High Purity Alumina Market Report

Published Date: 02 February 2026 | Report Code: high-purity-alumina

High Purity Alumina Market Size, Share, Industry Trends and Forecast to 2033

This report provides comprehensive insights into the High Purity Alumina market from 2023 to 2033, including market size, growth forecast, industry analysis, market segmentation, regional insights, and technological advancements shaping the industry.

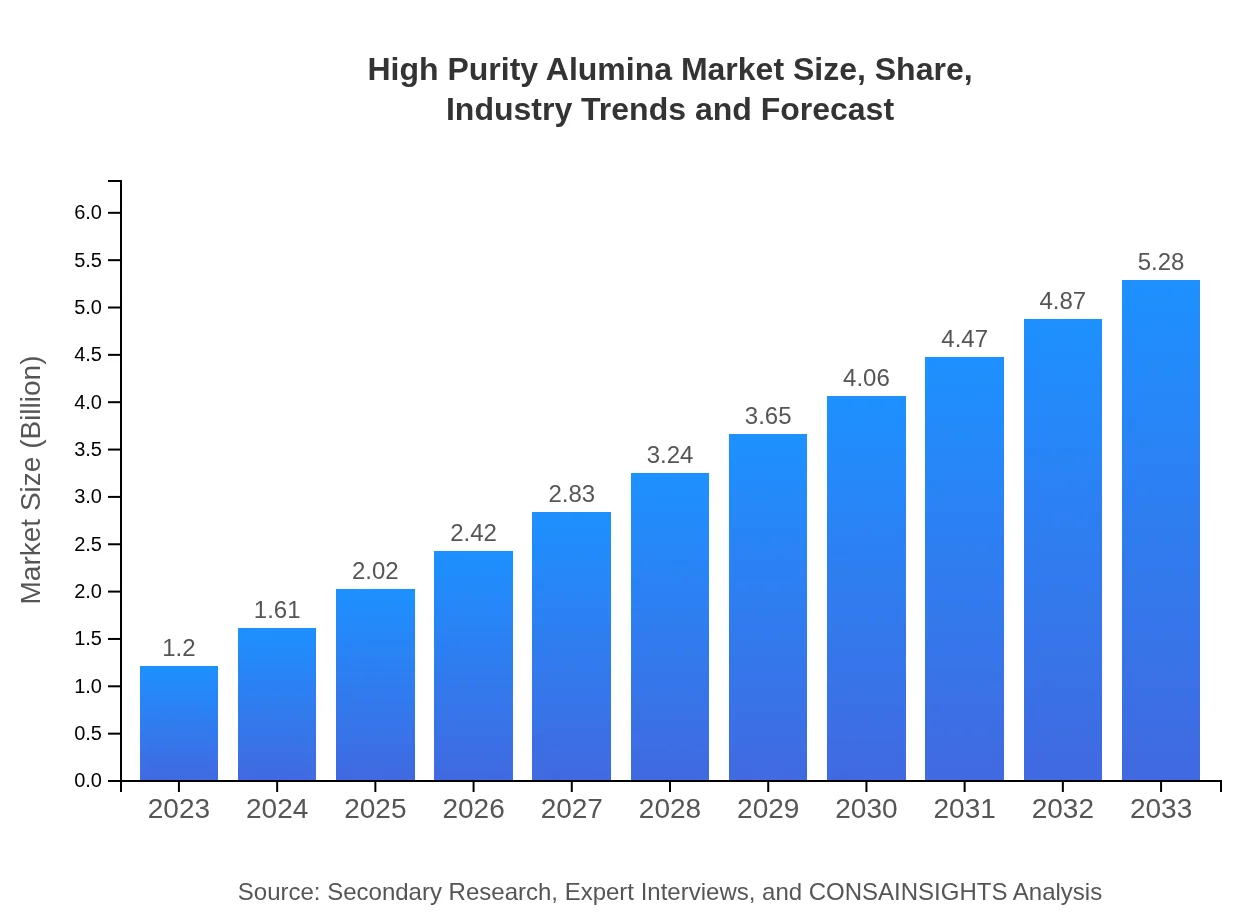

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $1.20 Billion |

| CAGR (2023-2033) | 15.2% |

| 2033 Market Size | $5.28 Billion |

| Top Companies | Alcoa Corporation, Sumitomo Chemical, Nabaltec AG, Sasol Limited, Hydro Aluminium AS |

| Last Modified Date | 02 February 2026 |

High Purity Alumina Market Overview

Customize High Purity Alumina Market Report market research report

- ✔ Get in-depth analysis of High Purity Alumina market size, growth, and forecasts.

