The Automotive Metal Stamping Market Report

Published Date: 02 February 2026 | Report Code: the-automotive-metal-stamping

The Automotive Metal Stamping Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the Automotive Metal Stamping market, including market size, growth projections, segmentation, and regional insights. It covers data from 2023 to 2033, offering predictions and trends that will shape the industry in the coming decade.

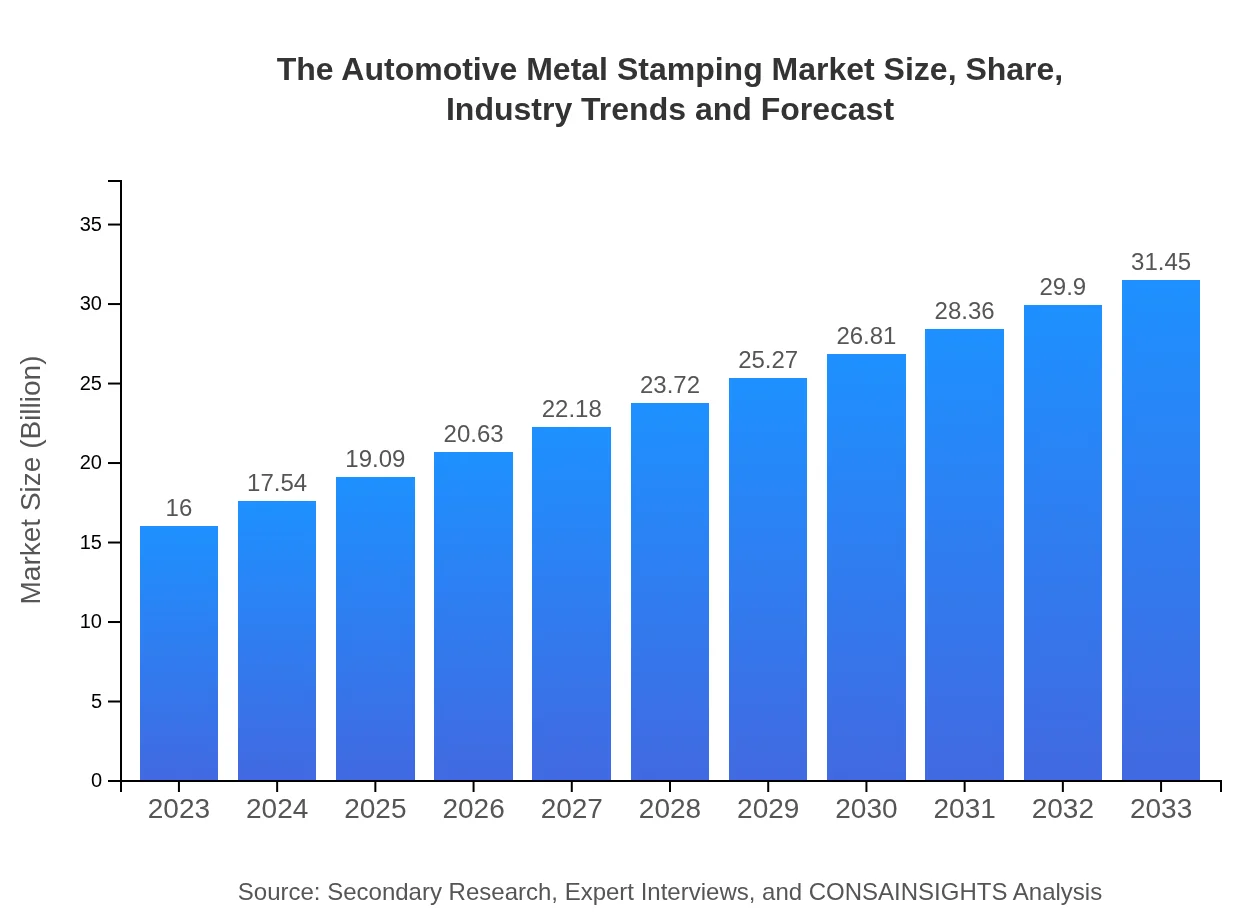

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $16.00 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $31.45 Billion |

| Top Companies | Progressive Stamping, Gestamp, Toyota Boshoku Corporation |

| Last Modified Date | 02 February 2026 |

The Automotive Metal Stamping Market Overview

Customize The Automotive Metal Stamping Market Report market research report

- ✔ Get in-depth analysis of The Automotive Metal Stamping market size, growth, and forecasts.

