Carbon Thermoplastic Market Report

Published Date: 02 February 2026 | Report Code: carbon-thermoplastic

Carbon Thermoplastic Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the Carbon Thermoplastic market, including key insights into market size, growth rates, technological advancements, and regional trends for the years 2023 to 2033.

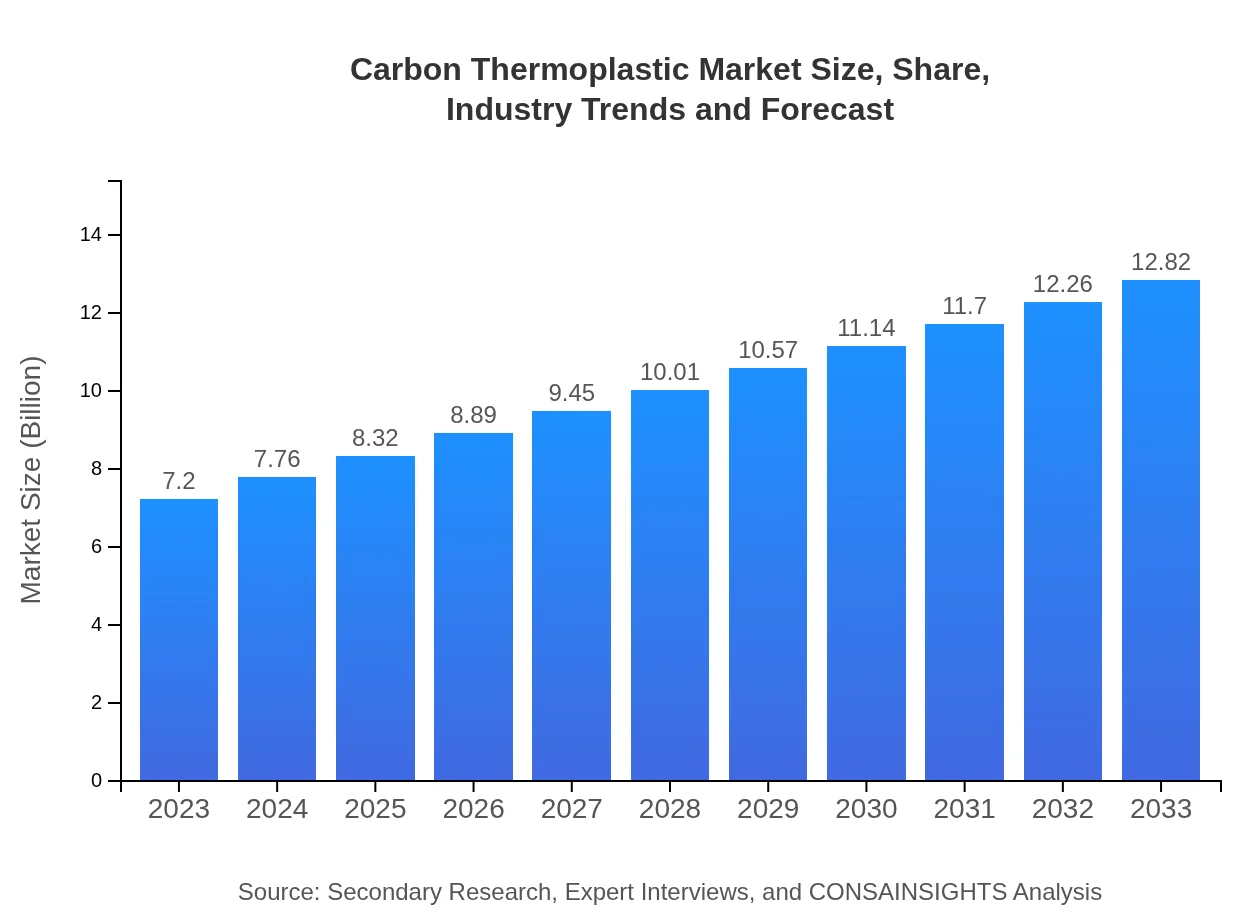

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $7.20 Billion |

| CAGR (2023-2033) | 5.8% |

| 2033 Market Size | $12.82 Billion |

| Top Companies | BASF SE, DuPont de Nemours, Inc., Solvay SA, Covestro AG |

| Last Modified Date | 02 February 2026 |

Carbon Thermoplastic Market Overview

Customize Carbon Thermoplastic Market Report market research report

- ✔ Get in-depth analysis of Carbon Thermoplastic market size, growth, and forecasts.

