Carbon Fiber Cf And Carbon Fiber Reinforced Plastic Cfrp Market Report

Published Date: 02 February 2026 | Report Code: carbon-fiber-cf-and-carbon-fiber-reinforced-plastic-cfrp

Carbon Fiber Cf And Carbon Fiber Reinforced Plastic Cfrp Market Size, Share, Industry Trends and Forecast to 2033

This comprehensive market report explores the carbon fiber (CF) and carbon fiber reinforced plastic (CFRP) industry, providing insights on growth forecasts, market dynamics, trends, and regional analyses for the period of 2023 to 2033.

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

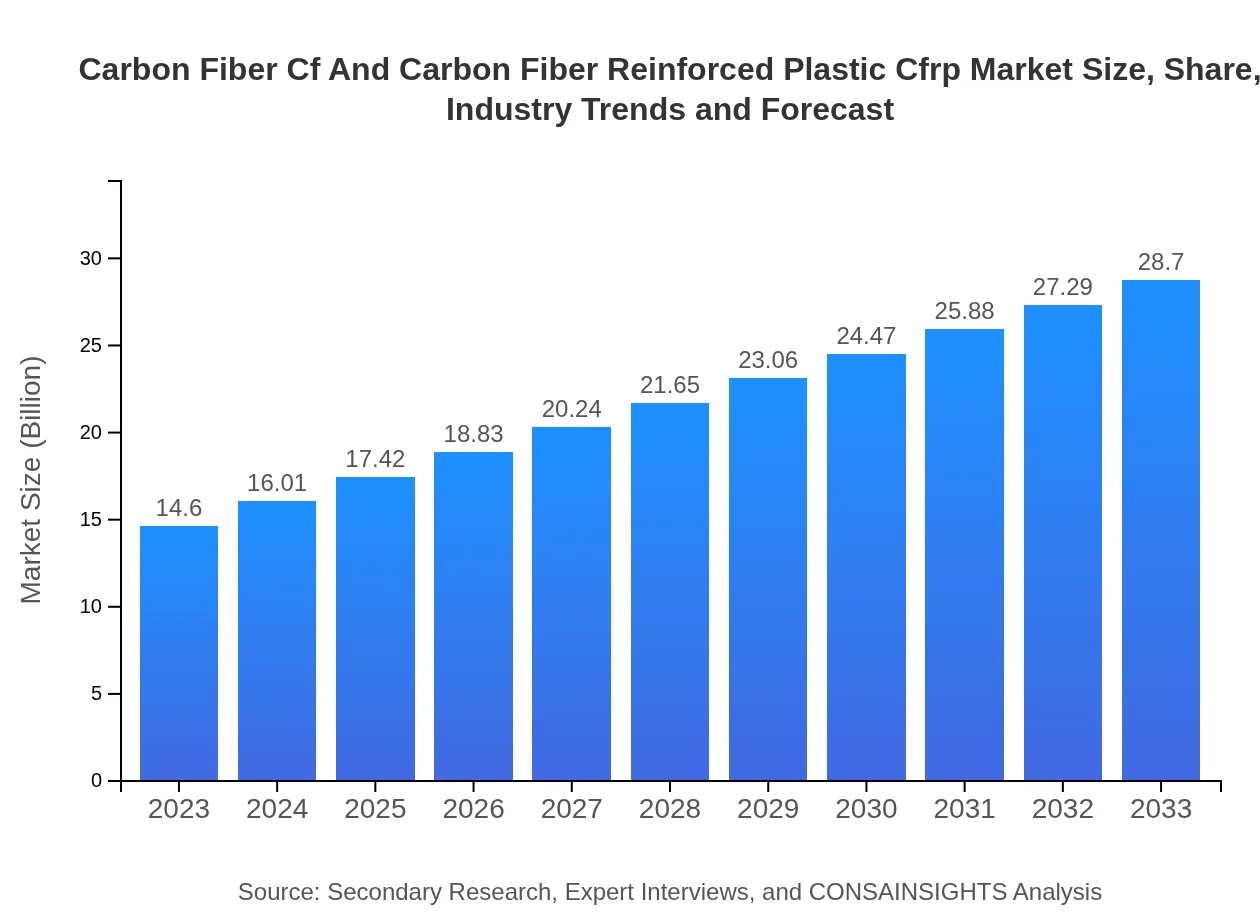

| 2023 Market Size | $14.60 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $28.70 Billion |

| Top Companies | Toray Industries, Hexcel Corporation, SGL Carbon SE, Teijin Limited, Mitsubishi Chemical Holdings Corporation |

| Last Modified Date | 02 February 2026 |

Carbon Fiber Cf And Carbon Fiber Reinforced Plastic Cfrp Market Overview

Customize Carbon Fiber Cf And Carbon Fiber Reinforced Plastic Cfrp Market Report market research report

- ✔ Get in-depth analysis of Carbon Fiber Cf And Carbon Fiber Reinforced Plastic Cfrp market size, growth, and forecasts.

