Nano Paints Coatings Market Report

Published Date: 02 February 2026 | Report Code: nano-paints-coatings

Nano Paints Coatings Market Size, Share, Industry Trends and Forecast to 2033

This report provides insightful analysis and forecast data for the Nano Paints Coatings market from 2023 to 2033. It covers market size, growth trends, regional analyses, industry dynamics, and profiles of key players to help stakeholders make informed decisions.

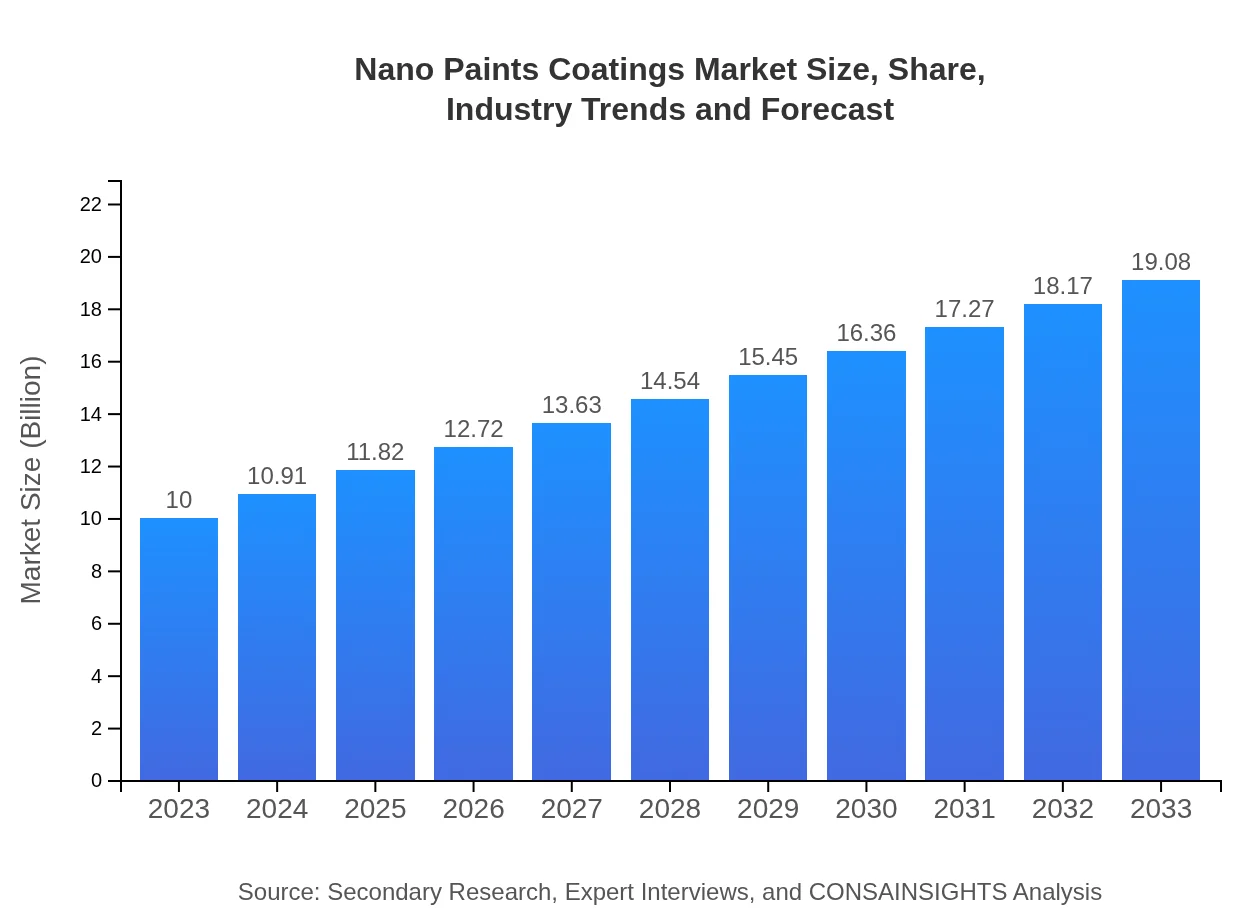

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $10.00 Billion |

| CAGR (2023-2033) | 6.5% |

| 2033 Market Size | $19.08 Billion |

| Top Companies | AkzoNobel, BASF, PPG Industries, DuPont |

| Last Modified Date | 02 February 2026 |

Nano Paints Coatings Market Overview

Customize Nano Paints Coatings Market Report market research report

- ✔ Get in-depth analysis of Nano Paints Coatings market size, growth, and forecasts.

