Protective Coating Resins Market Report

Published Date: 02 February 2026 | Report Code: protective-coating-resins

Protective Coating Resins Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Protective Coating Resins market from 2023 to 2033. It covers market size, growth trends, regional insights, segmentation analysis, and leading players, offering valuable data for industry stakeholders and potential investors.

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

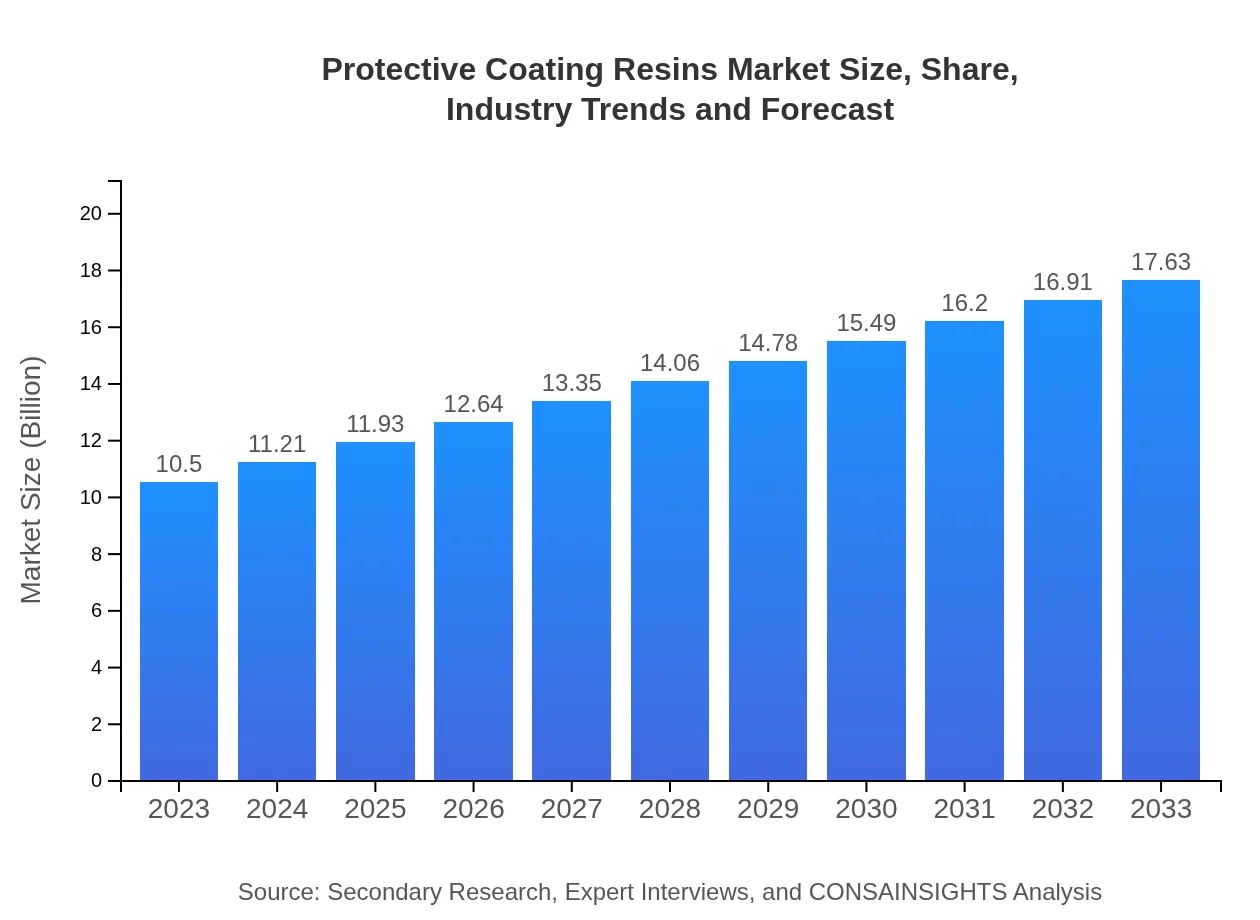

| 2023 Market Size | $10.50 Billion |

| CAGR (2023-2033) | 5.2% |

| 2033 Market Size | $17.63 Billion |

| Top Companies | BASF, AkzoNobel, Sherwin-Williams, PPG Industries, Henkel |

| Last Modified Date | 02 February 2026 |

Protective Coating Resins Market Overview

Customize Protective Coating Resins Market Report market research report

- ✔ Get in-depth analysis of Protective Coating Resins market size, growth, and forecasts.

