Miniature Parts Zinc Die Casting Market Report

Published Date: 02 February 2026 | Report Code: miniature-parts-zinc-die-casting

Miniature Parts Zinc Die Casting Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Miniature Parts Zinc Die Casting market, covering current trends, competitive landscape, regional dynamics, and future forecasts from 2023 to 2033.

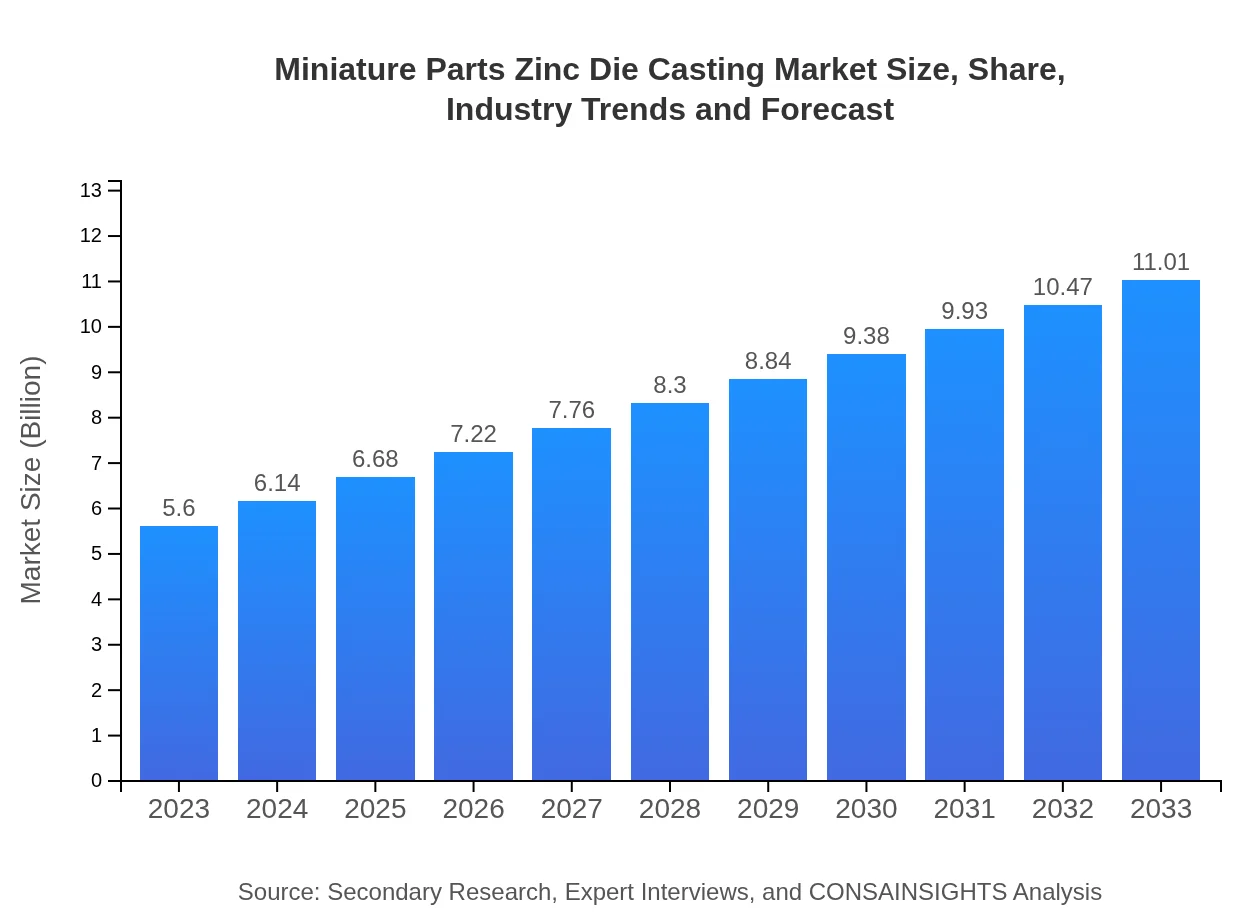

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $5.60 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $11.01 Billion |

| Top Companies | Pace Industries, Intercast, Dynacast, Die Casting Solutions |

| Last Modified Date | 02 February 2026 |

Miniature Parts Zinc Die Casting Market Overview

Customize Miniature Parts Zinc Die Casting Market Report market research report

- ✔ Get in-depth analysis of Miniature Parts Zinc Die Casting market size, growth, and forecasts.

