Power Plant Control System Market Report

Published Date: 22 January 2026 | Report Code: power-plant-control-system

Power Plant Control System Market Size, Share, Industry Trends and Forecast to 2033

This report explores the Power Plant Control System market, providing insights into market size, trends, segmentation, and regional analyses from 2023 to 2033. It sheds light on technological advancements, key players, and forecasts for future growth.

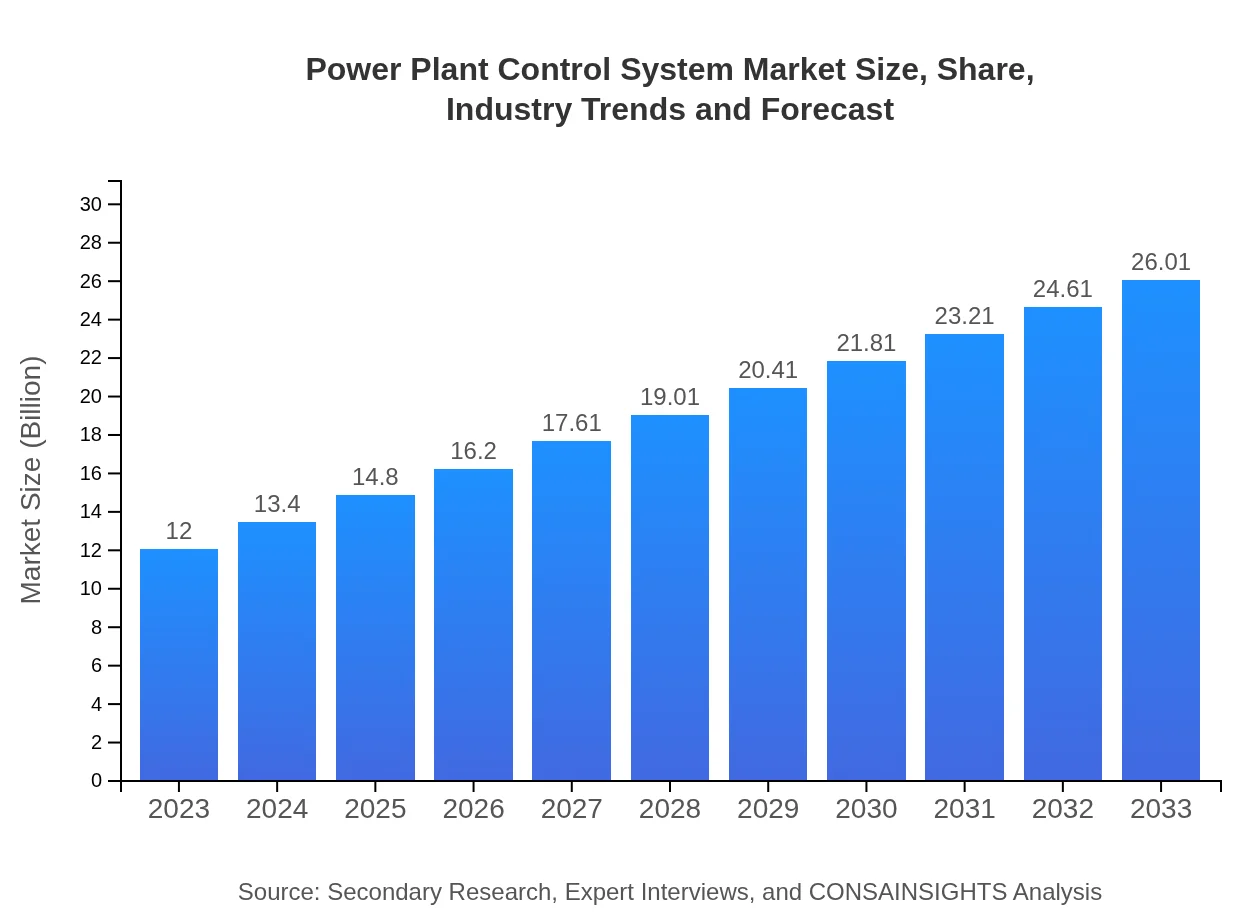

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $12.00 Billion |

| CAGR (2023-2033) | 7.8% |

| 2033 Market Size | $26.01 Billion |

| Top Companies | Siemens AG, Schneider Electric, General Electric Company, Honeywell International Inc. |

| Last Modified Date | 22 January 2026 |

Power Plant Control System Market Overview

Customize Power Plant Control System Market Report market research report

- ✔ Get in-depth analysis of Power Plant Control System market size, growth, and forecasts.

