Low Voc Adhesive Market Report

Published Date: 02 February 2026 | Report Code: low-voc-adhesive

Low Voc Adhesive Market Size, Share, Industry Trends and Forecast to 2033

This market report delves into the Low Voc Adhesive sector, providing insights into market size, growth forecasts, segmentation, and key trends from 2023 to 2033. It covers comprehensive analysis catering to industry stakeholders, ensuring informed decision-making.

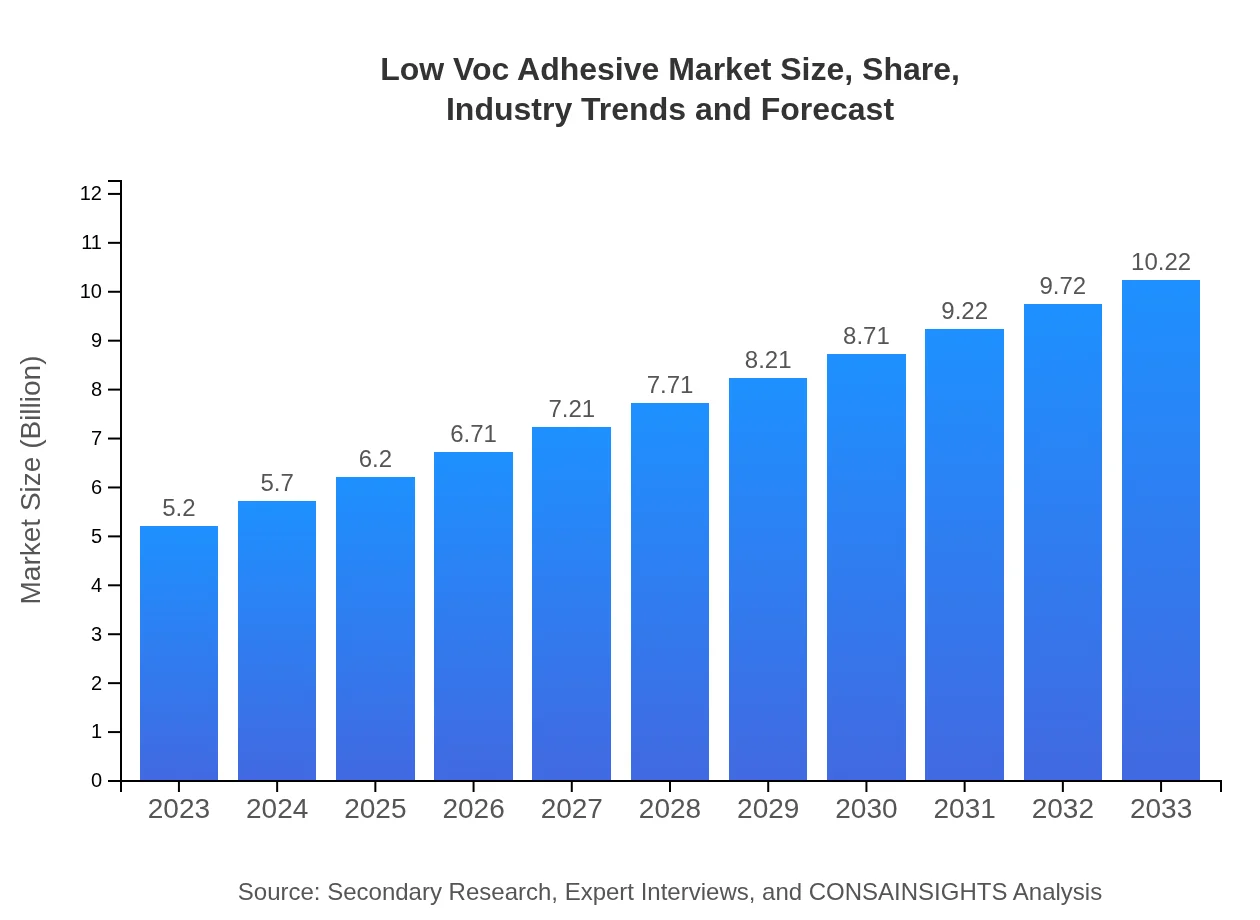

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $5.20 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $10.22 Billion |

| Top Companies | Henkel AG & Co. KGaA, BASF SE, Sika AG, 3M Company |

| Last Modified Date | 02 February 2026 |

Low Voc Adhesive Market Overview

Customize Low Voc Adhesive Market Report market research report

- ✔ Get in-depth analysis of Low Voc Adhesive market size, growth, and forecasts.