- ✔ Understand Miniature Parts Zinc Die Casting's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Miniature Parts Zinc Die Casting

What is the Market Size & CAGR of Miniature Parts Zinc Die Casting market in 2023?

Miniature Parts Zinc Die Casting Industry Analysis

Miniature Parts Zinc Die Casting Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Miniature Parts Zinc Die Casting Market Analysis Report by Region

Europe Miniature Parts Zinc Die Casting Market Report:

The European market for Miniature Parts Zinc Die Casting is characterized by advanced manufacturing technologies and stringent quality standards. The region's market size is $1.41 billion in 2023, projected to grow to $2.76 billion by 2033.Asia Pacific Miniature Parts Zinc Die Casting Market Report:

The Asia Pacific region holds a substantial share of the Miniature Parts Zinc Die Casting market, valued at $1.14 billion in 2023 and anticipated to grow to $2.25 billion by 2033. The region benefits from a strong manufacturing base, advancements in technology, and robust demand from automotive and consumer electronics sectors.North America Miniature Parts Zinc Die Casting Market Report:

North America showcases a significant market presence, with values starting at $1.79 billion in 2023 and expected to double to $3.52 billion by 2033. The automotive sector's growth, fueled by the demand for lightweight components, is a primary driver.South America Miniature Parts Zinc Die Casting Market Report:

In South America, the market is valued at $0.49 billion in 2023, projected to reach $0.96 billion by 2033. Factors driving growth include increasing industrialization and the adoption of zinc die casting in consumer goods and construction applications.Middle East & Africa Miniature Parts Zinc Die Casting Market Report:

The Middle East and Africa (MEA) region shows potential growth, with a market value of $0.77 billion in 2023, expected to reach $1.51 billion by 2033. The growth is attributed to improving manufacturing capabilities and demand from the construction sector.Tell us your focus area and get a customized research report.

