Metal-3d Printing

Published Date: 22 January 2026 | Report Code: metal-3d-printing

Metal-3d Printing Market Size, Share, Industry Trends and Forecast to 2033

This comprehensive market report on Metal-3D Printing examines the evolving landscape of the industry between 2024 and 2033. It provides critical insights on market size, CAGR, segmentation, regional performance, technological advancements, and product trends. The report also highlights key drivers, challenges, and emerging opportunities that are reshaping metal additive manufacturing processes.

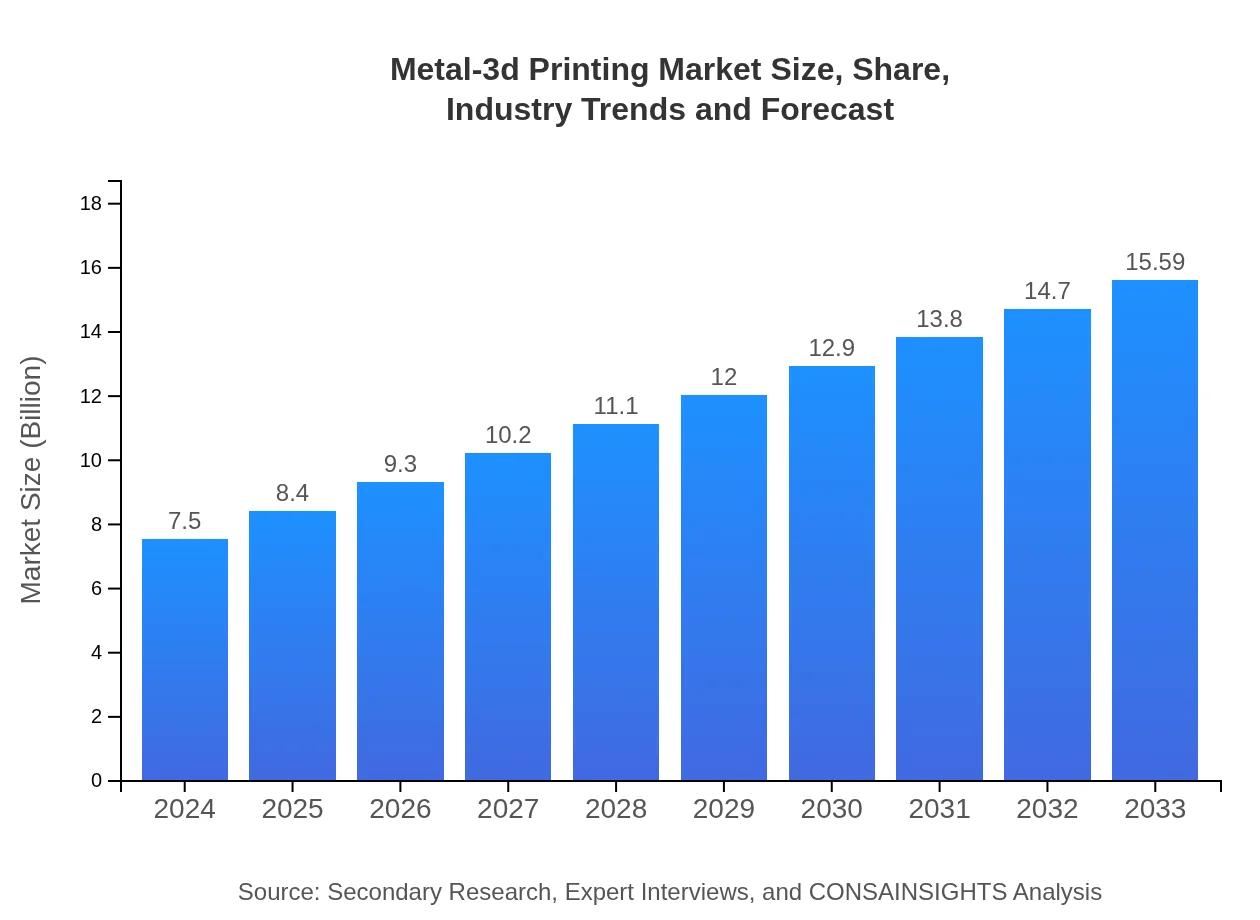

| Metric | Value |

|---|---|

| Study Period | 2024 - 2033 |

| 2024 Market Size | $7.50 Billion |

| CAGR (2024-2033) | 8.2% |

| 2033 Market Size | $15.59 Billion |

| Top Companies | XYZ Metals Inc, Additive Fabrication Solutions |

| Last Modified Date | 22 January 2026 |

Metal-3d Printing Market Overview

Customize Metal-3d Printing market research report

- ✔ Get in-depth analysis of Metal-3d Printing market size, growth, and forecasts.