- ✔ Understand Nano Paints Coatings's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Nano Paints Coatings

What is the Market Size & CAGR of Nano Paints Coatings market in 2023?

Nano Paints Coatings Industry Analysis

Nano Paints Coatings Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Nano Paints Coatings Market Analysis Report by Region

Europe Nano Paints Coatings Market Report:

Europe holds a prominent position in the Nano Paints Coatings market with a size growing from $2.95 billion in 2023 to $5.63 billion by 2033. Countries like Germany, France, and the UK are leading in technological advancements and sustainability efforts in coating solutions, enhancing demand in automotive and industrial applications.Asia Pacific Nano Paints Coatings Market Report:

The Asia Pacific region, with a market value of $1.84 billion in 2023 projected to grow to $3.50 billion by 2033, is a major hub for Nano Paints Coatings due to rapid industrialization and increasing demand for high-performance coatings in construction and automotive sectors. Countries like China and India are significant contributors to this growth, spurred by government initiatives to enhance manufacturing and infrastructure.North America Nano Paints Coatings Market Report:

The North American market is projected to expand significantly, from approximately $3.83 billion in 2023 to $7.32 billion in 2033. USA leads the market, driven by robust automotive and aerospace industries, along with strong R&D activities focused on innovative coating solutions. The increasing adoption of green technologies further supports this growth.South America Nano Paints Coatings Market Report:

In South America, the Nano Paints Coatings market is relatively nascent, valued at $0.07 billion in 2023 and expected to reach $0.12 billion by 2033. The growing construction industry in Brazil and Argentina is likely to drive demand, although the market faces challenges from economic instability.Middle East & Africa Nano Paints Coatings Market Report:

The market in the Middle East and Africa is anticipated to grow from $1.31 billion in 2023 to $2.51 billion in 2033, propelled by increasing investments in infrastructure and housing projects in Gulf Cooperation Council (GCC) countries. However, the market may be constrained by regulatory challenges and dependency on imports.Tell us your focus area and get a customized research report.