- ✔ Understand Low Voc Adhesive's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Low Voc Adhesive

What is the Market Size & CAGR of Low Voc Adhesive market in 2023?

Low Voc Adhesive Industry Analysis

Low Voc Adhesive Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Low Voc Adhesive Market Analysis Report by Region

Europe Low Voc Adhesive Market Report:

Europe's market for Low Voc Adhesive is poised for robust growth, moving from 1.62 billion USD in 2023 to 3.18 billion USD by 2033. The region's proactive stance on environmental protection and sustainable practices underpins its market leadership.Asia Pacific Low Voc Adhesive Market Report:

The Asia Pacific region is witnessing substantial growth in the Low Voc Adhesive market, with an estimated size of 0.93 billion USD in 2023, projected to reach 1.82 billion USD by 2033. This growth is fueled by rapid industrialization, infrastructural development, and stringent regulations pushing for eco-friendly alternatives.North America Low Voc Adhesive Market Report:

North America represents a significant portion of the Low Voc Adhesive market, estimated at 1.89 billion USD in 2023, with projections of 3.72 billion USD by 2033. Stringent regulations governing VOC emissions and a strong emphasis on green building practices are primary growth factors.South America Low Voc Adhesive Market Report:

In South America, the market for Low Voc Adhesive stands at 0.35 billion USD in 2023, expected to grow to 0.69 billion USD by 2033. The increasing construction activities and rising awareness of environmental sustainability are key drivers.Middle East & Africa Low Voc Adhesive Market Report:

The Middle East and Africa market is relatively small but growing, with an estimated size of 0.41 billion USD in 2023, expected to reach 0.80 billion USD by 2033. The drive towards sustainable construction methods is contributing to this growth.Tell us your focus area and get a customized research report.

