Hbpa Epoxy Resin Market Report

Published Date: 02 February 2026 | Report Code: hbpa-epoxy-resin

Hbpa Epoxy Resin Market Size, Share, Industry Trends and Forecast to 2033

This report provides comprehensive insights into the Hbpa Epoxy Resin market for the forecast period 2023 - 2033, covering market size, growth rates, segmentation, regional dynamics, and significant industry trends.

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

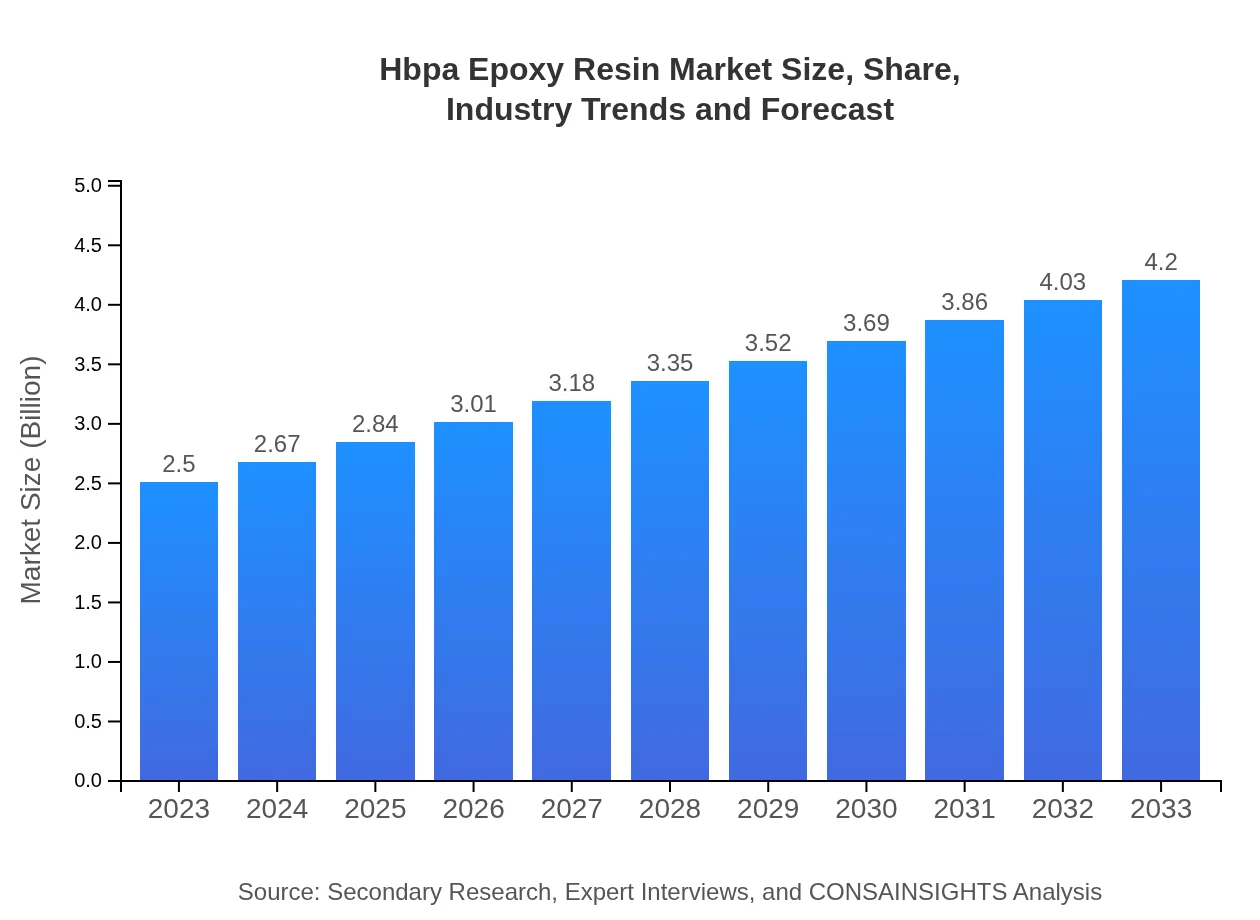

| 2023 Market Size | $2.50 Billion |

| CAGR (2023-2033) | 5.2% |

| 2033 Market Size | $4.20 Billion |

| Top Companies | Hexion Inc., BASF SE, Ferro Corporation, Mitsubishi Chemical Corporation |

| Last Modified Date | 02 February 2026 |

Hbpa Epoxy Resin Market Overview

Customize Hbpa Epoxy Resin Market Report market research report

- ✔ Get in-depth analysis of Hbpa Epoxy Resin market size, growth, and forecasts.