- ✔ Understand High Purity Alumina's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in High Purity Alumina

What is the Market Size & CAGR of High Purity Alumina market in 2023?

High Purity Alumina Industry Analysis

High Purity Alumina Market Segmentation and Scope

Tell us your focus area and get a customized research report.

High Purity Alumina Market Analysis Report by Region

Europe High Purity Alumina Market Report:

Europe's HPA market, starting at USD 0.36 billion in 2023, is projected to reach USD 1.59 billion by 2033. Key drivers include stringent environmental regulations and a strong focus on energy-efficient technologies, leading to increased demand in automotive and semiconductor applications.Asia Pacific High Purity Alumina Market Report:

In the Asia Pacific region, the market for High Purity Alumina was valued at USD 0.21 billion in 2023 and is expected to reach USD 0.93 billion by 2033. This growth is driven primarily by the rapid expansion of electronics manufacturing in countries such as China and Japan, where high demand for LED and semiconductor applications fuels market growth.North America High Purity Alumina Market Report:

The North American market is a robust segment, with a valuation of USD 0.47 billion in 2023, expected to grow to USD 2.05 billion by 2033. The significant push towards electric vehicles and high-performance electronics in the US and Canada significantly drives demand for High Purity Alumina.South America High Purity Alumina Market Report:

South America shows a modest growth trend, with the market valued at USD 0.12 billion in 2023 and projected to grow to USD 0.52 billion by 2033. The increase is spurred by rising investments in renewable energy technologies, with HPA being crucial in battery and other electronic applications.Middle East & Africa High Purity Alumina Market Report:

In the Middle East and Africa, the market for High Purity Alumina was valued at USD 0.04 billion in 2023 and is expected to reach USD 0.19 billion by 2033. This growth is primarily due to developing industrial sectors and increasing investments in technology-based solutions.Tell us your focus area and get a customized research report.

