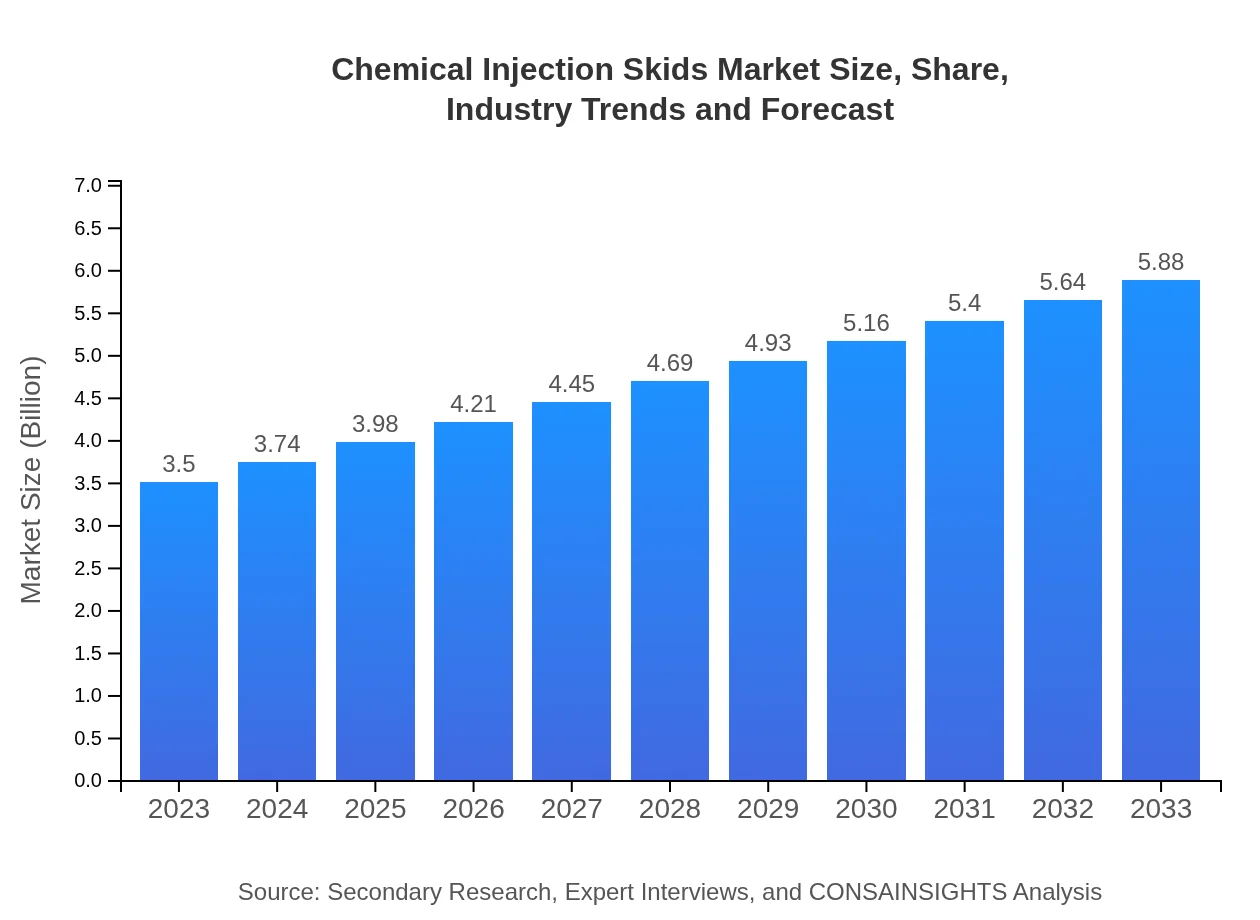

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $3.50 Billion |

| CAGR (2023-2033) | 5.2% |

| 2033 Market Size | $5.88 Billion |

| Top Companies | Schlumberger Limited, Honeywell International Inc., GE Water & Process Technologies |

| Last Modified Date | 02 February 2026 |

Chemical Injection Skids Market Overview

Customize Chemical Injection Skids Market Report market research report

- ✔ Get in-depth analysis of Chemical Injection Skids market size, growth, and forecasts.

