Composites Piezoelectric Material Market Report

Published Date: 02 February 2026 | Report Code: composites-piezoelectric-material

Composites Piezoelectric Material Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the composites piezoelectric material market, covering trends, segmentation, technological advancements, and forecasts for the years 2023 to 2033.

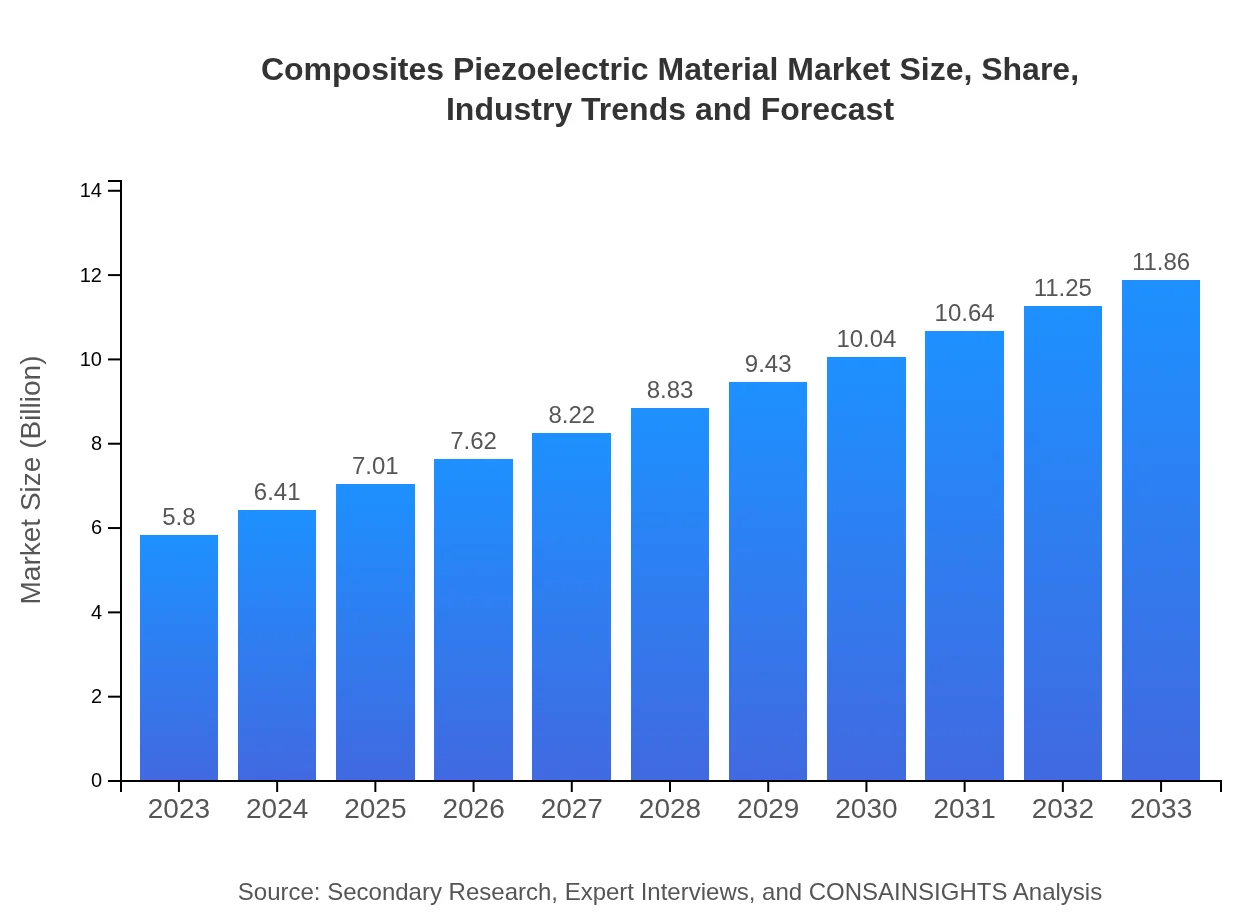

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $5.80 Billion |

| CAGR (2023-2033) | 7.2% |

| 2033 Market Size | $11.86 Billion |

| Top Companies | TRS Technologies, Inc., PI Ceramics, American Piezo Ceramics, Inc. |

| Last Modified Date | 02 February 2026 |

Composites Piezoelectric Material Market Overview

Customize Composites Piezoelectric Material Market Report market research report

- ✔ Get in-depth analysis of Composites Piezoelectric Material market size, growth, and forecasts.

- ✔ Understand Composites Piezoelectric Material's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Composites Piezoelectric Material

What is the Market Size & CAGR of Composites Piezoelectric Material market in 2023?