- ✔ Understand Metal-3d Printing's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Metal-3d Printing

What is the Market Size & CAGR of Metal-3d Printing market in 2024?

Metal-3d Printing Industry Analysis

Metal-3d Printing Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Metal-3d Printing Market Analysis Report by Region

Europe Metal-3d Printing:

Europe’s market is characterized by strong regulatory frameworks and an emphasis on quality and precision. With a market size of 2.21 in 2024 growing to 4.60 by 2033, European markets are bolstered by collaborative initiatives between academia and industry, supporting advancements in material integrity and process standardization.Asia Pacific Metal-3d Printing:

In the Asia Pacific region, the market is set for significant expansion, with 2024 figures at 1.50 and projections reaching 3.12 by 2033. Rapid industrialization, government support for advanced manufacturing, and growing R&D investments are driving market penetration. The region’s focus on technology adoption in sectors such as automotive and aerospace further enhances market prospects.North America Metal-3d Printing:

North America remains a strong market with a 2024 market size of 2.63 and an expected growth to 5.47 by 2033. The region benefits from high levels of innovation, robust infrastructure, and significant investments in digital manufacturing technologies. A mature ecosystem of key industry players and advanced supply chains further cements its market position.South America Metal-3d Printing:

The South American market, representing Latin America in this analysis, is emerging as a niche yet promising segment. With an estimated market value of 0.59 in 2024 and a projected increase to 1.22 by 2033, the region is witnessing gradual improvements in manufacturing capabilities and an increasing trend towards modernization of production processes.Middle East & Africa Metal-3d Printing:

The Middle East and Africa market, though smaller in scale with a 2024 value of 0.57 and a projected 2033 value of 1.18, is rapidly evolving. Increasing demand for customized manufacturing solutions and strategic partnerships aimed at technology transfer are contributing to steady growth in these regions.Tell us your focus area and get a customized research report.