- ✔ Understand Power Plant Control System's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Power Plant Control System

What is the Market Size & CAGR of Power Plant Control System market in 2023?

Power Plant Control System Industry Analysis

Power Plant Control System Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Power Plant Control System Market Analysis Report by Region

Europe Power Plant Control System Market Report:

Europe's market is set to expand from $3.05 billion in 2023 to $6.62 billion by 2033. The growth will be influenced by the European Union’s commitment to sustainability and decarbonization, along with a robust regulatory framework encouraging the adoption of advanced control systems.Asia Pacific Power Plant Control System Market Report:

The Asia Pacific region is poised for substantial growth, with the market expected to increase from $2.52 billion in 2023 to $5.47 billion by 2033. This growth is attributed to rapid industrialization, rising energy demands, and government initiatives to enhance renewable energy integration. Countries like China and India are investing heavily in modernizing their power infrastructure.North America Power Plant Control System Market Report:

North America is anticipated to experience significant growth, with the market size expected to rise from $3.90 billion in 2023 to $8.45 billion by 2033. The increase is fueled by modernization efforts in aging infrastructure and a shift towards smart grid technologies and renewable energy sources.South America Power Plant Control System Market Report:

In South America, the market is projected to grow from $1.05 billion in 2023 to $2.28 billion in 2033, driven by increasing investments in energy projects and a push towards renewable energy solutions. Brazil and Chile are leading the charge towards enhanced energy systems.Middle East & Africa Power Plant Control System Market Report:

The Middle East and Africa region's market is anticipated to grow from $1.47 billion in 2023 to $3.20 billion by 2033, reflecting the increasing investments in energy diversification and infrastructural development. Nations within this region are prioritizing technological upgrades to support energy transition efforts.Tell us your focus area and get a customized research report.