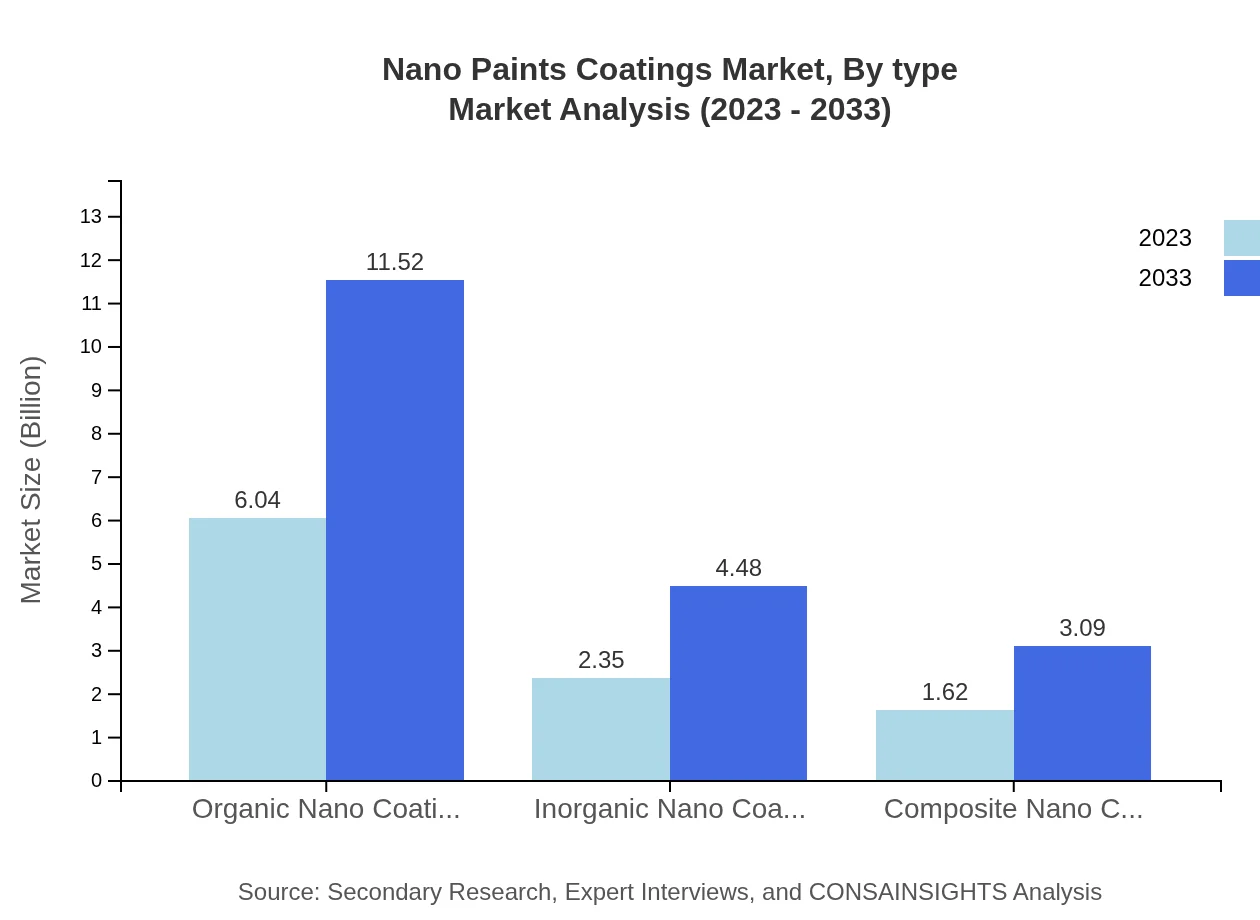

Nano Paints Coatings Market Analysis By Type

Nano Paints Coatings are primarily categorized into Organic, Inorganic, and Composite types. Organic Nano Coatings dominate the market with a size of $6.04 billion expected to reach $11.52 billion by 2033, holding 60.37% of the market share throughout the forecast period. Inorganic Nano Coatings are also significant, projected to grow from $2.35 to $4.48 billion, representing 23.46% share. Composite Nano Coatings, while smaller in size, are gaining traction for their unique properties, expanding from $1.62 billion to $3.09 billion (16.17% share).