- ✔ Understand The Automotive Metal Stamping's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in The Automotive Metal Stamping

What is the Market Size & CAGR of The Automotive Metal Stamping market in 2023-2033?

The Automotive Metal Stamping Industry Analysis

The Automotive Metal Stamping Market Segmentation and Scope

Tell us your focus area and get a customized research report.

The Automotive Metal Stamping Market Analysis Report by Region

Europe The Automotive Metal Stamping Market Report:

In Europe, the market is expanding due to stringent regulations on vehicle emissions and a strong push towards electric vehicles. The market was valued at USD 4.08 billion in 2023 and is anticipated to grow to USD 8.02 billion by 2033, as manufacturers invest in advanced stamping technologies.Asia Pacific The Automotive Metal Stamping Market Report:

The Asia Pacific region is experiencing notable growth in the Automotive Metal Stamping market, driven by increasing vehicle production in countries like China and India. The market size was USD 3.36 billion in 2023 and is expected to reach USD 6.60 billion by 2033, reflecting a strong demand for stamped components in various vehicle models.North America The Automotive Metal Stamping Market Report:

North America holds a significant share in the Automotive Metal Stamping market with a size of USD 5.68 billion in 2023, expected to expand to USD 11.17 billion by 2033. Factors contributing to this growth include the presence of established automotive manufacturers and increasing demand for electric and hybrid vehicles.South America The Automotive Metal Stamping Market Report:

In South America, the Automotive Metal Stamping market is emerging, with a market size of USD 0.94 billion in 2023 projected to grow to USD 1.84 billion by 2033. The growth is primarily attributed to rising automotive manufacturing activities and favorable government initiatives promoting local manufacturing.Middle East & Africa The Automotive Metal Stamping Market Report:

The Middle East and Africa region are also growing, albeit at a slower pace, with market sizes of USD 1.94 billion in 2023 climbing to USD 3.82 billion by 2033. The growth is linked to increasing investments in the automotive sector and infrastructural developments aimed at boosting manufacturing capabilities.Tell us your focus area and get a customized research report.