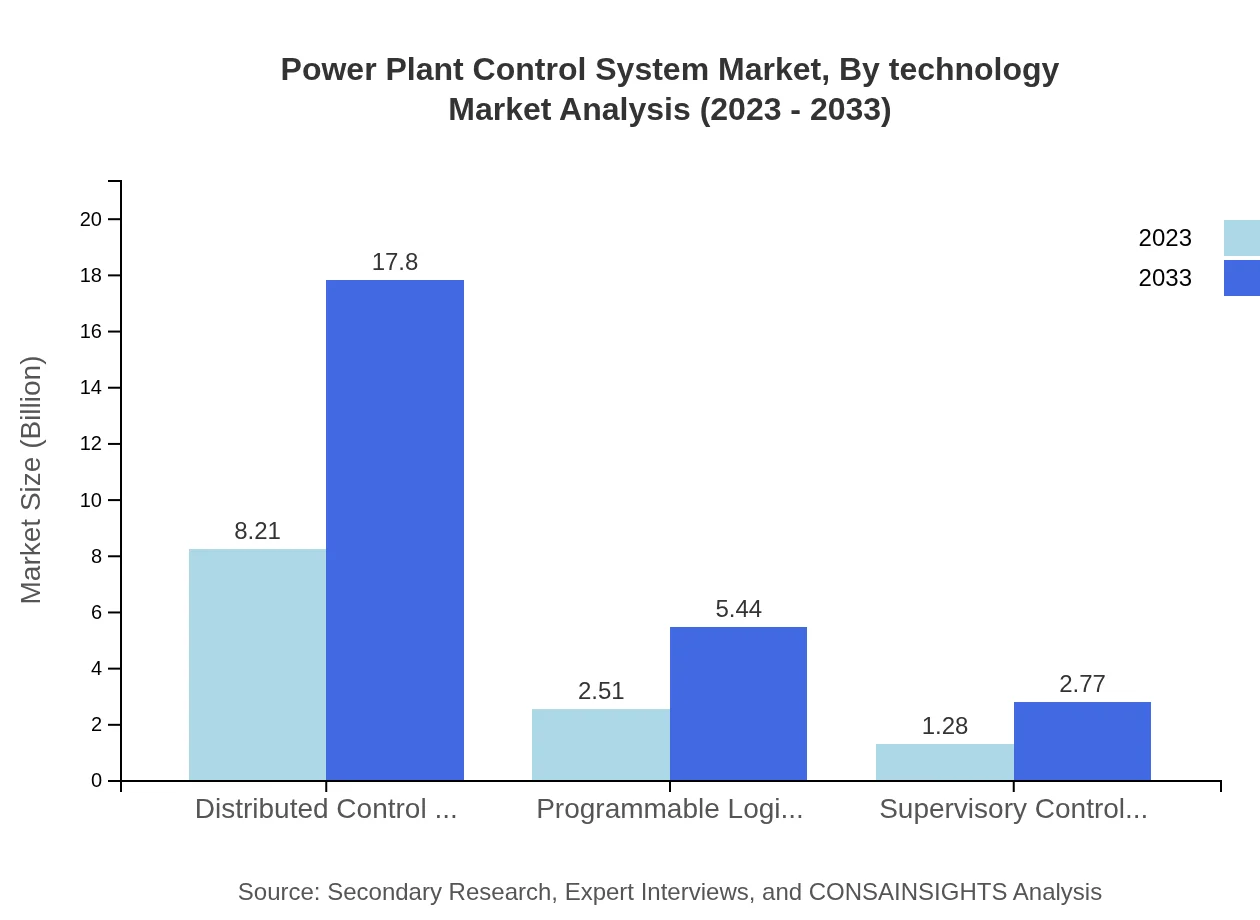

Power Plant Control System Market Analysis By Technology

By technology, Distributed Control Systems (DCS) dominate the Power Plant Control System market, generating a valuation of $8.21 billion in 2023, with a consistent market share of 68.43%. PLCs and SCADA make significant contributions as well, reflecting their critical role in automation and monitoring.