- ✔ Understand Carbon Thermoplastic's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Carbon Thermoplastic

What is the Market Size & CAGR of Carbon Thermoplastic market in 2023?

Carbon Thermoplastic Industry Analysis

Carbon Thermoplastic Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Carbon Thermoplastic Market Analysis Report by Region

Europe Carbon Thermoplastic Market Report:

The European market is anticipated to increase from $1.97 billion in 2023 to $3.50 billion in 2033, supported by stringent regulations on carbon emissions, driving demand for lightweight composites in the automotive sector.Asia Pacific Carbon Thermoplastic Market Report:

In the Asia Pacific region, the market is expected to grow from $1.42 billion in 2023 to $2.54 billion by 2033, driven by rising manufacturing activities and increased demand for automotive components.North America Carbon Thermoplastic Market Report:

North America is projected to grow from $2.57 billion in 2023 to $4.58 billion by 2033, led by advancements in aerospace and electric vehicle manufacturing, which require lightweight and durable materials.South America Carbon Thermoplastic Market Report:

The South American market will see growth from $0.58 billion in 2023 to $1.04 billion in 2033, primarily fueled by the expansion of the automotive and aerospace industries in countries like Brazil and Argentina.Middle East & Africa Carbon Thermoplastic Market Report:

The Middle East and Africa market is forecasted to grow from $0.65 billion in 2023 to $1.16 billion by 2033, as industries in these regions increasingly adopt carbon thermoplastic materials for various applications.Tell us your focus area and get a customized research report.