- ✔ Understand Carbon Fiber Cf And Carbon Fiber Reinforced Plastic Cfrp's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Carbon Fiber Cf And Carbon Fiber Reinforced Plastic Cfrp

What is the Market Size & CAGR of Carbon Fiber Cf And Carbon Fiber Reinforced Plastic Cfrp market in 2033?

Carbon Fiber Cf And Carbon Fiber Reinforced Plastic Cfrp Industry Analysis

Carbon Fiber Cf And Carbon Fiber Reinforced Plastic Cfrp Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Carbon Fiber Cf And Carbon Fiber Reinforced Plastic Cfrp Market Analysis Report by Region

Europe Carbon Fiber Cf And Carbon Fiber Reinforced Plastic Cfrp Market Report:

Europe is anticipated to have a strong market presence, with revenue expected to grow from $4.00 billion in 2023 to $7.87 billion by 2033. Sustainability initiatives and regulatory support for lightweight materials propel the demand in this region.Asia Pacific Carbon Fiber Cf And Carbon Fiber Reinforced Plastic Cfrp Market Report:

The Asia Pacific region is expected to witness significant growth, with a market size projected to increase from $2.90 billion in 2023 to $5.70 billion in 2033. This growth is attributed to increasing industrialization and demand for energy-efficient materials in various applications.North America Carbon Fiber Cf And Carbon Fiber Reinforced Plastic Cfrp Market Report:

North America currently holds the largest market share in the industry, with the market projected to expand from $5.47 billion in 2023 to reach approximately $10.74 billion by 2033. Key factors for this growth include advancements in aerospace technologies and the presence of major manufacturers in the region.South America Carbon Fiber Cf And Carbon Fiber Reinforced Plastic Cfrp Market Report:

The South American market for carbon fiber and CFRP is expected to grow modestly, with projections indicating an increase from $0.63 billion in 2023 to $1.25 billion by 2033. This growth is driven by the rising interest in renewable energy and lightweight materials in automotive manufacturing.Middle East & Africa Carbon Fiber Cf And Carbon Fiber Reinforced Plastic Cfrp Market Report:

The Middle East and Africa are expected to grow at a moderate pace, with market size increasing from $1.60 billion in 2023 to $3.14 billion by 2033. Investment in infrastructure and renewable energy projects is expected to drive growth in this region.Tell us your focus area and get a customized research report.

