Pvc Additives Market Report

Published Date: 02 February 2026 | Report Code: pvc-additives

Pvc Additives Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the PVC additives market, covering crucial insights, market dynamics, and forecasts from 2023 to 2033. It highlights market segmentation, regional analysis, industry trends, and profiles of leading companies.

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

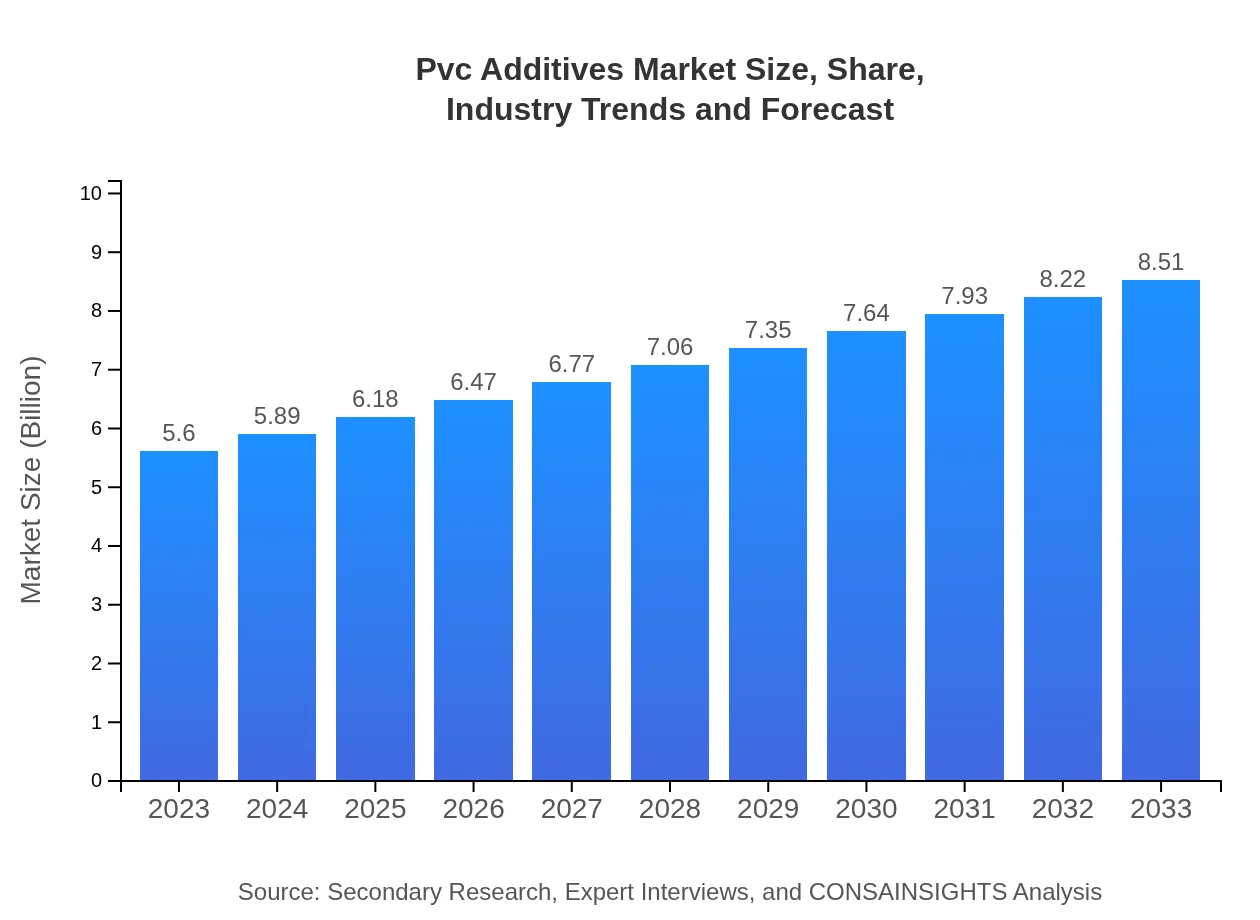

| 2023 Market Size | $5.60 Billion |

| CAGR (2023-2033) | 4.2% |

| 2033 Market Size | $8.51 Billion |

| Top Companies | BASF SE, Eastman Chemical Company, CLARIANT AG, Solvay SA, ADDINFO |

| Last Modified Date | 02 February 2026 |

PVC Additives Market Overview

Customize Pvc Additives Market Report market research report

- ✔ Get in-depth analysis of Pvc Additives market size, growth, and forecasts.