- ✔ Understand Protective Coating Resins's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Protective Coating Resins

What is the Market Size & CAGR of Protective Coating Resins market in 2023 and 2033?

Protective Coating Resins Industry Analysis

Protective Coating Resins Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Protective Coating Resins Market Analysis Report by Region

Europe Protective Coating Resins Market Report:

The European market is forecasted to expand from USD 3.24 billion in 2023 to USD 5.45 billion by 2033, owing to stringent regulations on environmental safety and a focus on sustainable coating solutions, largely in the automotive and industrial sectors.Asia Pacific Protective Coating Resins Market Report:

The Asia Pacific region, valued at USD 2.02 billion in 2023 and expected to reach USD 3.39 billion in 2033, is growing rapidly due to increasing construction and manufacturing activities. Countries like China and India are investing heavily in infrastructure, driving the demand for high-performance coatings.North America Protective Coating Resins Market Report:

North America, with a market size of USD 3.47 billion in 2023 projected to grow to USD 5.83 billion by 2033, is driven by advanced automotive and industrial sectors which demand innovative and effective protective coatings.South America Protective Coating Resins Market Report:

In South America, the market for Protective Coating Resins is valued at USD 0.45 billion in 2023, anticipated to grow to USD 0.75 billion by 2033. The growth is attributed to rising industrialization and a shift towards improved manufacturing processes.Middle East & Africa Protective Coating Resins Market Report:

The Middle East and Africa region's market, valued at USD 1.31 billion in 2023, is estimated to grow to USD 2.20 billion by 2033. Growth is propelled by increasing oil and gas exploration and construction activities.Tell us your focus area and get a customized research report.