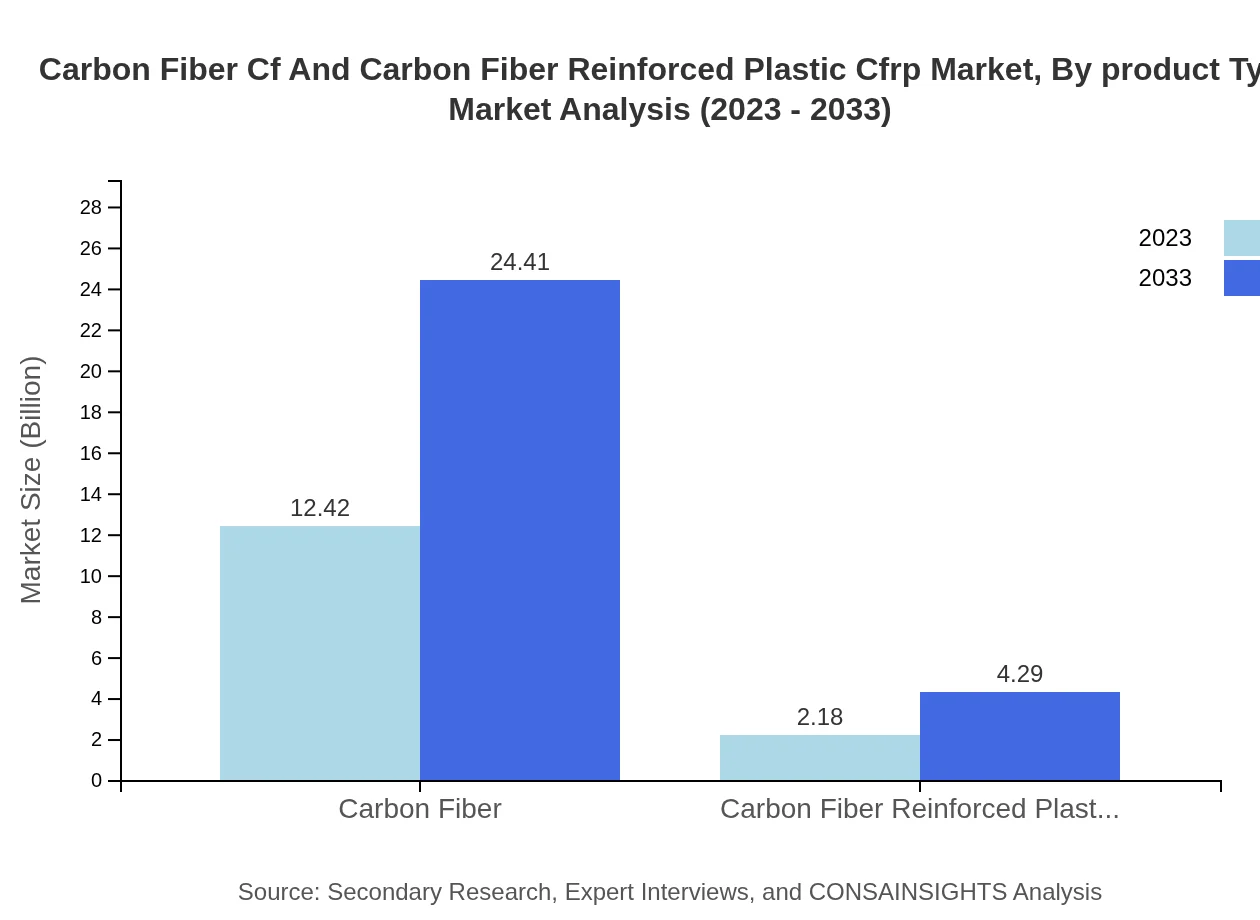

Carbon Fiber Cf And Carbon Fiber Reinforced Plastic Cfrp Market Analysis By Product Type

The market is largely dominated by carbon fiber products, expected to grow significantly from $12.42 billion in 2023 to $24.41 billion in 2033. CFRP is expected to account for a market size of $2.18 billion in 2023, increasing to $4.29 billion by 2033, driven by their lightweight and strong properties.