- ✔ Understand Hbpa Epoxy Resin's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Hbpa Epoxy Resin

What is the Market Size & CAGR of Hbpa Epoxy Resin market in 2023?

Hbpa Epoxy Resin Industry Analysis

Hbpa Epoxy Resin Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Hbpa Epoxy Resin Market Analysis Report by Region

Europe Hbpa Epoxy Resin Market Report:

The European market, valued at $0.67 billion in 2023, is forecasted to escalate to $1.12 billion by 2033. Stringent regulations and a push towards sustainable materials are leading to an increased uptake of eco-friendly epoxy solutions.Asia Pacific Hbpa Epoxy Resin Market Report:

The Asia Pacific region accounts for a significant share of the Hbpa Epoxy Resin market, valued at $0.52 billion in 2023 and expected to rise to $0.87 billion by 2033. The rapid industrialization and expanding automotive and construction sectors in countries like China and India are key drivers.North America Hbpa Epoxy Resin Market Report:

North America shows strong potential with a market size of $0.88 billion in 2023, anticipated to reach $1.48 billion by 2033. The automotive industry's emphasis on lightweight materials and durability is stimulating demand for epoxy resins.South America Hbpa Epoxy Resin Market Report:

In South America, the Hbpa Epoxy Resin market is projected to grow from $0.12 billion in 2023 to $0.20 billion in 2033. The growth is supported by increasing investments in infrastructure and construction projects in Brazil and Argentina.Middle East & Africa Hbpa Epoxy Resin Market Report:

The Middle East and Africa region demonstrates a growing market, projected to enhance from $0.31 billion in 2023 to $0.52 billion by 2033. Growth is driven by construction and automotive sectors, especially within the Gulf Cooperation Council countries.Tell us your focus area and get a customized research report.

