Impact Modifier Market Report

Published Date: 02 February 2026 | Report Code: impact-modifier

Impact Modifier Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Impact Modifier market, including insights on market size, growth rates, trends, segments, and forecasts for the period of 2023 to 2033.

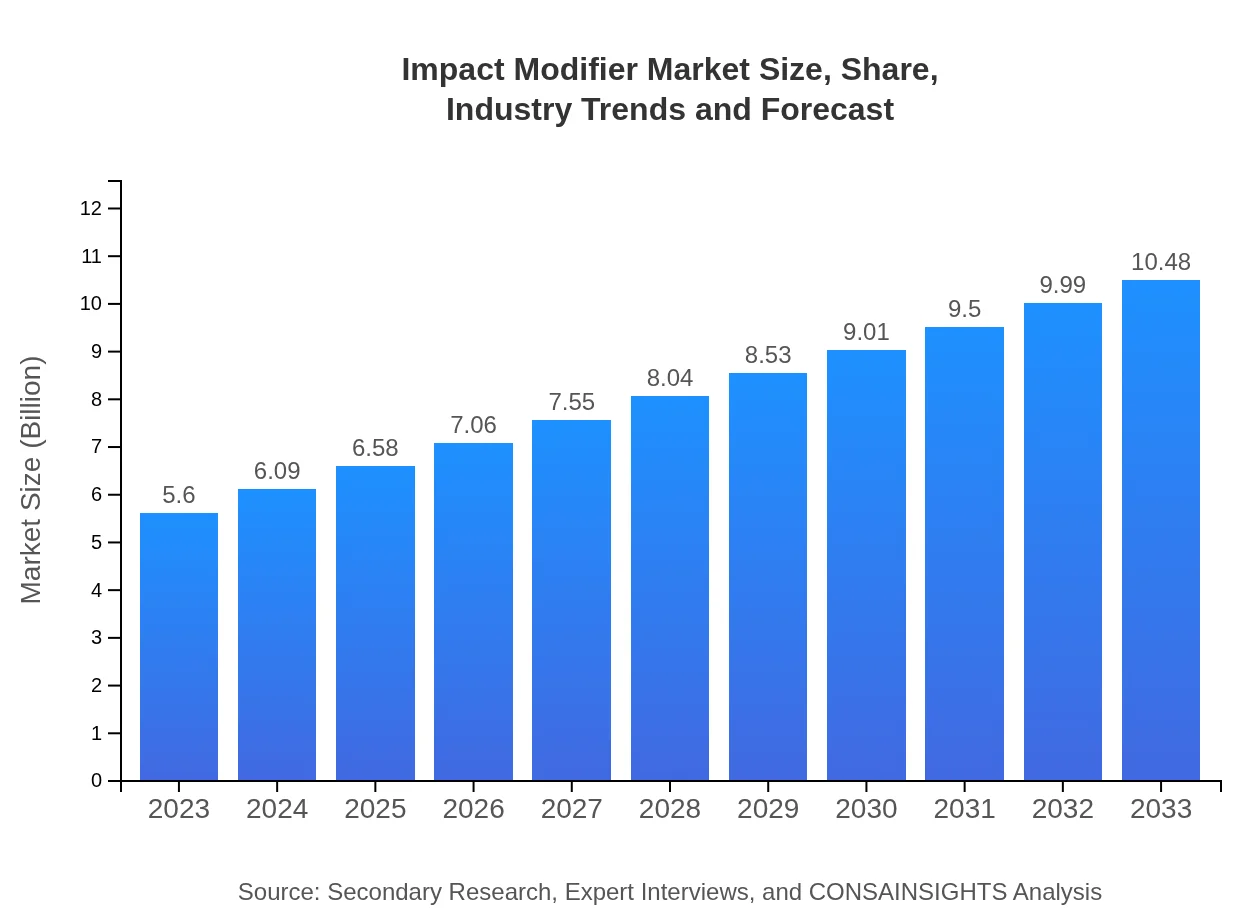

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $5.60 Billion |

| CAGR (2023-2033) | 6.3% |

| 2033 Market Size | $10.48 Billion |

| Top Companies | BASF, DuPont, Elastron, LG Chem, Chevron Phillips Chemical |

| Last Modified Date | 02 February 2026 |

Impact Modifier Market Overview

Customize Impact Modifier Market Report market research report

- ✔ Get in-depth analysis of Impact Modifier market size, growth, and forecasts.