- ✔ Understand Pvc Additives's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Pvc Additives

What is the Market Size & CAGR of PVC Additives market in 2023?

PVC Additives Industry Analysis

PVC Additives Market Segmentation and Scope

Tell us your focus area and get a customized research report.

PVC Additives Market Analysis Report by Region

Europe Pvc Additives Market Report:

Europe's PVC additives market stood at about $1.73 billion in 2023, expected to grow to $2.63 billion by 2033. The region witnesses a shift towards sustainability, prompting innovations in eco-friendly additives and growing recycling initiatives.Asia Pacific Pvc Additives Market Report:

In 2023, the Asia Pacific PVC additives market is valued at approximately $1.04 billion, expected to grow to $1.59 billion by 2033. The region's growth is driven by booming construction and manufacturing sectors, particularly in countries like China and India, where urbanization and infrastructure development are at the forefront.North America Pvc Additives Market Report:

In North America, the PVC additives market is estimated at $2.15 billion in 2023 with a forecasted increase to approximately $3.26 billion by 2033. The region shows strong demand due to sustained investments in infrastructure and remodeling projects, alongside the automotive industry's advancements.South America Pvc Additives Market Report:

The South American market for PVC additives was valued at roughly $0.38 billion in 2023 and is projected to reach $0.58 billion by 2033. Brazil and Argentina are the main contributors to this growth, benefiting from rising construction activities.Middle East & Africa Pvc Additives Market Report:

In 2023, the Middle East and Africa market for PVC additives is valued at approximately $0.30 billion, with an expected increase to about $0.45 billion by 2033. Growth in this region can be attributed to increasing construction activities fueled by economic diversification efforts.Tell us your focus area and get a customized research report.