- ✔ Understand Chemical Injection Skids's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Chemical Injection Skids

What is the Market Size & CAGR of Chemical Injection Skids market in 2023?

Chemical Injection Skids Industry Analysis

Chemical Injection Skids Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Chemical Injection Skids Market Analysis Report by Region

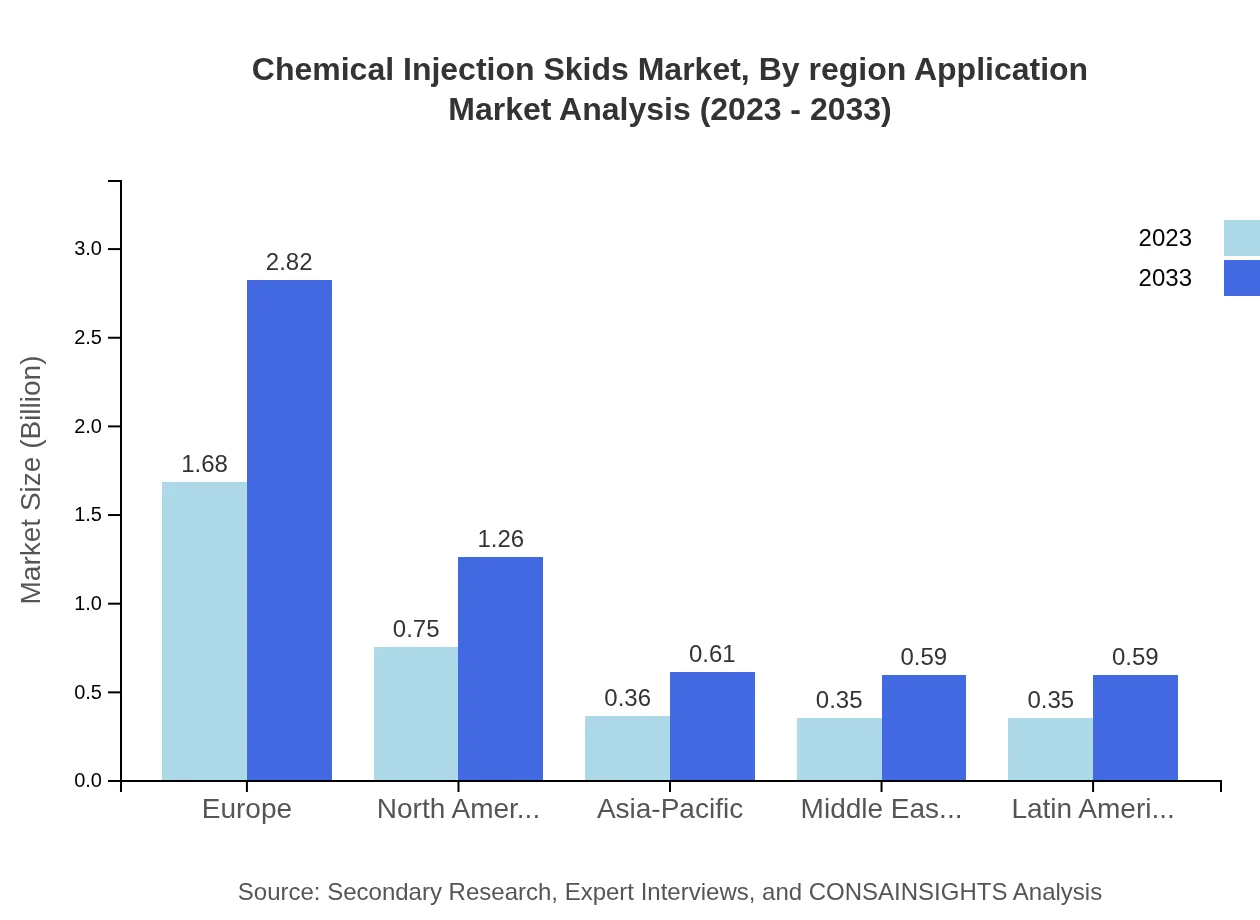

Europe Chemical Injection Skids Market Report:

The European market for Chemical Injection Skids is estimated to grow from $0.95 billion in 2023 to $1.60 billion by 2033. Environmental regulations and the focus on sustainable practices are driving demand in various applications.Asia Pacific Chemical Injection Skids Market Report:

The Asia Pacific region is expected to witness significant growth in the Chemical Injection Skids market, with its size projected to increase from $0.67 billion in 2023 to $1.13 billion by 2033. The growing industrial activities and investments in essential industries such as oil, gas, and mining drive this growth.North America Chemical Injection Skids Market Report:

North America holds a considerable share of the market, with a projected size increase from $1.18 billion in 2023 to $1.97 billion by 2033. The region's technologically advanced infrastructure and strong regulatory frameworks are facilitating increased adoption of advanced skid solutions.South America Chemical Injection Skids Market Report:

In South America, the market is estimated to grow from $0.27 billion in 2023 to $0.46 billion in 2033. The region's focus on enhancing its industrial capabilities amidst economic recovery is a key factor contributing to this growth.Middle East & Africa Chemical Injection Skids Market Report:

The Middle East and Africa region's market is expected to expand from $0.43 billion in 2023 to $0.72 billion in 2033, fueled by increasing oil extraction activities and chemical processing industries in the region.Tell us your focus area and get a customized research report.