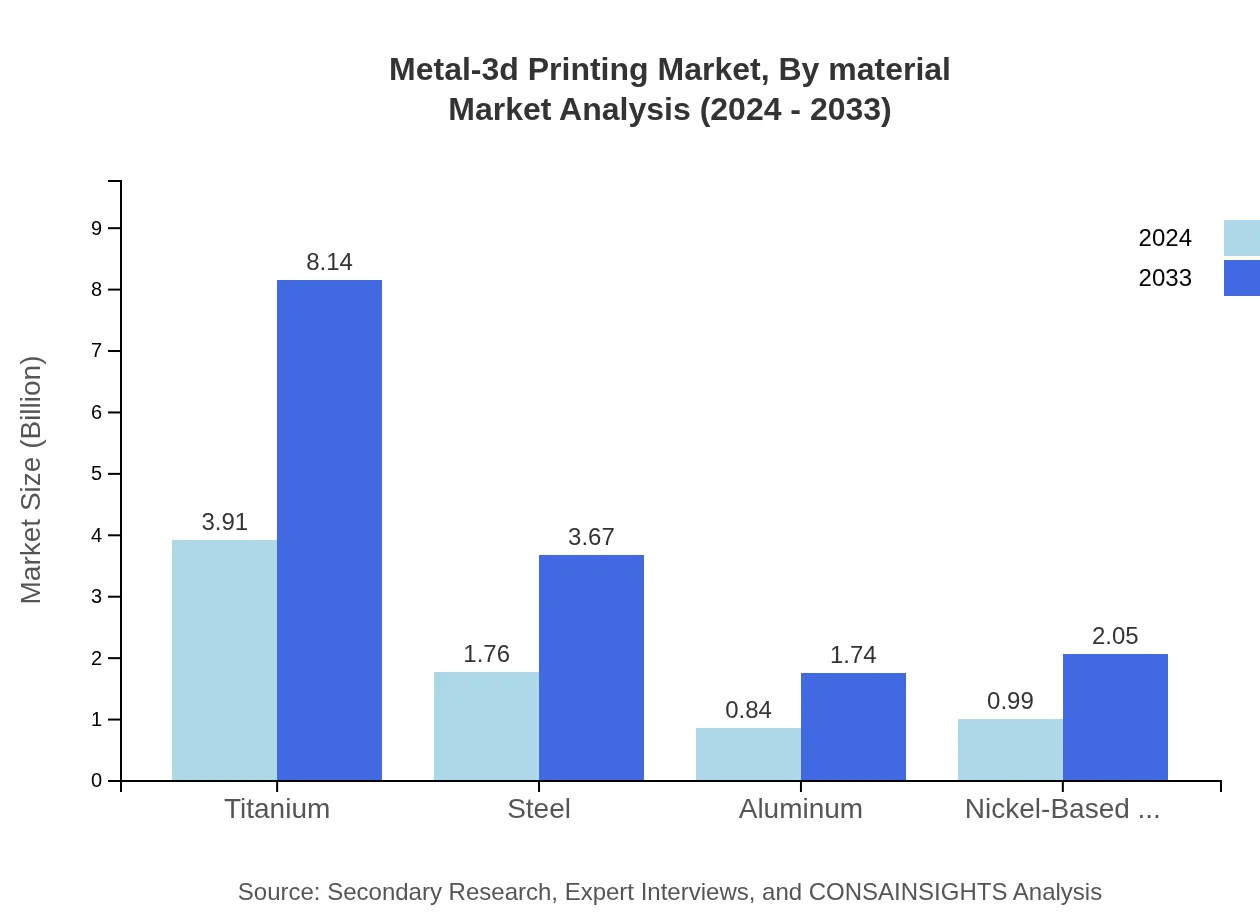

Metal-3d Printing Market Analysis By Material

This segment delves into the various materials used in metal 3D printing, such as Titanium, Steel, Aluminum, and Nickel-Based Alloys. Titanium dominates with a significant market share due to its strength and lightweight properties, while Steel offers cost-effective solutions. Aluminum and Nickel-Based Alloys are also gaining traction for specialized applications. The analysis stresses that material selection is crucial for ensuring performance and meeting specific industrial standards, with continuous improvements in alloy formulations shaping future trends.