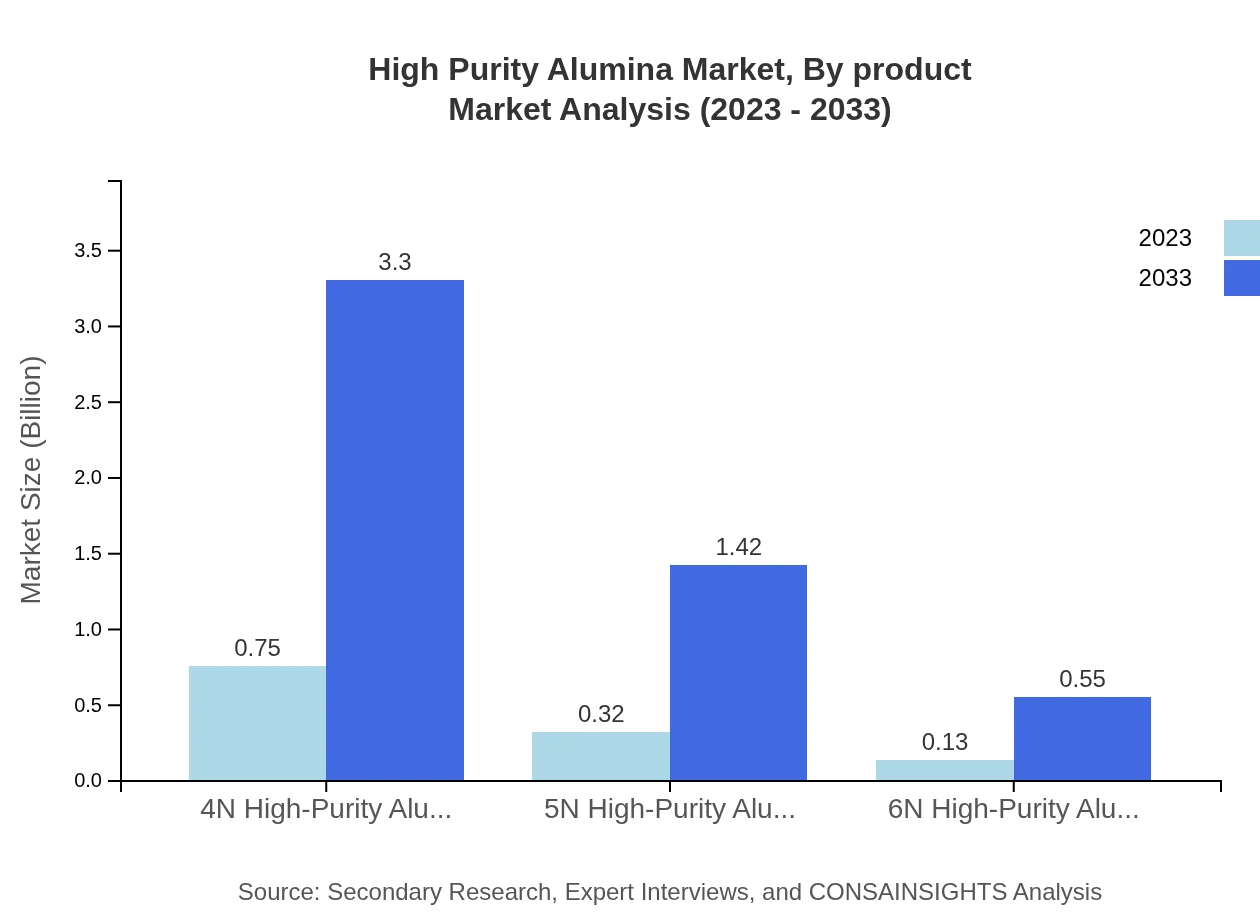

High Purity Alumina Market Analysis By Product

The product segmentation reveals that Bauxite contributes significantly with a market size of USD 1.06 billion in 2023, anticipated to grow to USD 4.66 billion by 2033, accounting for 88.26% market share. Meanwhile, 4N HPA is valued at USD 0.75 billion and is projected to reach USD 3.30 billion by 2033 (62.55% market share), illustrating the demand for specialized products.