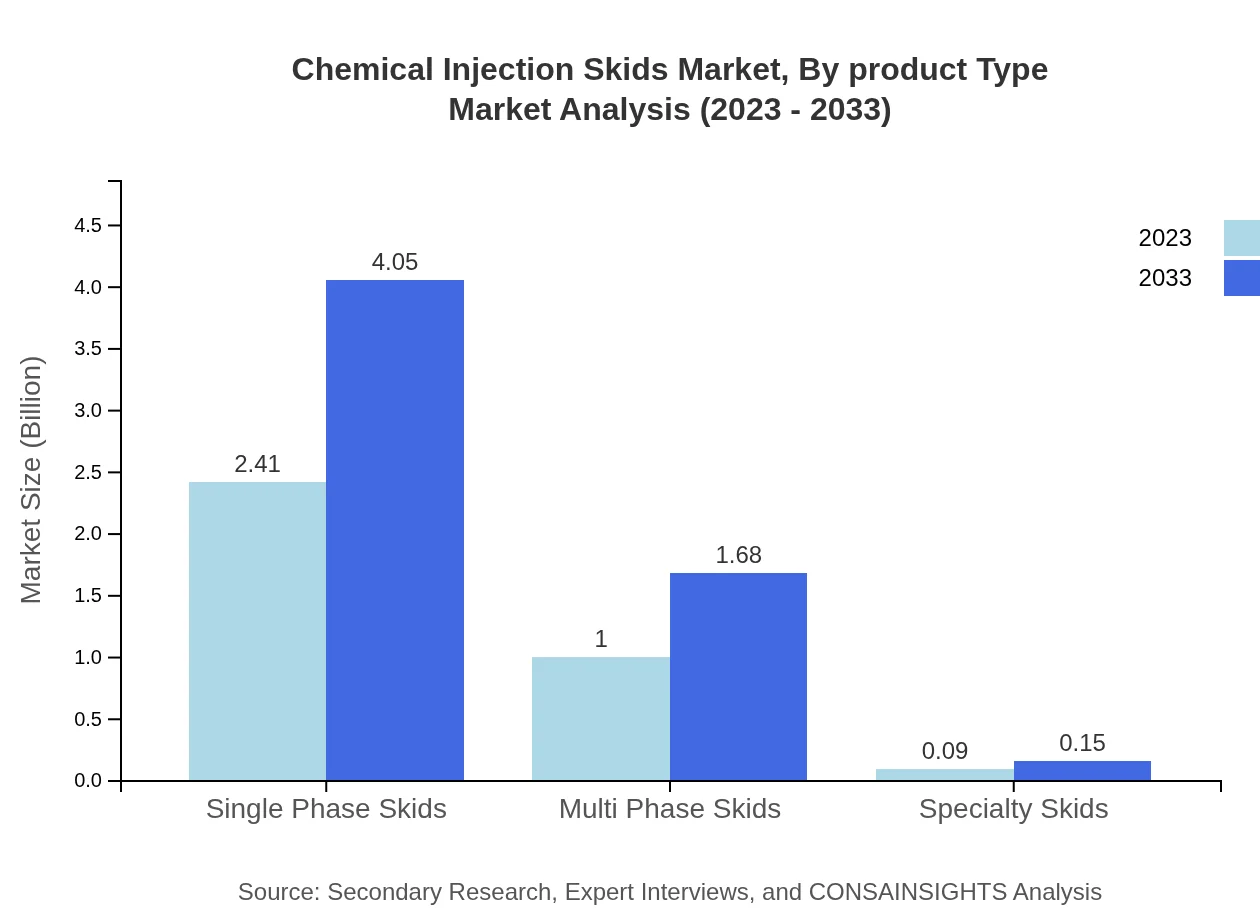

Chemical Injection Skids Market Analysis By Product Type

The market includes segments such as single-phase skids and multi-phase skids. Single-phase skids hold significant market share due to their wide applications in oil and gas industries, dominating with projected market growth from $2.41 billion in 2023 to $4.05 billion by 2033, maintaining 68.95% market share. Multi-phase skids, catering to varied oilfield outputs, grow from $1.00 billion to $1.68 billion in the same period.

