Chemical Mechanical Planarization Cmp Slurry Market Report

Published Date: 31 January 2026 | Report Code: chemical-mechanical-planarization-cmp-slurry

Chemical Mechanical Planarization Cmp Slurry Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Chemical Mechanical Planarization (CMP) slurry market, covering market size, growth forecasts, technological trends, and regional insights from 2023 to 2033.

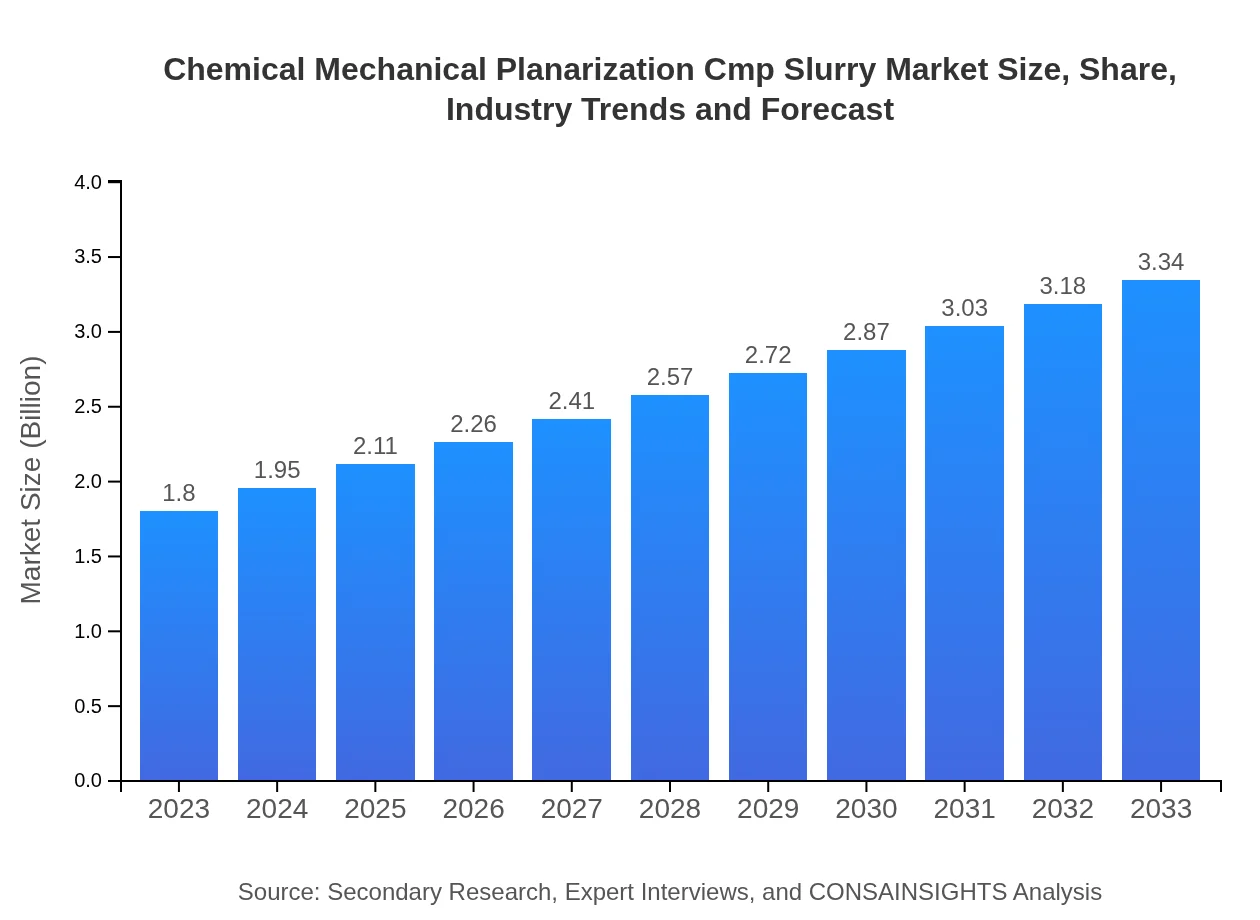

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $1.80 Billion |

| CAGR (2023-2033) | 6.2% |

| 2033 Market Size | $3.34 Billion |

| Top Companies | Cabot Microelectronics Corporation, Dow Chemical Company, Hitachi Chemical Co., Ltd., Fujimi Incorporated, JSR Corporation |

| Last Modified Date | 31 January 2026 |

Chemical Mechanical Planarization Cmp Slurry Market Overview

Customize Chemical Mechanical Planarization Cmp Slurry Market Report market research report

- ✔ Get in-depth analysis of Chemical Mechanical Planarization Cmp Slurry market size, growth, and forecasts.

