Tungsten Carbide Market Report

Published Date: 02 February 2026 | Report Code: tungsten-carbide

Tungsten Carbide Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Tungsten Carbide market covering trends, regional insights, and forecasts from 2023 to 2033. It investigates market size, growth rates, key players, and technological advancements shaping the industry.

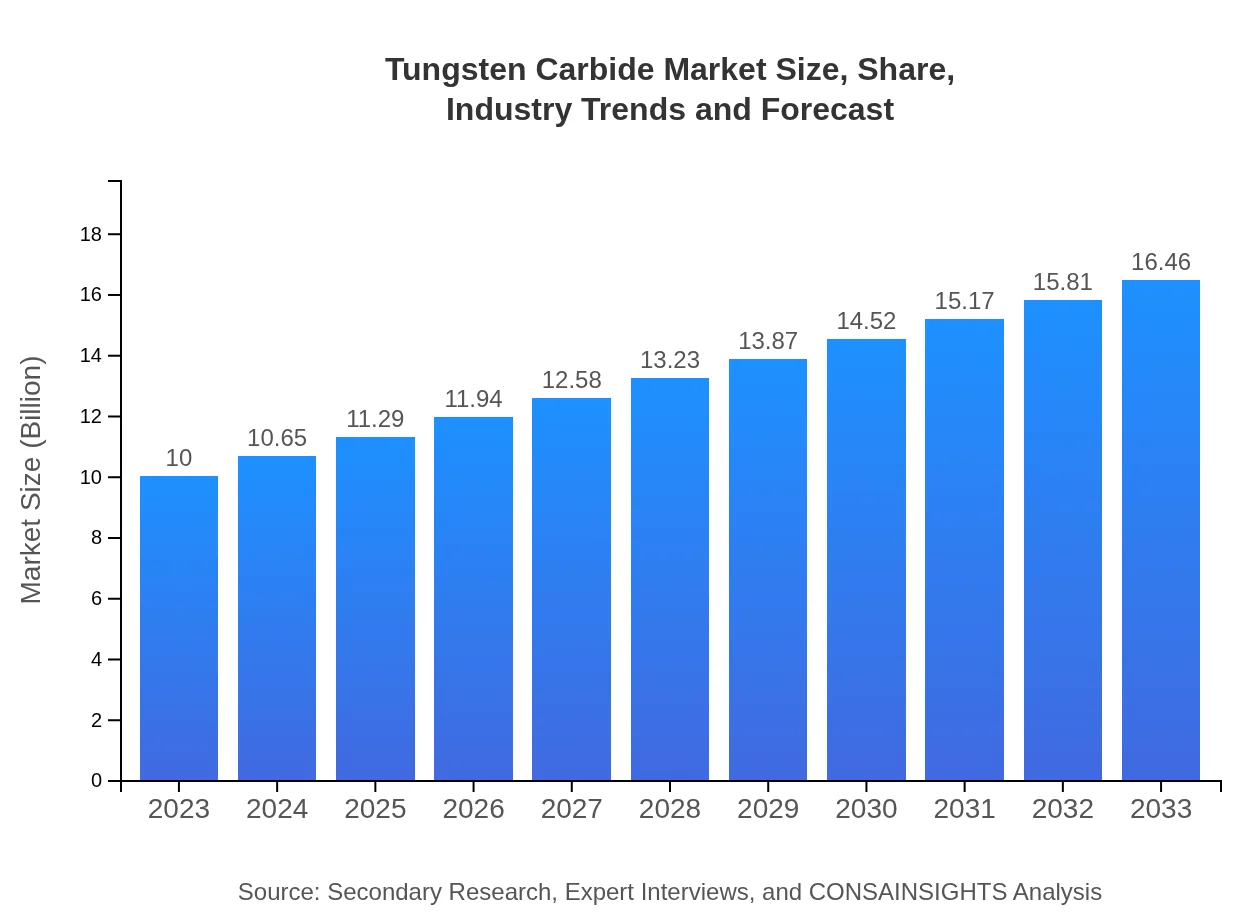

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $10.00 Billion |

| CAGR (2023-2033) | 5% |

| 2033 Market Size | $16.46 Billion |

| Top Companies | Kennametal Inc., Wolfram Company, Sandvik AB, A.L.M.T. Corp., Mitsubishi Materials Corporation |

| Last Modified Date | 02 February 2026 |

Tungsten Carbide Market Overview

Customize Tungsten Carbide Market Report market research report

- ✔ Get in-depth analysis of Tungsten Carbide market size, growth, and forecasts.