- ✔ Understand Impact Modifier's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Impact Modifier

What is the Market Size & CAGR of the Impact Modifier market in 2023?

Impact Modifier Industry Analysis

Impact Modifier Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Impact Modifier Market Analysis Report by Region

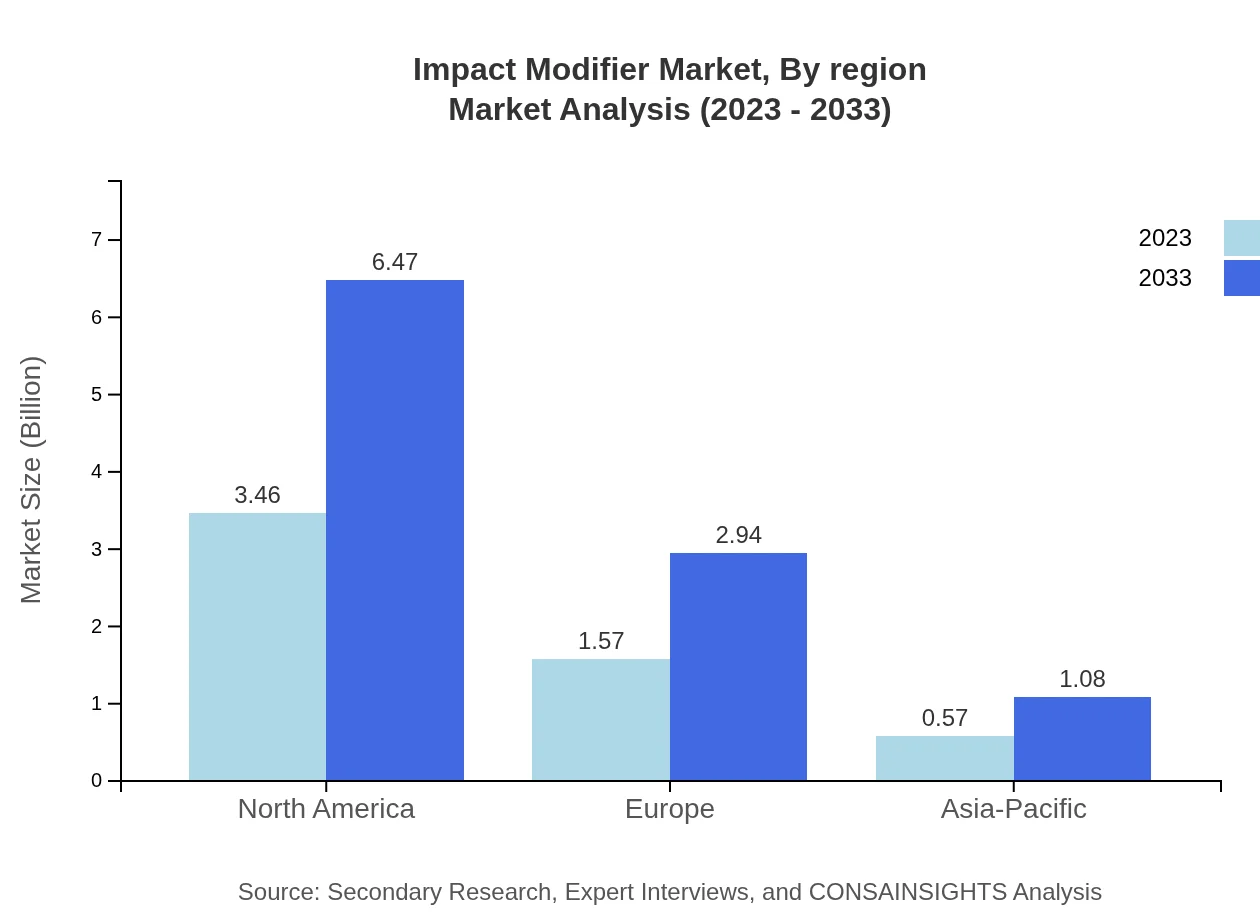

Europe Impact Modifier Market Report:

In Europe, the market is valued at USD 1.63 billion in 2023 and is anticipated to grow to USD 3.04 billion by 2033. Stringent regulations on material performance and an increased emphasis on sustainable construction practices are key drivers in this region.Asia Pacific Impact Modifier Market Report:

In the Asia Pacific region, the Impact Modifier market is valued at USD 1.08 billion in 2023 and is expected to reach USD 2.01 billion by 2033. The region's rapid industrialization and infrastructure development are driving demand for impact modifiers, particularly in construction applications.North America Impact Modifier Market Report:

The North American Impact Modifier market is substantial, with a size of USD 2.05 billion in 2023, expected to grow to USD 3.84 billion by 2033. The region's focus on technological advancements and sustainable practices in manufacturing is fuelling growth.South America Impact Modifier Market Report:

South America shows a modest growth trajectory for the Impact Modifier market, with a size of USD 0.19 billion in 2023 projected to increase to USD 0.36 billion by 2033. The growth is supported by demand in construction and automotive sectors, alongside an emphasis on improving product durability.Middle East & Africa Impact Modifier Market Report:

The Middle East and Africa’s Impact Modifier market is expected to escalate from USD 0.65 billion in 2023 to USD 1.22 billion by 2033, with infrastructural projects boosting demand and the gradual focus on enhancing product quality and resilience in varied applications.Tell us your focus area and get a customized research report.