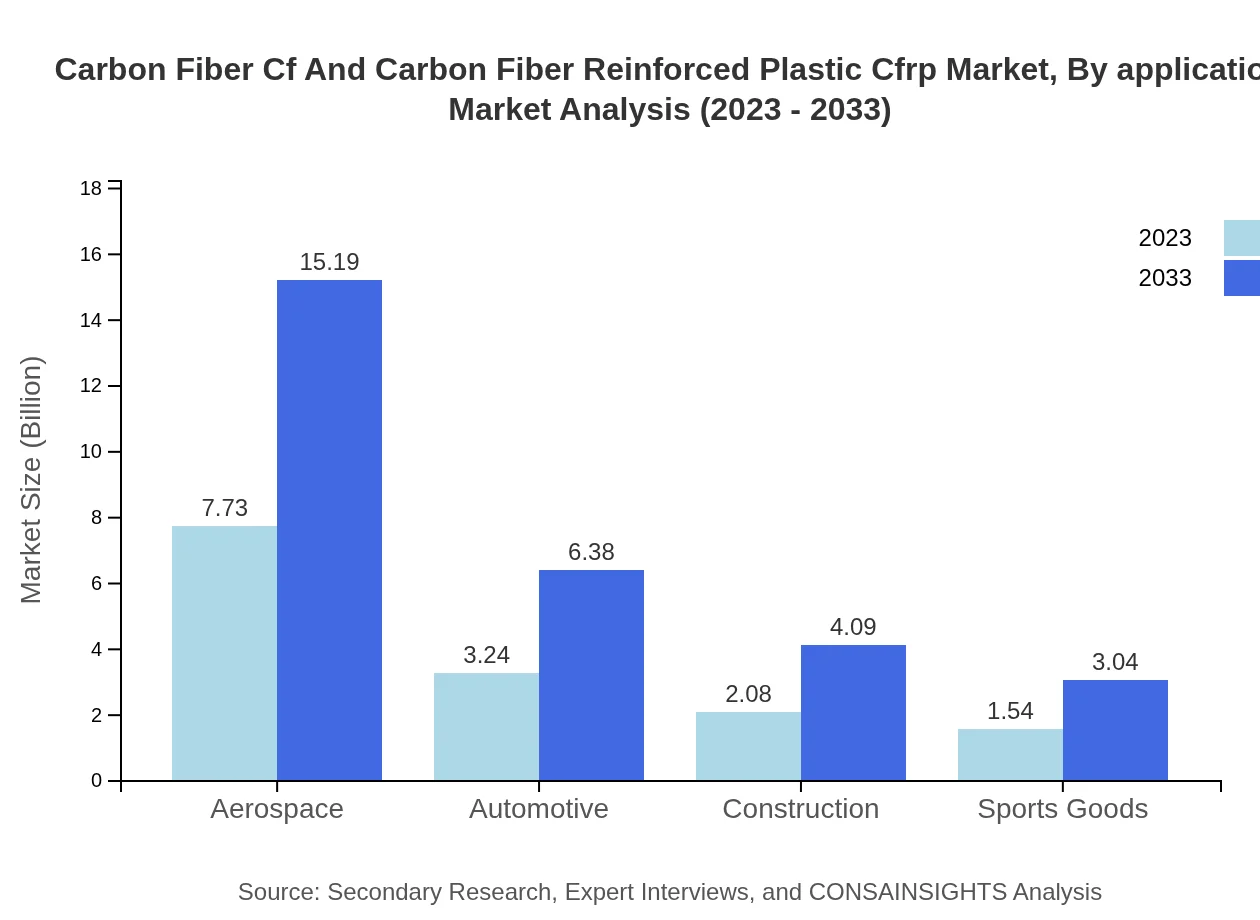

Carbon Fiber Cf And Carbon Fiber Reinforced Plastic Cfrp Market Analysis By Application

Aerospace is the major application segment, commanding a market share of 52.93% in 2023. The automotive sector follows, expected to increase from $3.24 billion in 2023 to $6.38 billion by 2033, holding a 22.22% market share.