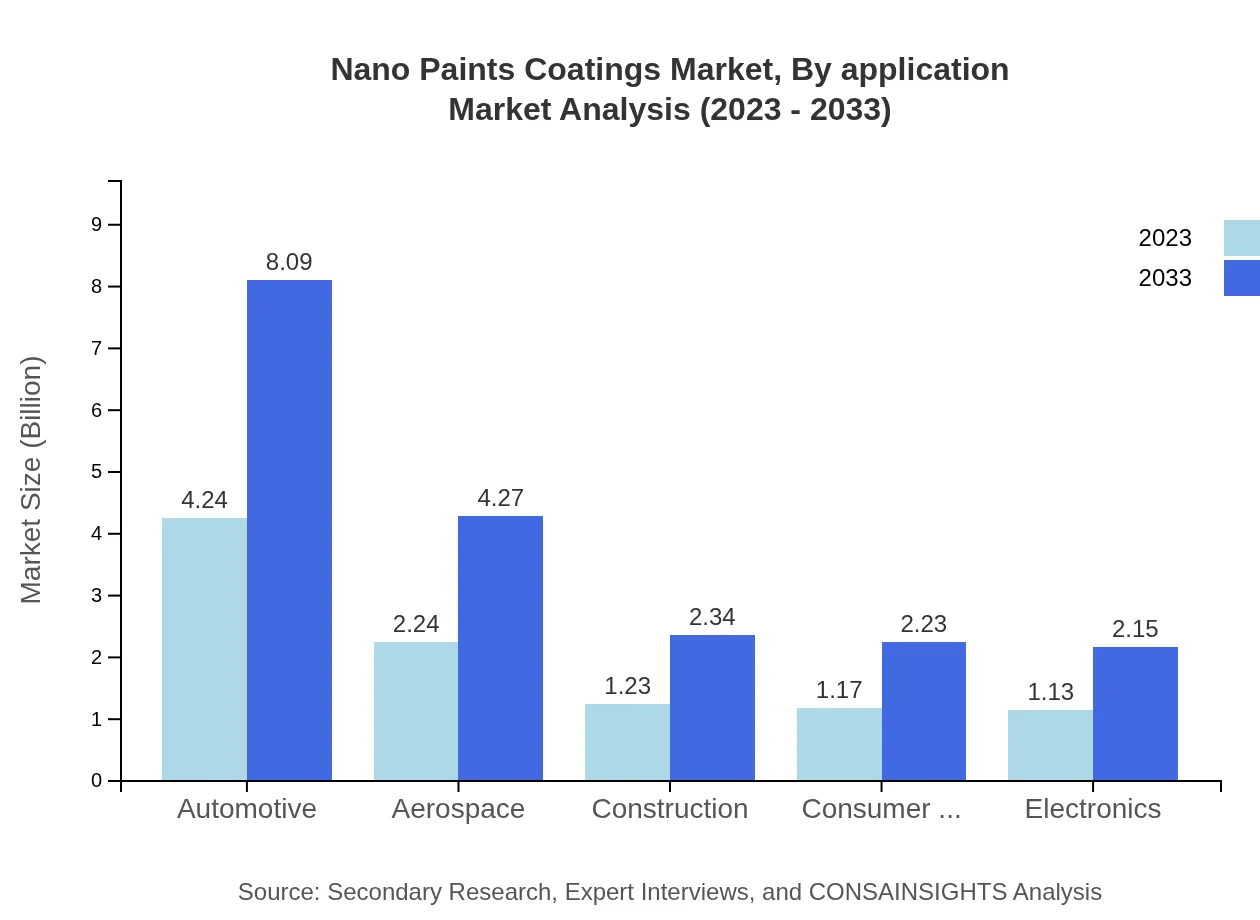

Nano Paints Coatings Market Analysis By Application

The primary applications of Nano Paints Coatings are found across Automotive, Aerospace, Construction, Consumer Goods, Electronics, Industrial and more. The Automotive sector leads with a size of $4.24 billion, projected to rise to $8.09 billion. Significant growth is also observed in Aerospace ($2.24 billion to $4.27 billion), followed by Construction ($1.23 billion to $2.34 billion) and Consumer Goods ($1.17 billion to $2.23 billion).