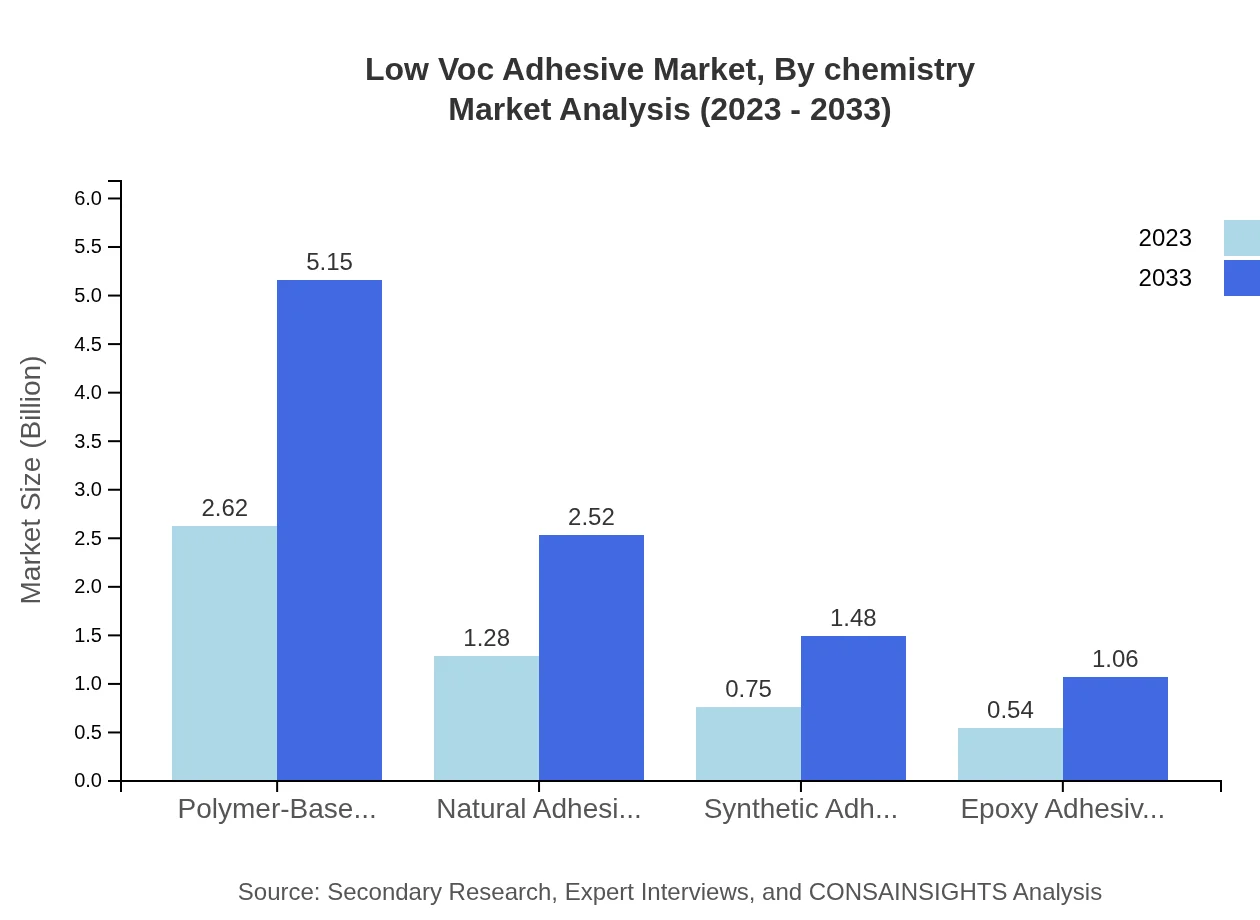

Low Voc Adhesive Market Analysis By Product Type

The Low VOC Adhesive market's product types include polymer-based adhesives, natural adhesives, and synthetic adhesives, with polymer-based adhesives holding the largest market share due to their versatility and effectiveness. In 2023, polymer-based adhesives accounted for a market size of approximately 2.62 billion USD, expecting to grow to 5.15 billion USD by 2033.