- ✔ Understand Chemical Mechanical Planarization Cmp Slurry's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Chemical Mechanical Planarization Cmp Slurry

What is the Market Size & CAGR of Chemical Mechanical Planarization Cmp Slurry market in 2023?

Chemical Mechanical Planarization Cmp Slurry Industry Analysis

Chemical Mechanical Planarization Cmp Slurry Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Chemical Mechanical Planarization Cmp Slurry Market Analysis Report by Region

Europe Chemical Mechanical Planarization Cmp Slurry Market Report:

In Europe, the CMP slurry market is valued at $0.54 billion in 2023 and is projected to grow to $0.99 billion by 2033. The market benefits from stringent manufacturing standards and an emphasis on high-performance electronic components.Asia Pacific Chemical Mechanical Planarization Cmp Slurry Market Report:

The Asia Pacific region is a pivotal market for CMP slurries, with a size of $0.36 billion in 2023, expected to grow to $0.67 billion by 2033. The rapid growth of the semiconductor industry in countries like China, Japan, and South Korea drives the demand for high-quality CMP slurries, catering to both local and global markets.North America Chemical Mechanical Planarization Cmp Slurry Market Report:

North America stands out with a market size of $0.59 billion in 2023, increasing to $1.10 billion in 2033. The presence of major semiconductor manufacturers and a focus on innovation in technologies drives robust market growth in this region.South America Chemical Mechanical Planarization Cmp Slurry Market Report:

In South America, the CMP slurry market size was $0.06 billion in 2023, projected to reach $0.11 billion by 2033. The region is gradually adopting advanced manufacturing technologies, which will anchor market expansion as local industries begin to embrace semiconductor production.Middle East & Africa Chemical Mechanical Planarization Cmp Slurry Market Report:

The Middle East and Africa region had a market size of $0.25 billion in 2023, forecasted to grow to $0.46 billion by 2033. Investment in technological infrastructure and increasing awareness of advanced manufacturing processes are pivotal for growth in this region.Tell us your focus area and get a customized research report.