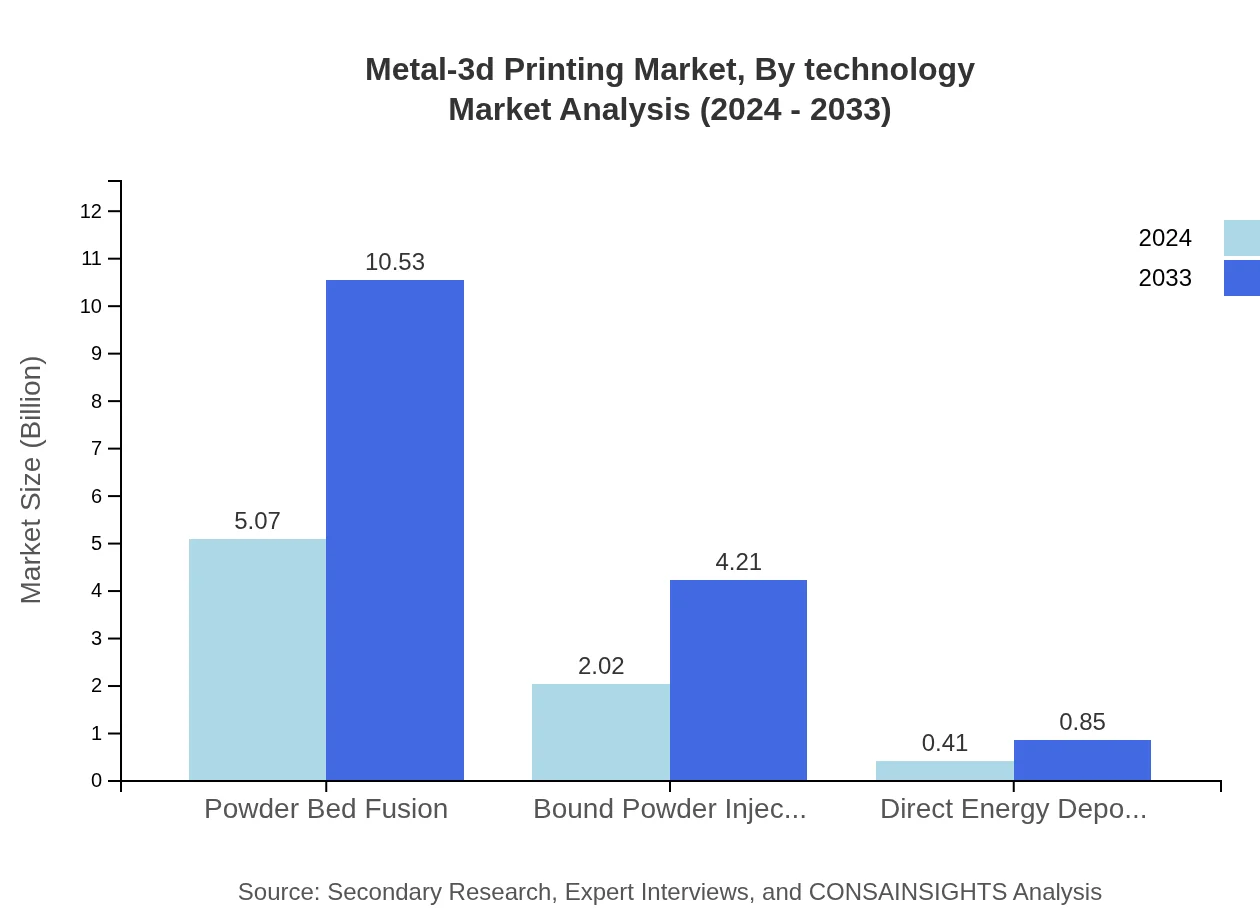

Metal-3d Printing Market Analysis By Technology

The technology segment focuses on advanced manufacturing techniques including Powder Bed Fusion, Bound Powder Injection, and Direct Energy Deposition. Each technology offers distinct advantages in terms of print resolution, build speed, and energy efficiency. Innovations in these processes are reducing waste and refining detail in complex geometries, allowing industries to move toward on-demand and custom manufacturing. The ongoing development of hybrid technologies also promises to integrate the best of multiple methods, driving further market expansion.