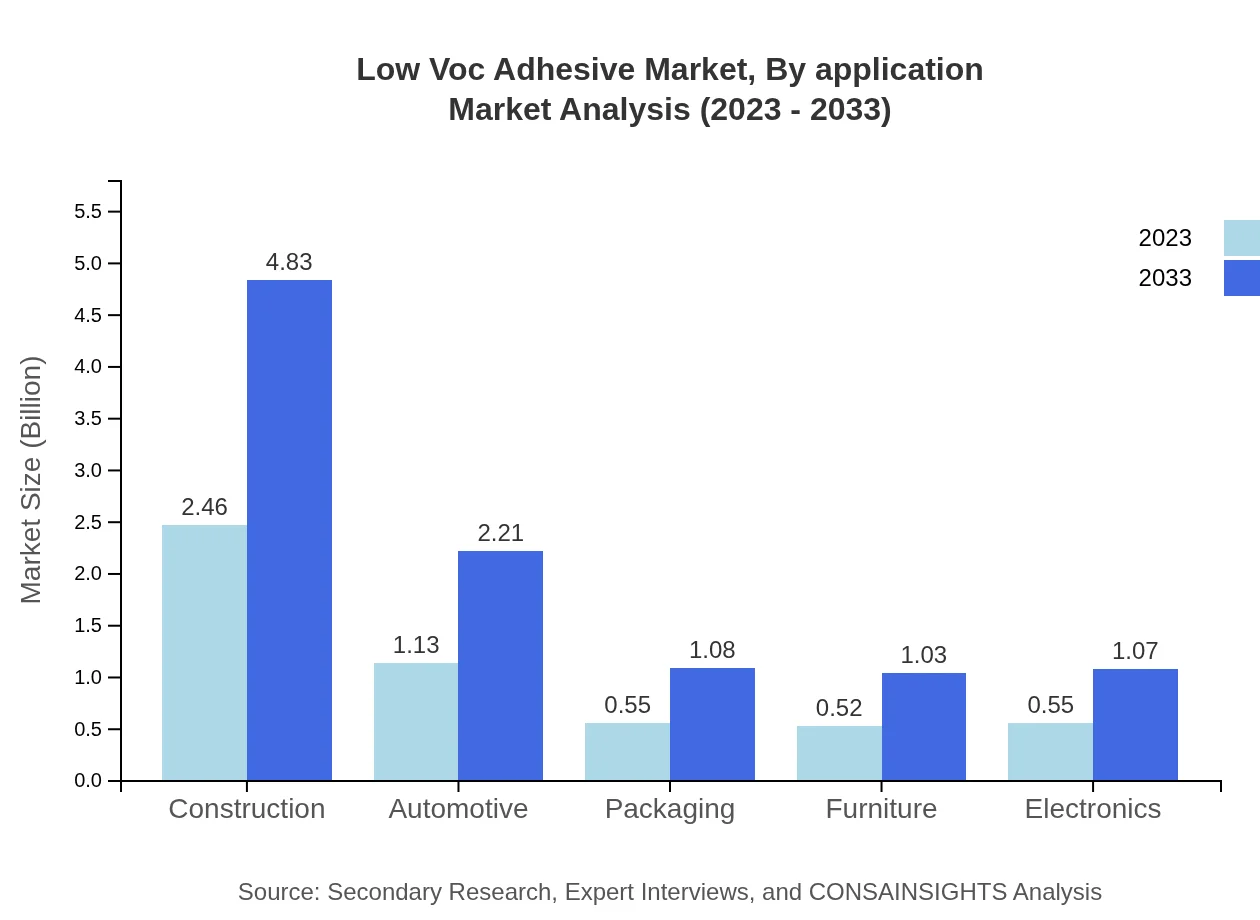

Low Voc Adhesive Market Analysis By Application

The applications of Low Voc Adhesives span across construction, automotive, furniture manufacturing, packaging, and electronics. Notable segments include construction which dominated the market with 2.46 billion USD in 2023, projected to reach 4.83 billion USD by 2033, due to the rising demand for sustainable building materials.