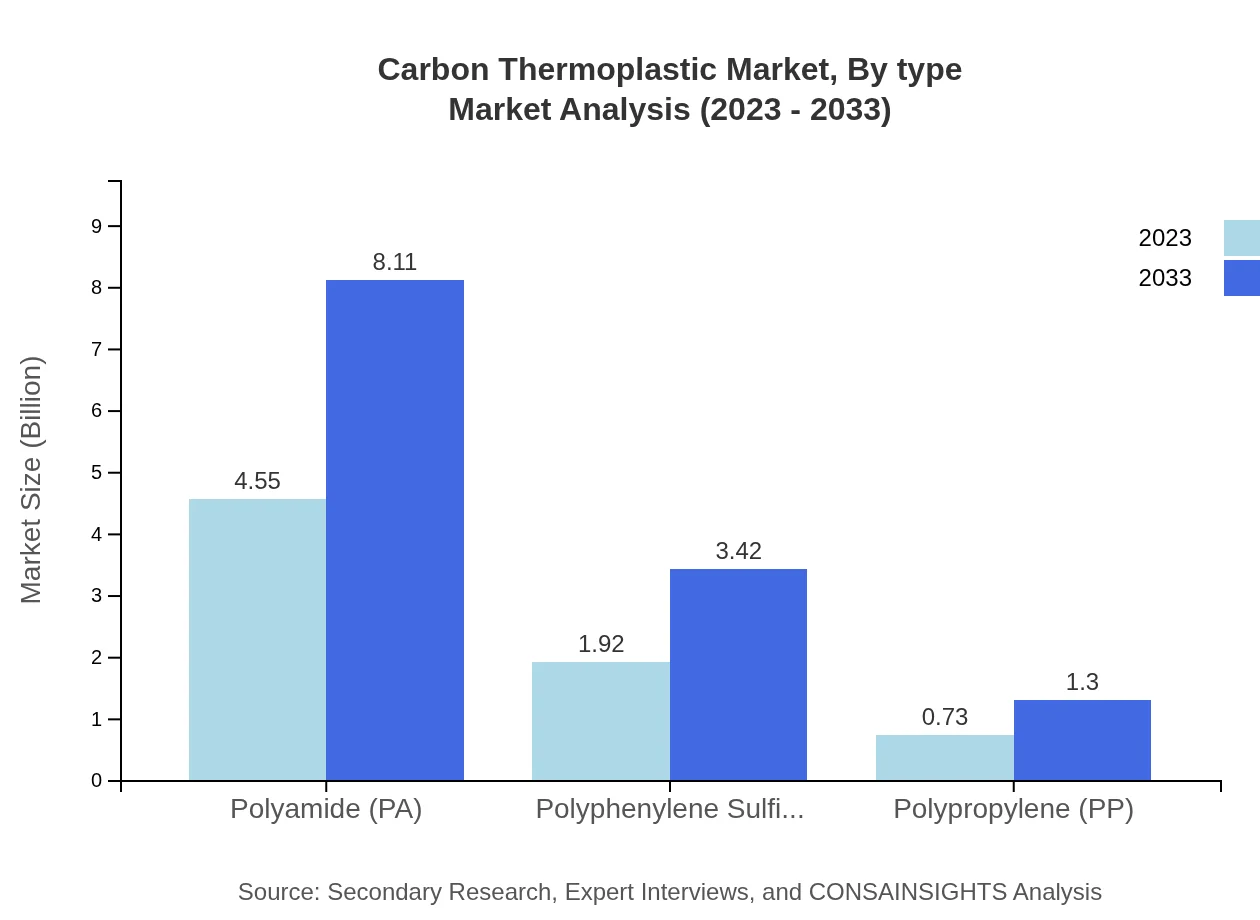

Carbon Thermoplastic Market Analysis By Type

In terms of product types, Polyamide (PA) leads the market with a size of $4.55 billion and a market share of 63.26% in 2023. This segment is expected to grow to $8.11 billion by 2033, driven by its extensive use in automotive parts and consumer goods. Polyphenylene Sulfide (PPS) follows, with a market size of $1.92 billion (26.64% share) in 2023, expected to reach $3.42 billion by 2033, and Polypropylene (PP) which is projected to grow from $0.73 billion to $1.30 billion.