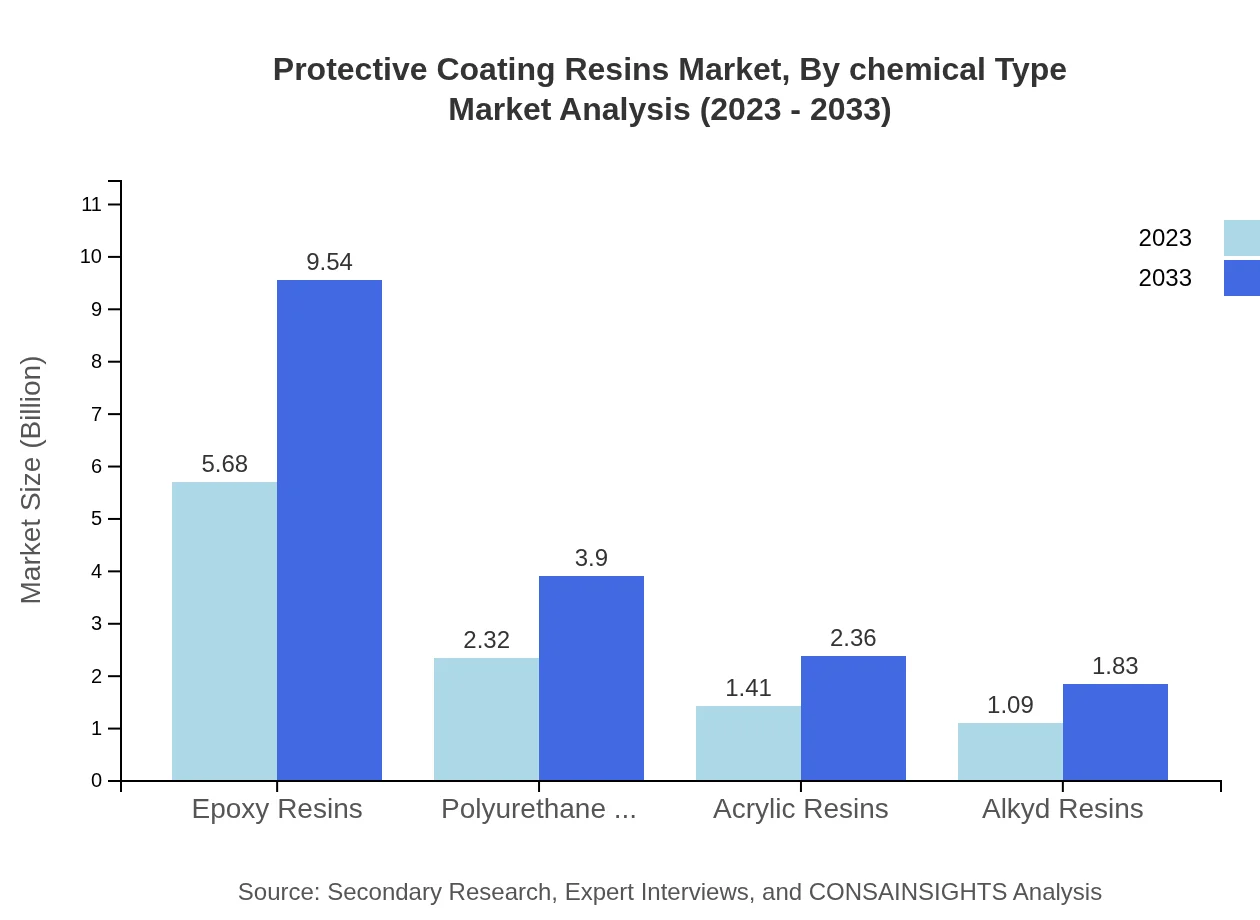

Protective Coating Resins Market Analysis By Chemical Type

Epoxy resins, representing 54.14% of the market share in 2023, are highly favored due to their chemical resistance and durability. Other significant types include Polyurethane (22.11%) and Acrylic (13.39%), each bringing unique advantages to various applications.