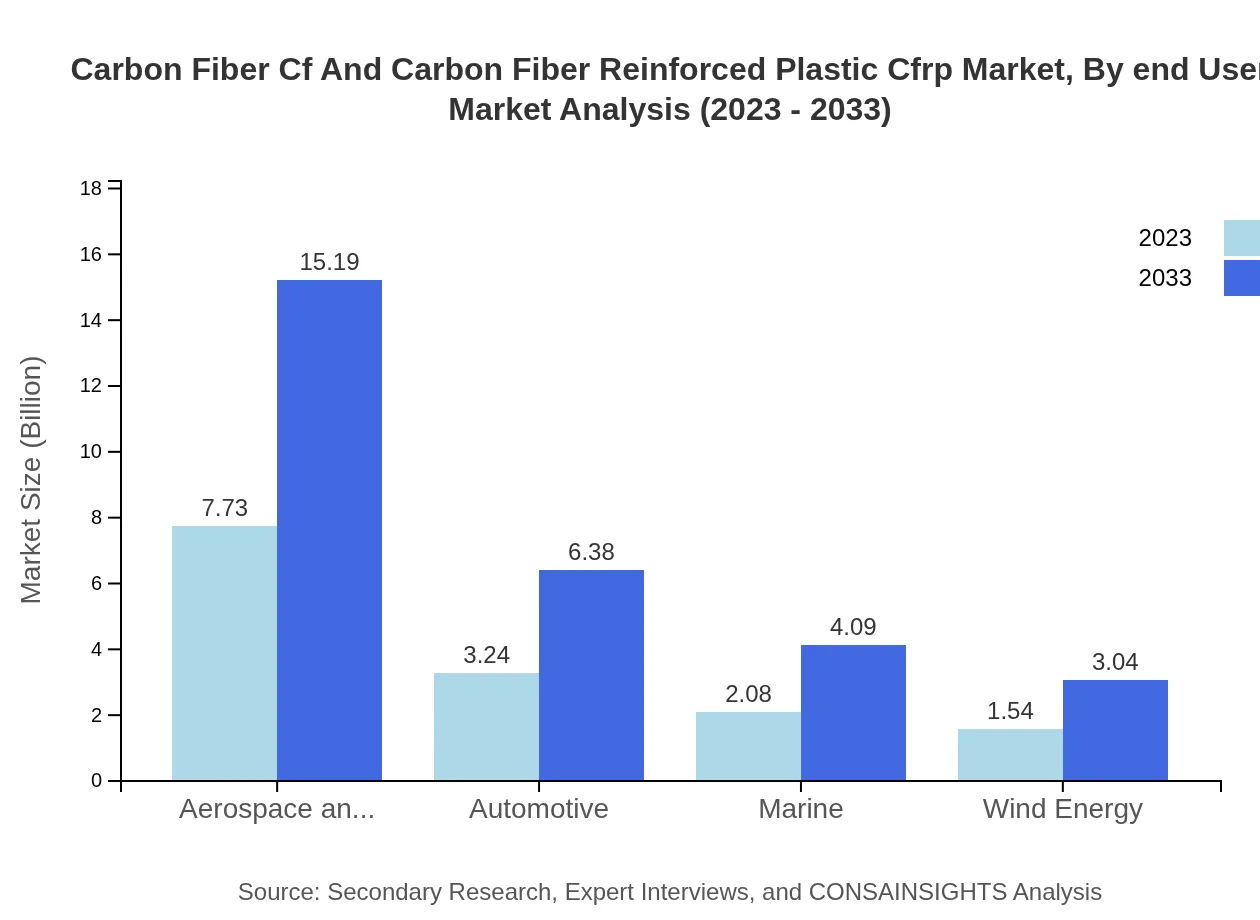

Carbon Fiber Cf And Carbon Fiber Reinforced Plastic Cfrp Market Analysis By End User

End-users include aerospace, automotive, construction, wind energy, and sports goods industries. Aerospace leads with $7.73 billion in 2023, with construction projected to grow amidst the need for durable and lightweight building materials.