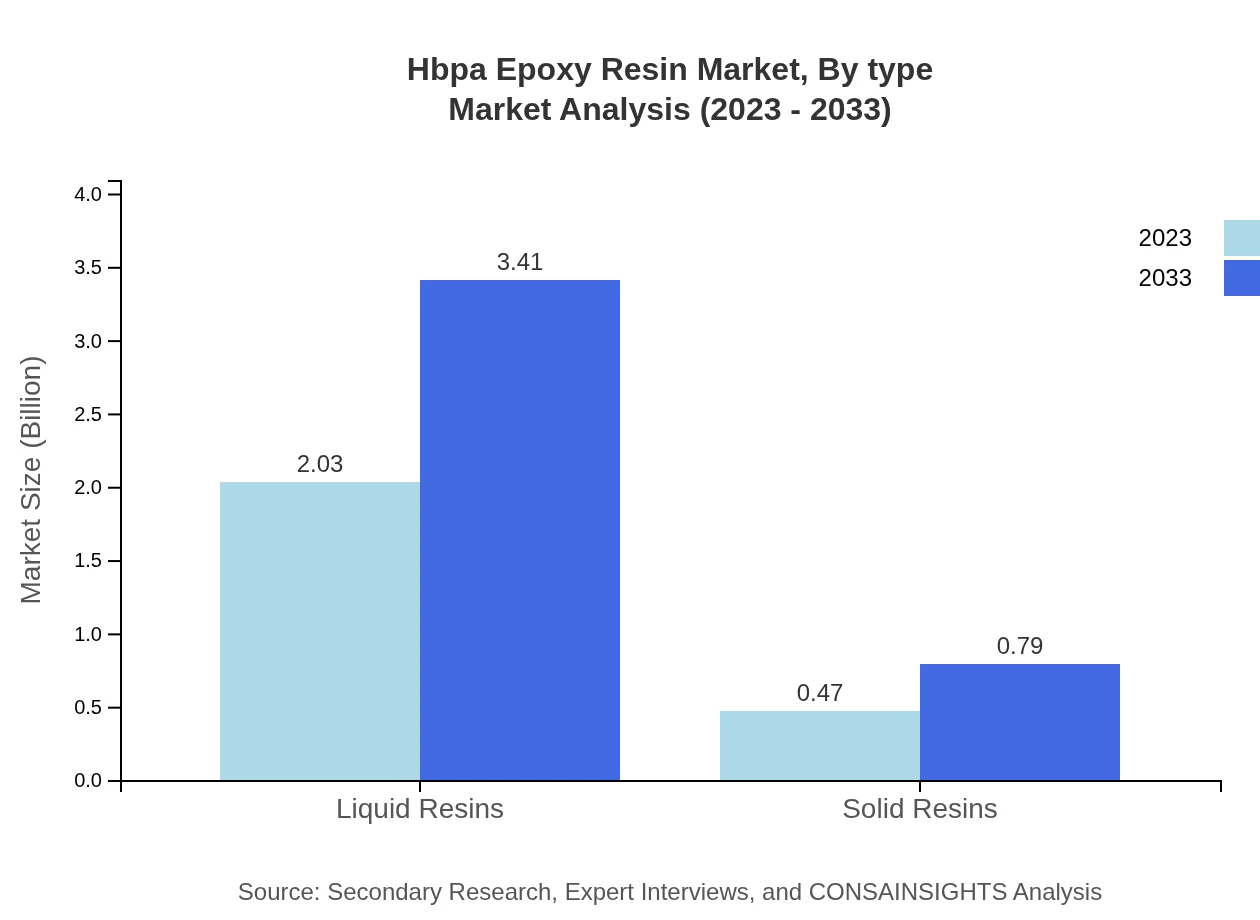

Hbpa Epoxy Resin Market Analysis By Type

The type segmentation of the Hbpa Epoxy Resin market identifies liquid resins as the dominant segment, valued at $2.03 billion in 2023 and expected to rise to $3.41 billion by 2033, accounting for 81.14% share. Solid resins, although smaller, projected to experience growth from $0.47 billion to $0.79 billion, representing 18.86% market share.