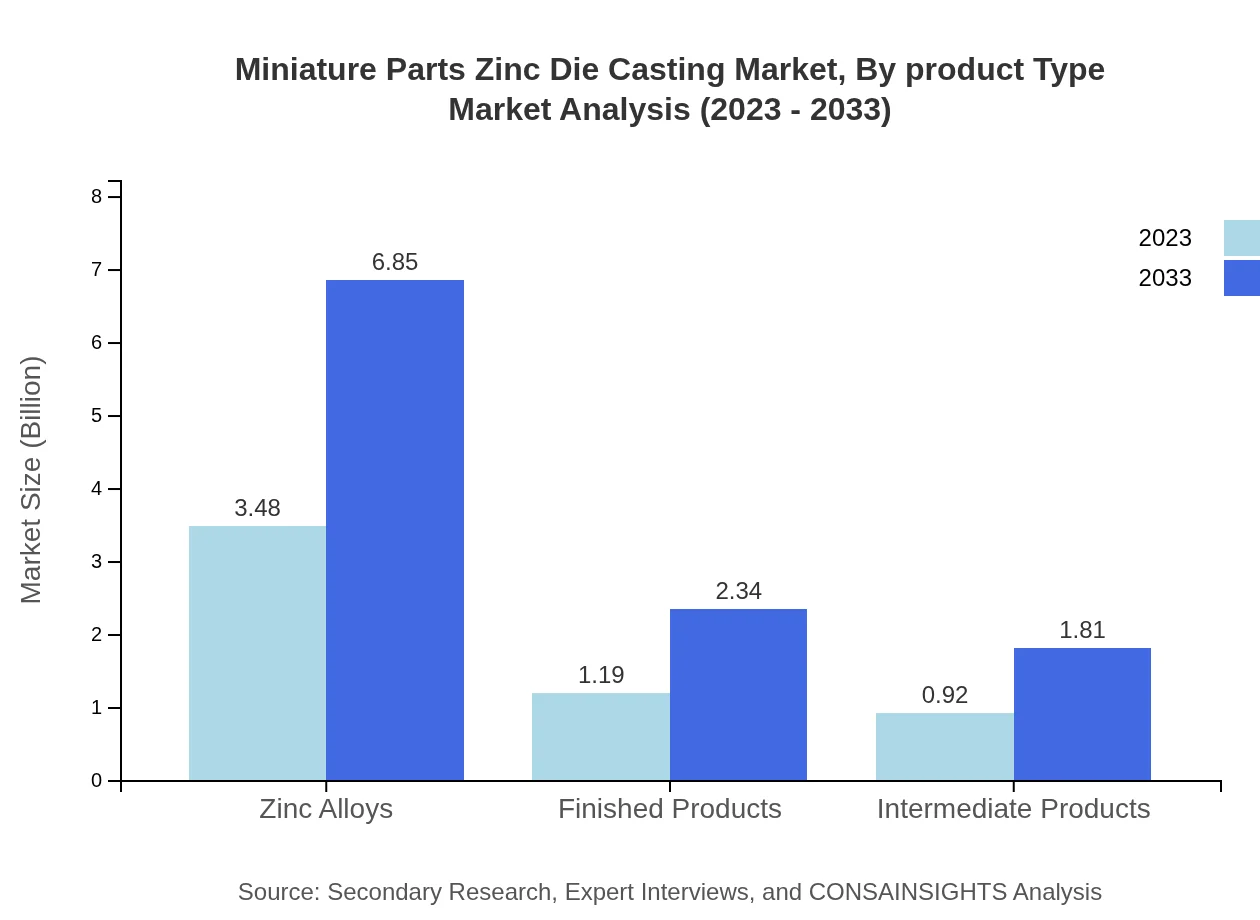

Miniature Parts Zinc Die Casting Market Analysis By Product Type

In 2023, the product type market segment for Miniature Parts Zinc Die Casting is projected to be led by high-pressure die casting, valued at $3.48 billion, representing 62.22% of the market share. Gravity die casting follows with a market value of $1.19 billion (21.29% share) and other methods accounting for $0.92 billion (16.49% share). By 2033, these segments will grow correspondingly, underlining the continued preference for efficient and cost-effective manufacturing methods.