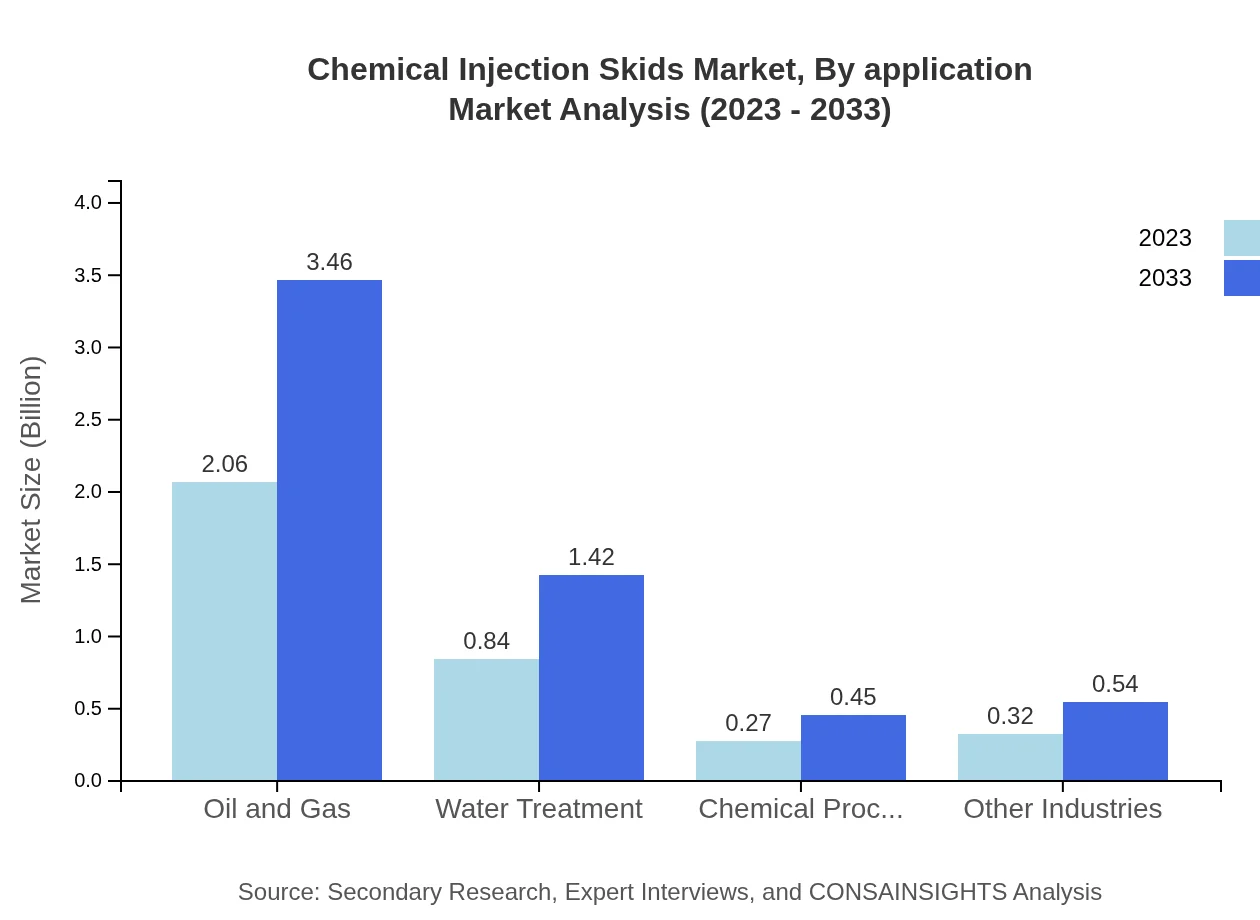

Chemical Injection Skids Market Analysis By Application

Chemical Injection Skids find applications mainly in Oil and Gas, Municipalities, Water Treatment, Chemical Processing, and other industries. The Oil and Gas sector exhibits prominent growth, from $2.06 billion to $3.46 billion, while the Municipalities sector expands from $1.00 billion to $1.68 billion. Water Treatment holds a pivotal role with growth from $0.84 billion to $1.42 billion, emphasizing sustainable practices.