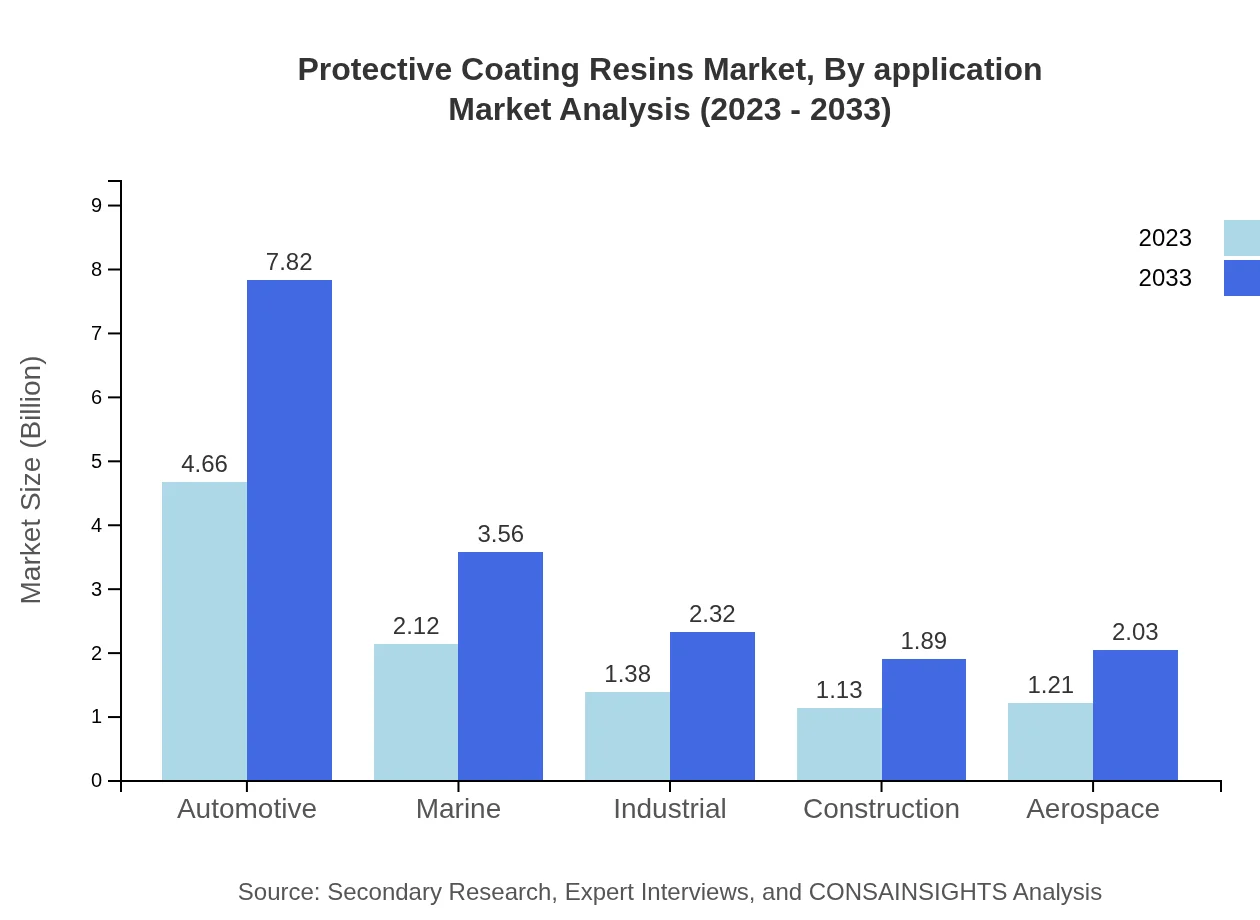

Protective Coating Resins Market Analysis By Application

Automotive applications dominate the segment, with a size of USD 4.66 billion in 2023 expected to grow to USD 7.82 billion by 2033. Other notable applications encompass industrial and construction segments, each playing a crucial role due to their protective requirements.