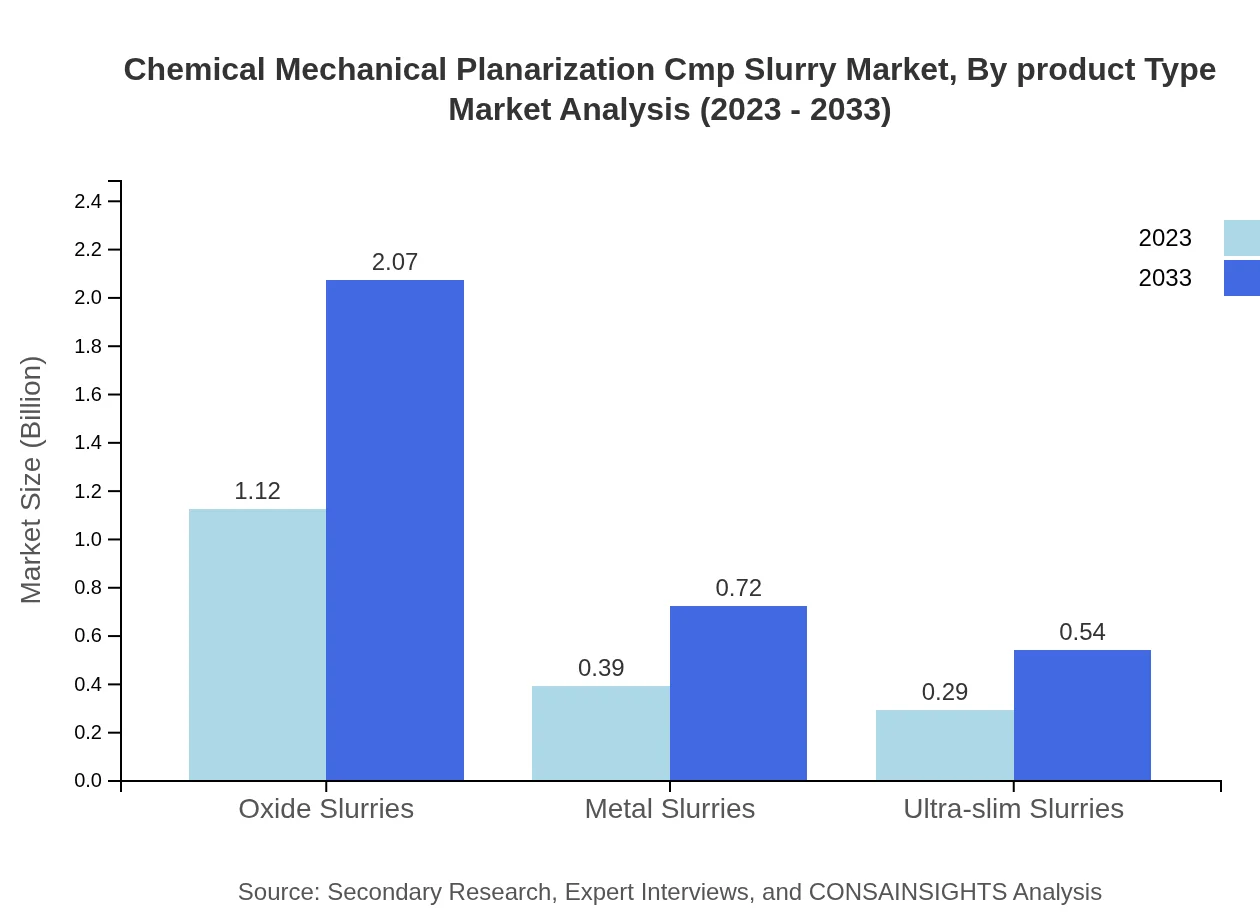

Chemical Mechanical Planarization Cmp Slurry Market Analysis By Product Type

In 2023, the oxide slurries segment dominates the market, with a size of $1.12 billion (62.18% market share). Metal slurries contribute $0.39 billion (21.70% market share), while ultra-slim slurries are valued at $0.29 billion (16.12% market share). By 2033, the oxide slurries segment is expected to grow to $2.07 billion, maintaining a steady market share, while metal and ultra-slim slurries will also see considerable growth.