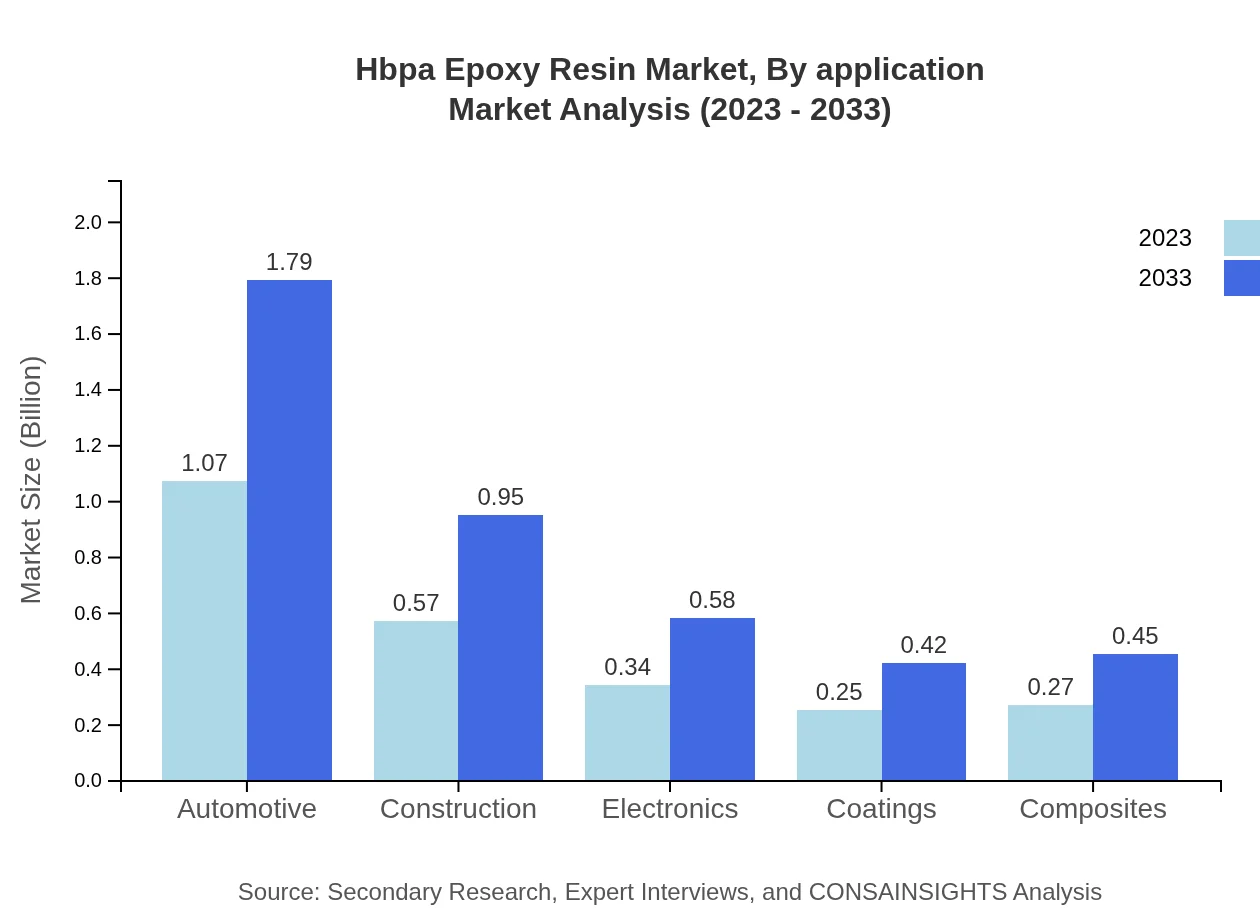

Hbpa Epoxy Resin Market Analysis By Application

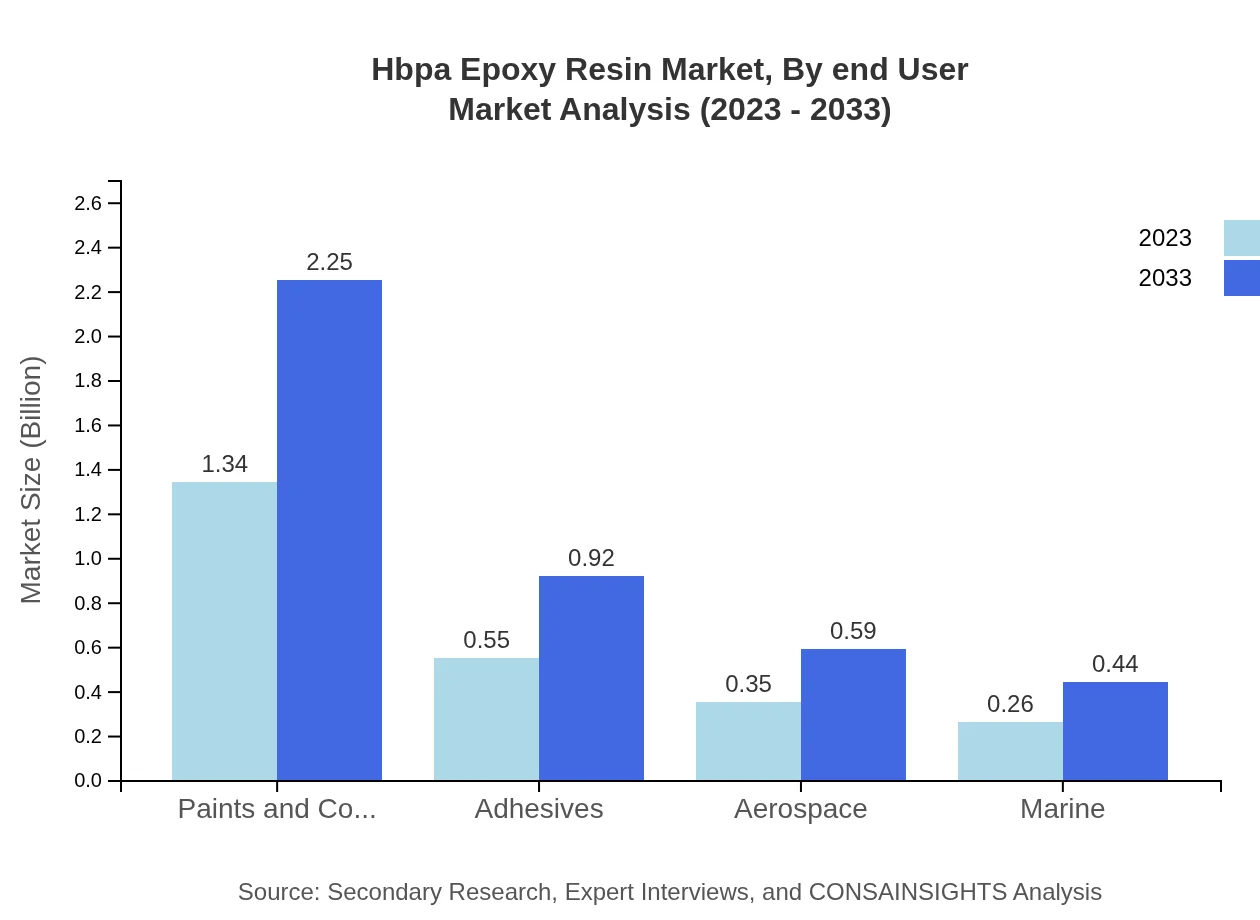

Within applications, paints and coatings lead with a market size of $1.34 billion in 2023, increasing to $2.25 billion by 2033 (53.54% share). Significantly, adhesives will also grow from $0.55 billion to $0.92 billion, capturing 21.82% of the market share. Other notable sectors include aerospace and automotive, demonstrating strong consumption rates.

Hbpa Epoxy Resin Market Analysis By End User

The automotive sector dominates the end-user industry segment, accounting for 42.75% share with market values of $1.07 billion in 2023 projected to rise to $1.79 billion by 2033. Construction and aerospace also represent significant markets, illustrating the widespread applicability of Hbpa Epoxy Resins.