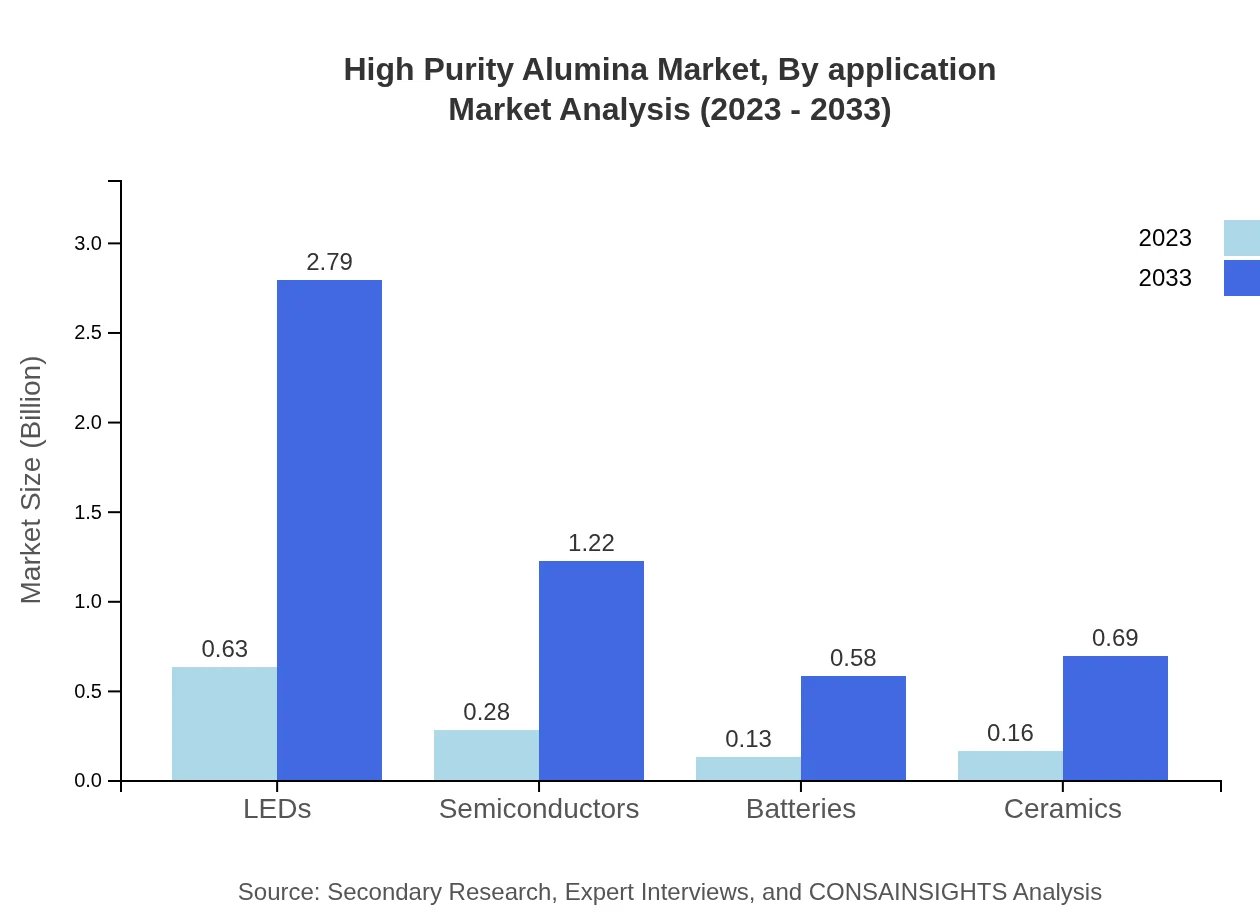

High Purity Alumina Market Analysis By Application

In application segmentation, the demand for High Purity Alumina in LED and semiconductors is substantial, with market sizes hitting USD 0.63 billion in 2023 for LEDs and projected to grow to USD 2.79 billion by 2033 (52.91% market share), while semiconductors hold a market size of USD 0.28 billion expected to rise to USD 1.22 billion (23.07% market share).