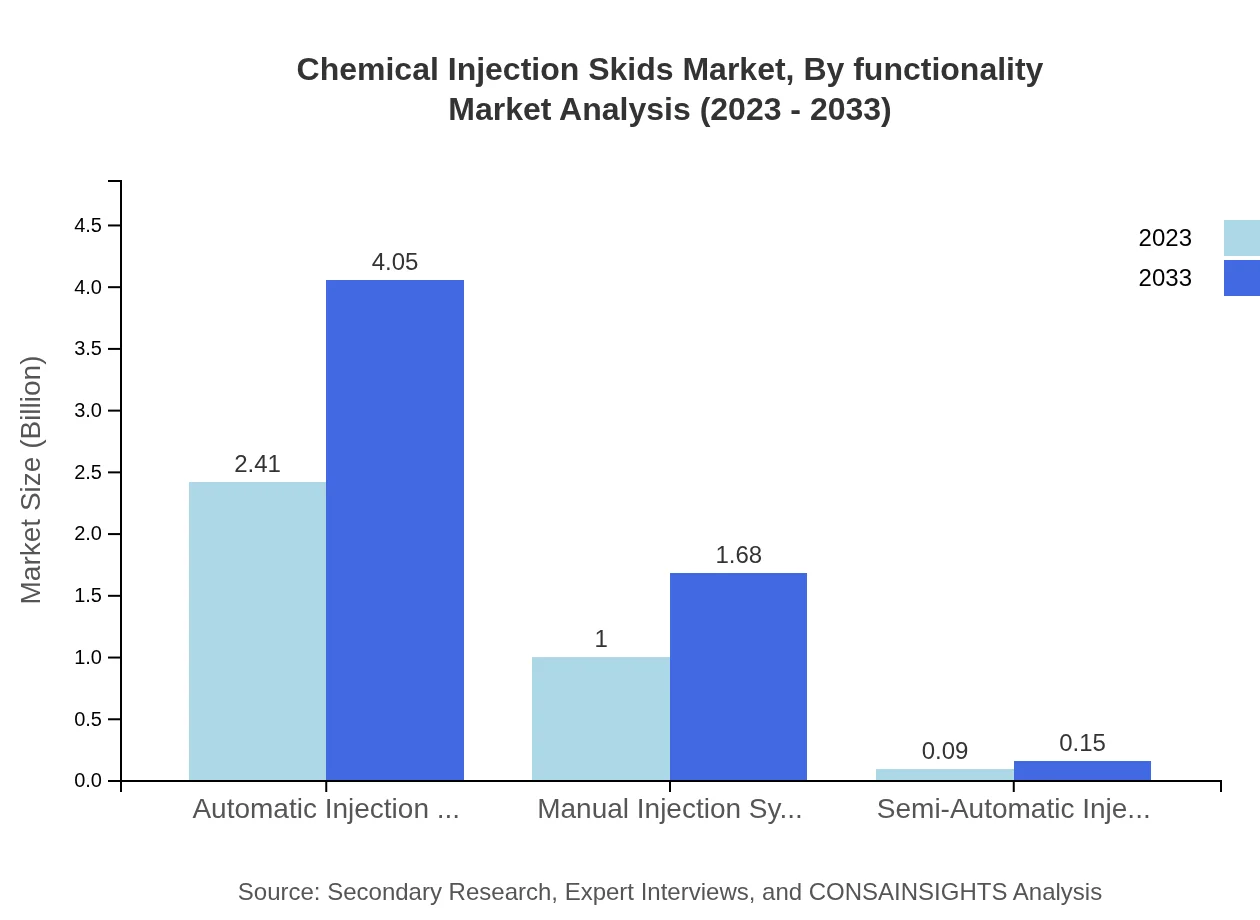

Chemical Injection Skids Market Analysis By Functionality

The market consists of automatic, manual, and semi-automatic injection systems. Automatic systems lead with robust growth from $2.41 billion to $4.05 billion, whilst manual systems grow from $1.00 billion to $1.68 billion. The increasing preference for automation highlights the industry's push towards efficiency and diminished operational costs.