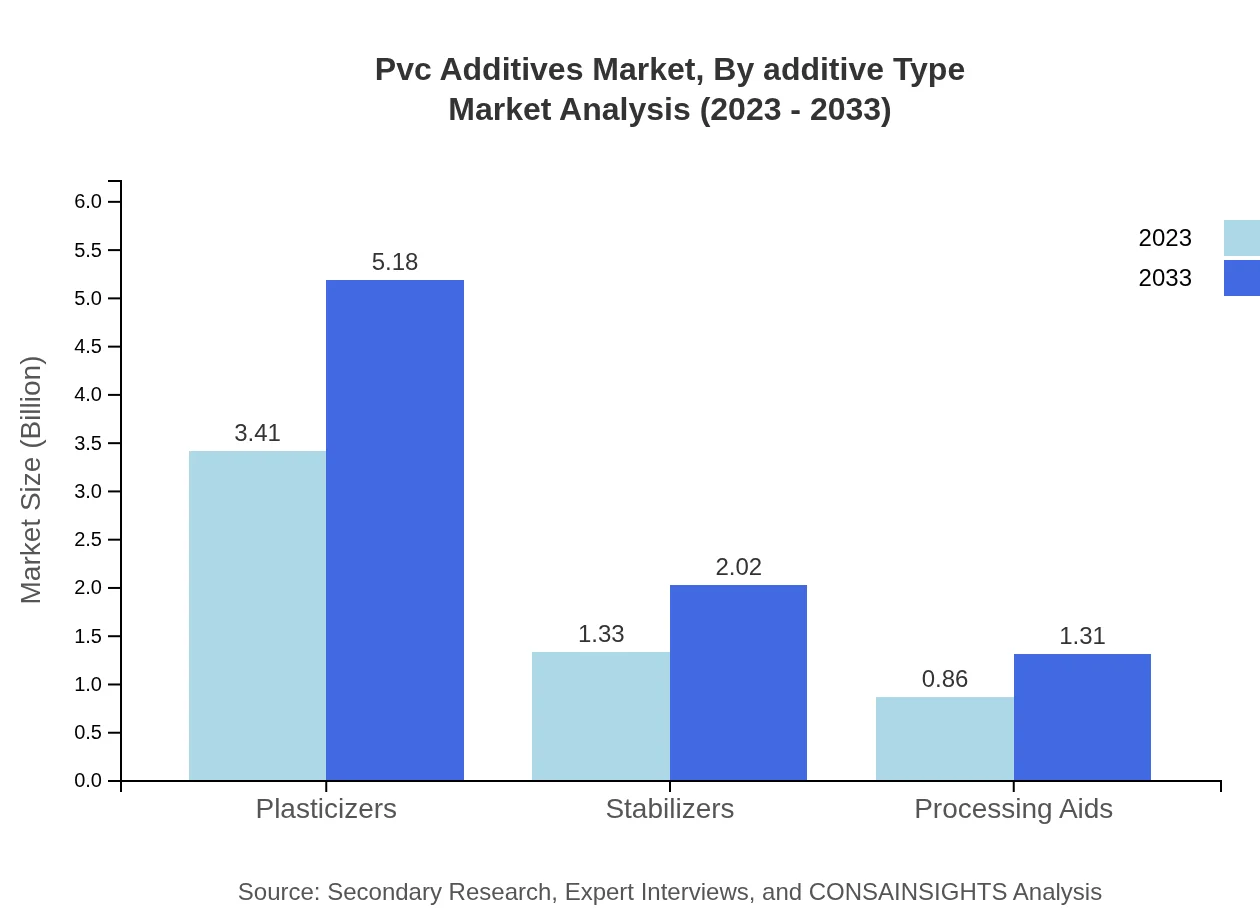

Pvc Additives Market Analysis By Additive Type

Plasticizers currently dominate the PVC additives market, representing 60.83% of the market share in 2023. Stabilizers follow, accounting for 23.76%. The plasticizers segment is projected to grow from $3.41 billion in 2023 to $5.18 billion by 2033, while stabilizers are expected to rise from $1.33 billion to $2.02 billion during the same period.