- ✔ Understand Tungsten Carbide's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Tungsten Carbide

What is the Market Size & CAGR of Tungsten Carbide market in 2023?

Tungsten Carbide Industry Analysis

Tungsten Carbide Market Segmentation and Scope

Tell us your focus area and get a customized research report.

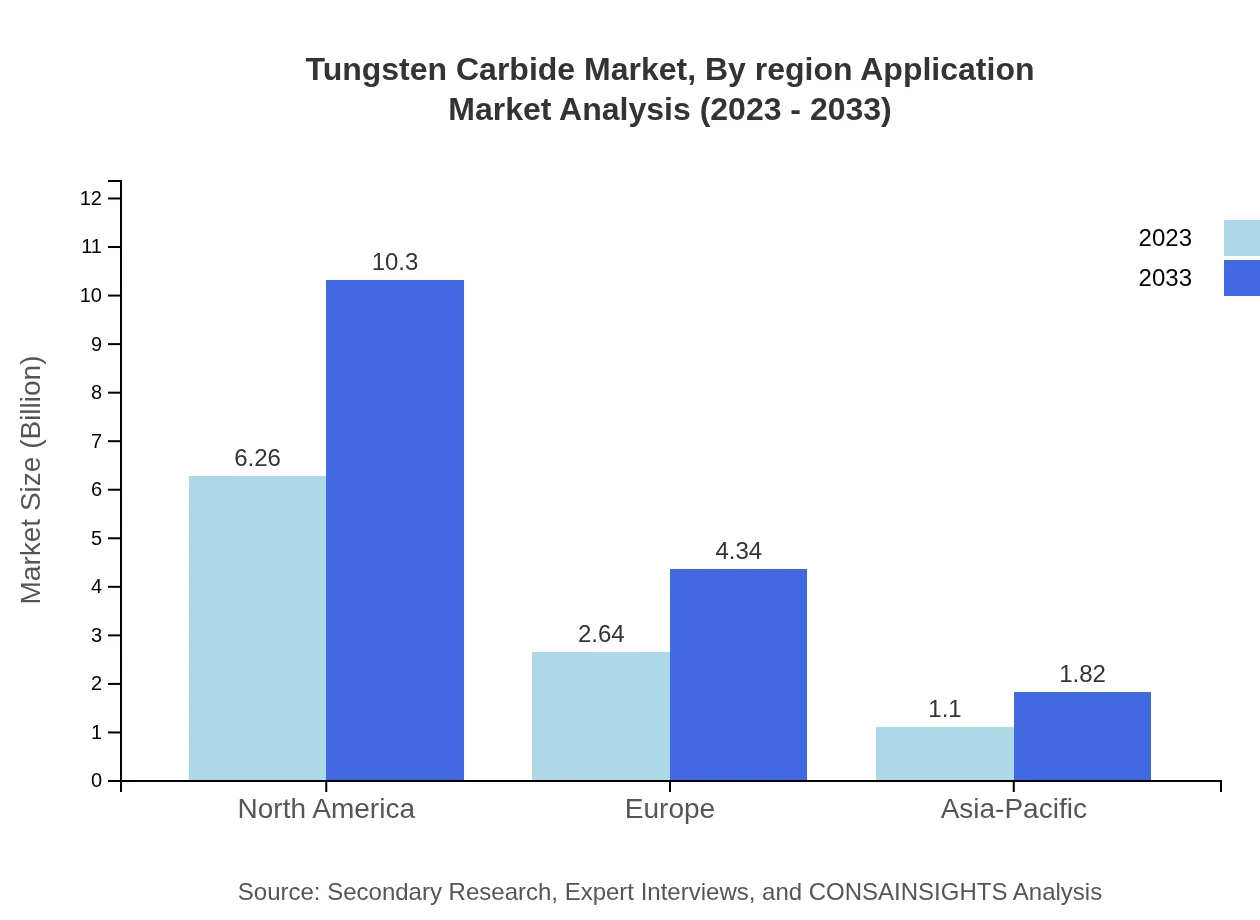

Tungsten Carbide Market Analysis Report by Region

Europe Tungsten Carbide Market Report:

In Europe, the market is anticipated to grow from USD 2.64 billion in 2023 to USD 4.34 billion by 2033, as demand for high-performance tools and components in defense and automotive applications rises.Asia Pacific Tungsten Carbide Market Report:

In Asia Pacific, the market in 2023 is valued at USD 1.94 billion and expected to reach USD 3.20 billion by 2033, driven by expansions in manufacturing and increased investments in mining and construction activities.North America Tungsten Carbide Market Report:

North America is a key player with a market size of USD 3.72 billion in 2023, projected to grow to USD 6.12 billion by 2033, primarily due to advancements in aerospace and automotive manufacturing processes.South America Tungsten Carbide Market Report:

South America's Tungsten Carbide market, valued at USD 0.41 billion in 2023, is forecasted to grow to USD 0.67 billion by 2033, supported by a developing mining sector and growing industrialization.Middle East & Africa Tungsten Carbide Market Report:

The Middle East and Africa market is valued at USD 1.29 billion in 2023, expected to expand to USD 2.13 billion by 2033, as development projects in construction and oil & gas sectors gain momentum.Tell us your focus area and get a customized research report.

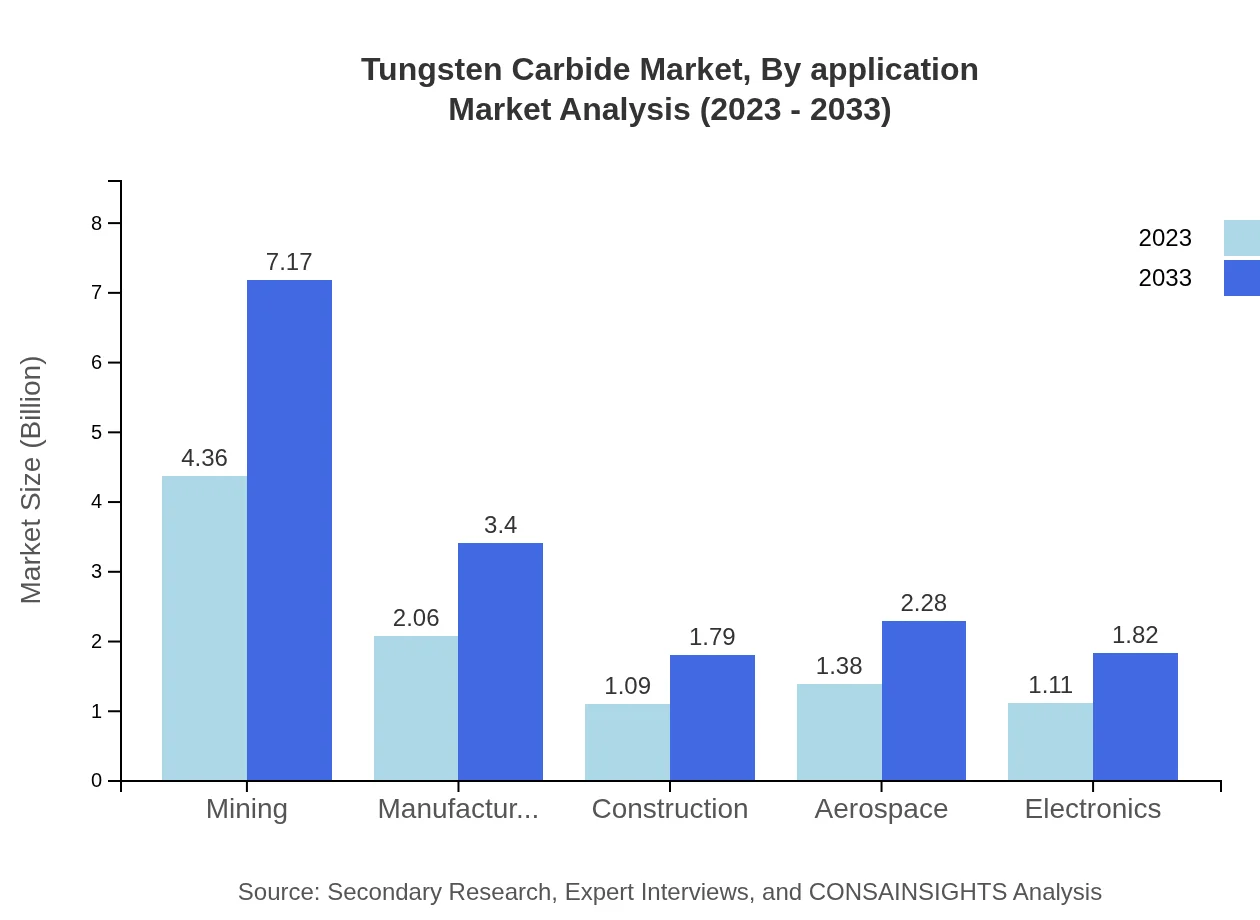

Tungsten Carbide Market Analysis By Application

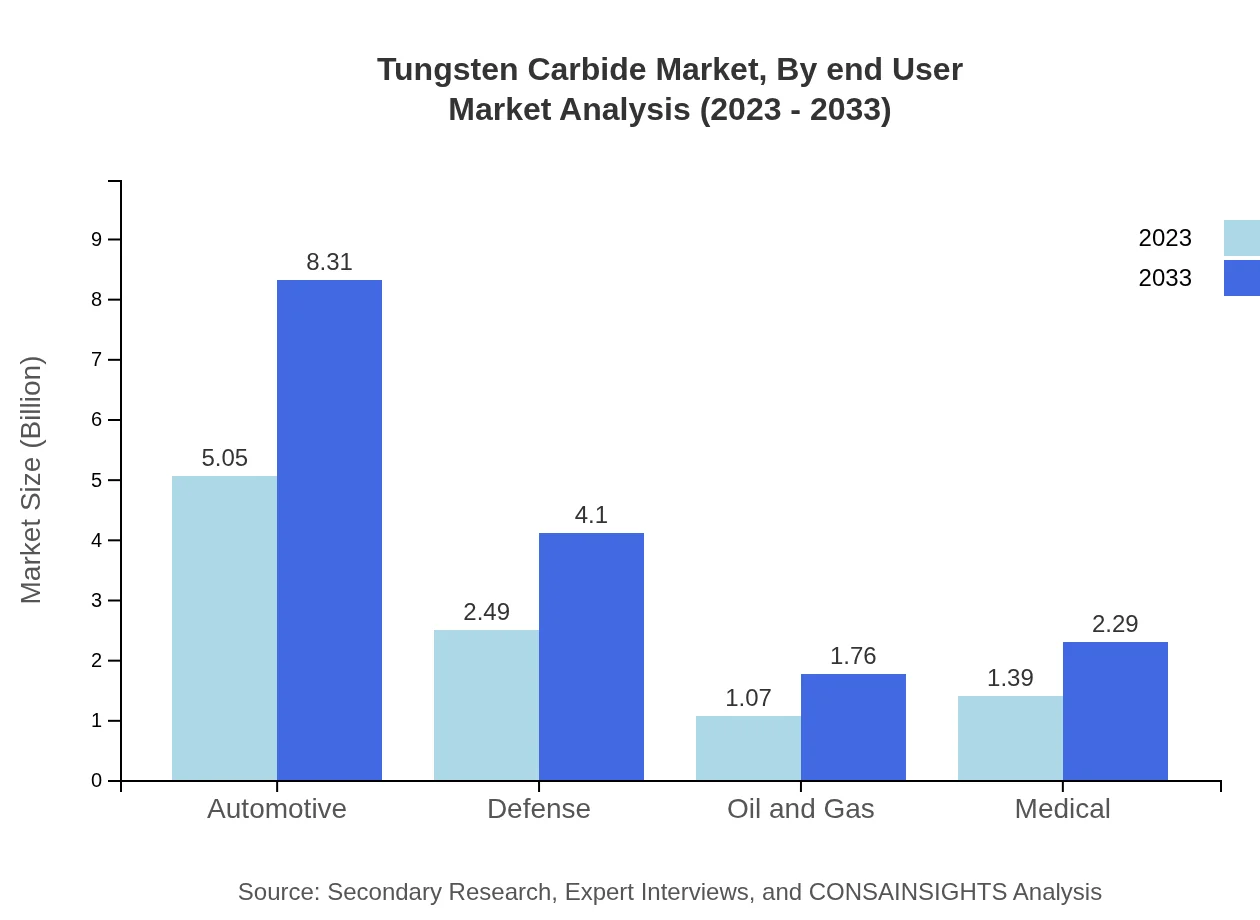

In 2023, the automotive segment dominates the Tungsten Carbide market, valued at USD 5.05 billion and expected to grow significantly by 2033. The mining sector also plays a crucial role, representing 43.56% of the market share, reflecting strong growth in resource extraction activities.