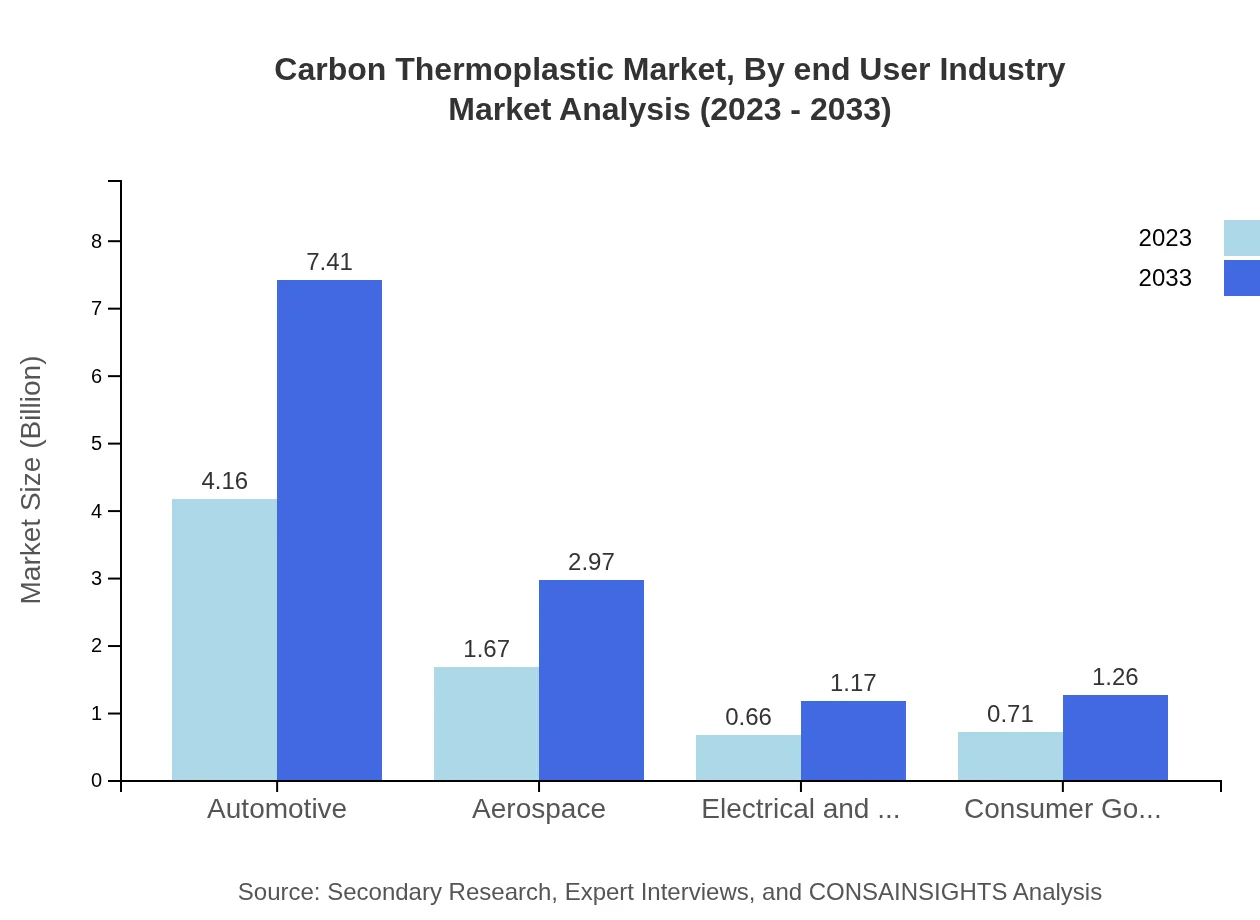

Carbon Thermoplastic Market Analysis By End User Industry

In 2023, the automotive sector dominates the market with a size of $4.16 billion (57.81% share), reflecting the rising trend of lightweight materials for fuel-efficient vehicles. The aerospace industry, valued at $1.67 billion (23.19% share), shows growth prospects due to the demand for high-performance materials in aircraft manufacturing. Other segments include electrical and electronics, consumer goods, and industrial equipment, all contributing to market diversification.