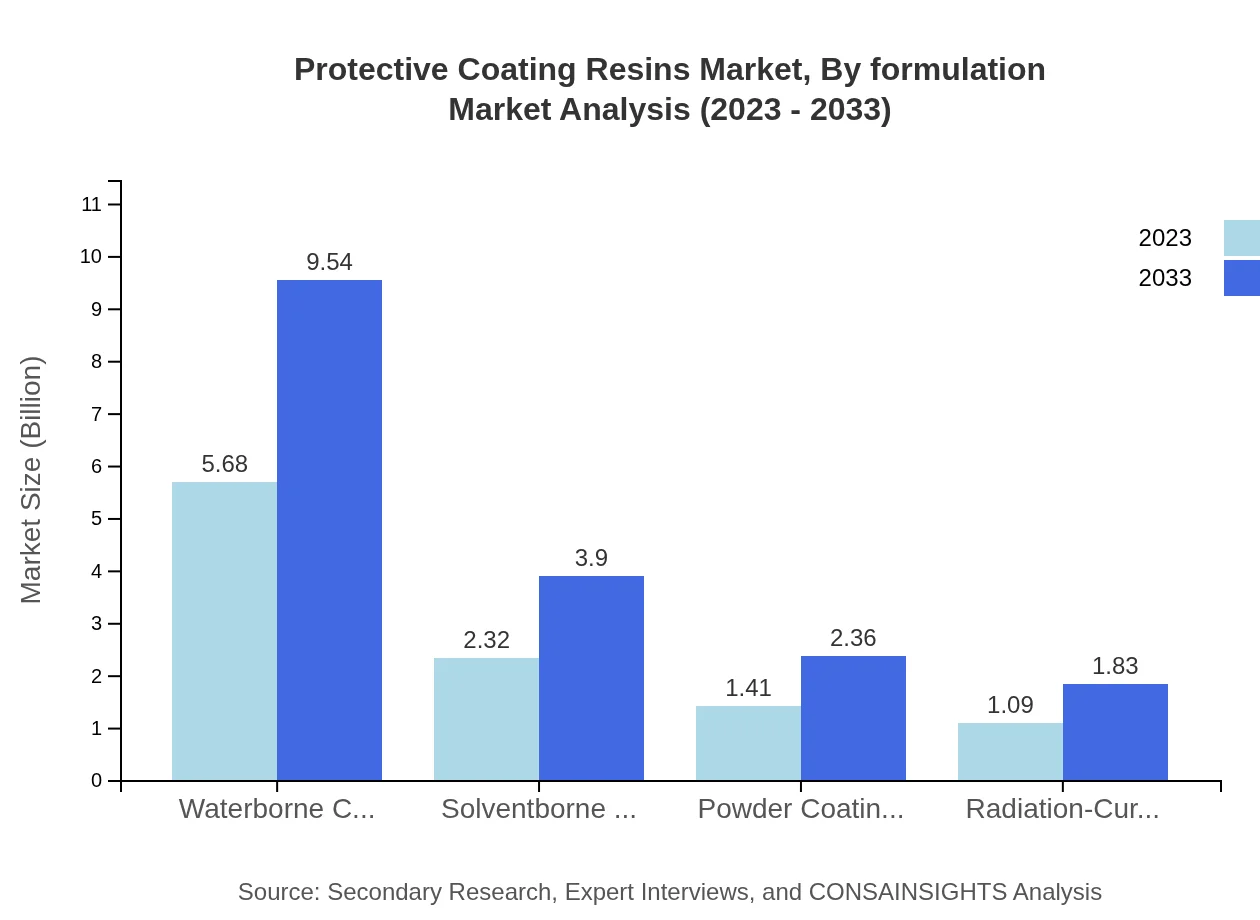

Protective Coating Resins Market Analysis By Formulation

Waterborne coatings, capturing a significant market share of 54.14% in 2023, are increasingly preferred due to their low environmental impact. Solventborne coatings (22.11%) continue to be important, particularly in regions with less stringent regulations.