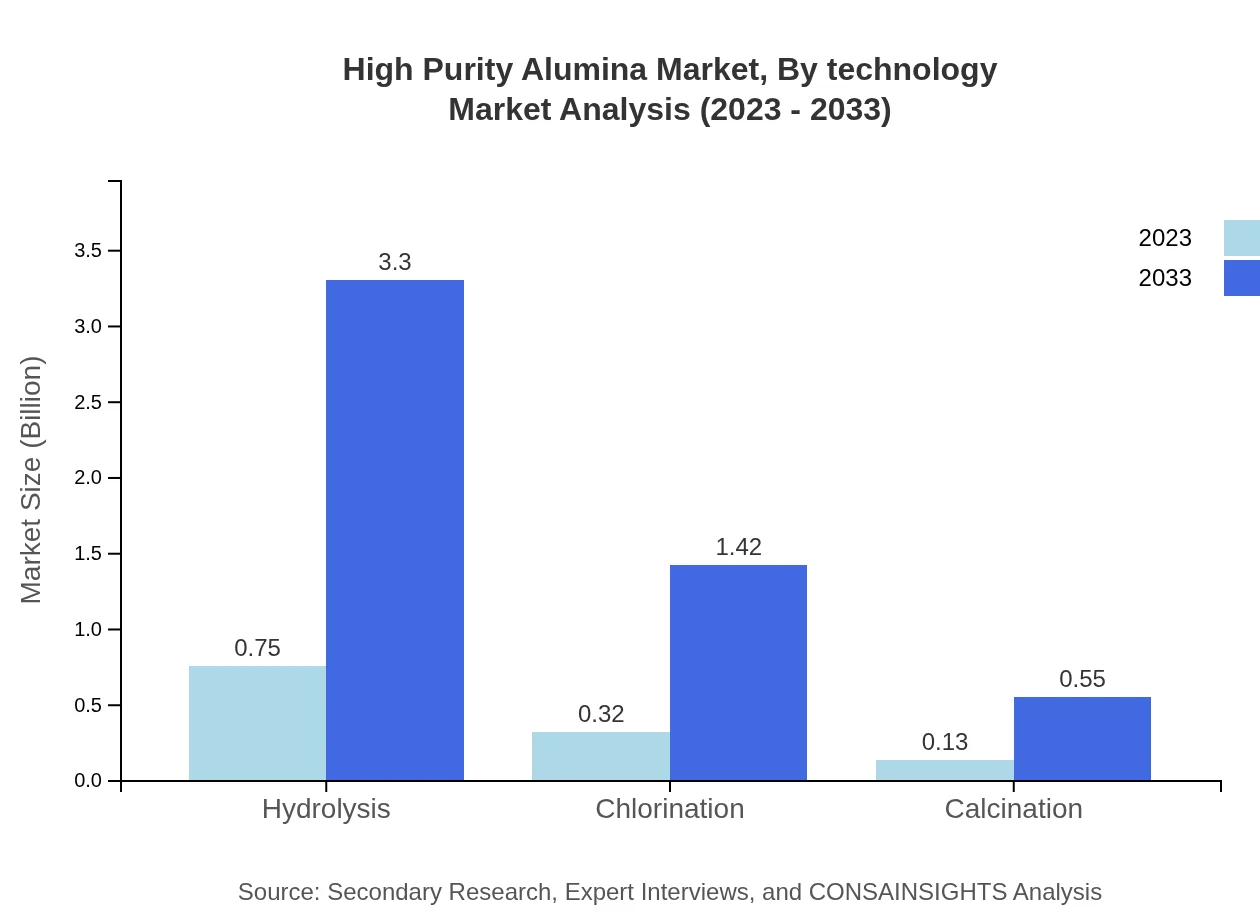

High Purity Alumina Market Analysis By Technology

Regarding technology, hydrolysis dominates with a market size of USD 0.75 billion in 2023 and expected growth to USD 3.30 billion by 2033 (62.55% market share). Chlorination and calcination technologies also contribute significantly, valued at USD 0.32 billion and USD 0.13 billion respectively in 2023, with expected growth trends matching those of hydrolysis.