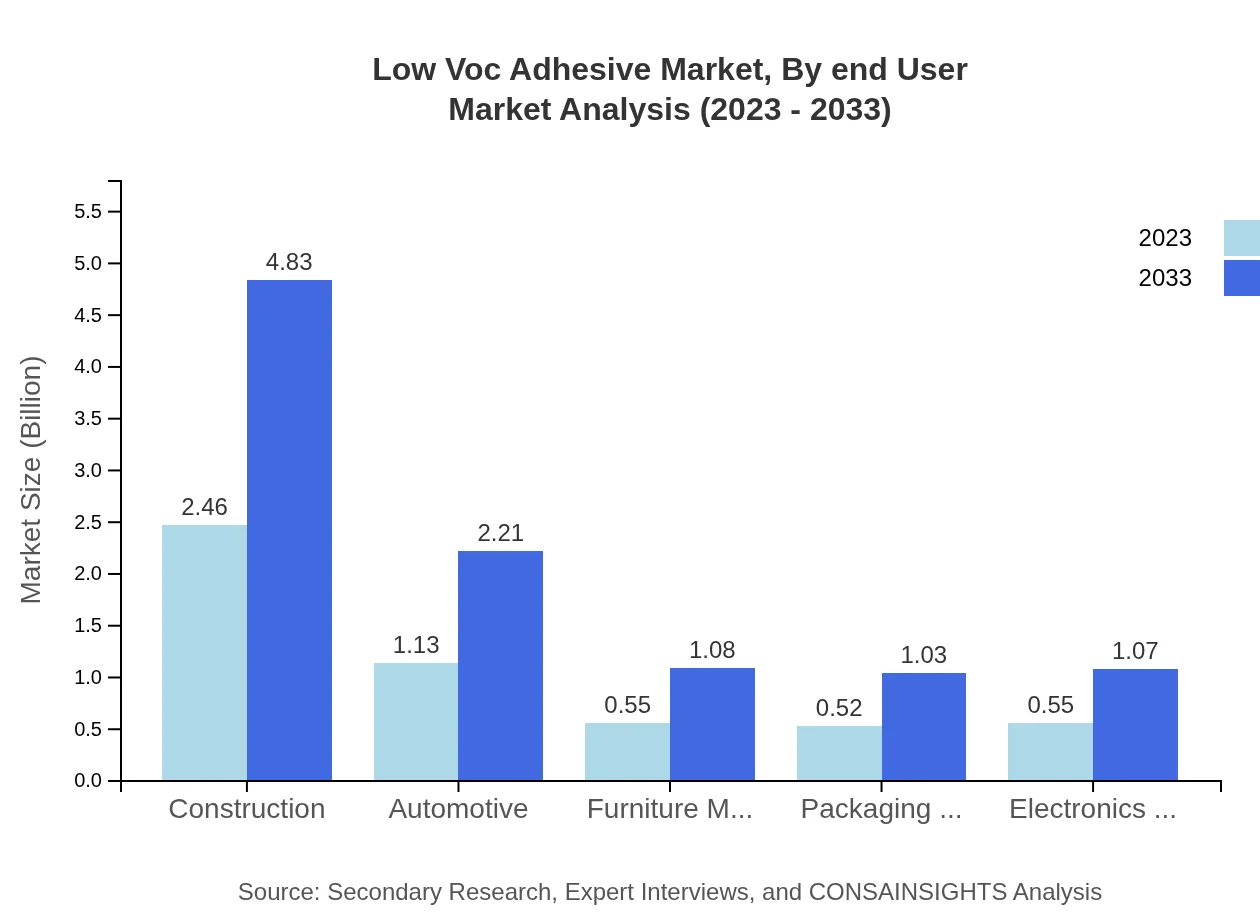

Low Voc Adhesive Market Analysis By End User

The end-user industries for Low VOC adhesives mainly include construction, automotive, and electronics manufacturing. The construction sector represented around 47.26% of the market share in 2023, significantly contributing to the substantial growth of Low Voc adhesives with increased green building initiatives.