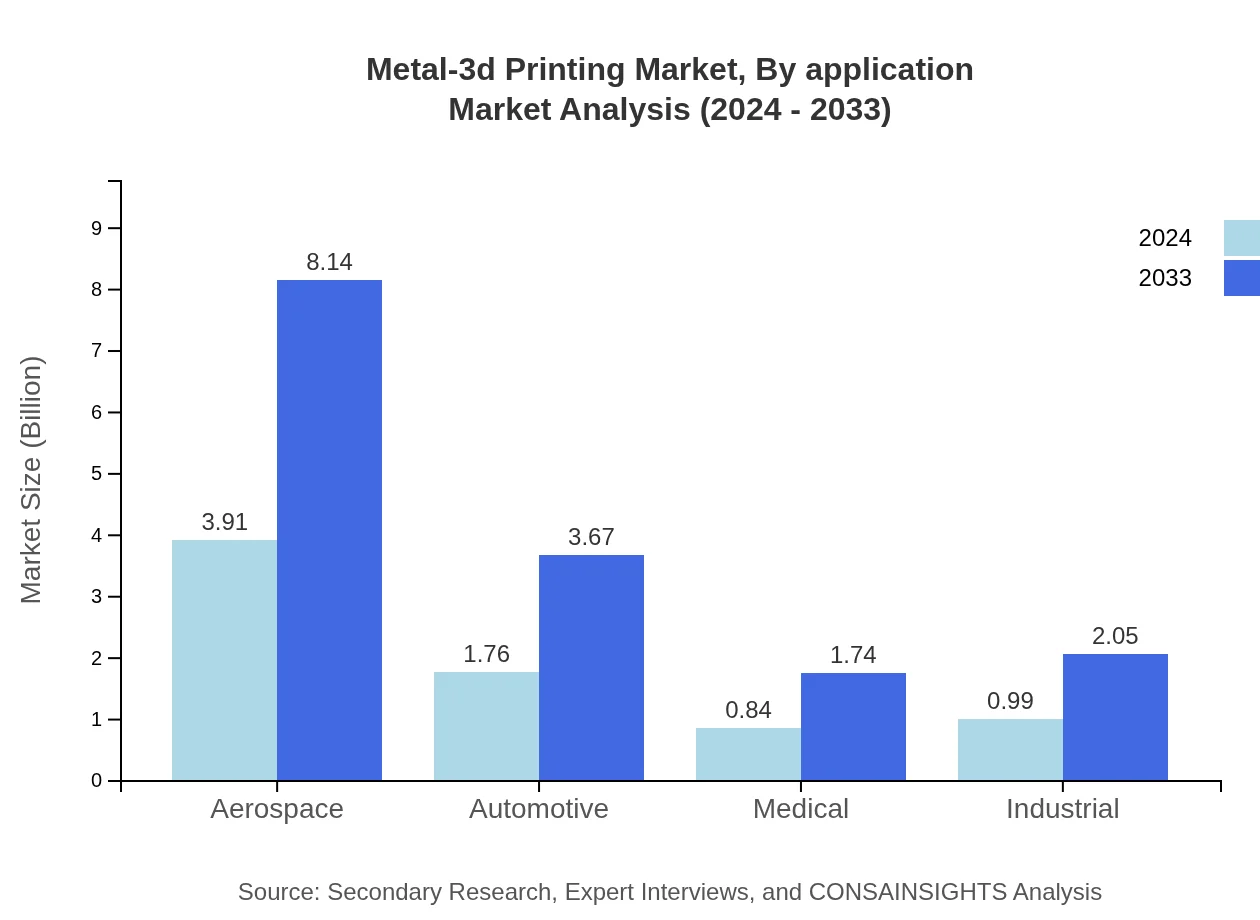

Metal-3d Printing Market Analysis By Application

Applications of metal 3D printing span across diverse sectors such as Aerospace, Automotive, Medical, and Industrial. The aerospace and automotive industries benefit from weight reduction and enhanced design flexibility, while the medical sector leverages customization for implants and prosthetics. Industrial applications are increasingly using metal printing for specialized components that require high durability. This segmentation highlights the expansive reach of metal 3D printing and its critical role in advancing product performance and driving innovation in high-tech sectors.