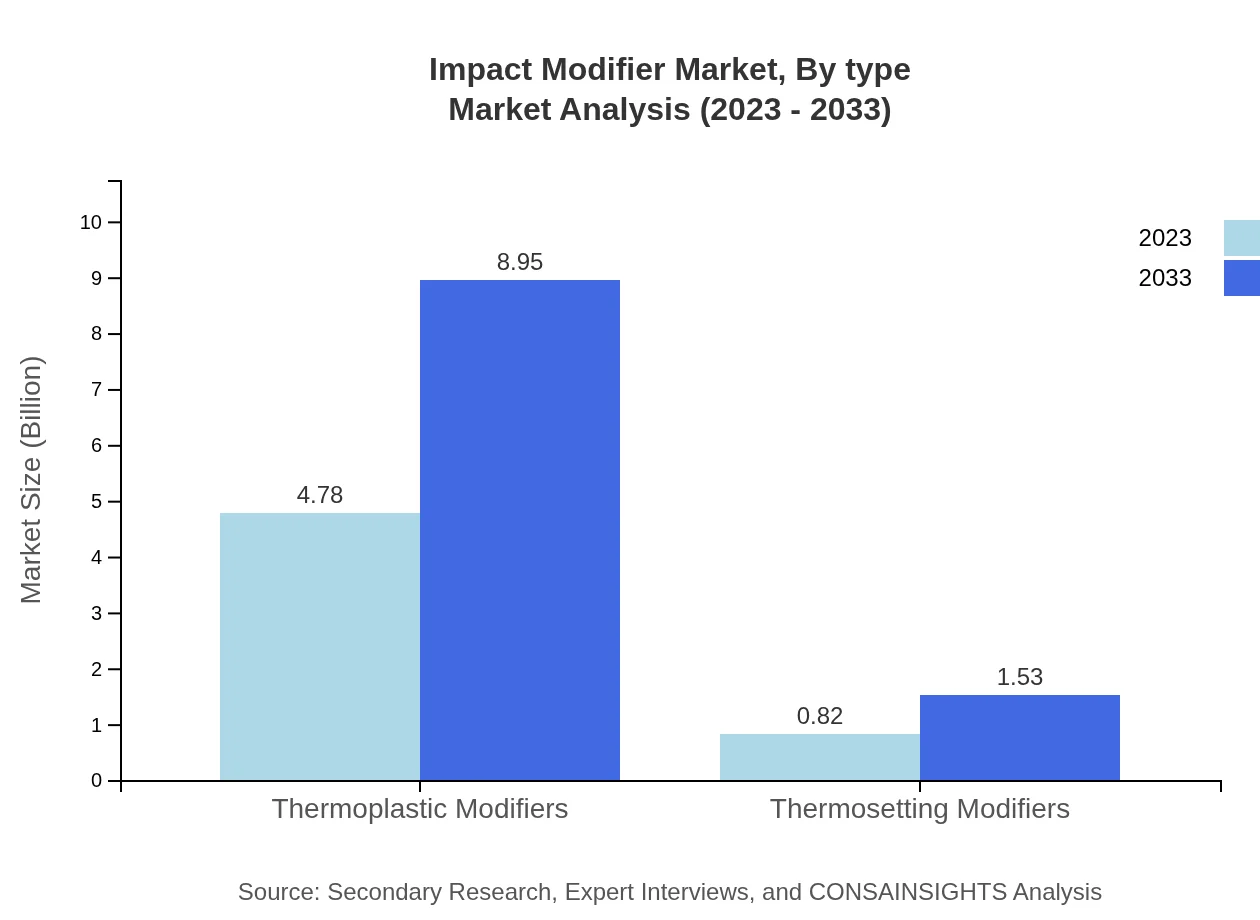

Impact Modifier Market Analysis By Type

The segment analysis reveals that thermoplastic modifiers are dominant with a market size of USD 4.78 billion in 2023, rising to USD 8.95 billion by 2033, sharing 85.41% of the market. Powder modifiers also hold a significant share, while liquid and thermosetting modifiers show gradual growth.