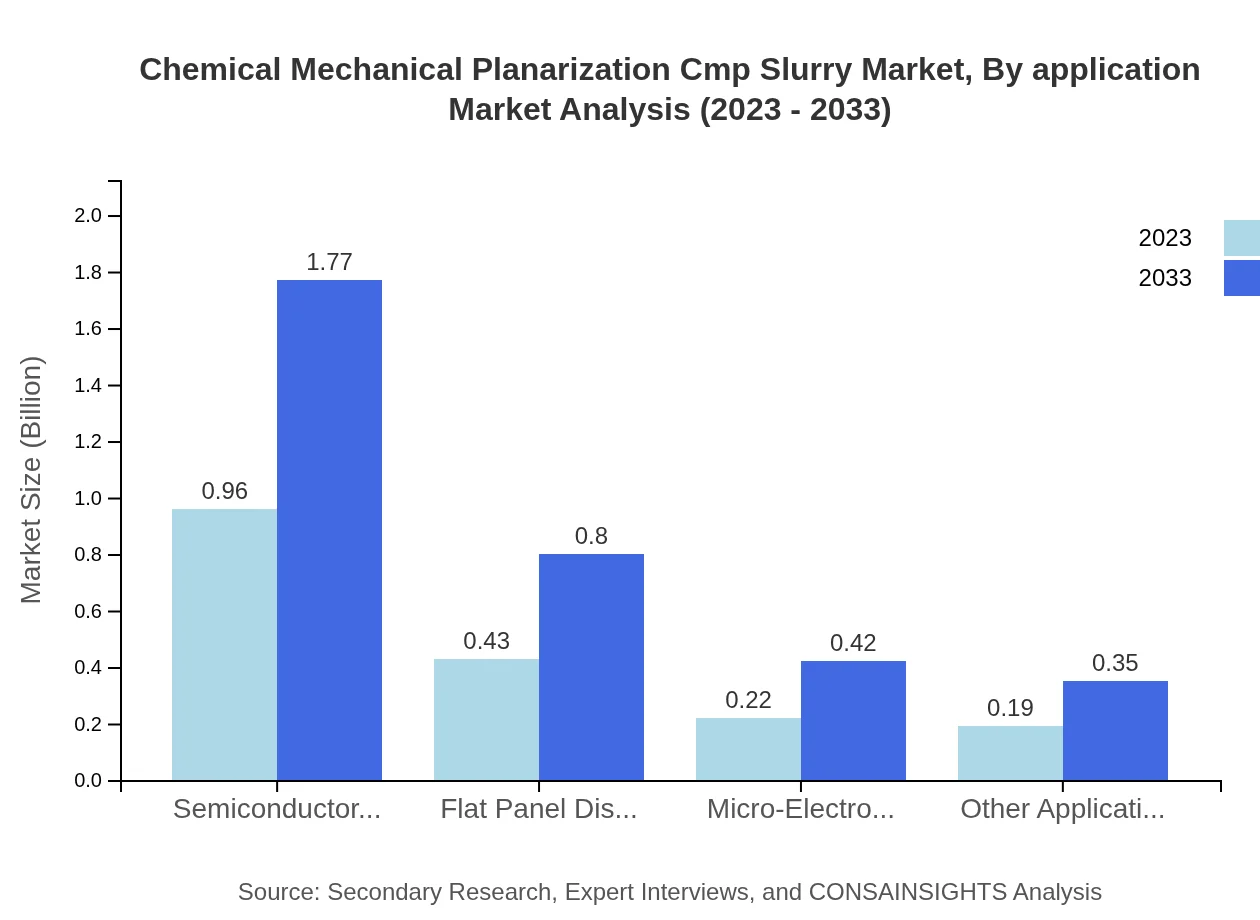

Chemical Mechanical Planarization Cmp Slurry Market Analysis By Application

The semiconductor manufacturing application leads the market with a size of $0.96 billion (53.12% market share) in 2023, expected to increase to $1.77 billion by 2033. Telecommunications follows with a current market size of $0.42 billion (23.07% market share) and projected growth to $0.77 billion. Other applications including automotive and healthcare equipment are also showing promising growth, with growing market shares as industries expand.