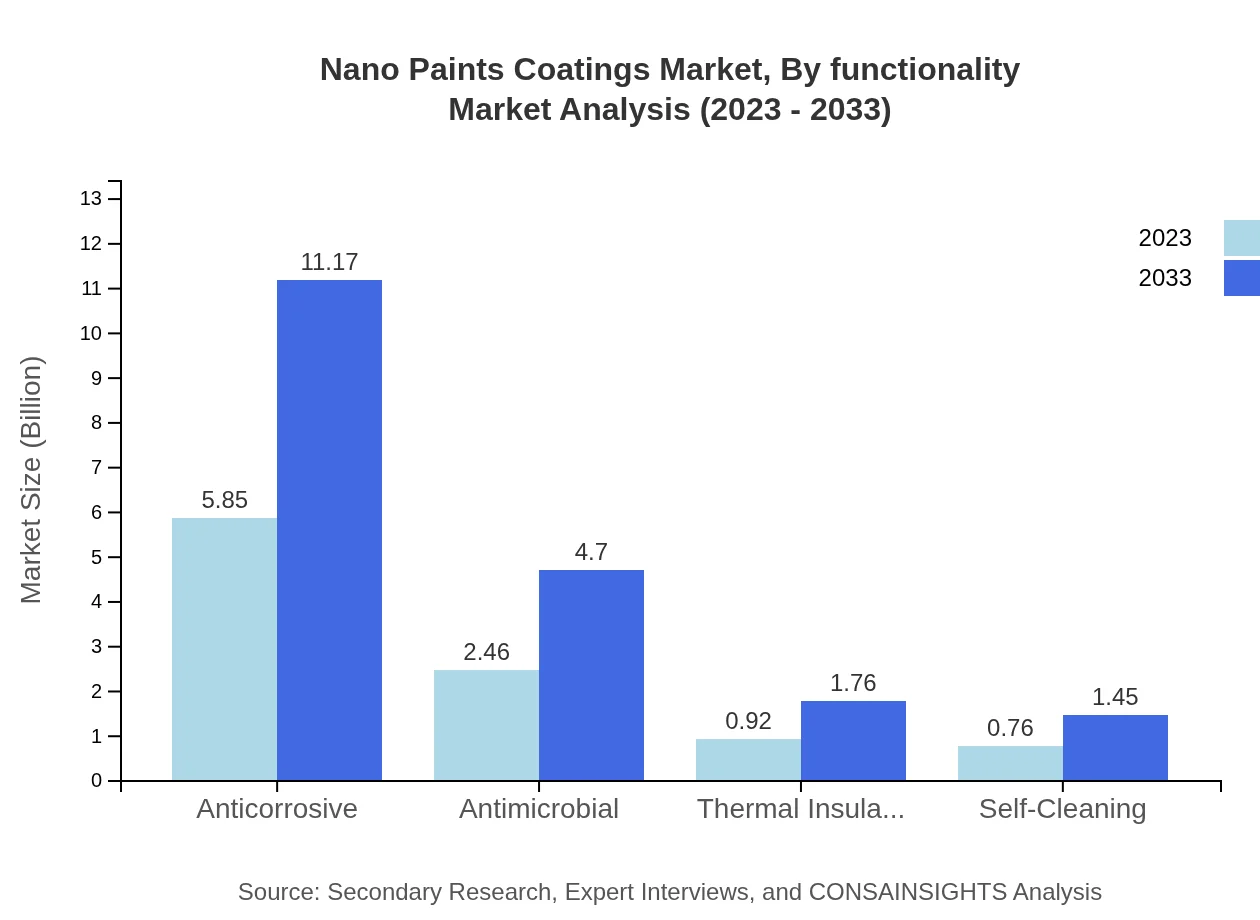

Nano Paints Coatings Market Analysis By Functionality

Functional categories include Anticorrosive, Antimicrobial, Thermal Insulation, Self-Cleaning, and others. The Anticorrosive segment stands out with a market size of $5.85 billion in 2023 expected to double to $11.17 billion by 2033. Antimicrobial coatings hold a share of 24.61%, expanding from $2.46 to $4.70 billion. The Thermal Insulation functionality is witnessing increased interest, particularly for energy-efficient applications.