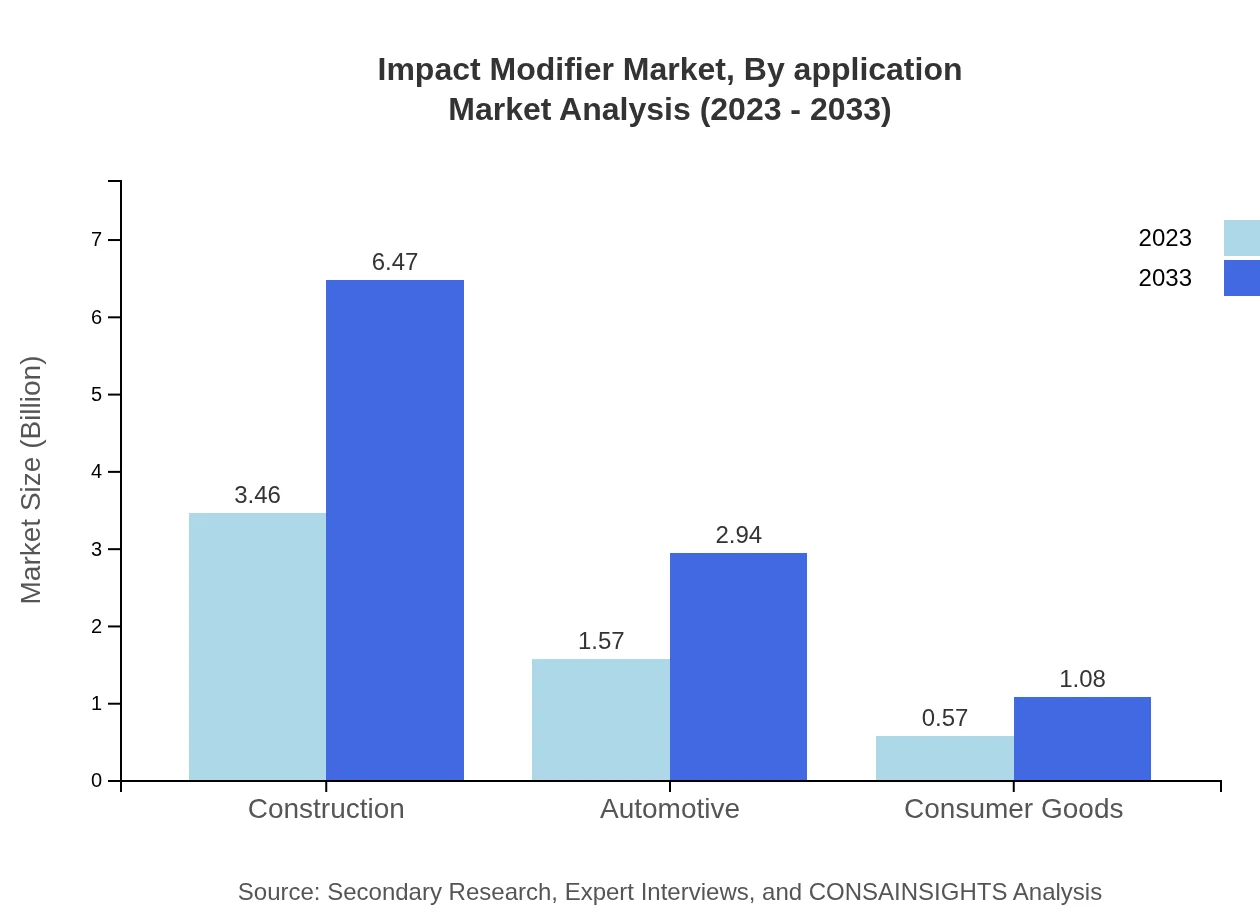

Impact Modifier Market Analysis By Application

The construction and automotive industries are the largest segments, holding 61.7% and 28.04% market shares, respectively. Consumer goods represent a smaller share but still exhibit growth, reflecting the versatility of impact modifiers across various applications.