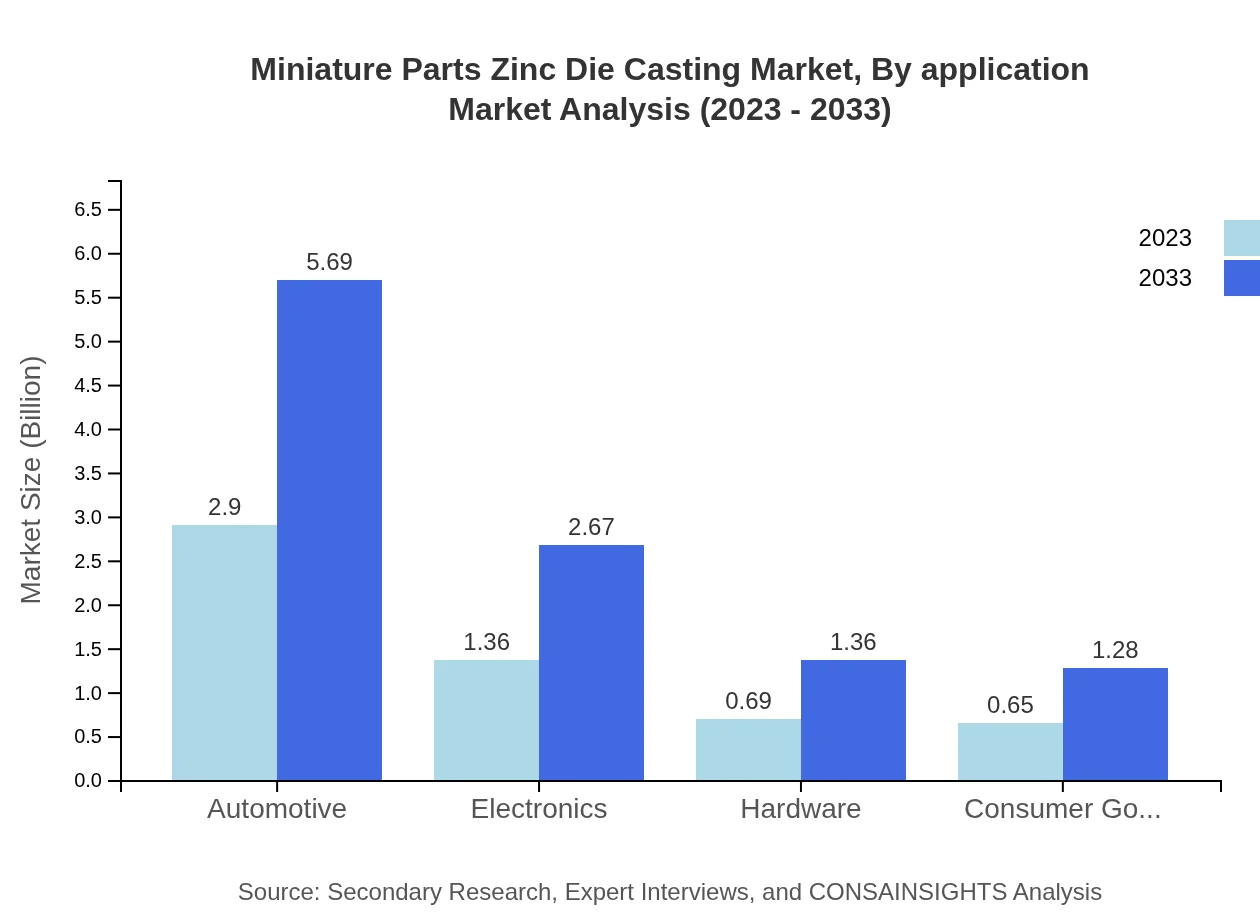

Miniature Parts Zinc Die Casting Market Analysis By Application

The automotive application segment stands out with a market size of $2.90 billion in 2023 and maintains a dominant market share of 51.74%. Electronics follow with a market of $1.36 billion (24.22% share). The construction and furniture industries also contribute, valued at $0.69 billion (12.39% share) and $0.65 billion (11.65% share) respectively. By 2033, growth in these segments will reflect advancements in product design and technology.