Pvc Additives Market Analysis By Application

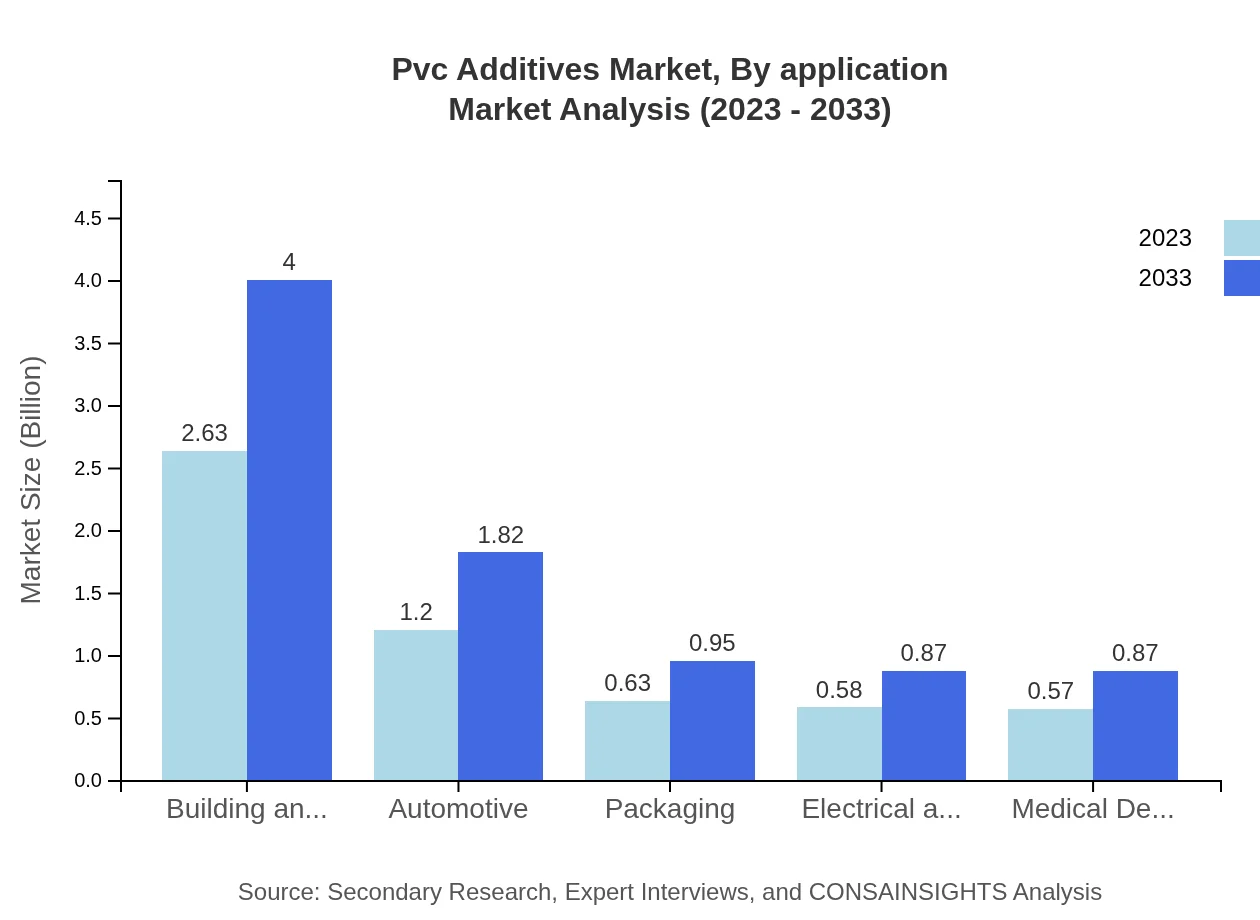

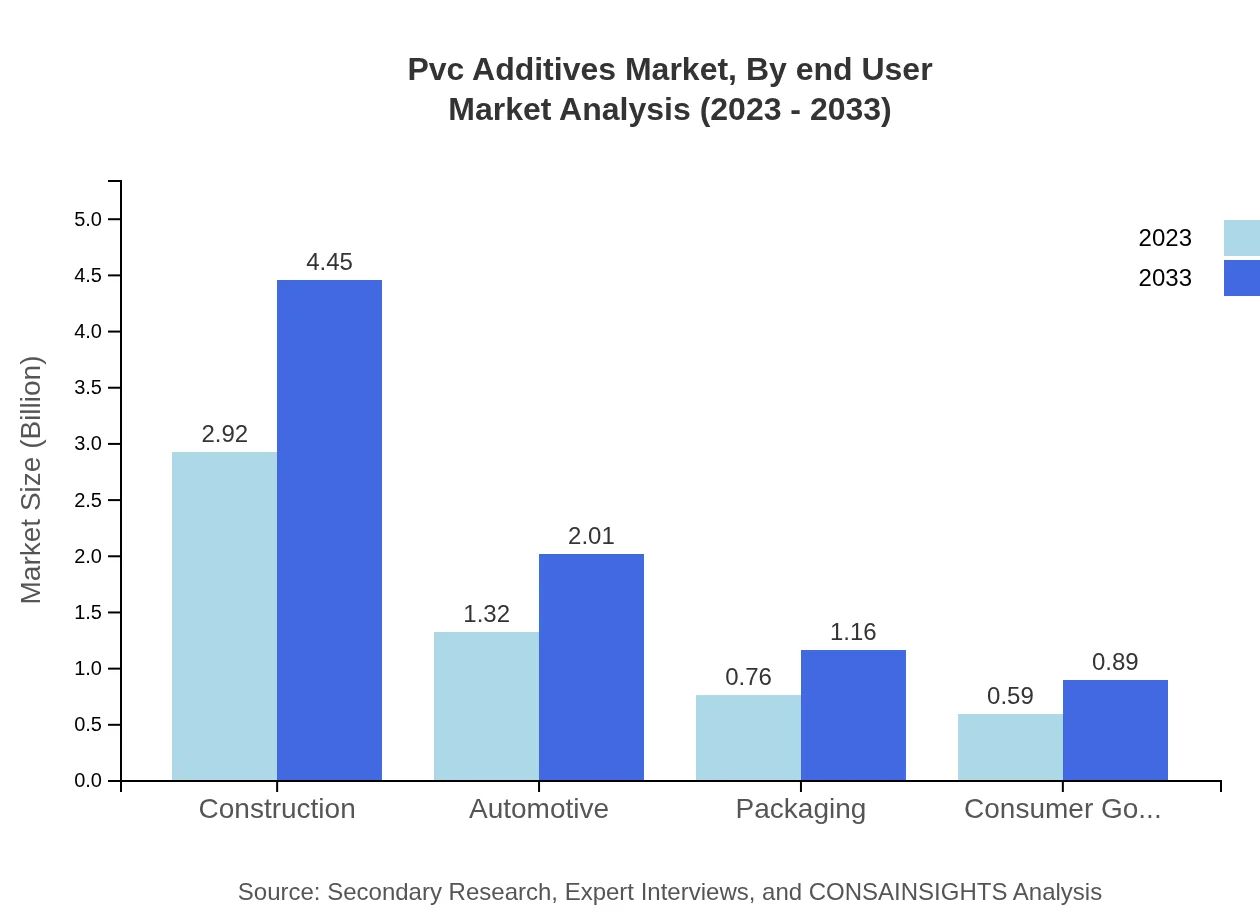

Construction remains the largest application area for PVC additives, capturing a market size of $2.92 billion in 2023 with sustained growth to $4.45 billion by 2033. Automotive and packaging applications also show strong potential, growing from $1.32 billion to $2.01 billion and from $0.76 billion to $1.16 billion, respectively, illustrating the diverse usability across industries.