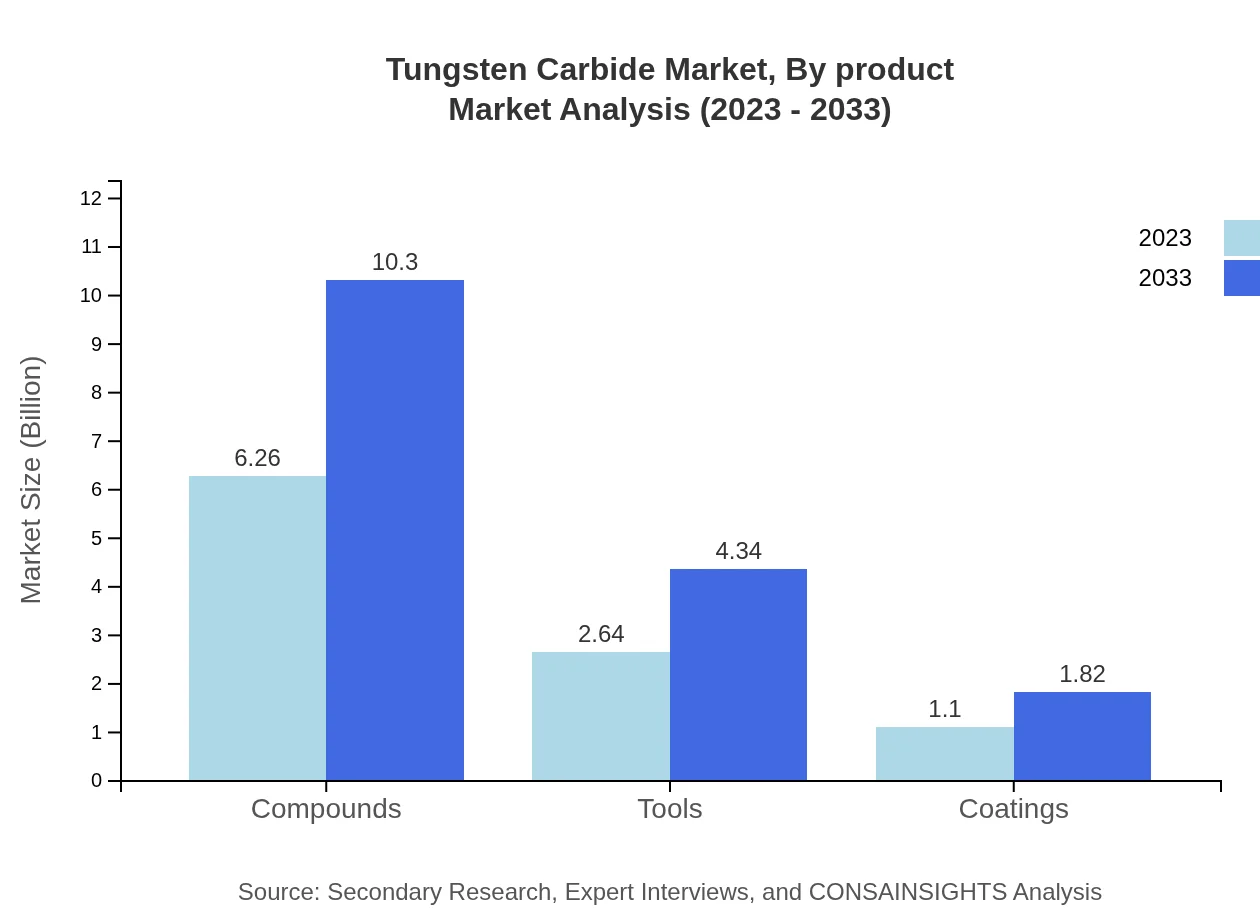

Tungsten Carbide Market Analysis By Product

In terms of product size, Compounds account for USD 6.26 billion in 2023 and are projected to grow to USD 10.30 billion by 2033, fueled by high demand for cutting and drilling tools in industrial applications.

Tungsten Carbide Market Analysis By End User

The manufacturing sector continues to be a significant end-user, with a projected market size increasing from USD 2.06 billion in 2023 to USD 3.40 billion by 2033, driven by advancements in material sciences and precise machining requirements.

Tungsten Carbide Market Analysis By Region Application

Geographically, North America and Europe represent a substantial share of the market, as technological advancements and high-quality production standards drive the adoption of Tungsten Carbide in diverse applications.

Tungsten Carbide Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Tungsten Carbide Industry

Kennametal Inc.:

A global leader in manufacturing cutting tools and wear-resistant components, Kennametal specializes in Tungsten Carbide products and is known for its innovative solutions in industrial operations.Wolfram Company:

Wolfram Company specializes in Tungsten Carbide powder and associated products, focusing on high-quality materials for various industrial applications.Sandvik AB:

Sandvik AB offers a wide range of products, including Tungsten Carbide tools and components, delivering robust performance and innovation for their clients.A.L.M.T. Corp.:

Focusing on high-performance materials, A.L.M.T. Corp provides Tungsten Carbide products that meet rigorous industrial standards and diverse application needs.Mitsubishi Materials Corporation:

Mitsubishi Materials Corporation is a prominent player focused on manufacturing Tungsten Carbide tools and components, prioritizing quality and technology in production.We're grateful to work with incredible clients.

FAQs

What is the market size of tungsten Carbide?

The global tungsten carbide market size is projected to reach approximately $10 billion by 2033, growing at a CAGR of 5%. In 2023, the market was valued at $6.26 billion, indicating significant growth potential over the decade.