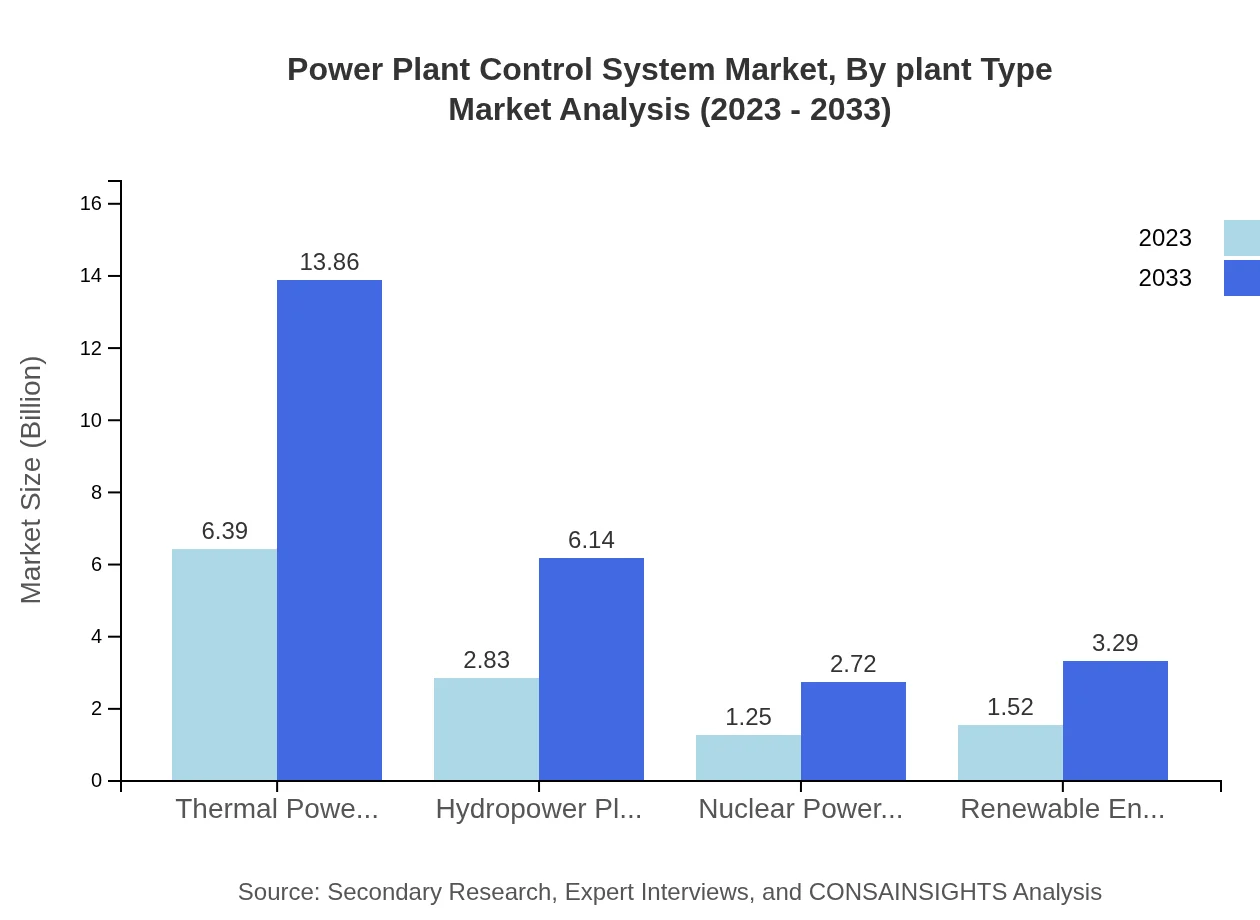

Power Plant Control System Market Analysis By Plant Type

Thermal Power Plants hold a major share of the market with a revenue of $6.39 billion in 2023, expected to increase to $13.86 billion by 2033. Complementarily, Hydropower and Nuclear Power sectors exhibit steady growth, driven by enhanced efficiency and environmentally friendly operations.