Pvc Additives Market Analysis By Formulation

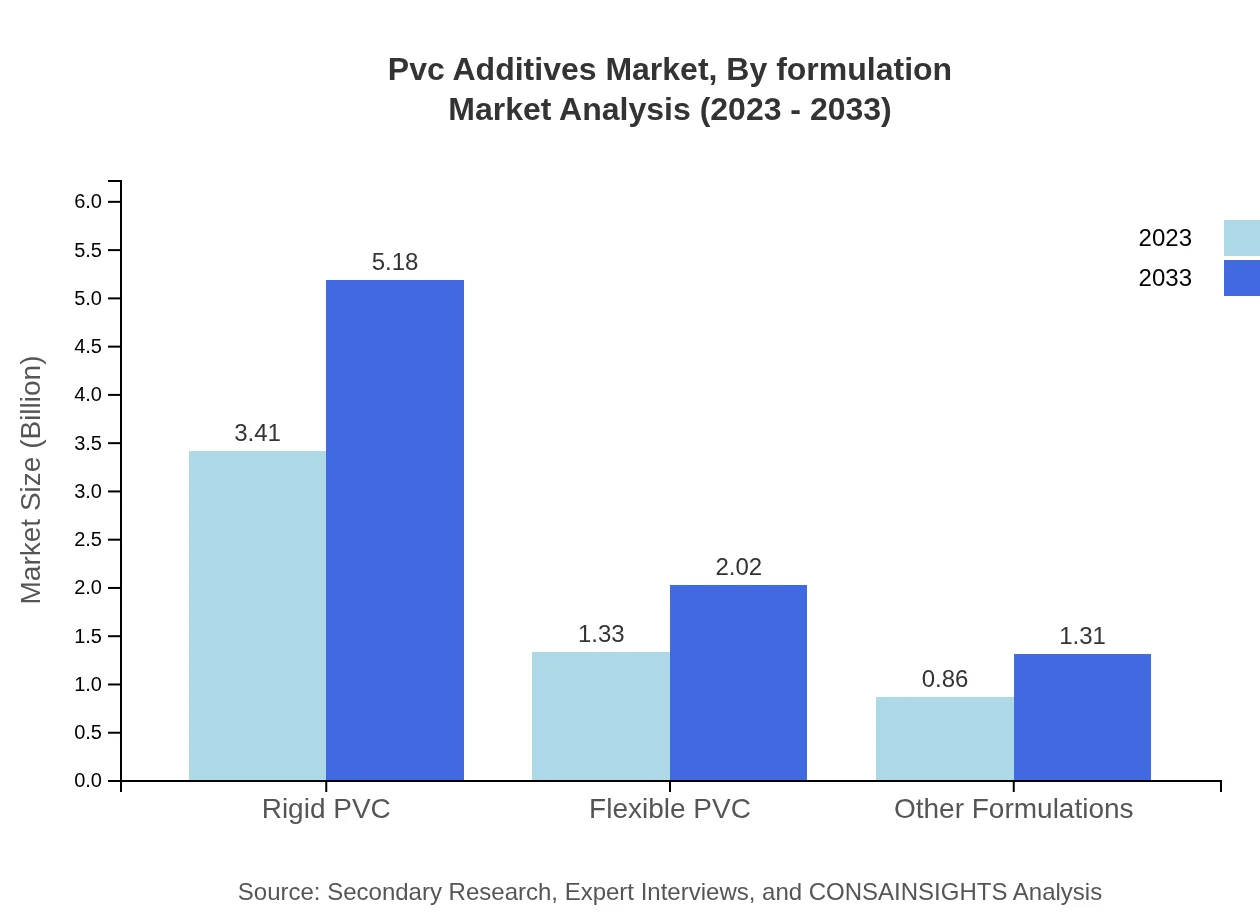

Rigid PVC holds the majority market share at 60.83%, valued at $3.41 billion in 2023, with expectations to reach $5.18 billion by 2033. Flexible PVC also shows significant growth from $1.33 billion to $2.02 billion, reflecting the demand across various applications.

Pvc Additives Market Analysis By End User

The major end-user segment is construction, with a projected market size increase from $2.63 billion in 2023 to $4.00 billion by 2033. Other notable end-users include automotive and consumer goods sectors which follow closely, highlighting the versatility and essential nature of PVC additives.