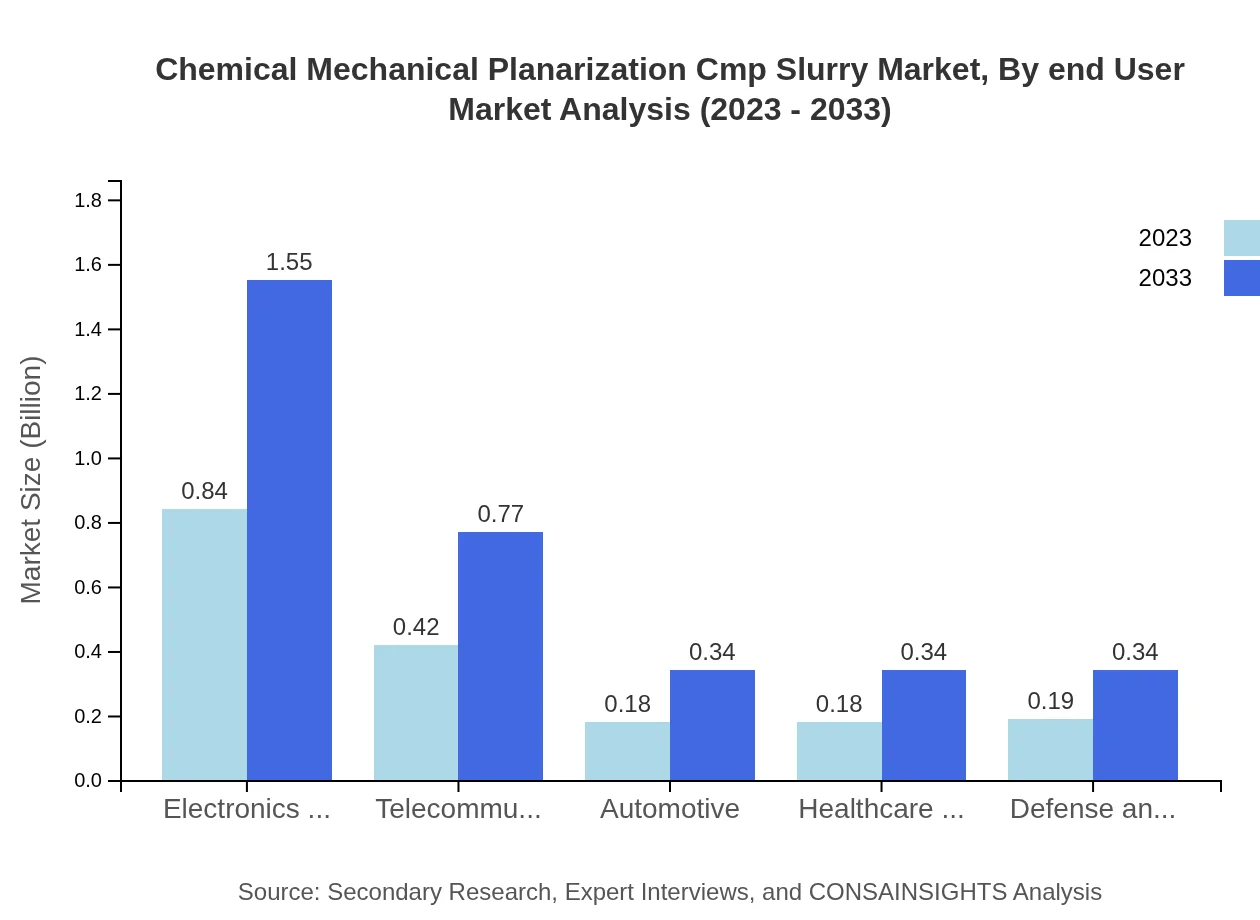

Chemical Mechanical Planarization Cmp Slurry Market Analysis By End User

The electronics industry holds a significant share of the CMP slurry market, valued at $0.84 billion (46.42% market share) in 2023 and expected to grow to $1.55 billion by 2033. The automotive, telecommunications, and healthcare sectors also represent substantial shares of the market, indicating diverse applications and the increasing integration of CMP processes in various industries.