Composites Piezoelectric Material Industry Analysis

Composites Piezoelectric Material Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Composites Piezoelectric Material Market Analysis Report by Region

Europe Composites Piezoelectric Material Market Report:

Europe's market is forecast to rise from USD 1.56 billion in 2023 to USD 3.18 billion by 2033. The region's focus on sustainability and advanced manufacturing technologies is fostering demand for composites piezoelectric materials.Asia Pacific Composites Piezoelectric Material Market Report:

In Asia Pacific, the market is projected to grow from USD 1.12 billion in 2023 to USD 2.29 billion by 2033, driven by increasing industrial automation and the proliferation of consumer electronics. Countries like China and Japan are leading in the adoption of advanced piezoelectric applications.North America Composites Piezoelectric Material Market Report:

North America stands as a substantial market, estimated to grow from USD 2.09 billion in 2023 to USD 4.28 billion by 2033. The US leads the market due to high investments in research and development, especially in healthcare and aerospace sectors.South America Composites Piezoelectric Material Market Report:

The South American market is expected to expand from USD 0.36 billion in 2023 to USD 0.73 billion by 2033. Brazil and Argentina are driving growth, focusing on renewable energy sectors which benefit from piezoelectric materials.Middle East & Africa Composites Piezoelectric Material Market Report:

The Middle East and Africa market is projected to grow from USD 0.67 billion in 2023 to USD 1.37 billion by 2033. Growing interest in industrial automation and smart sensors in various industries is driving this growth.Tell us your focus area and get a customized research report.