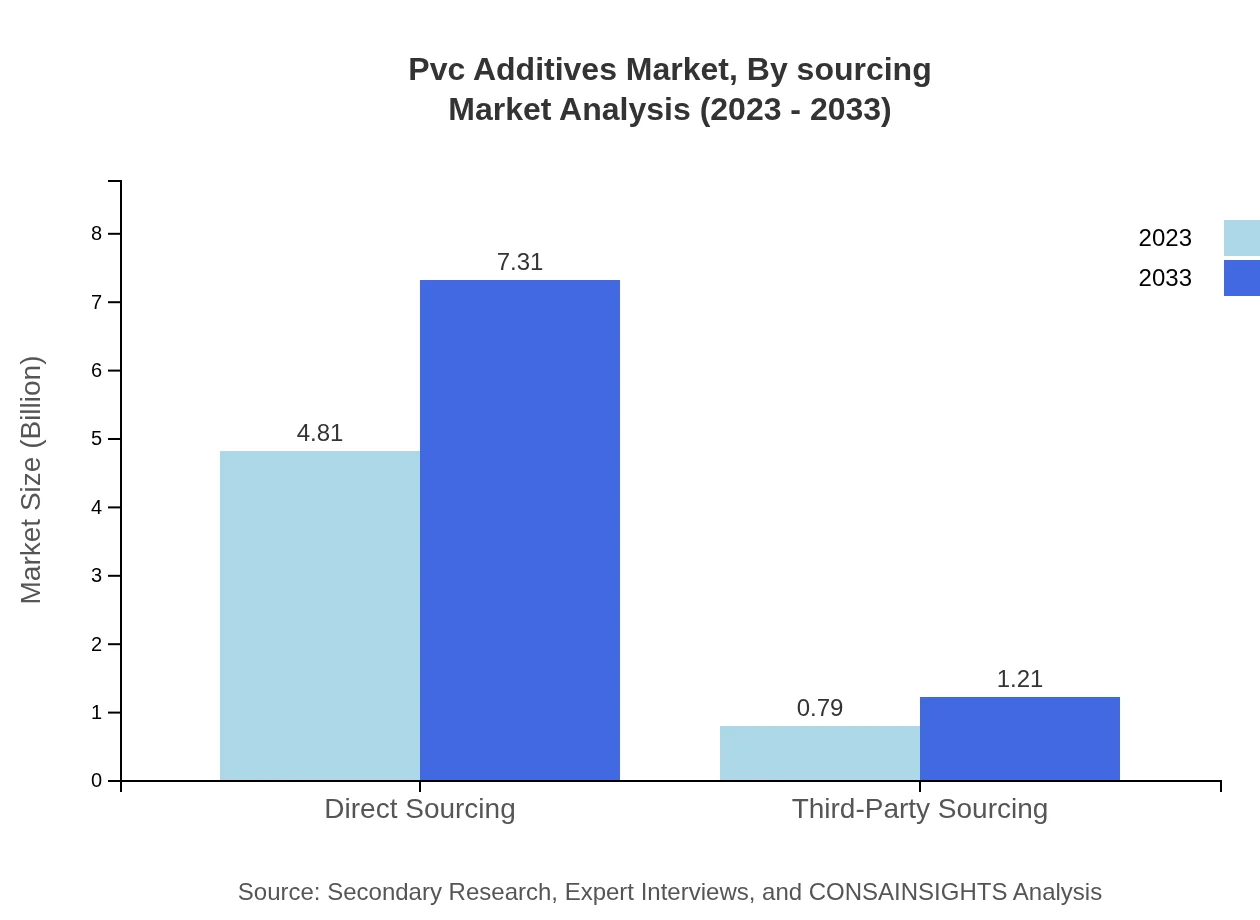

Pvc Additives Market Analysis By Sourcing

Direct sourcing holds a significant market share at 85.84%, valued at $4.81 billion in 2023 and expected to rise to $7.31 billion by 2033. Third-party sourcing is also notable, expected to grow from $0.79 billion to $1.21 billion, indicating shifts in procurement practices in the industry.

PVC Additives Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in PVC Additives Industry

BASF SE:

A leader in chemical production, BASF provides a wide range of PVC additives that enhance product performance and sustainability.Eastman Chemical Company:

Known for innovative additives, Eastman focuses on improving the sustainability and efficiency of PVC applications.CLARIANT AG:

Clariant specializes in environmentally friendly additives and contributes significantly to advancements in the PVC additives market.Solvay SA:

Solvay is notable for its comprehensive portfolio of PVC additives, focusing on sustainable solutions to address market needs.ADDINFO:

A prominent player in the PVC additives landscape, ADDINFO specializes in niche applications and is known for its R&D capabilities.We're grateful to work with incredible clients.

FAQs

What is the market size of pvc Additives?

The global PVC additives market is valued at 5.6 billion in 2023 and is projected to grow at a CAGR of 4.2% through 2033, reflecting increasing demands in various applications such as construction and automotive.

What are the key market players or companies in this pvc Additives industry?

Key players in the PVC additives market typically include major chemical and material companies that specialize in plastic manufacturing. These include manufacturers of stabilizers, plasticizers, lubricants, and processing aids, ensuring high product quality and sustainability.

What are the primary factors driving the growth in the pvc Additives industry?

Growth in the PVC additives industry is driven by increasing construction activities, rising automotive production, and the growing demand for packaging solutions. Moreover, advancements in material technology and eco-friendliness in production processes enhance market attractiveness.

Which region is the fastest Growing in the pvc Additives?

The fastest-growing region in the PVC additives market is North America, with the market projected to grow from 2.15 billion in 2023 to 3.26 billion by 2033. Europe and Asia Pacific also show significant growth potential, reflecting overall market trends.

Does ConsaInsights provide customized market report data for the pvc Additives industry?

Yes, ConsaInsights offers tailored market research reports for the PVC additives industry, focusing on specific client needs, market conditions, and trends to provide comprehensive insights that drive strategic decision-making.

What deliverables can I expect from this pvc Additives market research project?

Clients can expect detailed market analysis reports, including market size, growth forecasts, segment performance, and competitor analysis, along with actionable insights and strategic recommendations relevant to the PVC additives industry.

What are the market trends of pvc Additives?

Current trends in the PVC additives market emphasize sustainable practices, innovation in product formulation, and the rise of bio-based additives. The shift towards environmentally friendly materials is influencing product development and consumer preferences.