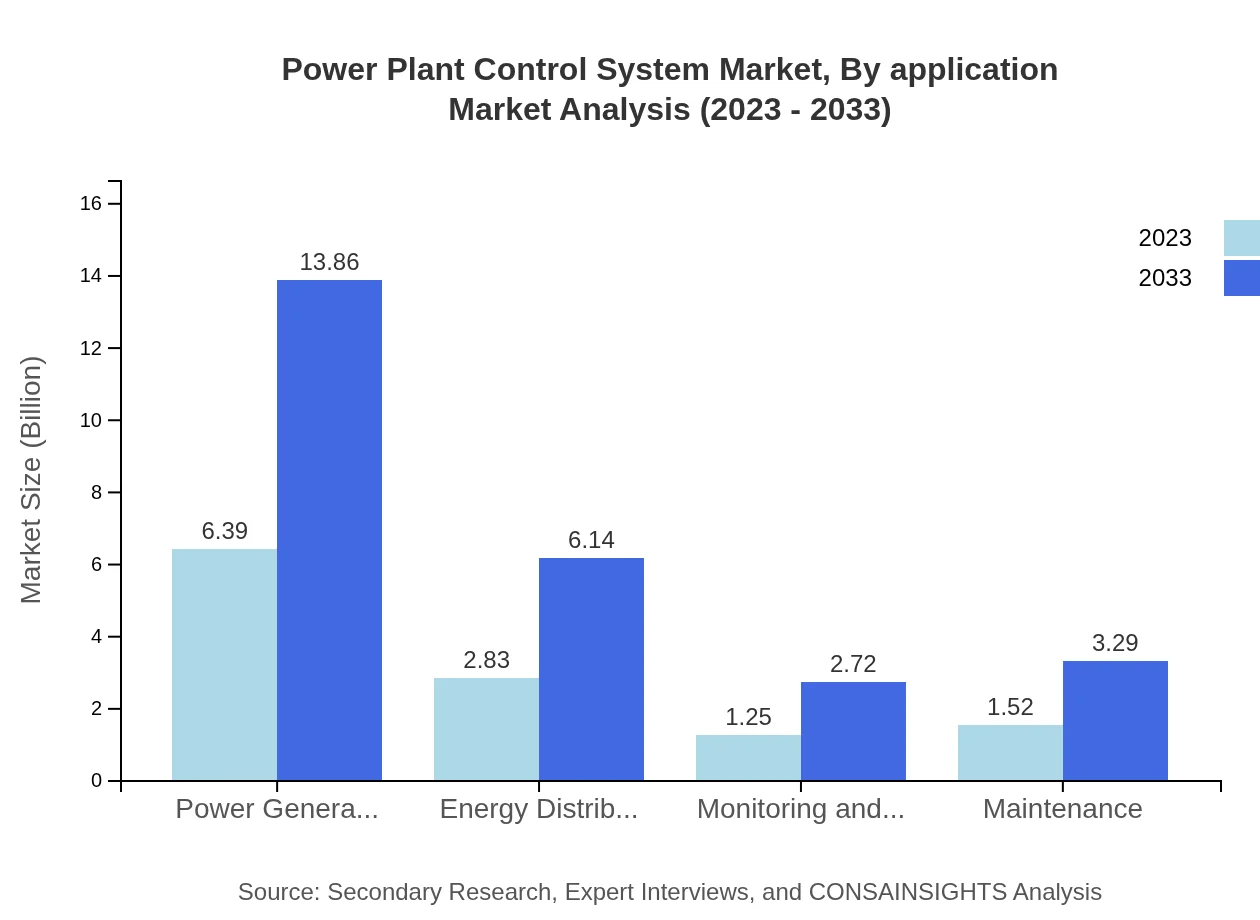

Power Plant Control System Market Analysis By Application

Power Generation and Energy Distribution are the leading applications within the market. They accounted for $6.39 billion and $2.83 billion respectively in 2023, anticipated to grow substantially as demand for efficient energy systems rises.