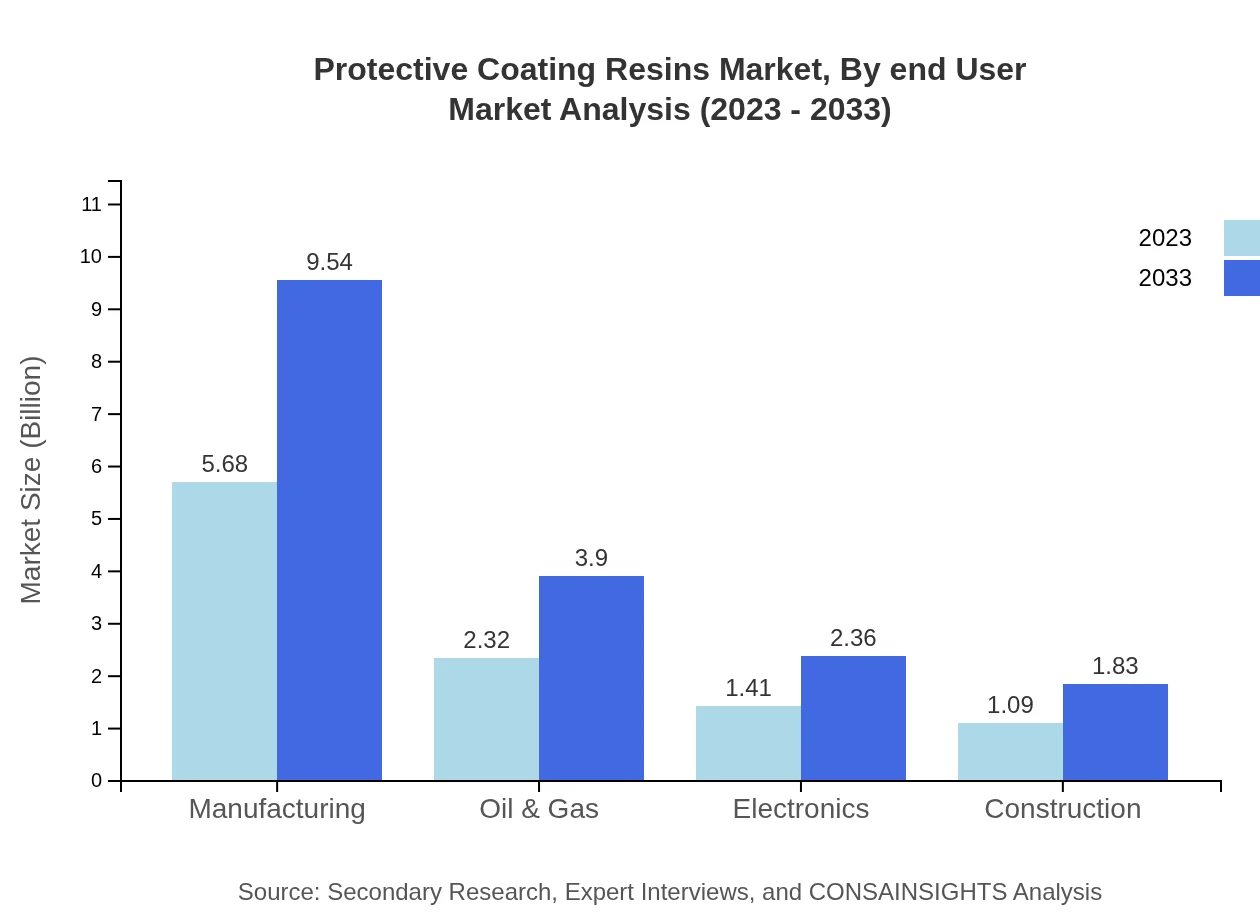

Protective Coating Resins Market Analysis By End User

The automotive sector contributes the largest share, at 44.39% in 2023, followed closely by industries such as construction (10.36%) and marine (20.18%), reflecting the demand across diverse sectors for protective coatings.

Protective Coating Resins Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Protective Coating Resins Industry

BASF:

A leading global chemical company known for its innovative coating solutions and commitment to sustainability. BASF produces a wide range of protective coating resins for various applications across multiple industries.AkzoNobel:

Known for its advanced coating technologies, AkzoNobel provides high-performance protective coatings for varied applications, focusing on sustainability and customer satisfaction.Sherwin-Williams:

A major player in the coatings industry, Sherwin-Williams offers protective coating resins tailored for industries like automotive, construction, and industrial, emphasizing high-quality and durability.PPG Industries:

PPG is a global supplier of paints, coatings, and specialty materials, recognized for its innovative protective coating solutions engineered for optimal performance.Henkel:

Henkel produces a vast array of adhesives and coatings, leading in innovative protective solutions focusing on ecological sustainability and efficient application processes.We're grateful to work with incredible clients.

FAQs

What is the market size of protective Coating Resins?

The protective coating resins market is currently valued at approximately $10.5 billion as of 2023, with a projected CAGR of 5.2% up to 2033, indicating robust growth potential in this sector.

What are the key market players or companies in this protective Coating Resins industry?

Key players driving the protective coating resins industry include BASF SE, PPG Industries, Sherwin-Williams, and AkzoNobel, which significantly contribute to innovation and market share across different regions.

What are the primary factors driving the growth in the protective Coating Resins industry?

Growth in the protective coating resins market is primarily driven by demand in construction, automotive, and oil & gas sectors, alongside the increasing need for environmental-friendly products and advancements in resin technology.

Which region is the fastest Growing in the protective Coating Resins?

The Asia Pacific region is the fastest-growing market for protective coating resins, expanding from $2.02 billion in 2023 to $3.39 billion by 2033, fueled by industrialization and infrastructure development.

Does ConsaInsights provide customized market report data for the protective Coating Resins industry?

Yes, ConsaInsights offers customized market report data for the protective coating resins industry, enabling clients to receive tailored insights to meet their specific market needs and strategic goals.

What deliverables can I expect from this protective Coating Resins market research project?

Deliverables from the protective coating resins market research project include detailed market analysis, segmentation data, regional performance reports, industry trends, and forecasts, enhancing decision-making for stakeholders.

What are the market trends of protective Coating Resins?

Notable market trends for protective coating resins include a shift toward sustainable materials, increased application in advanced industries, and rising adoption of smart coatings, showcasing the sector's evolution.