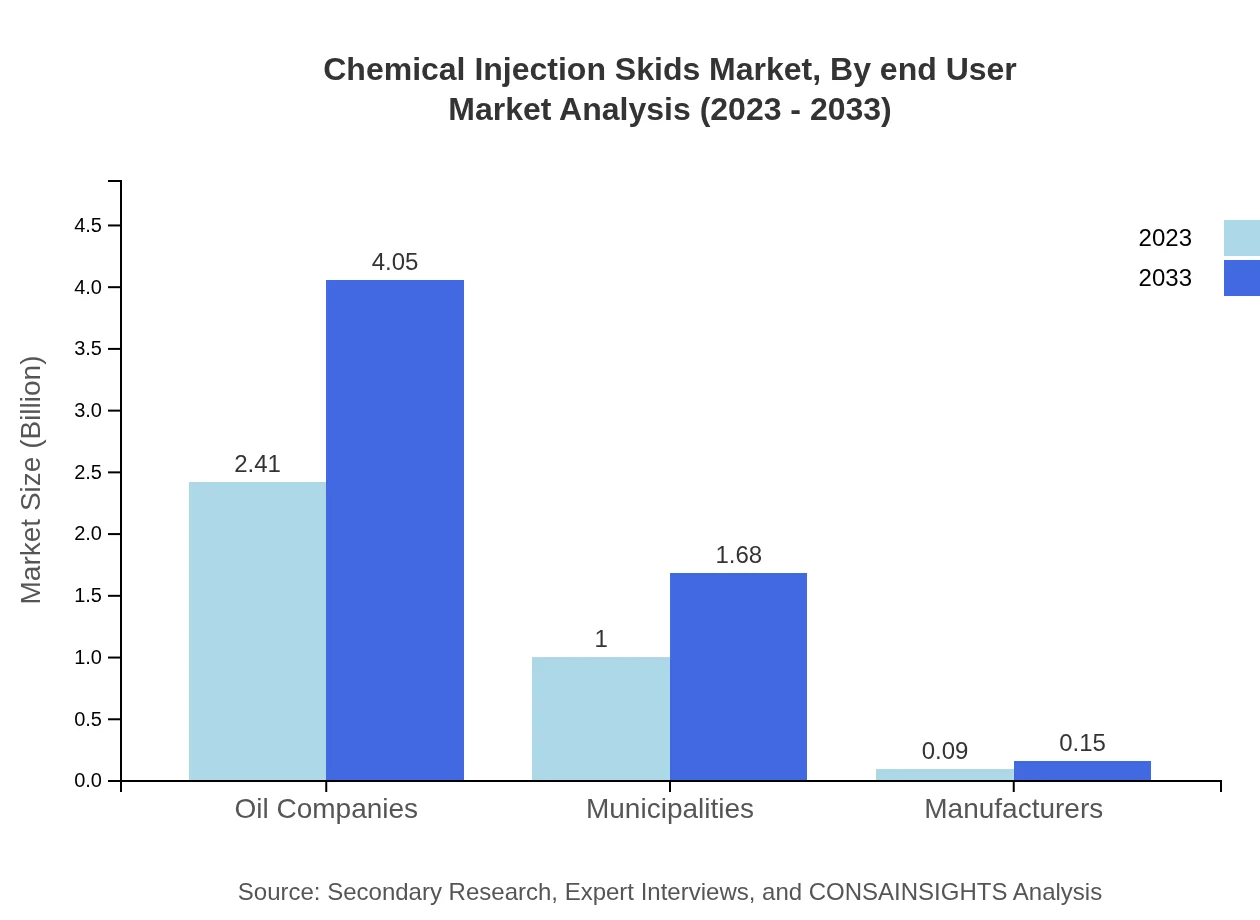

Chemical Injection Skids Market Analysis By End User

Key end-users of Chemical Injection Skids include Oil and Gas corporations, municipalities, manufacturers, and chemical processing firms. The Oil and Gas sector expects substantial growth, projected at $2.41 billion to $4.05 billion over the period, followed by water treatment applications that emphasize eco-friendliness and sustainability.

Chemical Injection Skids Market Analysis By Region Application

Regionally, North America, Europe, and Asia Pacific are leading in applications for Chemical Injection Skids, attributed to their established industrial sectors and investment in technological advancements. The integrated approaches towards improving chemical handling in these areas are crucial to understanding market dynamics.

Chemical Injection Skids Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Chemical Injection Skids Industry

Schlumberger Limited:

A leading oilfield services company, Schlumberger offers a range of innovative solutions for chemical injection skids designed to enhance energy efficiency and safety in chemical handling across industries.Honeywell International Inc.:

Honeywell provides advanced automation and integration solutions, including chemical injection systems that focus on process optimization, adhering to safety and regulatory standards.GE Water & Process Technologies:

Part of GE, this division specializes in chemical injection technologies for industrial applications, focusing on enhancing water treatment processes and other chemical management needs.We're grateful to work with incredible clients.

FAQs

What is the market size of chemical Injection Skids?

The chemical injection skids market is valued at USD 3.5 billion in 2023, with a projected growth at a CAGR of 5.2%. By 2033, it is expected to reach significant market dimensions as industries adopt advanced injection methods.

What are the key market players or companies in this chemical Injection Skids industry?

The chemical injection skids industry features prominent players including major engineering firms and manufacturers specializing in oil and gas, water treatment, and chemical processing. Leading companies continuously innovate to enhance product offerings, ensuring growth.

What are the primary factors driving the growth in the chemical Injection Skids industry?

Growth in the chemical injection skids industry is driven by increased oil and gas production, rising demand for efficient water treatment solutions, and advances in automation technologies. These factors collectively enhance operational efficiency in various sectors.

Which region is the fastest Growing in the chemical Injection Skids?

The Asia-Pacific region is the fastest-growing market for chemical injection skids, projected to grow from USD 0.67 billion in 2023 to USD 1.13 billion by 2033. This growth is fueled by industrial expansion and increased energy demands.

Does ConsaInsights provide customized market report data for the chemical Injection Skids industry?

Yes, ConsaInsights offers customized market reports for the chemical injection skids industry, tailored to specific client needs. These reports encompass detailed insights, trends, and forecasts to aid strategic decision-making.

What deliverables can I expect from this chemical Injection Skids market research project?

Deliverables from the chemical injection skids market research project typically include comprehensive reports, market analysis, segmentation data, growth forecasts, and competitive landscape insights, enabling informed business strategies.

What are the market trends of chemical Injection Skids?

Current trends in the chemical injection skids market include increasing automation in injection systems, a shift towards environmentally friendly products, and the adoption of advanced technologies for enhanced efficiency across various applications.