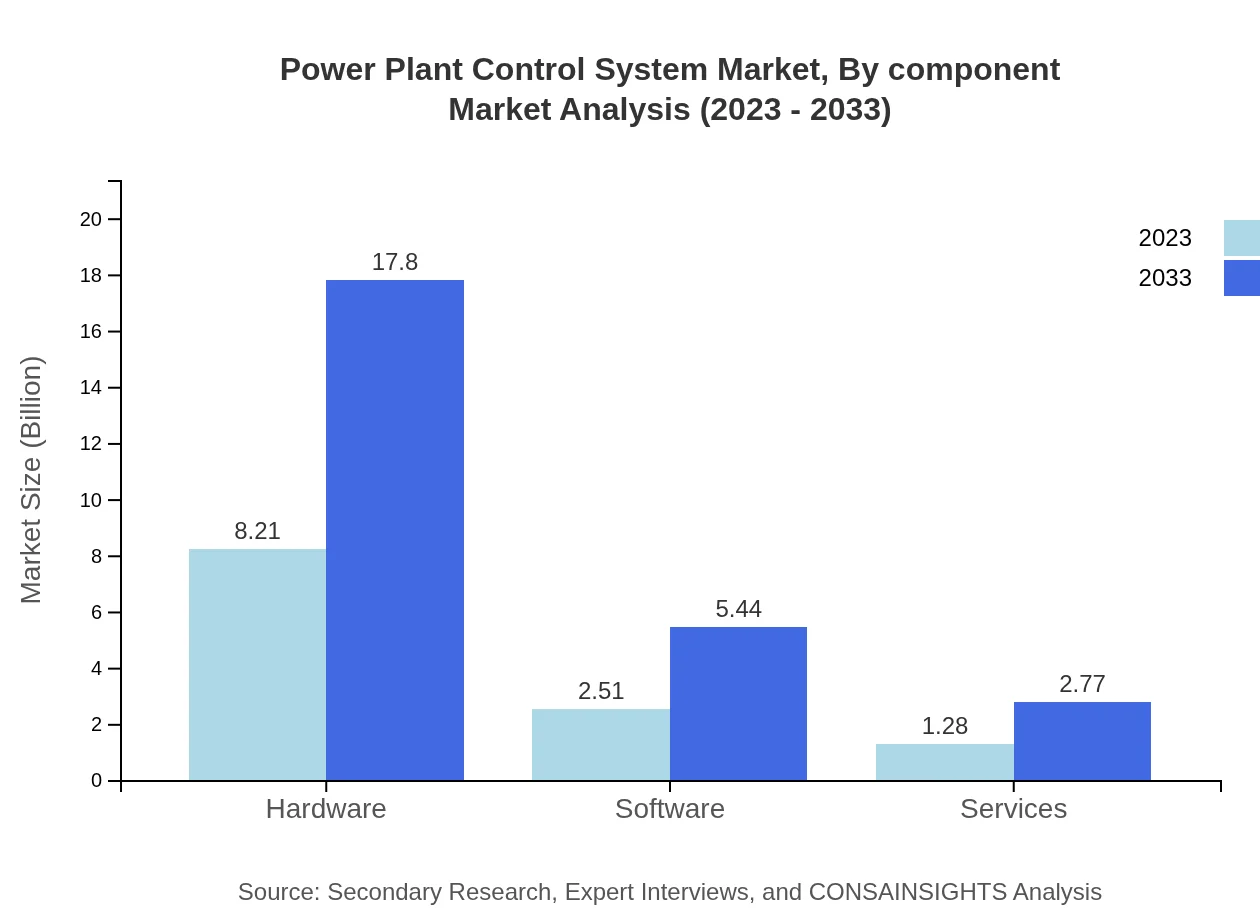

Power Plant Control System Market Analysis By Component

Hardware remains the largest segment, valued at $8.21 billion in 2023. It is closely followed by Software and Services, reflecting an upward trend towards digital solutions and responsive service offerings in the industry.