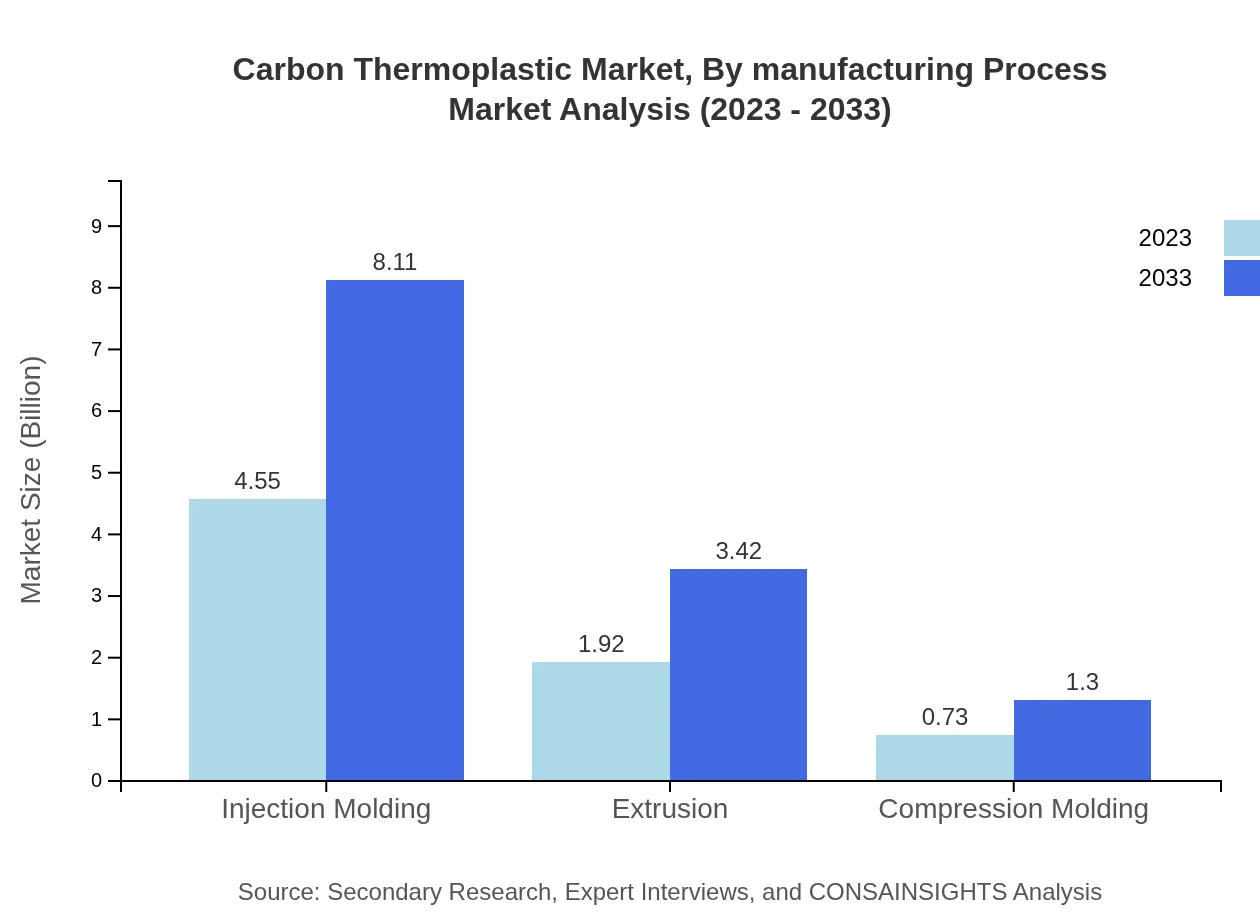

Carbon Thermoplastic Market Analysis By Manufacturing Process

The primary manufacturing processes for Carbon Thermoplastic include Injection Molding ($4.55 billion, 63.26% share), Extrusion ($1.92 billion, 26.64% share), and Compression Molding ($0.73 billion, 10.1% share). Injection molding's dominance is attributed to its efficiency in producing complex geometries, which is critical for automotive and aerospace parts.