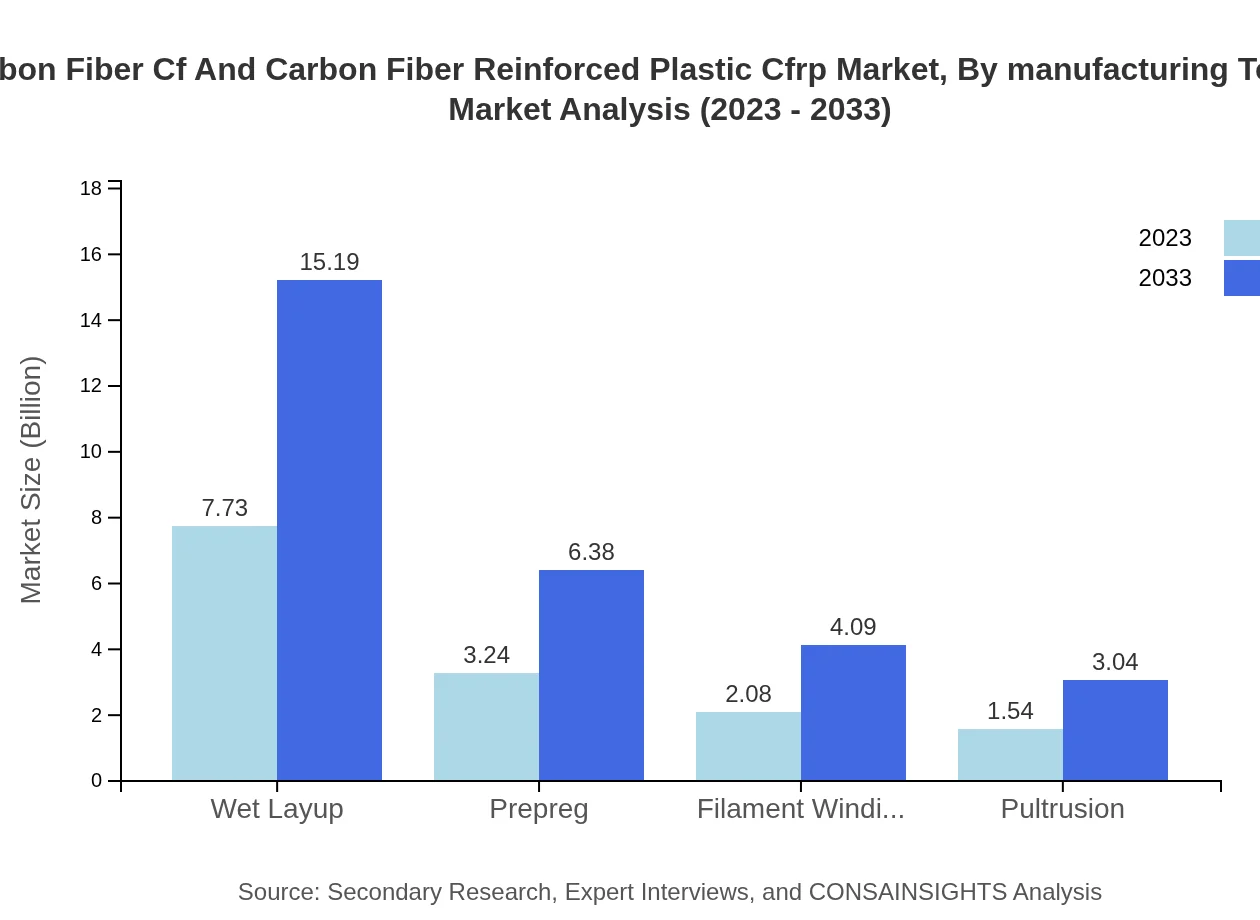

Carbon Fiber Cf And Carbon Fiber Reinforced Plastic Cfrp Market Analysis By Manufacturing Technique

Primary manufacturing techniques for carbon fiber include wet layup and prepreg processes, with wet layup holding a significant market share of 52.93% in 2023. Filament winding and pultrusion are also vital manufacturing techniques impacting production.