What are the key market players or companies in this tungsten Carbide industry?

Key players in the tungsten carbide market include notable companies such as Kennametal Inc., Sandvik AB, and Carbide Depot. These organizations drive innovation and market competition within the tungsten carbide segment, ensuring diverse applications across various industries.

What are the primary factors driving the growth in the tungsten Carbide industry?

Growth in the tungsten carbide market is primarily driven by increasing demand in the oil and gas sector, advancements in manufacturing technologies, and a growing construction sector. These factors create robust opportunities for market expansion and product innovation.

Which region is the fastest Growing in the tungsten Carbide market?

The Asia-Pacific region is the fastest-growing market for tungsten carbide, projected to grow from $1.94 billion in 2023 to $3.20 billion by 2033. This growth can be attributed to rising industrialization and increasing demand across diverse applications.

Does ConsaInsights provide customized market report data for the tungsten Carbide industry?

Yes, ConsaInsights offers customized market report data tailored to the tungsten carbide industry. Clients can request specific insights and analyses to meet their unique business needs, ensuring comprehensive market understanding and strategy development.

What deliverables can I expect from this tungsten Carbide market research project?

From the tungsten carbide market research project, clients can expect deliverables such as in-depth market analysis, growth forecasts, regional breakdowns, segmentation data, competitive landscape overview, and strategic recommendations tailored to their business objectives.

What are the market trends of tungsten Carbide?

Current market trends for tungsten carbide include increasing applications in the mining and automotive industries, innovations in carbide tools, and a surge in eco-friendly manufacturing processes. These trends indicate a shift towards sustainable and efficient production methods.