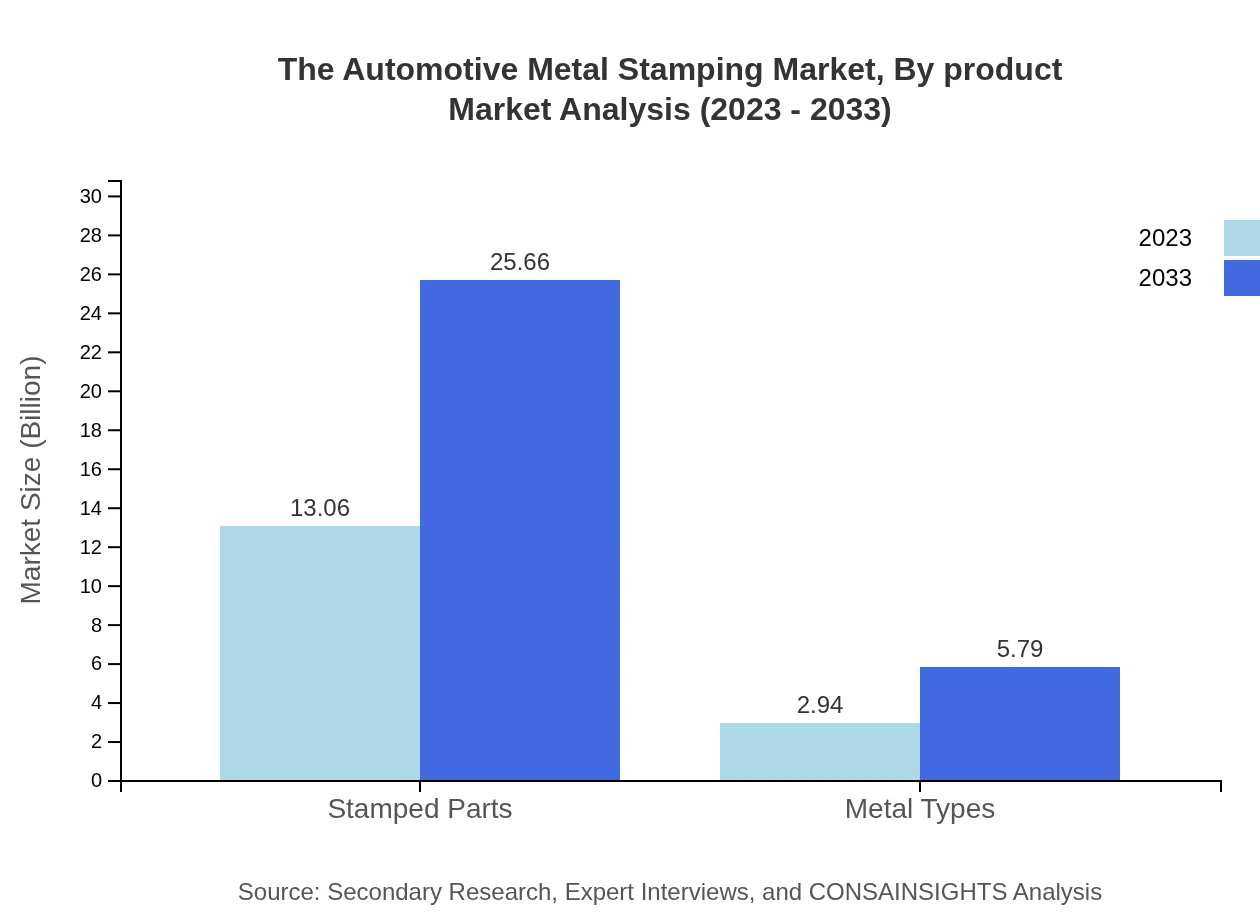

The Automotive Metal Stamping Market Analysis By Product

The Stamped Parts segment leads the Automotive Metal Stamping market, with a size of USD 13.06 billion in 2023, projected to reach USD 25.66 billion by 2033, capturing 81.6% of the market share. The demand for OEM and aftermarket stamped parts is growing. Additionally, segments like Electrical Components and Mechanical Components are witnessing increased demand due to innovations in vehicle technology.