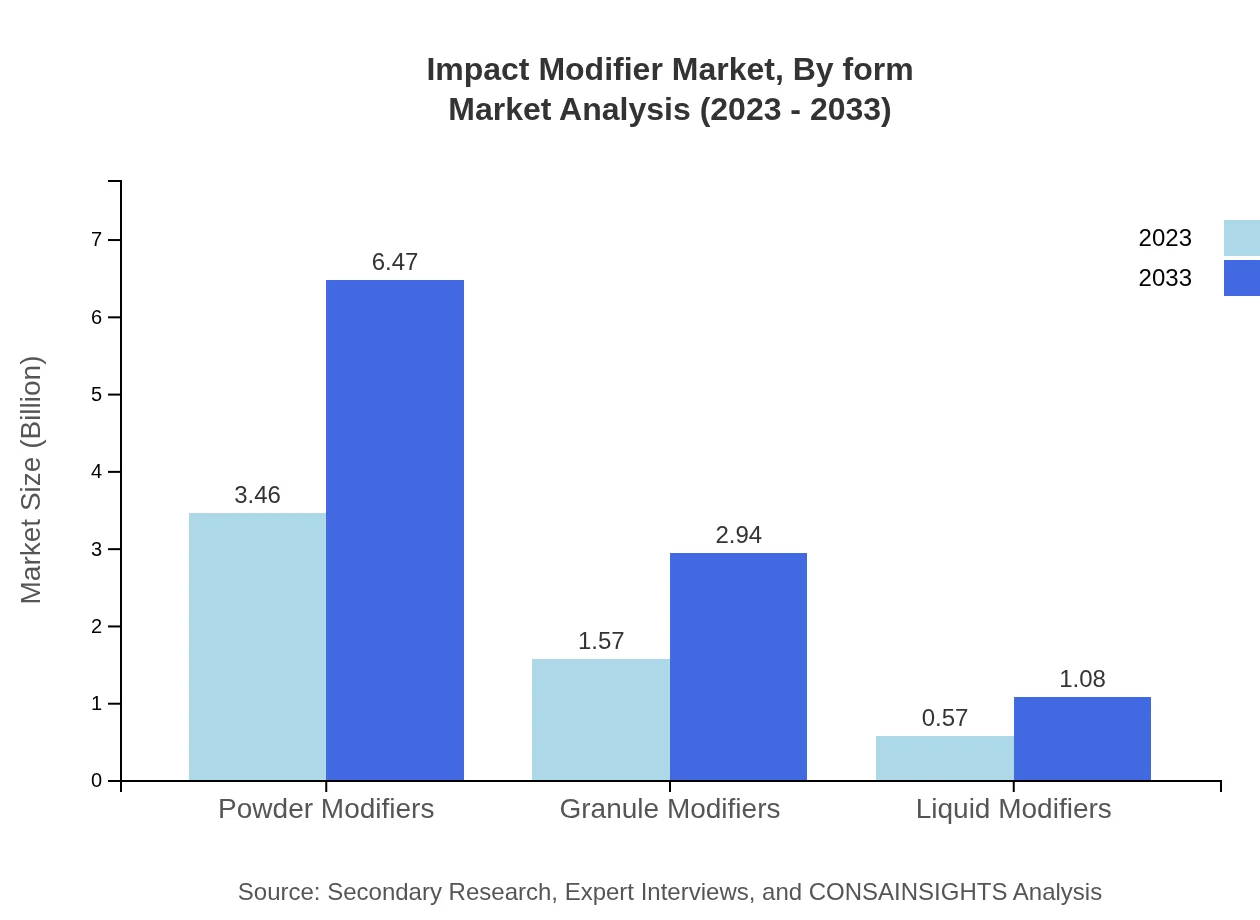

Impact Modifier Market Analysis By Form

Different forms of Impact Modifiers, such as powder, granule, and liquid, cater to varying application needs. Powder modifiers dominate the market, likely due to widespread use in numerous manufacturing processes.