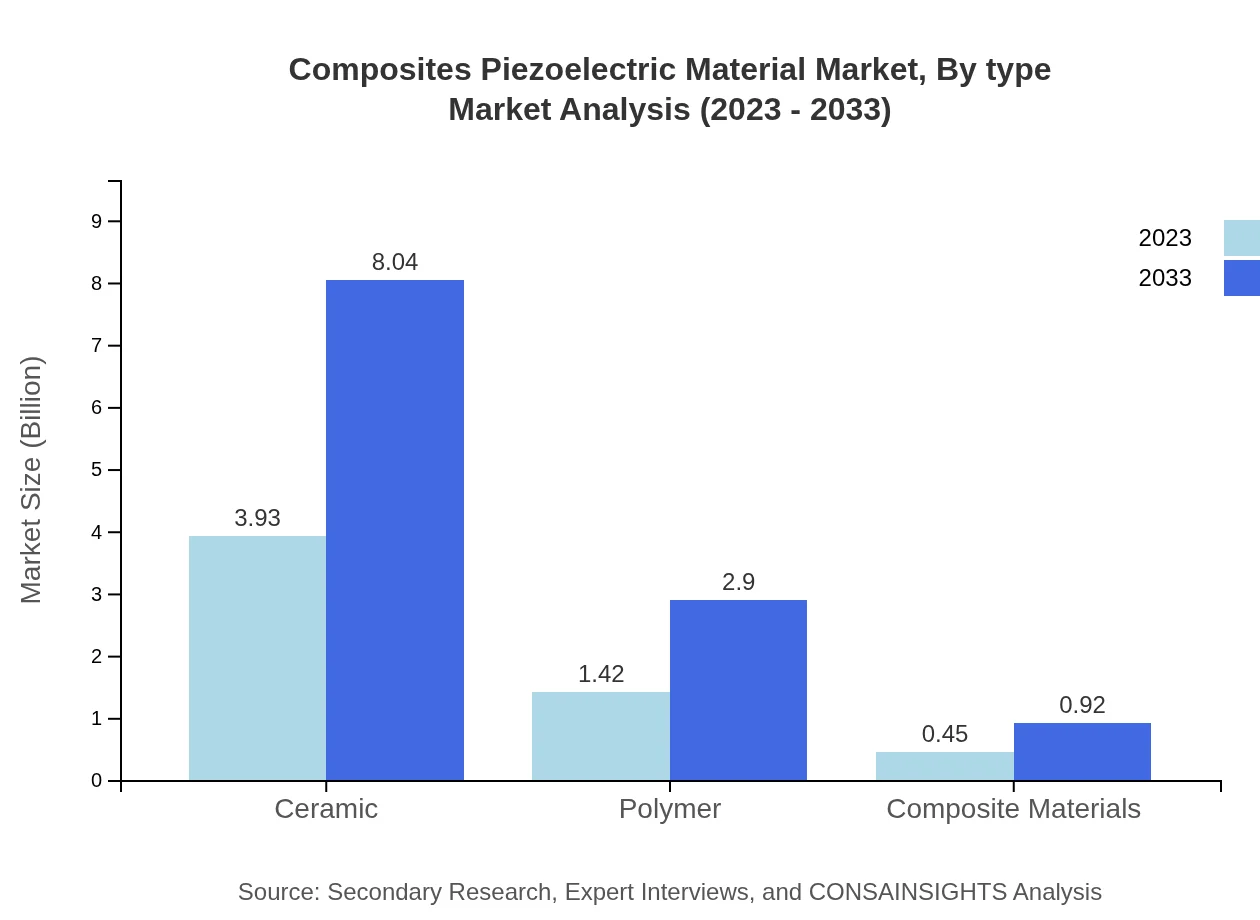

Composites Piezoelectric Material Market Analysis By Type

By type, the composites piezoelectric market includes ceramics, polymers, and composite materials. Ceramics dominate the market, expected to grow from USD 3.93 billion in 2023 to USD 8.04 billion by 2033. Polymers and composites also play significant roles, with polymers projected to reach USD 2.90 billion and composites growing to USD 0.92 billion in the same period.

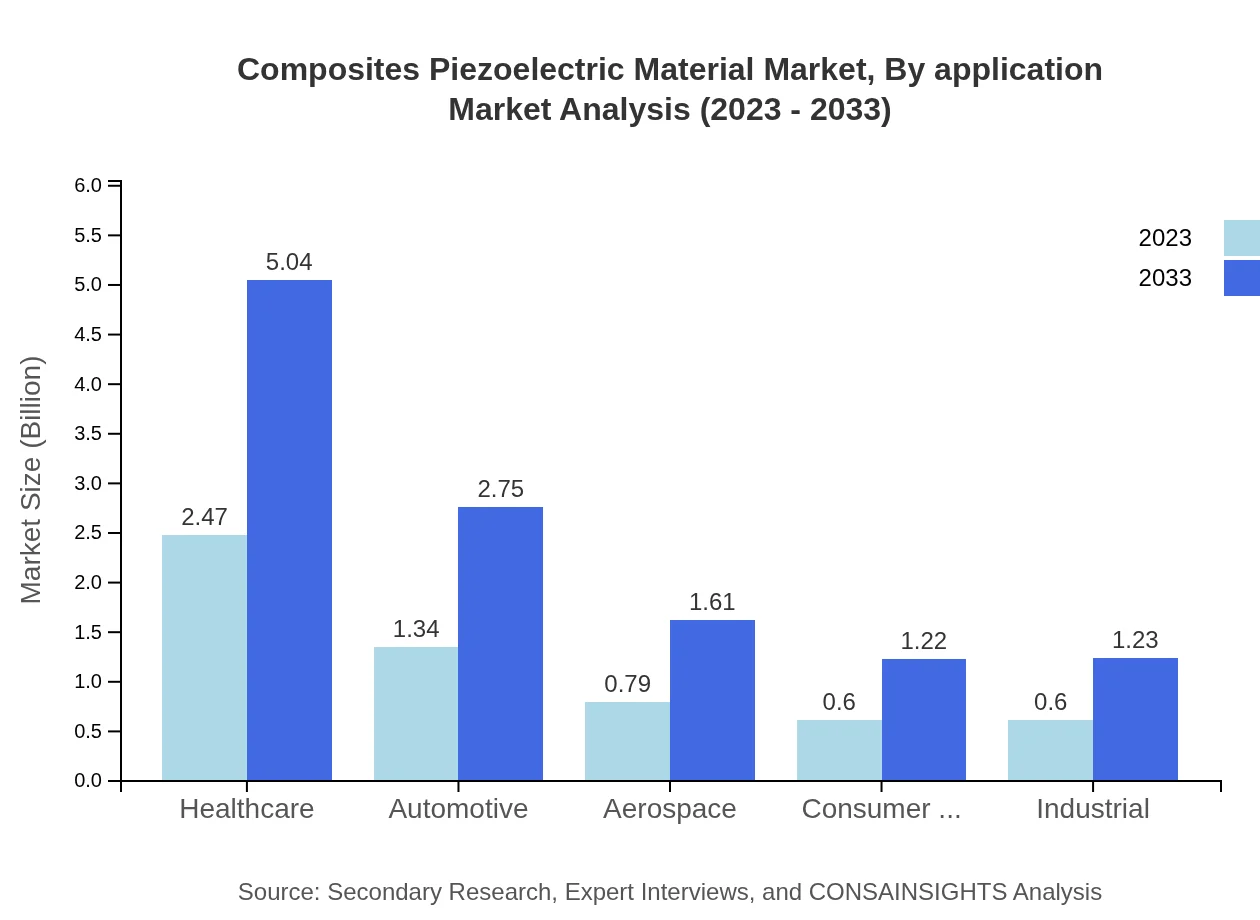

Composites Piezoelectric Material Market Analysis By Application

The main applications include healthcare, automotive, aerospace, consumer electronics, and industrial uses. Healthcare applications lead the market with a size of USD 2.47 billion in 2023, growing to USD 5.04 billion by 2033. Automotive and aerospace sectors are also growing segments driven by demand for smart technologies.