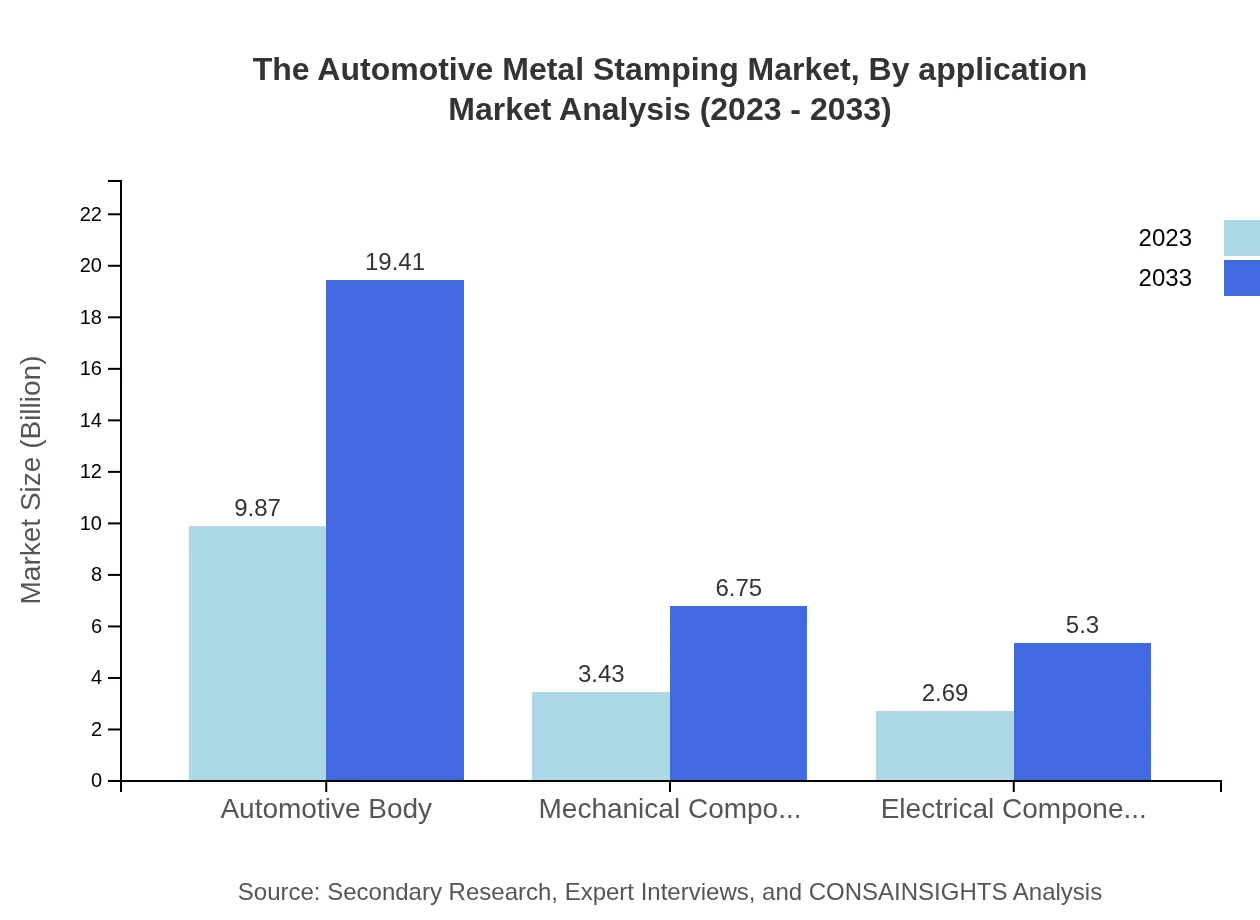

The Automotive Metal Stamping Market Analysis By Application

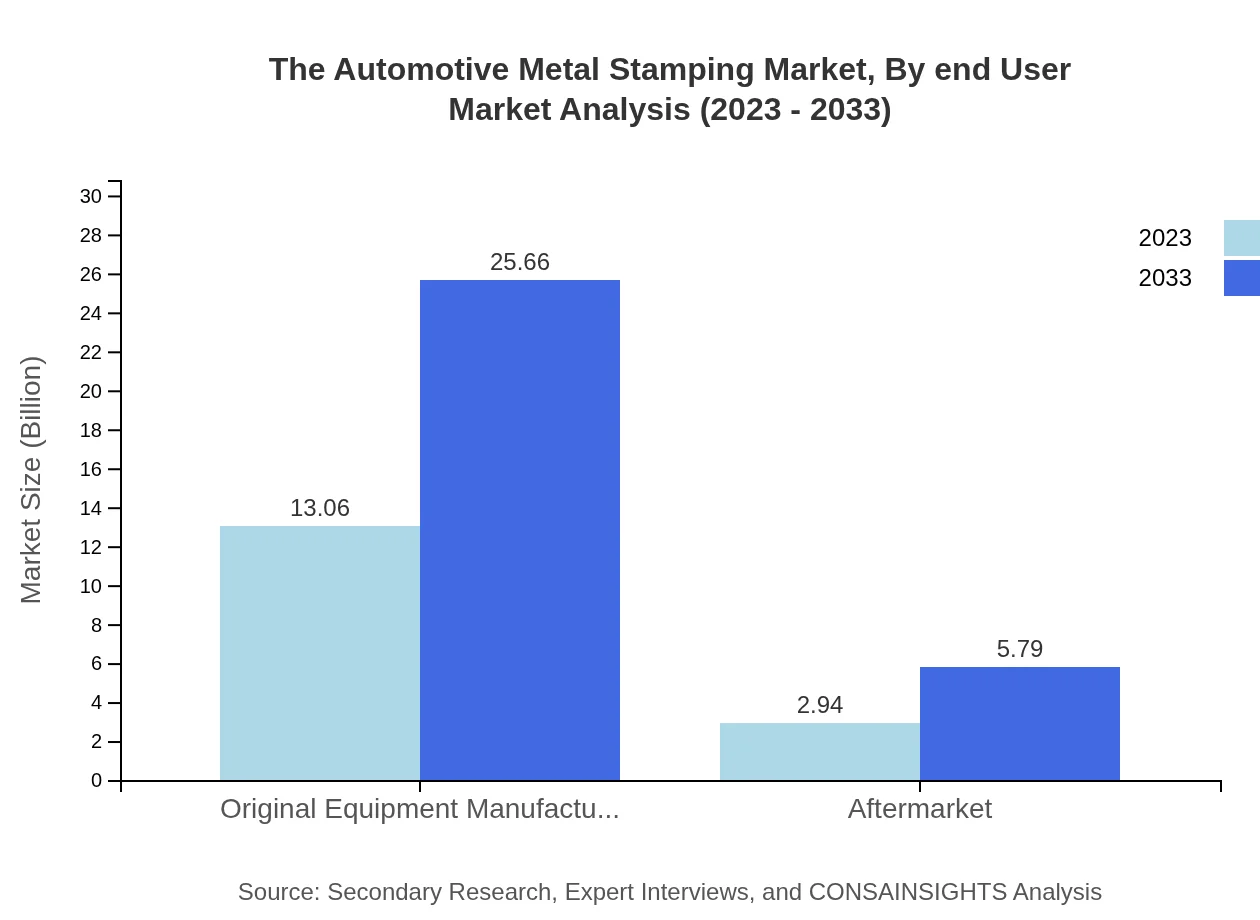

The market is further segmented into OEMs and Aftermarket segments. The OEM segment holds the majority market share of 81.6%, equating to USD 13.06 billion in 2023, growing to USD 25.66 billion by 2033. The aftermarket segment, while smaller, is experiencing growth driven by increasing vehicle age and consumer preferences for replacement parts.