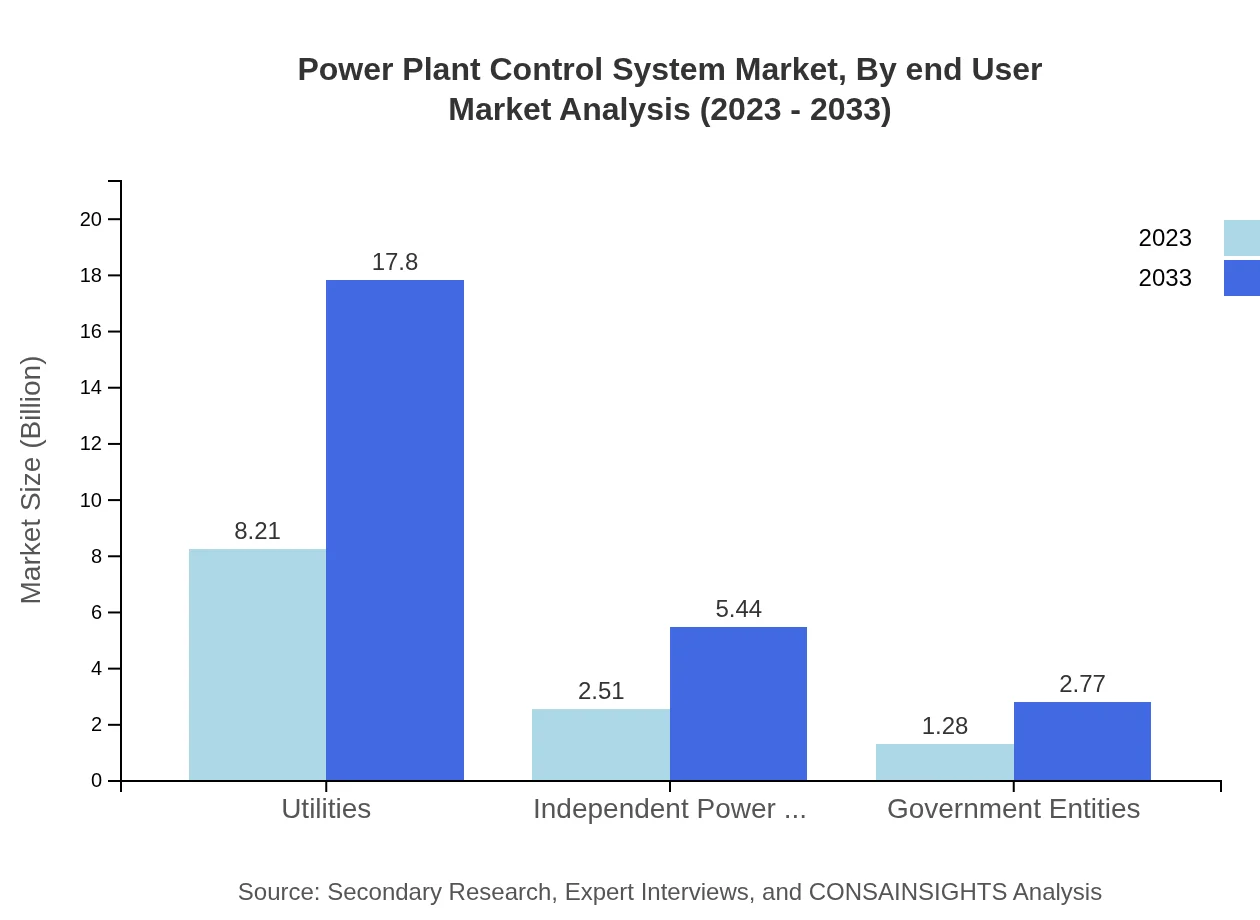

Power Plant Control System Market Analysis By End User

Utilities dominate the end-user segment, capturing a market share of 68.43%, valued at $8.21 billion in 2023. Independent Power Producers and Government Entities are also significant contributors, as they adapt to new technologies and regulatory mandates.

Power Plant Control System Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Power Plant Control System Industry

Siemens AG:

Siemens AG is a global leader in automation and control systems, renowned for its innovative solutions that enhance the operational efficiency of power plants.Schneider Electric:

Schneider Electric specializes in energy management and automation solutions, focusing on technologies that foster sustainability and enhance the management of power plants.General Electric Company:

GE is a key player in power generation and control systems, offering extensive solutions for improving efficiency and reducing emissions in energy production.Honeywell International Inc.:

Honeywell is a prominent provider of control technologies and automation solutions, empowering power plants to achieve seamless operations.We're grateful to work with incredible clients.

FAQs

What is the market size of power Plant Control System?

The global power plant control system market is valued at approximately $12 billion in 2023, with an anticipated compound annual growth rate (CAGR) of 7.8%, projecting significant growth towards 2033 as efficiency and automation demands increase.

What are the key market players or companies in this power Plant Control System industry?

Key players in the power plant control system market include Siemens, General Electric, Honeywell, Mitsubishi Electric, and Schneider Electric, among others, contributing to innovative solutions that enhance plant efficiency and reduce operational costs.

What are the primary factors driving the growth in the power Plant Control System industry?

Drivers of growth in the power plant control system market include the increasing demand for renewable energy, advancements in automation technologies, government regulations promoting energy efficiency, and the need for improved reliability and safety in energy production.

Which region is the fastest Growing in the power Plant Control System?

The fastest-growing region in the power plant control system market is North America, with a market size projected to grow from $3.90 billion in 2023 to $8.45 billion in 2033, driven by technological advancements and investment in modernization initiatives.

Does ConsaInsights provide customized market report data for the power Plant Control System industry?

Yes, ConsaInsights offers customized market report data tailored to specific client needs within the power plant control system industry, ensuring the insights align with unique business requirements and market opportunities.

What deliverables can I expect from this power Plant Control System market research project?

Deliverables from the power plant control system market research project include detailed market size analyses, growth forecasts, competitive landscape overviews, segmentation data, and insights into key trends influencing the industry.

What are the market trends of power Plant Control System?

Current market trends in the power plant control system space include the increasing adoption of IoT technologies, emphasis on cybersecurity for operational integrity, growing integration of renewable energy sources, and automation to enhance efficiency and reduce labor costs.