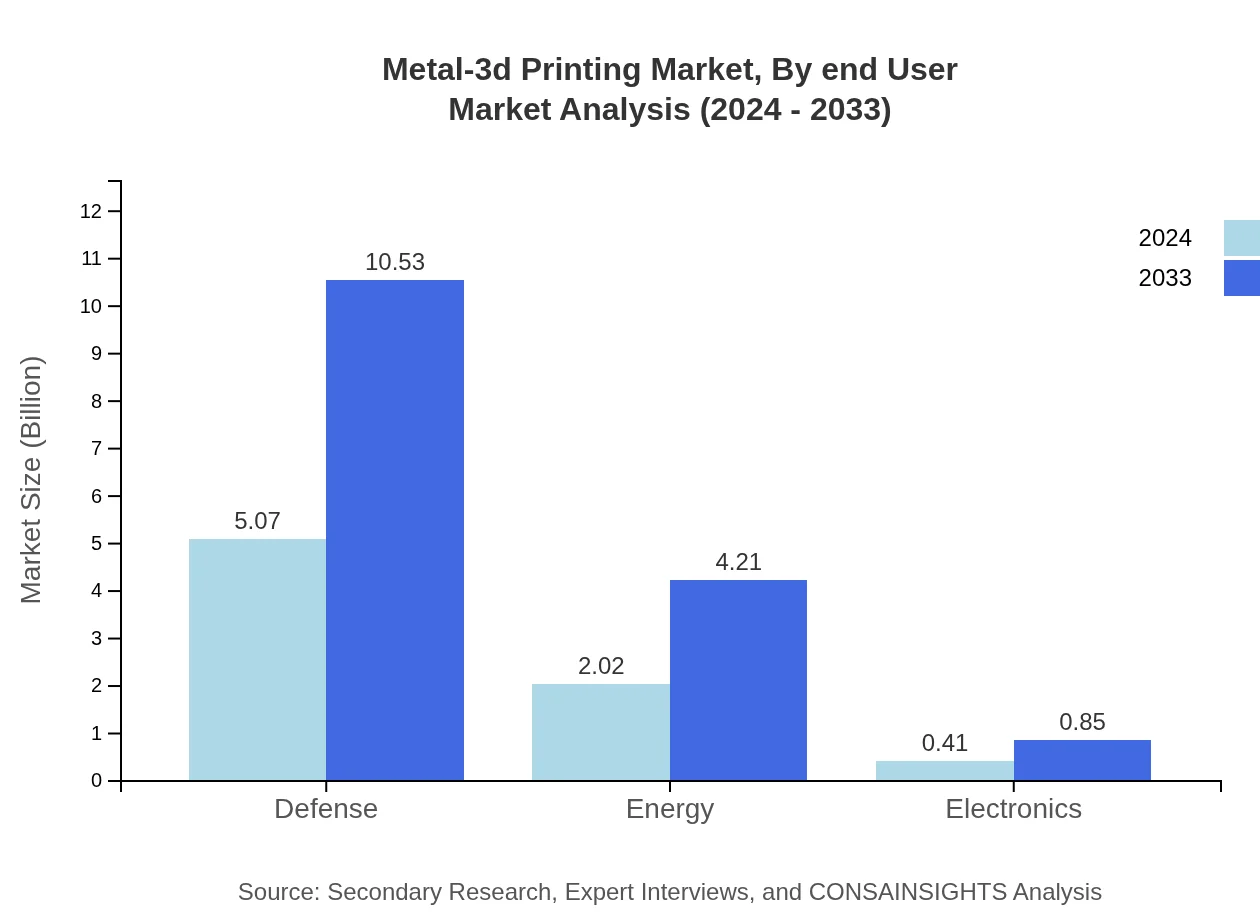

Metal-3d Printing Market Analysis By End User

The end-user segmentation examines industries that are rapidly integrating metal 3D printing into their operations. Key sectors include defense, energy, and consumer electronics, along with emerging opportunities in renewable energy installations and smart manufacturing. Firms in these industries are increasingly adopting metal printing to achieve rapid prototyping, cost reduction, and enhanced product customization. This shift is enabling companies to respond quickly to market demands while also achieving operational efficiencies.