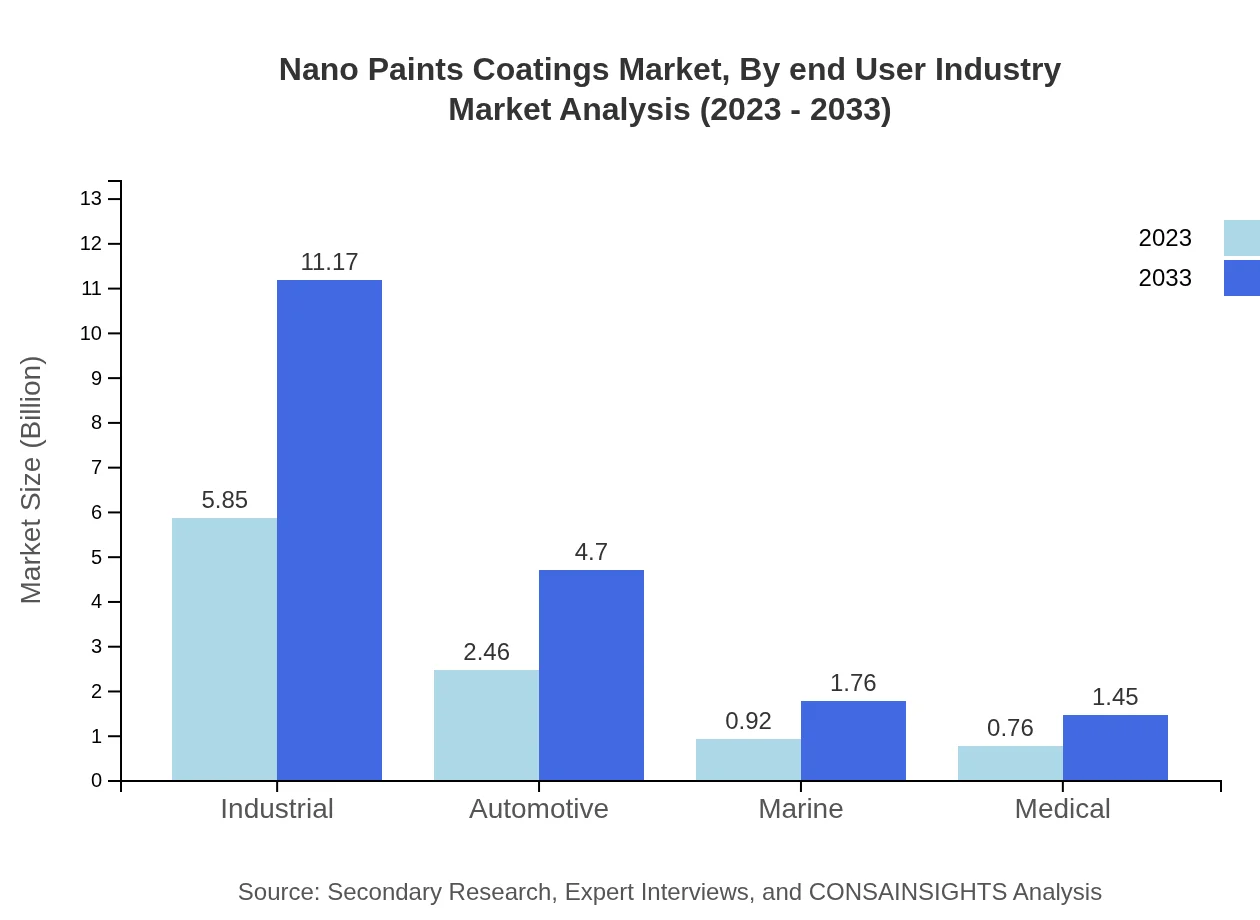

Nano Paints Coatings Market Analysis By End User Industry

End-user industries for Nano Paints Coatings cover Automotive, Aerospace, Industrial, Medical, Marine, and others. The Industrial sector dominates with a share of 58.54%, expected growth from $5.85 billion to $11.17 billion. Automotive and Aerospace are also critical segments with respective shares of 24.61% and 22.4%. Medical and Marine applications are expanding but constitute a smaller share of the overall market.

Nano Paints Coatings Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Nano Paints Coatings Industry

AkzoNobel:

A leading global paints and coatings company offering innovative nano-coating solutions aimed at enhancing surface protection and durability.BASF:

A pioneer in chemical production that develops advanced nano-coating technologies for various industrial applications, ensuring high performance and sustainability.PPG Industries:

A global supplier of paints, coatings, and specialty materials, committed to providing advanced nano-coating solutions that meet diverse customer needs.DuPont:

A science and technology company known for innovative solutions in nanotechnology, enhancing the performance and functionality of coatings.We're grateful to work with incredible clients.

FAQs

What is the market size of Nano Paints Coatings?

The Nano Paints Coatings market is valued at approximately $10 billion as of 2023. With a projected CAGR of 6.5%, it is set to grow significantly, reflecting an increasing demand across various sectors by 2033.

What are the key market players or companies in the Nano Paints Coatings industry?

Key players in the Nano Paints Coatings industry include significant global manufacturers and innovators focused on sustainable and high-performance coatings. These companies are continuously investing in R&D to create cutting-edge solutions.

What are the primary factors driving the growth in the Nano Paints Coatings industry?

Factors driving growth in the Nano Paints Coatings industry include increasing demand for advanced materials, technological advancements in nanotechnology, urbanization trends, and heightened environmental regulations promoting eco-friendly solutions.

Which region is the fastest Growing in the Nano Paints Coatings?

The North America region is the fastest-growing market for Nano Paints Coatings, projected to grow from $3.83 billion in 2023 to $7.32 billion by 2033, driven by robust industrial production and innovative applications.

Does ConsaInsights provide customized market report data for the Nano Paints Coatings industry?

Yes, ConsaInsights offers customized market report data for the Nano Paints Coatings industry. This includes tailored insights and analyses that cater to specific business needs and strategic objectives.

What deliverables can I expect from this Nano Paints Coatings market research project?

From the Nano Paints Coatings market research project, you can expect detailed reports including market size, growth forecasts, trend analyses, competitor insights, and regional performance metrics essential for informed decision-making.

What are the market trends of Nano Paints Coatings?

Current market trends in Nano Paints Coatings include a shift towards eco-friendly formulations, increasing adoption in automotive and aerospace sectors, and innovations in self-cleaning and antimicrobial coatings that enhance surface durability.