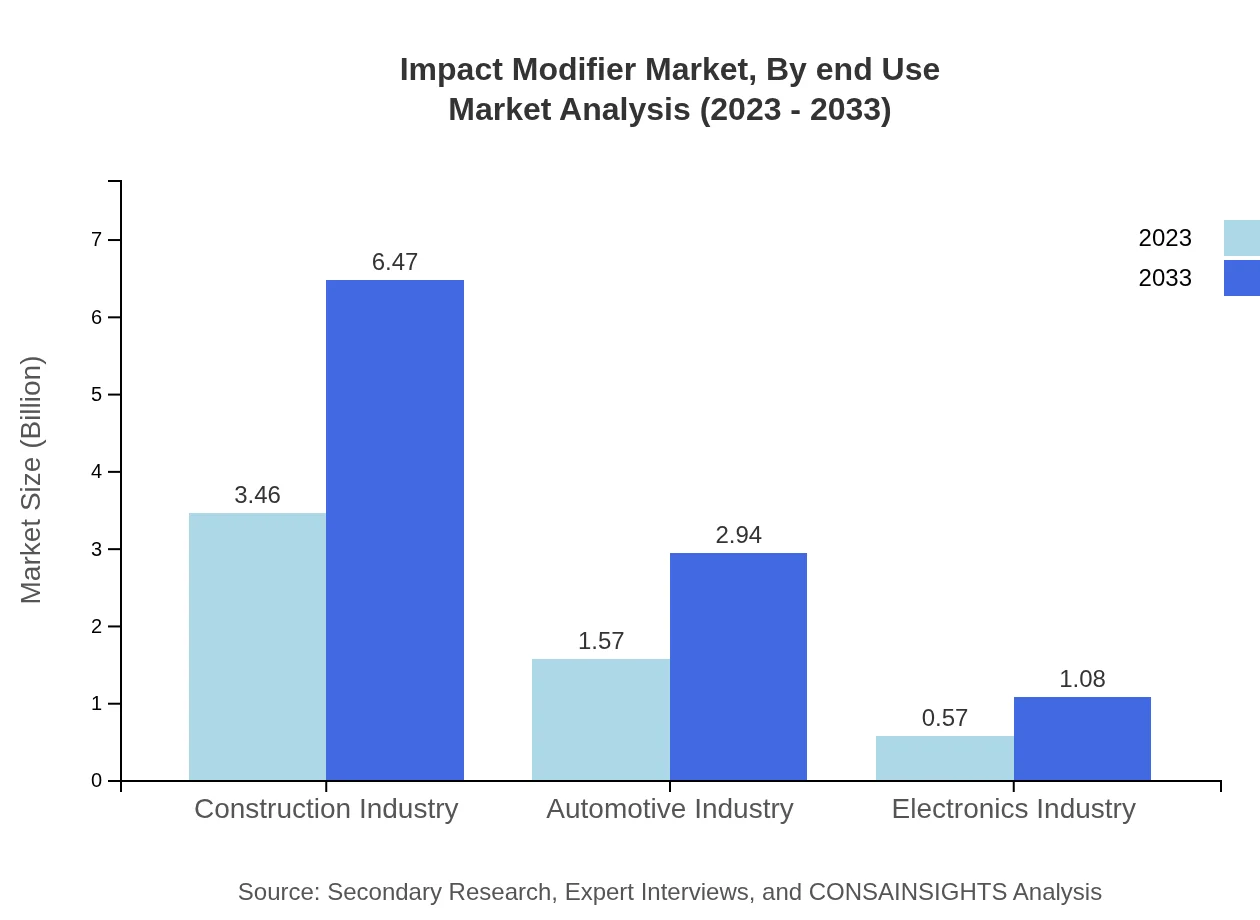

Impact Modifier Market Analysis By End Use

The end-user industry analysis indicates that construction, automotive, and electronics are the top industries leveraging impact modifiers to enhance product performance and longevity, highlighting the importance of these modifications in both safety and efficiency.

Impact Modifier Market Analysis By Region

Regional segmentation emphasizes North America and Europe as key markets, with emerging economies in Asia Pacific showing the fastest growth due to urbanization and industrial initiatives.

Impact Modifier Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Impact Modifier Industry

BASF:

BASF leads the market with a wide range of impact modifiers aimed at enhancing plastic materials, renowned for its innovative and sustainable product lines.DuPont:

DuPont is recognized for its advanced engineering materials, providing specialized impact modifiers designed for specific applications in construction and automotive industries.Elastron:

Elastron specializes in thermoplastic elastomers, offering high-performance impact modifiers used in various polymer applications, particularly in demanding industries.LG Chem:

LG Chem is a major player in the chemical sector, producing impact modifiers that greatly enhance the properties of plastics, catering to global markets.Chevron Phillips Chemical:

Chevron Phillips focuses on providing innovative plastic materials with integrated impact modifiers, ensuring durability and enhanced performance.We're grateful to work with incredible clients.

FAQs

What is the market size of impact Modifier?

The impact modifier market is currently valued at approximately $5.6 billion, with a projected CAGR of 6.3%. By 2033, the market is expected to expand significantly, reflecting robust growth in various sectors.

What are the key market players or companies in this impact Modifier industry?

Key players in the impact modifier industry include large chemical manufacturers and specialized polymer companies that drive innovation and market demand. Their strategic partnerships and investments in research significantly influence market dynamics.

What are the primary factors driving the growth in the impact Modifier industry?

Growth in the impact modifier industry is driven by increasing demand from construction and automotive sectors, advancements in polymer technology, and the need for enhanced product durability in consumer goods. These factors collectively spur innovation and market expansion.

Which region is the fastest Growing in the impact Modifier?

Asia-Pacific is the fastest-growing region in the impact modifier market, projected to grow from $1.08 billion in 2023 to $2.01 billion by 2033, highlighting the region's increasing industrial activities and investments in polymer solutions.

Does ConsaInsights provide customized market report data for the impact Modifier industry?

Yes, Consainsights offers customized market report data tailored to specific requests within the impact-modifier industry, ensuring clients receive insights that cater directly to their strategic and market analysis needs.

What deliverables can I expect from this impact Modifier market research project?

Deliverables from the impact-modifier market research project include detailed market analysis, regional insights, industry trends, and competitive landscape reports, providing a comprehensive overview for informed decision-making.

What are the market trends of impact Modifier?

Current trends in the impact modifier market include a shift towards eco-friendly materials, rising application in emerging industries, and increasing customization in product formulations to meet specific customer needs.