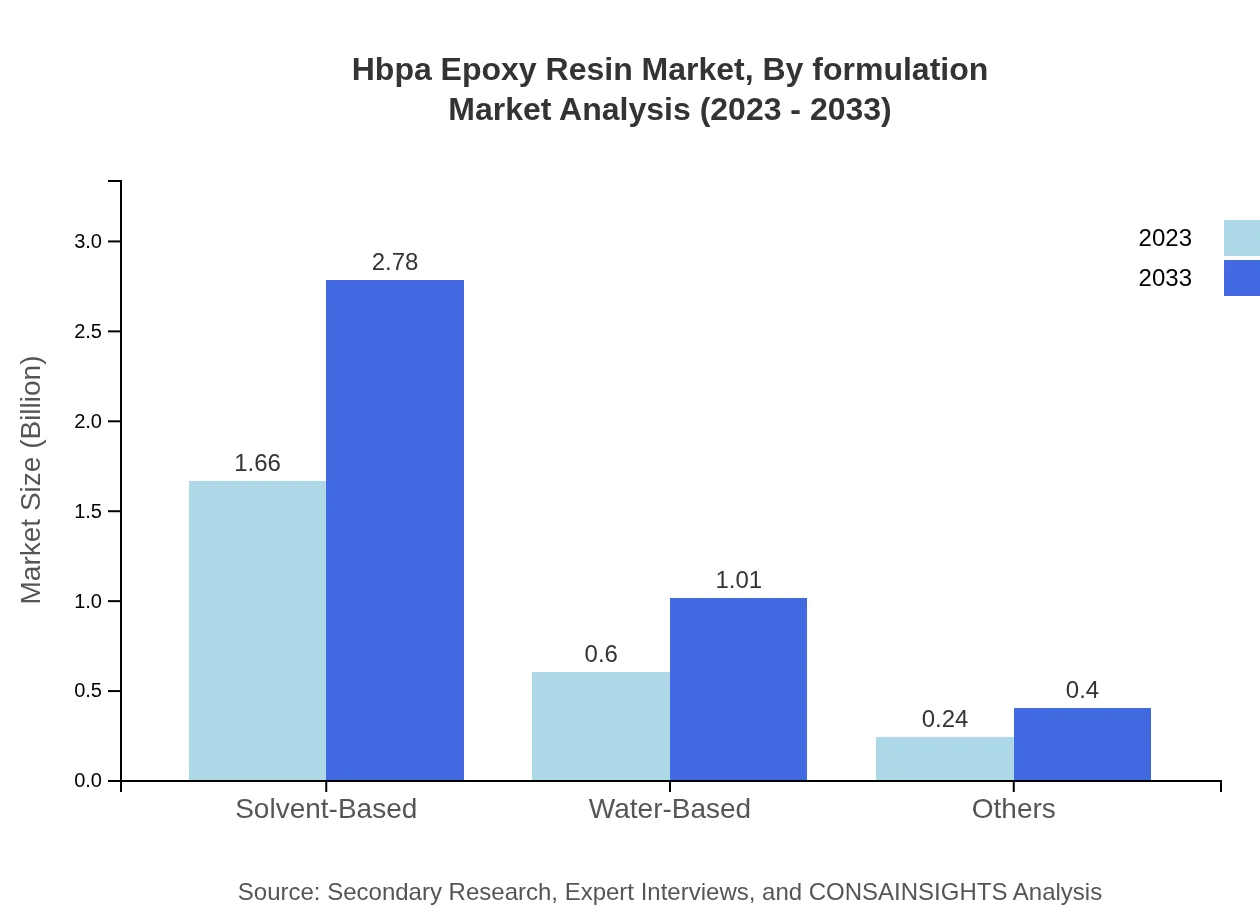

Hbpa Epoxy Resin Market Analysis By Formulation

Market segmentation by formulation shows solvent-based resins leading with a size of $1.66 billion in 2023 and expected to reach $2.78 billion by 2033 (66.3% share), while water-based and other formulations will grow significantly, driven by sustainability trends.

Hbpa Epoxy Resin Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Hbpa Epoxy Resin Industry

Hexion Inc.:

A leading supplier of thermoset resins, Hexion offers a broad range of Epoxy Resins including advanced formulations for industries like aerospace and automotive.BASF SE:

BASF is a key player in the chemical market providing innovative resin solutions including Hbpa Epoxy Resins for construction and industrial applications.Ferro Corporation:

Ferro specializes in performance materials, including specialty resins and additives that enhance surface coatings and adhesive applications.Mitsubishi Chemical Corporation:

Mitsubishi Chemical produces various epoxy resins, focusing on creating sustainable and high-performance materials.We're grateful to work with incredible clients.

FAQs

What is the market size of hbpa Epoxy Resin?

The hbpa-epoxy-resin market is currently valued at approximately $2.5 billion in 2023, with a steady growth forecast at a CAGR of 5.2% until 2033. This growth reflects increasing demand across various sectors, particularly in manufacturing and construction.

What are the key market players or companies in the hbpa Epoxy Resin industry?

Key players in the hbpa-epoxy-resin industry include large chemical manufacturers and specialty resin producers who are instrumental in positioning and driving innovation. These companies focus on maintaining quality standards and expanding their product lines to meet diverse customer needs.

What are the primary factors driving the growth in the hbpa Epoxy Resin industry?

The growth in the hbpa-epoxy-resin industry is primarily driven by expanding applications in construction, automotive, and electronics. Additionally, advancements in resin formulations and increased demand for durable coatings are also contributing factors, along with the push for sustainable solutions.

Which region is the fastest Growing in the hbpa Epoxy Resin?

The Asia Pacific region is the fastest-growing market for hbpa-epoxy-resin, expected to reach $0.87 billion by 2033 from $0.52 billion in 2023. This growth is fueled by rapid industrialization and increasing consumer needs in manufacturing and construction sectors.

Does ConsaInsights provide customized market report data for the hbpa Epoxy Resin industry?

Yes, ConsaInsights offers customized market reports specifically tailored for the hbpa-epoxy-resin industry. These reports provide detailed analysis and insights to help stakeholders make informed decisions based on unique business needs and market dynamics.

What deliverables can I expect from this hbpa Epoxy Resin market research project?

You can expect comprehensive deliverables including detailed market analysis, industry trends, competitor landscape, and forecasts. Additionally, specific segment insights and regional breakdowns will be part of the research outcomes to facilitate strategic planning.

What are the market trends of hbpa Epoxy Resin?

Current market trends in hbpa-epoxy-resin include a shift towards environmentally-friendly products, increasing adoption in the automotive and construction sectors, and the growing popularity of water-based formulations. These trends are shaping the future direction of market strategies and innovation.