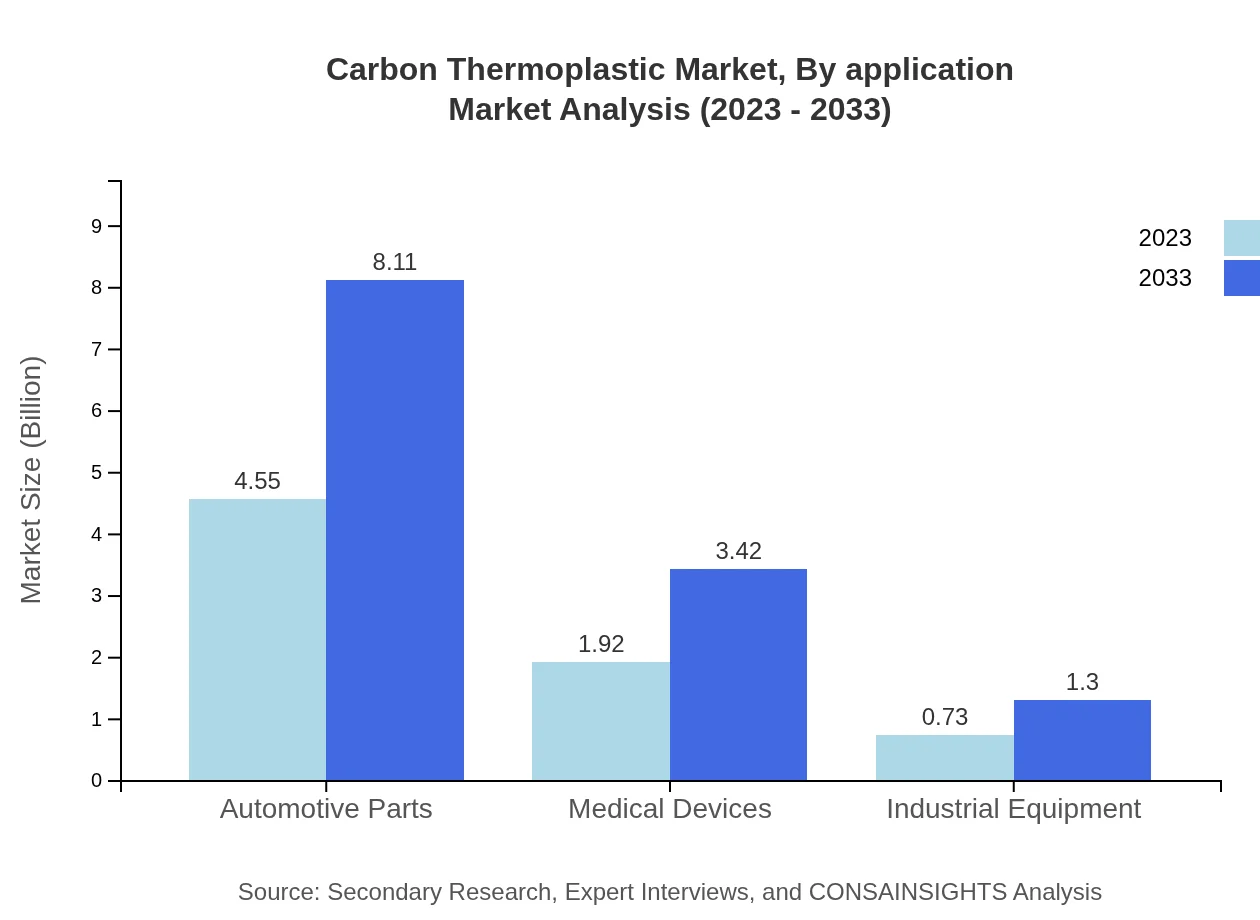

Carbon Thermoplastic Market Analysis By Application

Applications of Carbon Thermoplastic are prominently in automotive parts, medical devices, and aerospace components. Automotive parts lead the application sector with a market size of $4.55 billion (63.26% share), followed by medical devices at $1.92 billion (26.64% share), and aerospace components, valued at $1.67 billion. The increasing adoption of these materials in design frameworks enhances performance while reducing weight.