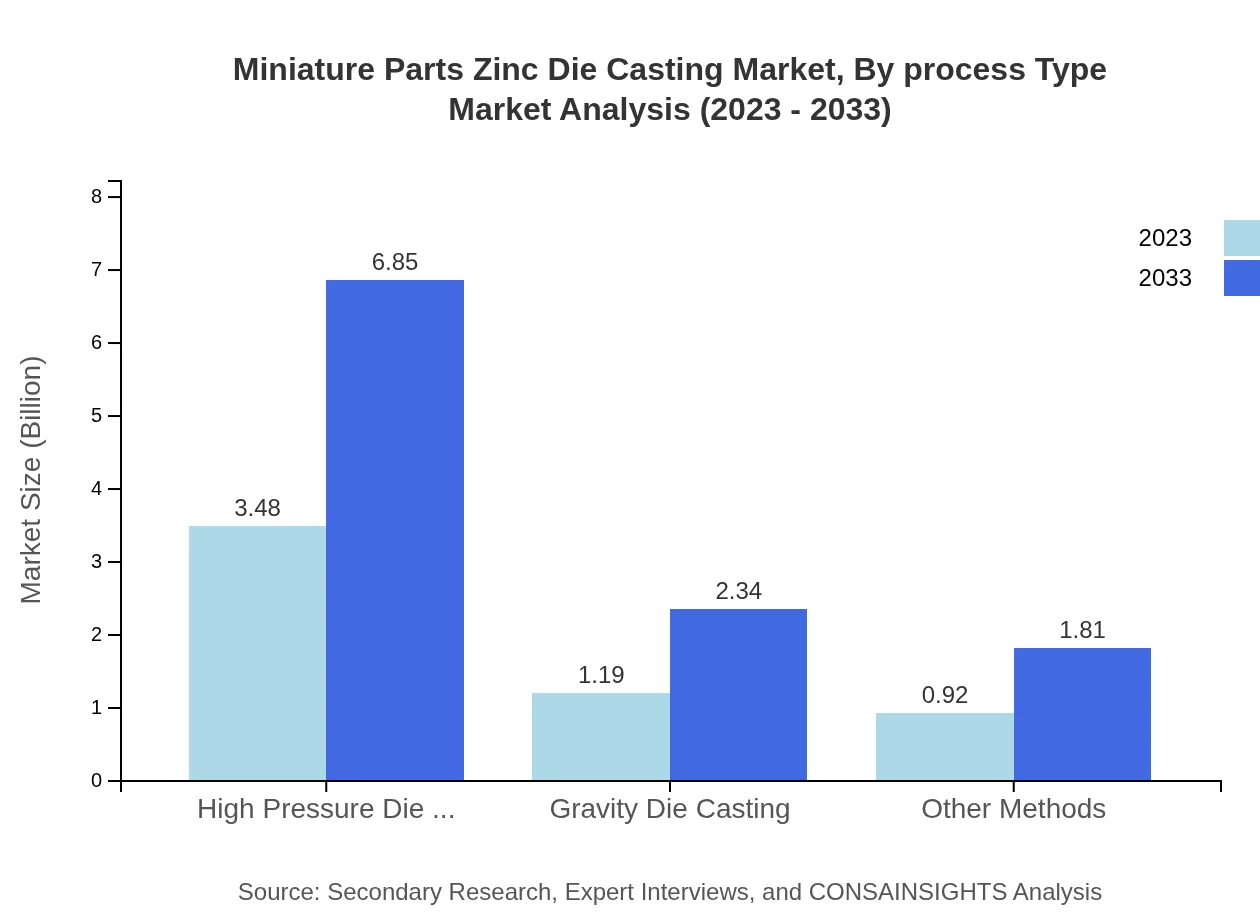

Miniature Parts Zinc Die Casting Market Analysis By Process Type

High-pressure die casting remains prevalent, expected to grow from $3.48 billion in 2023 to $6.85 billion by 2033, maintaining a market share around 62.22%. Gravity die casting and other methods also show promising growth, with current valuations at $1.19 billion and $0.92 billion respectively, anticipated to rise significantly as industries evolve towards more complex designs.