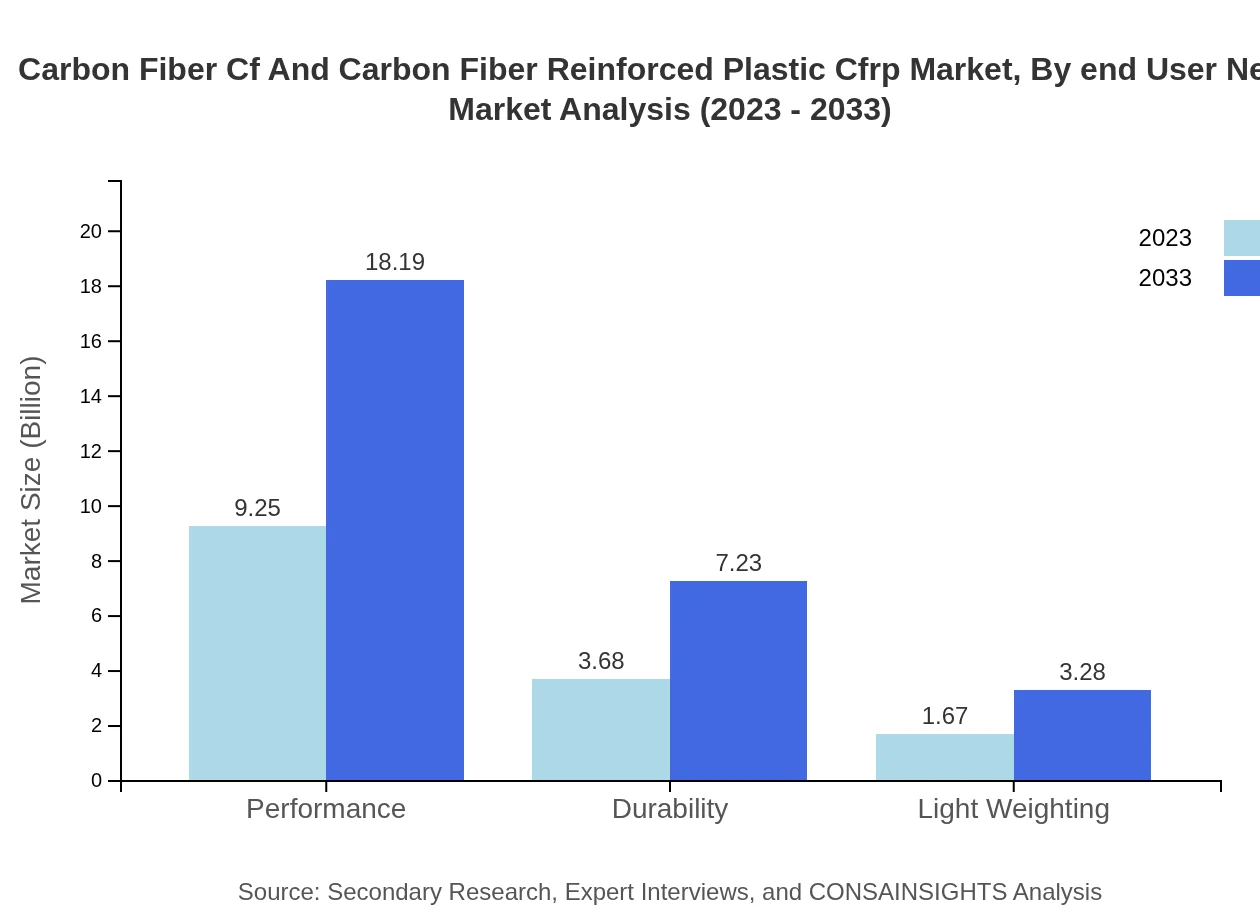

Carbon Fiber Cf And Carbon Fiber Reinforced Plastic Cfrp Market Analysis By End User Needs

Key end-user needs driving market growth include performance, durability, and lightweighting solutions. Performance is significant, holding 63.38% market share in 2023, while durability and lightweighting are also becoming increasingly important.

Carbon Fiber Cf And Carbon Fiber Reinforced Plastic Cfrp Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Carbon Fiber Cf And Carbon Fiber Reinforced Plastic Cfrp Industry

Toray Industries:

A leading supplier of carbon fiber and composites known for innovative applications in aerospace and automotive.Hexcel Corporation:

Specializes in high-performance materials, including carbon fiber and composites for various industrial applications.SGL Carbon SE:

Known for manufacturing carbon fibers and specialty materials for diverse applications across multiple sectors.Teijin Limited:

A prominent innovator in carbon fiber production, focusing on sustainable practices and advanced materials technology.Mitsubishi Chemical Holdings Corporation:

Involved in the production of carbon fiber and composites, providing solutions primarily for aerospace and automotive industries.We're grateful to work with incredible clients.

FAQs

What is the market size of carbon Fiber Cf And Carbon Fiber Reinforced Plastic Cfrp?

The global market for Carbon Fiber (CF) and Carbon Fiber Reinforced Plastic (CFRP) is projected to reach approximately $14.6 billion by 2033, growing at a CAGR of 6.8% from current estimates.

What are the key market players or companies in the carbon Fiber Cf And Carbon Fiber Reinforced Plastic Cfrp industry?

Key players in the CF and CFRP market include companies like Toray Industries, Solvay S.A., Hexcel Corporation, Mitsubishi Rayon Co., and Teijin Limited, which are heavily involved in innovation and sustainable practices.

What are the primary factors driving the growth in the carbon Fiber Cf And Carbon Fiber Reinforced Plastic Cfrp industry?

The growth is driven by the demand for lightweight materials in industries such as aerospace and automotive, advancements in carbon fiber technology, and increasing investments in renewable energy, especially wind energy.

Which region is the fastest Growing in the carbon Fiber Cf And Carbon Fiber Reinforced Plastic Cfrp?

The fastest-growing region in the carbon fiber industry is projected to be North America, with the market expected to grow from $5.47 billion in 2023 to $10.74 billion by 2033, showcasing significant demand.

Does ConsaInsights provide customized market report data for the carbon Fiber Cf And Carbon Fiber Reinforced Plastic Cfrp industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs including regional analysis, segments, and market trends unique to the carbon fiber CF and CFRP industry.

What deliverables can I expect from this carbon Fiber Cf And Carbon Fiber Reinforced Plastic Cfrp market research project?

Deliverables include comprehensive market reports, detailed segment analyses, growth forecasts, competitive landscape assessments, and insights into regional market dynamics.

What are the market trends of carbon Fiber Cf And Carbon Fiber Reinforced Plastic Cfrp?

Key market trends include increasing adoption in various applications such as aerospace, automotive, and construction, alongside innovations in manufacturing processes and sustainability in materials.