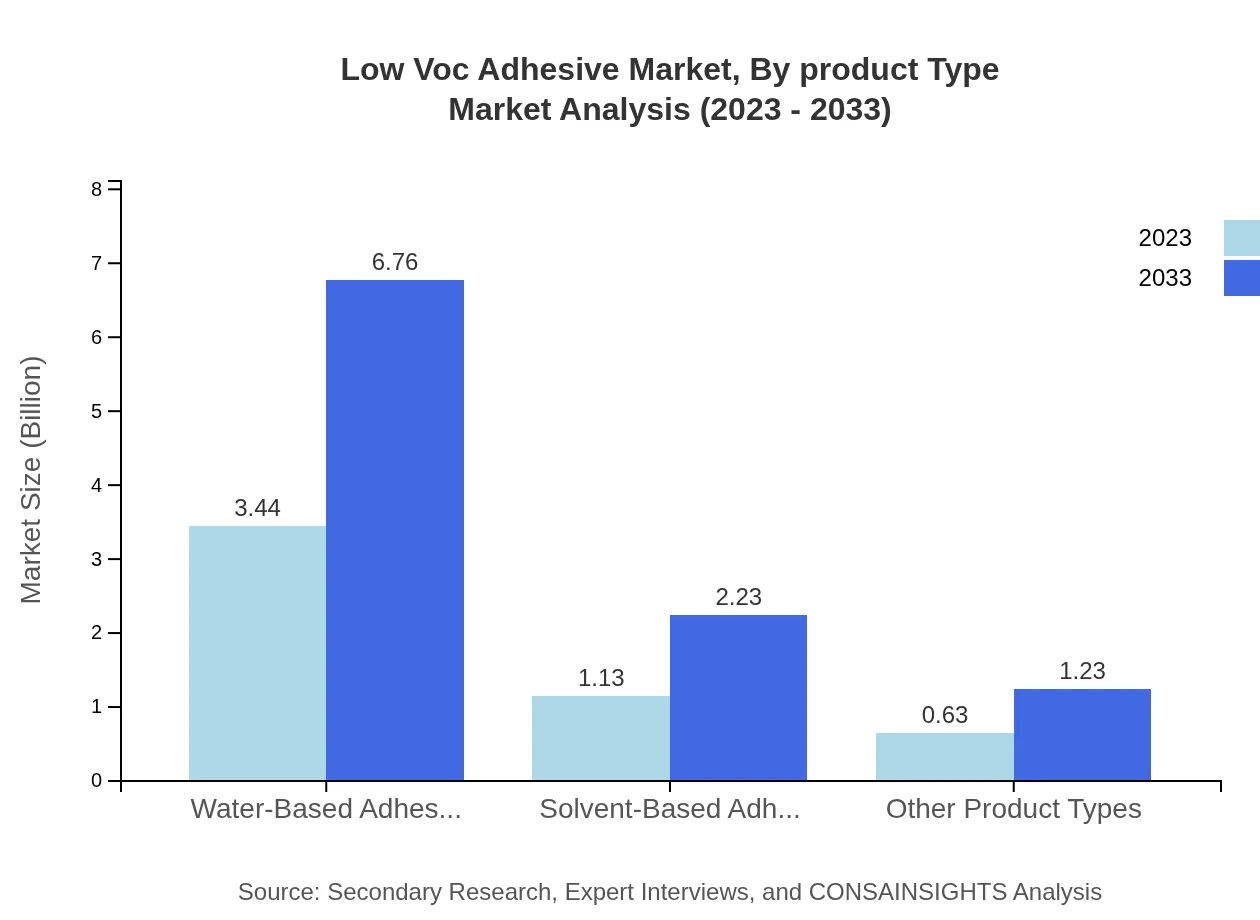

Low Voc Adhesive Market Analysis By Chemistry

The market is also segmented based on chemistry, including water-based, solvent-based, and others. Water-based adhesives dominate the segment with a significant share of 66.1% in 2023, reflecting the industry’s preference for eco-friendly solutions.