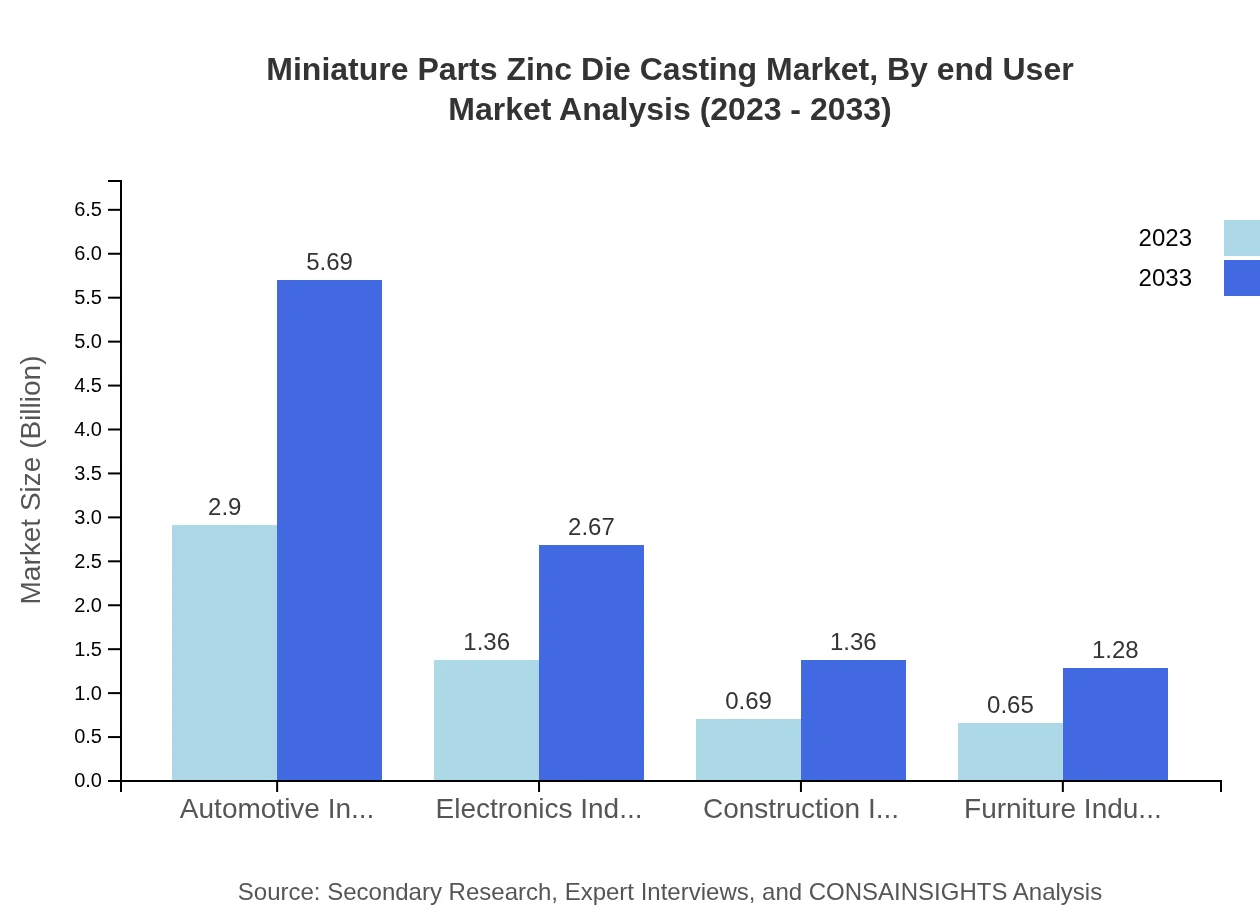

Miniature Parts Zinc Die Casting Market Analysis By End User

The automotive end-user segment leads with a projected market of $2.90 billion in 2023 and expected growth to $5.69 billion by 2033. The electronics industry shows robust growth with a size of $1.36 billion (24.22% share), followed by construction and consumer goods, which are projected to expand as the demand for miniature components increases across sectors.

Miniature Parts Zinc Die Casting Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Miniature Parts Zinc Die Casting Industry

Pace Industries:

Pace Industries is a leading provider of aluminum and zinc die casting solutions, focusing on innovation and quality in manufacturing. Their expertise extends across various sectors, including automotive and consumer goods.Intercast:

Intercast specializes in zinc die casting, offering customized solutions for multiple industries. Their commitment to sustainability and efficiency drives their manufacturing processes, enhancing product performance while reducing environmental impact.Dynacast:

Dynacast is a global leader in precision die casting solutions. They leverage state-of-the-art technology to deliver high-quality components, primarily serving industries such as automotive, medical, and electronics.Die Casting Solutions:

With a focus on scalable manufacturing, Die Casting Solutions delivers advanced zinc die casting services that cater to both small and large production runs. They are noted for their ability to integrate innovative designs into their casting processes.We're grateful to work with incredible clients.

FAQs

What is the market size of miniature Parts Zinc Die Casting?

The global miniature parts zinc die casting market is projected to reach $5.6 billion by 2033, growing at a CAGR of 6.8%. This growth is attributed to increasing demand across various sectors, including automotive and electronics.

What are the key market players or companies in the miniature Parts Zinc Die Casting industry?

Key players in the miniature parts zinc die casting market include prominent manufacturers that specialize in die casting technologies. These companies leverage advanced manufacturing processes to deliver high-quality and precise miniature parts, catering to automotive, electronics, and other industries.

What are the primary factors driving the growth in the miniature Parts Zinc Die Casting industry?

Growth in the miniature parts zinc die casting sector is driven by rising demand for lightweight and durable components in industries like automotive and electronics. Additionally, advancements in casting technologies and an increase in end-user applications are also significant contributors.

Which region is the fastest Growing in the miniature Parts Zinc Die Casting?

The fastest-growing region in the miniature parts zinc die casting market is North America, expected to grow from $1.79 billion in 2023 to $3.52 billion by 2033. Other significant regions include Europe and Asia-Pacific, both showing robust growth rates.

Does ConsaInsights provide customized market report data for the miniature Parts Zinc Die Casting industry?

Yes, ConsaInsights offers customized market reports tailored to client specifications in the miniature parts zinc die casting industry. Clients can request specific segment analysis, regional insights, or focus on particular aspects of market trends.

What deliverables can I expect from this miniature Parts Zinc Die Casting market research project?

Deliverables from the miniature parts zinc die casting market research include comprehensive reports, detailed analysis on trends and forecasts, competitive landscape overviews, and specific insights on market segmentation based on application, technology, and geography.

What are the market trends of miniature Parts Zinc Die Casting?

Current market trends indicate a shift towards sustainable manufacturing practices in miniature parts zinc die casting, coupled with the integration of advanced technologies such as automation and precision engineering. There is also growing interest in using recycled materials.