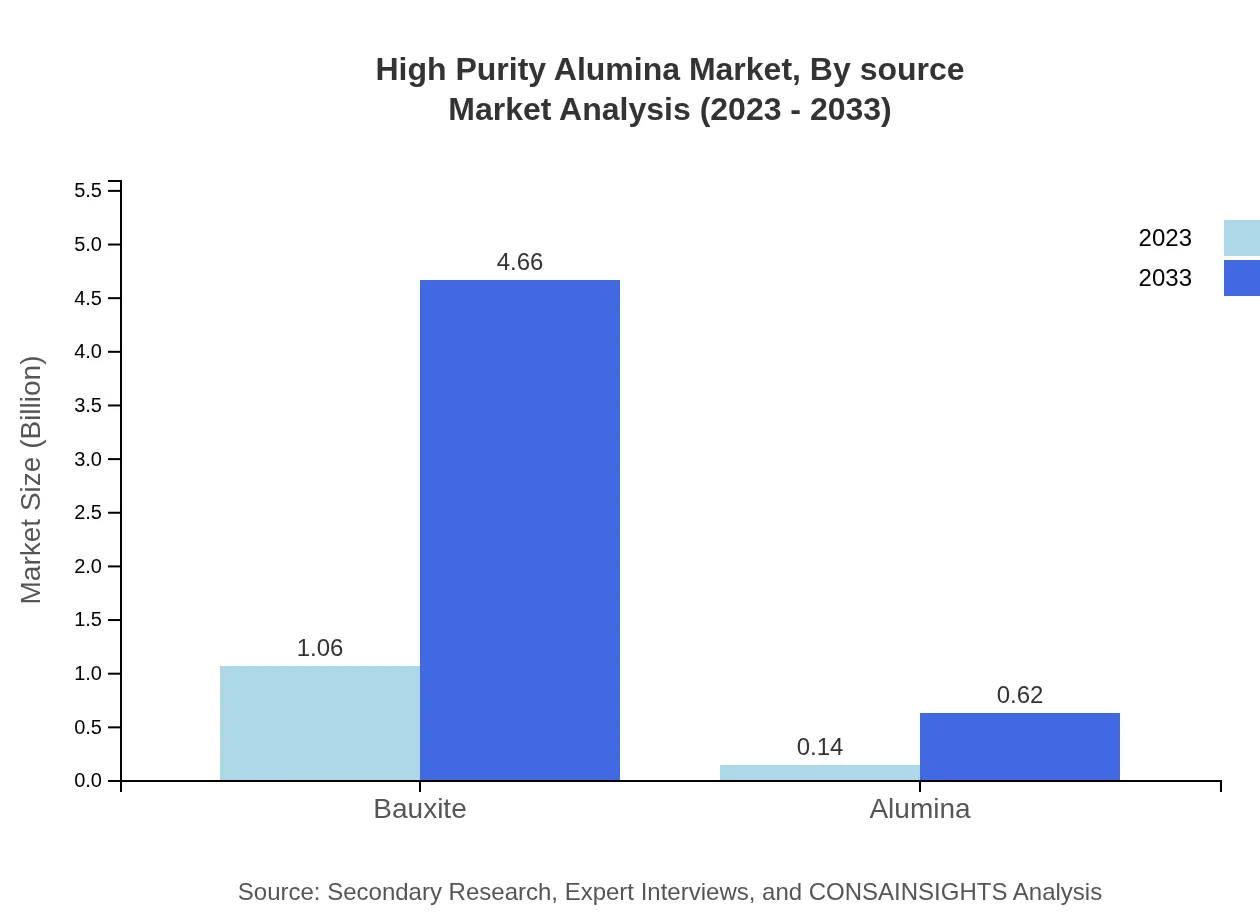

High Purity Alumina Market Analysis By Source

The source-based segmentation indicates bauxite as the primary source, with a size of USD 1.06 billion in 2023 and expected to grow to USD 4.66 billion by 2033. This source plays a critical role in maintaining the supply chain for High Purity Alumina, particularly in regions rich in aluminum deposits.

High Purity Alumina Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in High Purity Alumina Industry

Alcoa Corporation:

A major player in the Aluminum industry, Alcoa focuses on sustainable practices and innovative technology to enhance the quality and purity of its products.Sumitomo Chemical:

Specializes in advanced materials, Sumitomo Chemical leads in the production of High Purity Alumina, primarily for semiconductor and LED applications.Nabaltec AG:

Nabaltec AG is recognized for its high-quality specialty aluminas, contributing significantly to the global HPA market through innovative production facilities.Sasol Limited:

Sasol is a global integrated chemicals and energy company that holds a significant footprint in the High Purity Alumina industry due to its diverse product offerings.Hydro Aluminium AS:

A major alumina producer that focuses on developing high-purity aluminum and alumina products, contributing to the electronics and energy sectors.We're grateful to work with incredible clients.

FAQs

What is the market size of high Purity alumina?

The global market size for high-purity alumina is projected to reach approximately $1.2 billion by 2033, growing at a CAGR of 15.2% from its current valuation in 2023.

What are the key market players or companies in the high Purity alumina industry?

Key market players in the high-purity alumina industry include companies like Alcoa Corporation, Nouryon, and Huber Engineered Materials among others, which drive innovation and market share.

What are the primary factors driving the growth in the high Purity alumina industry?

Growth in the high-purity alumina industry is driven by increasing demand for LEDs, semiconductors, and battery technologies, along with advancements in material purity and manufacturing processes.

Which region is the fastest Growing in the high Purity alumina?

The North America region is expected to be the fastest-growing area, with its market size projected to grow from $0.47 billion in 2023 to $2.05 billion by 2033.

Does ConsaInsights provide customized market report data for the high Purity alumina industry?

Yes, ConsaInsights specializes in providing customized market report data tailored to meet specific needs within the high-purity alumina industry, offering insights and detailed analysis.

What deliverables can I expect from this high Purity alumina market research project?

Deliverables include comprehensive reports, in-depth analysis, market forecasts, and strategic recommendations tailored to the high-purity alumina market.

What are the market trends of high Purity alumina?

Key market trends for high-purity alumina include an increase in applications in electronics, a shift toward sustainable manufacturing processes, and the rise of smart technology sectors.