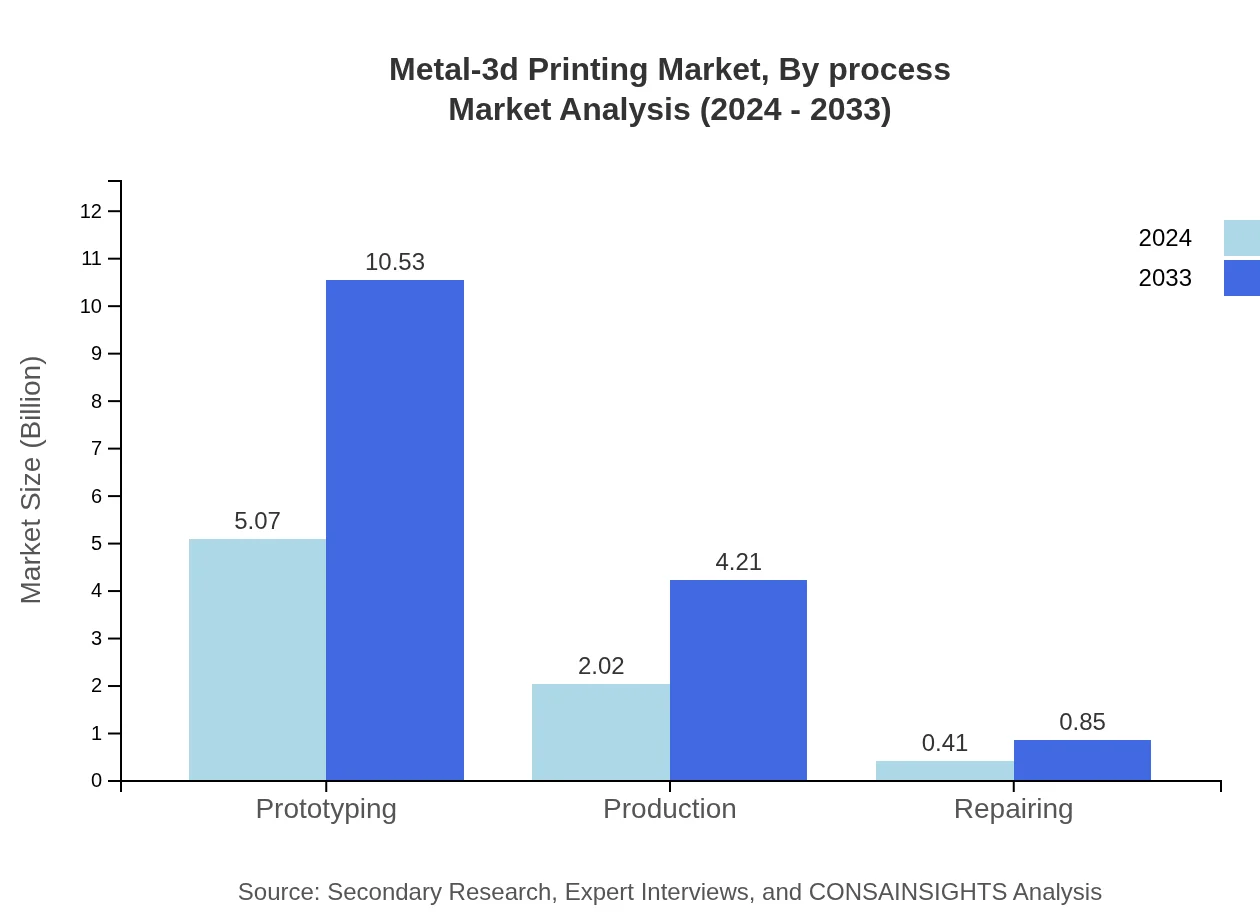

Metal-3d Printing Market Analysis By Process

This segment reviews the various manufacturing processes that underpin metal 3D printing. It provides insights into process optimization, quality control, and the integration of digital tools that enhance overall production efficiency. From initial prototyping to full-scale production, the evolution of processes such as additive manufacturing is driven by automation and improved energy management. The analysis underscores that advancements in process technology are central to achieving higher throughput, minimizing material wastage, and ensuring consistent build quality.

Metal-3d Printing Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Metal-3d Printing Industry

XYZ Metals Inc:

A leading innovator in metal additive manufacturing, XYZ Metals Inc offers cutting-edge printing solutions that enhance production precision and efficiency across a diverse range of industries. Their commitment to R&D has positioned them as a market pioneer.Additive Fabrication Solutions:

Known for their comprehensive suite of metal 3D printing services, Additive Fabrication Solutions has been instrumental in driving technological advancements in the industry. They are recognized for their high-quality, customized production capabilities and global market outreach.We're grateful to work with incredible clients.

FAQs

What is the market size of metal-3d Printing?

The metal 3D printing market is valued at approximately $7.5 billion in 2024, with an anticipated CAGR of 8.2% through 2033. This growth indicates increasing adoption across various industries, driven by advancements in printing technologies and materials.

What are the key market players or companies in this metal-3d Printing industry?

The metal 3D printing industry includes major companies such as Stratasys, EOS GmbH, 3D Systems, and Renishaw. These players are at the forefront of technological innovation, providing a range of solutions from industrial machinery to metal powders.

What are the primary factors driving the growth in the metal-3d Printing industry?

Key factors include the demand for customization in manufacturing, reduced lead times, and the ability to produce complex geometries that traditional methods cannot achieve. Moreover, the push for sustainability fosters interest in additive manufacturing.

Which region is the fastest Growing in the metal-3d Printing?

The North American region is projected to see significant growth, increasing from approximately $2.63 billion in 2024 to $5.47 billion by 2033. Europe follows closely, showcasing robust expansion in aerospace and automotive industries.

Does ConsaInsights provide customized market report data for the metal-3d Printing industry?

Yes, ConsaInsights offers tailored market report data specific to the metal 3D printing industry, accommodating the unique requirements of businesses for strategic decision-making and market positioning.

What deliverables can I expect from this metal-3d Printing market research project?

Expect comprehensive reports featuring market size, growth forecasts, competitive analysis, segmentation data, and trend analysis. Deliverables also include custom insights to aid in critical business strategies and investment decisions.

What are the market trends of metal-3d Printing?

Current trends in metal 3D printing include increased use of titanium and aluminum, as well as advancements in binder jetting technology, enhancing the efficiency and quality of parts produced, particularly in aerospace and medical applications.