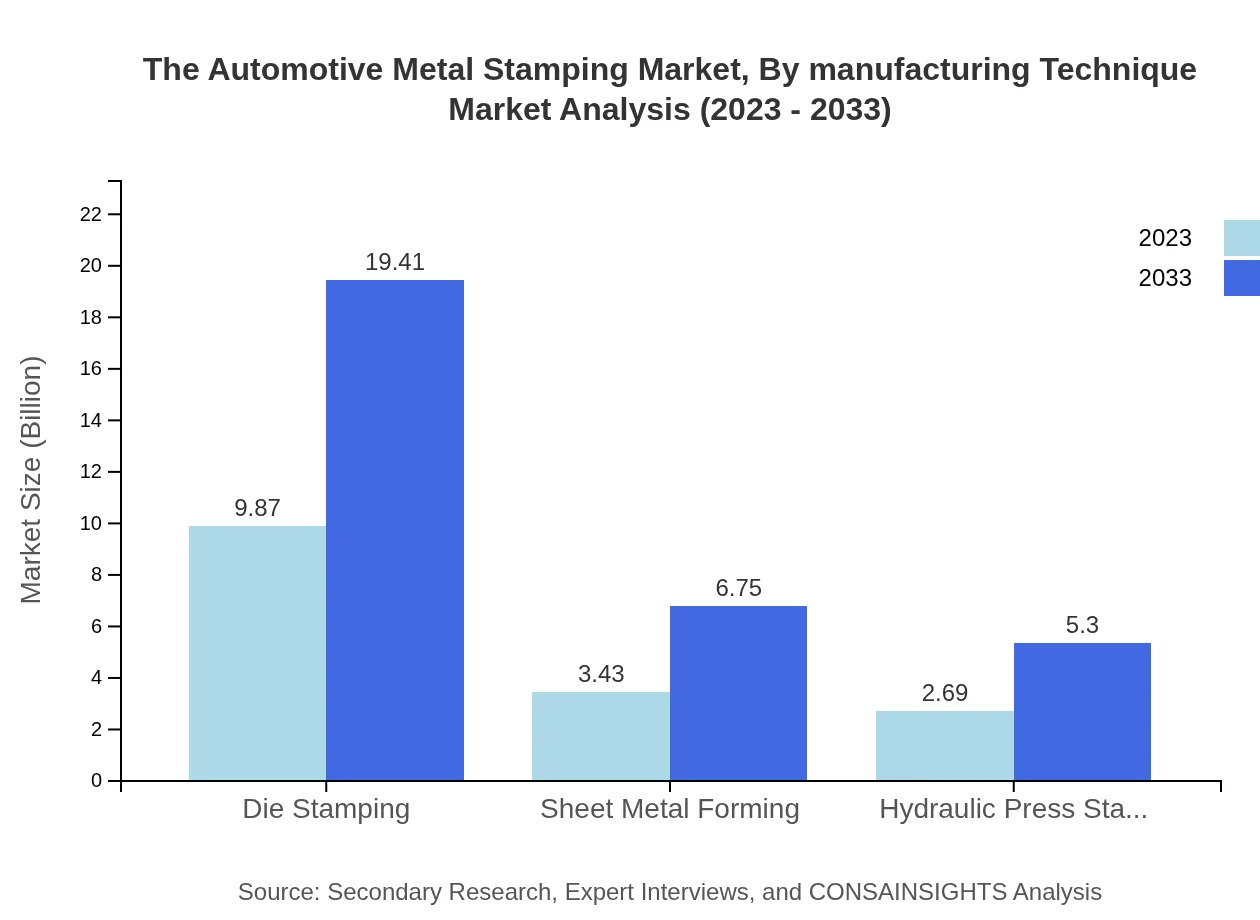

The Automotive Metal Stamping Market Analysis By Manufacturing Technique

Different manufacturing techniques such as die stamping, sheet metal forming, and hydraulic press stamping are critical to the Automotive Metal Stamping market. Die stamping constitutes the majority share at 61.71%, with a size of USD 9.87 billion in 2023, expected to reach USD 19.41 billion by 2033. The adoption of these techniques is driven by the need for precision and efficiency.

The Automotive Metal Stamping Market Analysis By End User

The primary end-users include passenger vehicles and commercial vehicles. The passenger vehicle segment is significant, making up a substantial portion of the market due to the high vehicle production rates. The commercial vehicles segment, although smaller, is expected to grow as infrastructure developments accelerate.

The Automotive Metal Stamping Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in The Automotive Metal Stamping Industry

Progressive Stamping:

Progressive Stamping is known for innovative stamping solutions and is a leading supplier for many major OEMs, specializing in precision parts.Gestamp:

Gestamp is a global leader in the development and manufacturing of metal components for the automotive industry, known for its focus on sustainable development.Toyota Boshoku Corporation:

A key supplier of automotive parts including those made through metal stamping, Toyota Boshoku emphasizes quality and R&D in product development.We're grateful to work with incredible clients.

FAQs

What is the market size of the Automotive Metal Stamping?

The global automotive metal stamping market was valued at $16 billion in 2023, with a projected growth at a CAGR of 6.8% over the next decade, indicating a robust demand for stamped automotive parts.

What are the key market players or companies in this the Automotive Metal Stamping industry?

Major players in the automotive metal stamping industry include companies such as Magna International, AIDA Engineering, and Tower International, which are recognized for their innovative stamping solutions tailored for automakers.

What are the primary factors driving the growth in the the Automotive Metal Stamping industry?

Key drivers for growth in the automotive metal stamping market include increasing demand for lightweight materials, advancements in stamping technology, and the surge in vehicle production globally.

Which region is the fastest Growing in the the Automotive Metal Stamping?

North America is the fastest-growing region in the automotive metal stamping market, with a market size projected to grow from $5.68 billion in 2023 to $11.17 billion by 2033, driven by innovative automotive manufacturing.

Does ConsaInsights provide customized market report data for the the Automotive Metal Stamping industry?

Yes, ConsaInsights offers tailored market report solutions that cater to specific needs in the automotive metal stamping sector, allowing clients to access detailed insights and analytics.

What deliverables can I expect from this the Automotive Metal Stamping market research project?

Deliverables from the automotive metal stamping market research include comprehensive market analysis, segment data, regional insights, and competitive landscape reports, ensuring informed decision-making.

What are the market trends of the Automotive Metal Stamping?

Current trends in automotive metal stamping include increased adoption of automation in manufacturing processes, a shift towards electric vehicle production, and greater emphasis on sustainability in material sourcing.