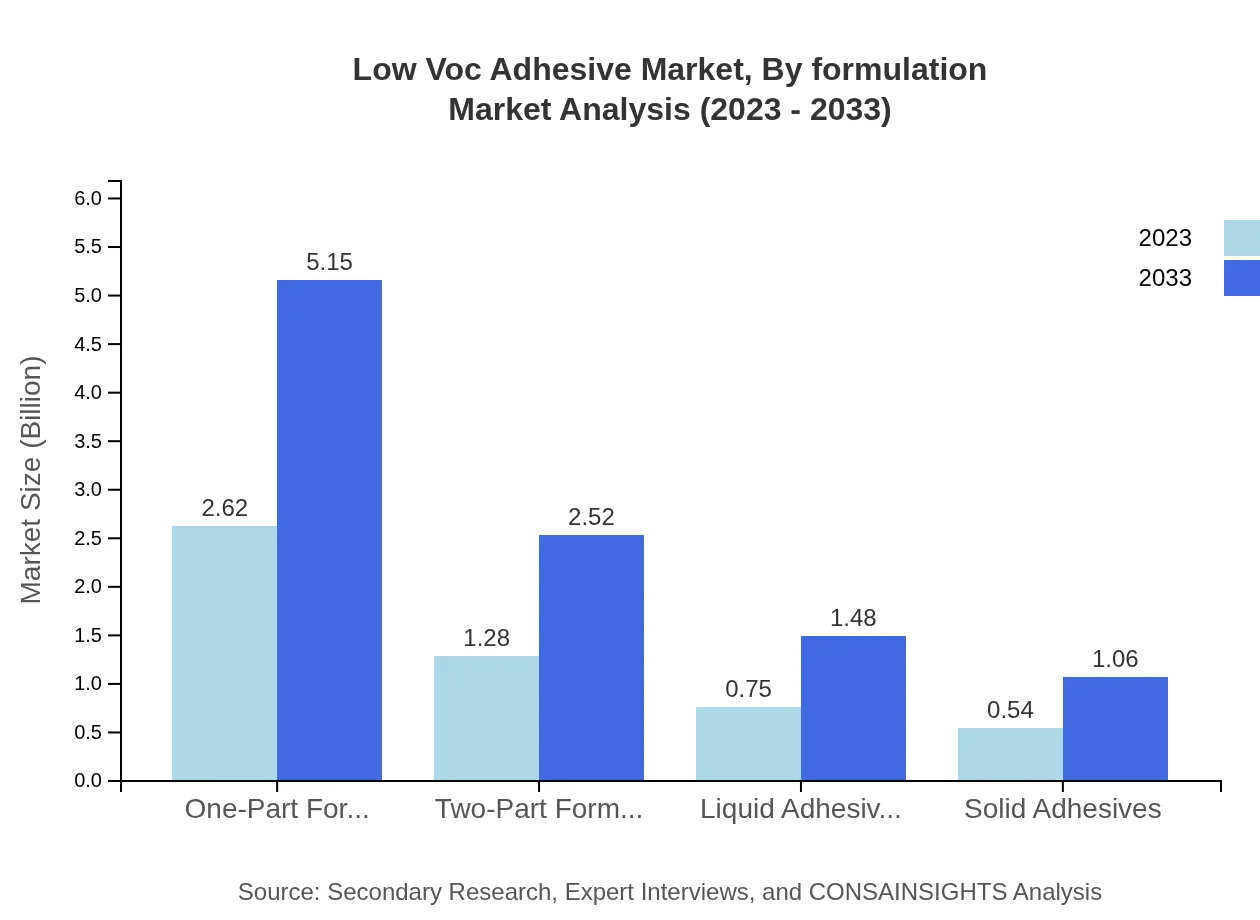

Low Voc Adhesive Market Analysis By Formulation

In terms of formulation, the segments include one-part formulations, two-part formulations, liquid adhesives, and solid adhesives. One-part formulations lead the market with around 50.42% market share in 2023, favoring their ease of use and application across multiple industries.

Low Voc Adhesive Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Low Voc Adhesive Industry

Henkel AG & Co. KGaA:

A global leader in adhesive technologies, Henkel offers a diverse portfolio of Low Voc solutions catering to various industries, aiming at sustainability and performance.BASF SE:

BASF is renowned for its chemical solutions and is heavily invested in producing innovative Low Voc adhesives, contributing to both environmental preservation and market growth.Sika AG:

Sika is well-known for its advanced construction solutions, including Low VOC adhesives, focusing on durability and sustainability in the building industry.3M Company:

3M’s extensive adhesive product range includes Low Voc adhesives, emphasizing performance and environmental compliance across multiple sectors.We're grateful to work with incredible clients.

FAQs

What is the market size of low Voc Adhesive?

The global low-VOC adhesive market is expected to reach approximately $5.2 billion by 2033, exhibiting a CAGR of 6.8% from the current year. This growth reflects an increasing demand across various industries emphasizing sustainability.

What are the key market players or companies in this low Voc Adhesive industry?

Key players in the low-VOC adhesive market include major companies such as Henkel AG & Co. KGaA, 3M Company, Sika AG, and Dow Inc. These companies are actively investing in research and development to innovate and expand their product portfolios.

What are the primary factors driving the growth in the low Voc Adhesive industry?

The growth of the low-VOC adhesive industry is primarily driven by stringent environmental regulations, increasing consumer awareness of health impacts, and a rising demand for eco-friendly products in construction, automotive, and packaging sectors.

Which region is the fastest Growing in the low Voc Adhesive?

The fastest-growing region in the low-VOC adhesive market is Europe, with projections indicating market growth from $1.62 billion in 2023 to $3.18 billion by 2033, driven by regulatory support and sustainability initiatives.

Does ConsaInsights provide customized market report data for the low Voc Adhesive industry?

Yes, ConsaInsights offers customized market report data tailored to the specific needs of clients in the low-VOC adhesive industry. This allows businesses to gain insights that are relevant to their strategic objectives.

What deliverables can I expect from this low Voc Adhesive market research project?

Deliverables from the low-VOC adhesive market research project include comprehensive market analysis reports, detailed competitor insights, growth forecasts, and segment data breakdown, all designed to aid strategic decision-making.

What are the market trends of low Voc Adhesive?

Current market trends for low-VOC adhesives indicate a shift towards water-based formulations, a focus on bio-based raw materials, and increased investment in sustainable manufacturing processes across various industries.