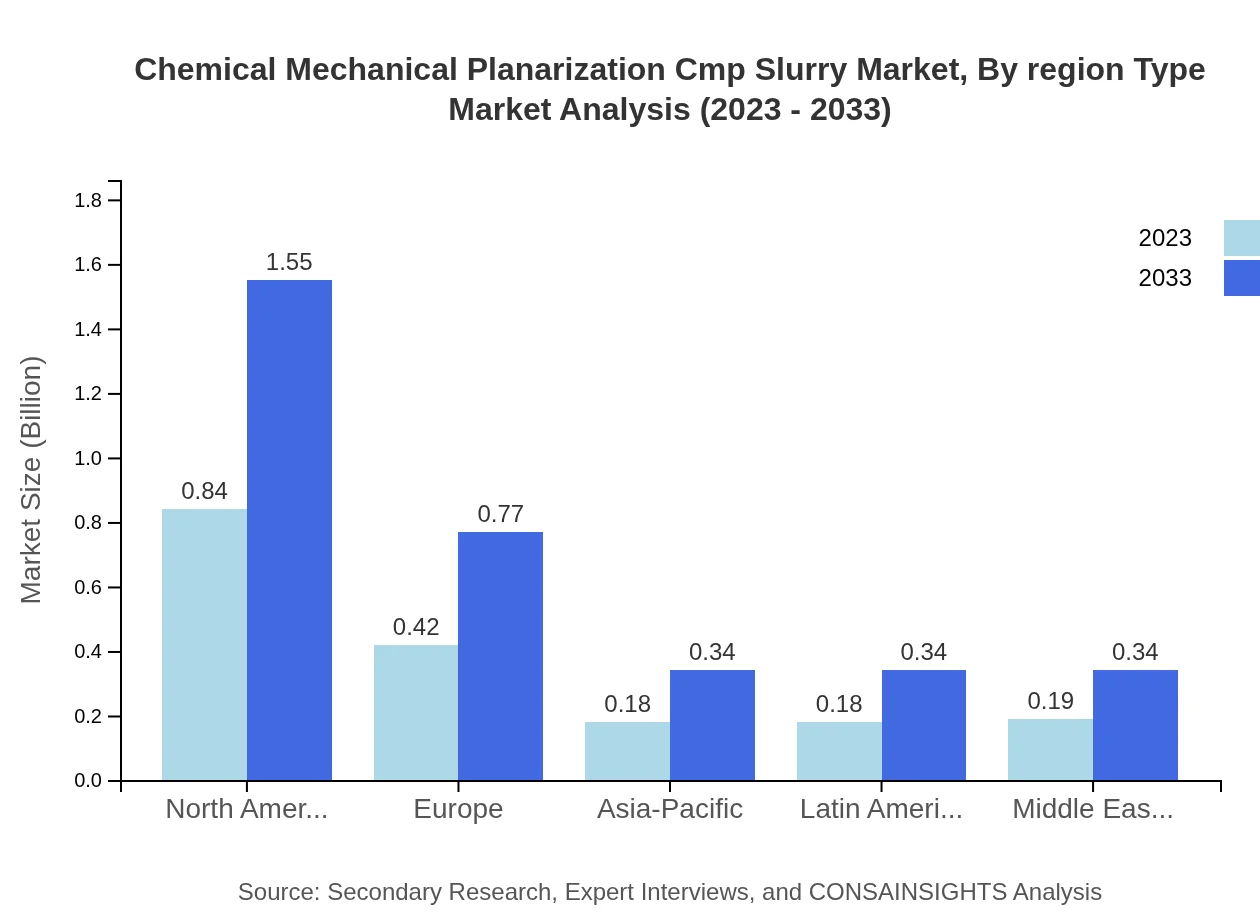

Chemical Mechanical Planarization Cmp Slurry Market Analysis By Region Type

Regional analysis indicates North America as a leader, with a size of $0.84 billion (46.42% market share) in 2023, expected to consistently lead until 2033. The Asia-Pacific market, worth $0.18 billion (10.11%), is expected to experience significant growth as semiconductor industries flourish. Europe also maintains a notable position with a 23.07% market share, reflecting the region's technological advancements.

Chemical Mechanical Planarization Cmp Slurry Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Chemical Mechanical Planarization Cmp Slurry Industry

Cabot Microelectronics Corporation:

A leading manufacturer of CMP slurries, known for its innovative products and extensive R&D efforts in enhancing slurry performance.Dow Chemical Company:

A key player in the CMP sector, Dow provides a range of high-quality slurry formulations that cater to diverse semiconductor applications.Hitachi Chemical Co., Ltd.:

Hitachi is recognized for its advanced CMP slurries and significant experience in the semiconductor manufacturing industry.Fujimi Incorporated:

Fujimi offers specialized CMP slurries and continuously invests in new technologies to support global semiconductor fabrication.JSR Corporation:

JSR is well-regarded for its commitment to high-performance materials in semiconductor manufacturing, including CMP slurries.We're grateful to work with incredible clients.

FAQs

What is the market size of chemical Mechanical Planarization Cmp Slurry?

The global Chemical Mechanical Planarization (CMP) slurry market is estimated at $1.8 billion in 2023, with a projected CAGR of 6.2% from 2023 to 2033, reflecting significant growth potential in this industry.

What are the key market players or companies in this chemical Mechanical Planarization Cmp Slurry industry?

Key players in the CMP slurry market include major companies like Cabot Microelectronics, Fujifilm, and Dow—pioneering advancements in CMP technology and enhancing product portfolios to cater to the evolving electronics sector.

What are the primary factors driving the growth in the chemical Mechanical Planarization Cmp Slurry industry?

Growth in the CMP slurry market is driven by the expanding semiconductor manufacturing sector, increasing demand for advanced electronic devices, and continuous improvements in CMP slurry formulations for enhanced performance.

Which region is the fastest Growing in the chemical Mechanical Planarization Cmp Slurry?

Asia-Pacific is the fastest-growing region for CMP slurry, projected to grow from $0.36 billion in 2023 to $0.67 billion in 2033, attributed to burgeoning semiconductor industries in Taiwan, South Korea, and China.

Does ConsaInsights provide customized market report data for the chemical Mechanical Planarization Cmp Slurry industry?

Yes, ConsaInsights offers tailored market reports for the CMP slurry industry, enabling clients to access specific data, trends, and forecasts that fit their unique business needs.

What deliverables can I expect from this chemical Mechanical Planarization Cmp Slurry market research project?

Deliverables include comprehensive market analysis, segment insights, competitive landscape overview, customized data insights, and strategic recommendations aimed at enhancing business decision-making.

What are the market trends of chemical Mechanical Planarization Cmp Slurry?

Trends in the CMP slurry market include increasing use of eco-friendly formulations, advancements in slurry technologies, and growing adoption in sectors such as telecommunications and healthcare equipment.