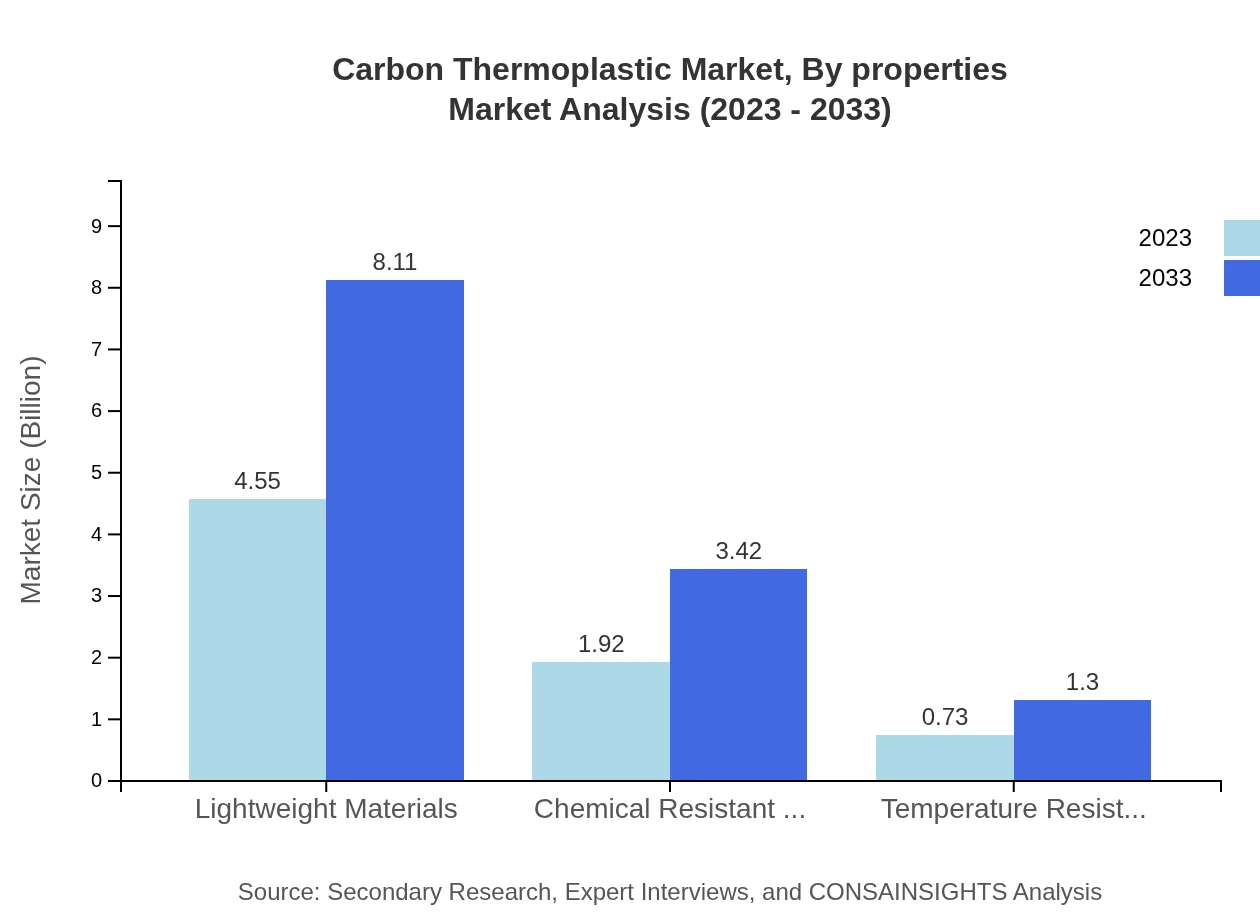

Carbon Thermoplastic Market Analysis By Properties

Key properties defining performance include lightweight materials ($4.55 billion, 63.26% share), chemical-resistant materials ($1.92 billion, 26.64% share), and temperature-resistant materials ($0.73 billion, 10.1% share). Lightweight materials are crucial for applications demanding decreased weight without sacrificing performance, particularly in the automotive and aerospace sectors.

Carbon Thermoplastic Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Carbon Thermoplastic Industry

BASF SE:

BASF SE is a global leader in the production of high-performance materials used in automotive and aerospace applications, offering a wide range of carbon thermoplastic solutions.DuPont de Nemours, Inc.:

DuPont is known for its innovative advancements in thermoplastics, particularly in developing materials with enhanced mechanical properties for various industries.Solvay SA:

Solvay is a multinational corporation specializing in specialty chemicals and advanced materials, including a comprehensive portfolio of carbon thermoplastics.Covestro AG:

Covestro AG is recognized for its environmentally friendly production methods and high-quality thermoplastic materials used across multiple applications.We're grateful to work with incredible clients.

FAQs

What is the market size of carbon Thermoplastic?

The Carbon Thermoplastic market is valued at approximately $7.2 billion in 2023, with an expected CAGR of 5.8%. This growth reflects the rising adoption of carbon thermoplastic materials across various industries, predicting an expanded market size by 2033.

What are the key market players or companies in the carbon Thermoplastic industry?

Key players in the carbon thermoplastic industry include global manufacturers and innovators committed to advancing material technology. Companies are investing heavily in R&D to enhance product performance and sustainability, reflecting a competitive landscape that continually evolves.

What are the primary factors driving growth in the carbon Thermoplastic industry?

Growth drivers in the carbon thermoplastic industry include increased demand for lightweight materials, sustainability initiatives, and advancements in manufacturing processes. The automotive and aerospace sectors particularly fuel this growth with stringent regulations for reducing emissions.

Which region is the fastest Growing in the carbon Thermoplastic market?

The fastest-growing region for carbon thermoplastics is projected to be North America, expanding from $2.57 billion in 2023 to $4.58 billion by 2033. This growth is driven by innovations in automotive and aerospace applications.

Does ConsaInsights provide customized market report data for the carbon Thermoplastic industry?

Yes, ConsaInsights specializes in providing customized market report data tailored to the carbon thermoplastic industry. Our reports cater to specific client needs, ensuring relevant insights and analysis of market dynamics.

What deliverables can I expect from this carbon Thermoplastic market research project?

Expect detailed market analysis reports, segmentation insights, competitive landscape reviews, and forecasts of market trends. The deliverables are designed to assist strategic planning and decision-making based on comprehensive market data.

What are the market trends of carbon Thermoplastic?

Key market trends in carbon thermoplastics include increasing adoption for automotive lightweighting, growth in the aerospace sector, and a focus on sustainable materials. Innovations in processing technologies are also shaping the future of applications.