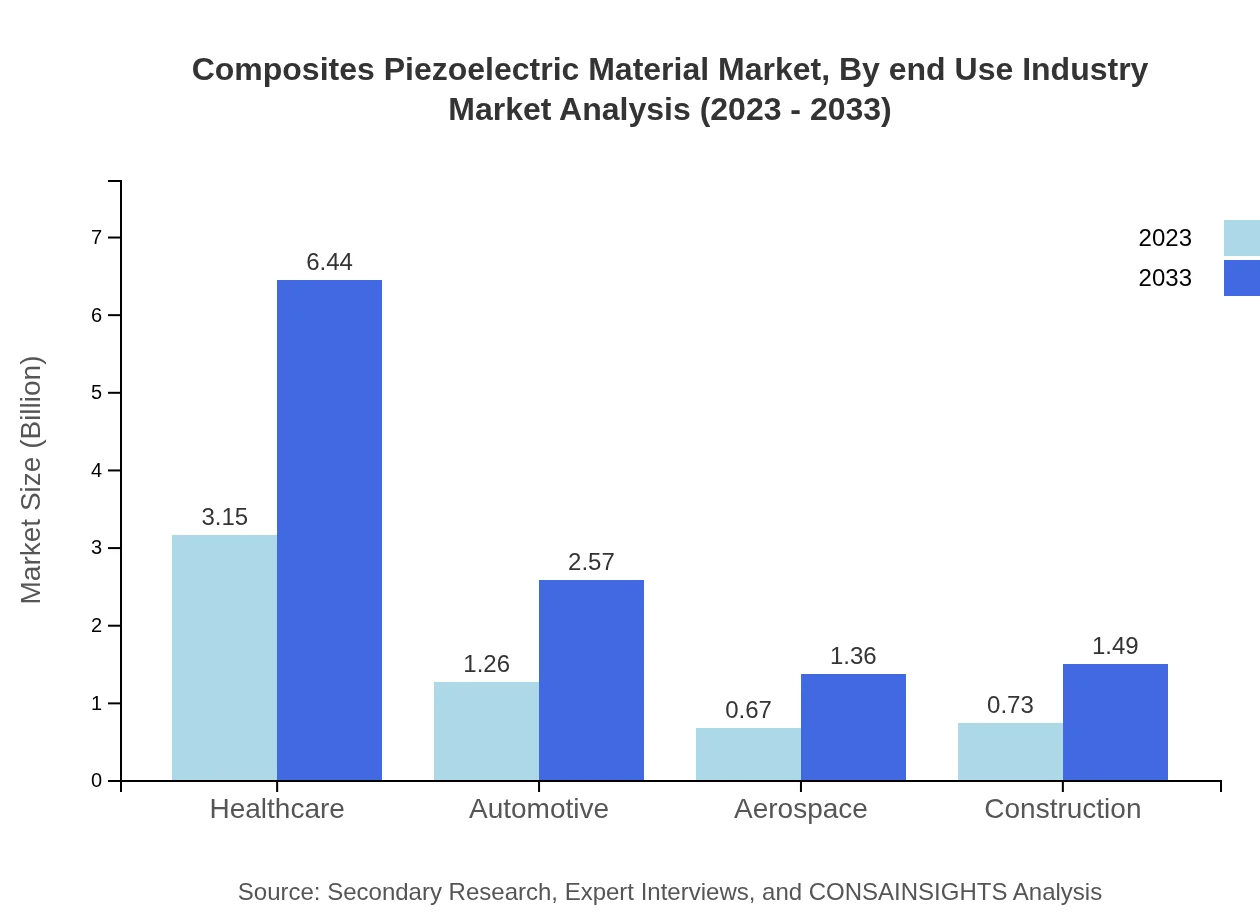

Composites Piezoelectric Material Market Analysis By End Use Industry

End-use industries are diverse, with significant contributions from healthcare, automotive, aerospace, and industrial segments. Each of these sectors is critical in driving the demand for innovative piezoelectric solutions to enhance performance and reliability in applications.

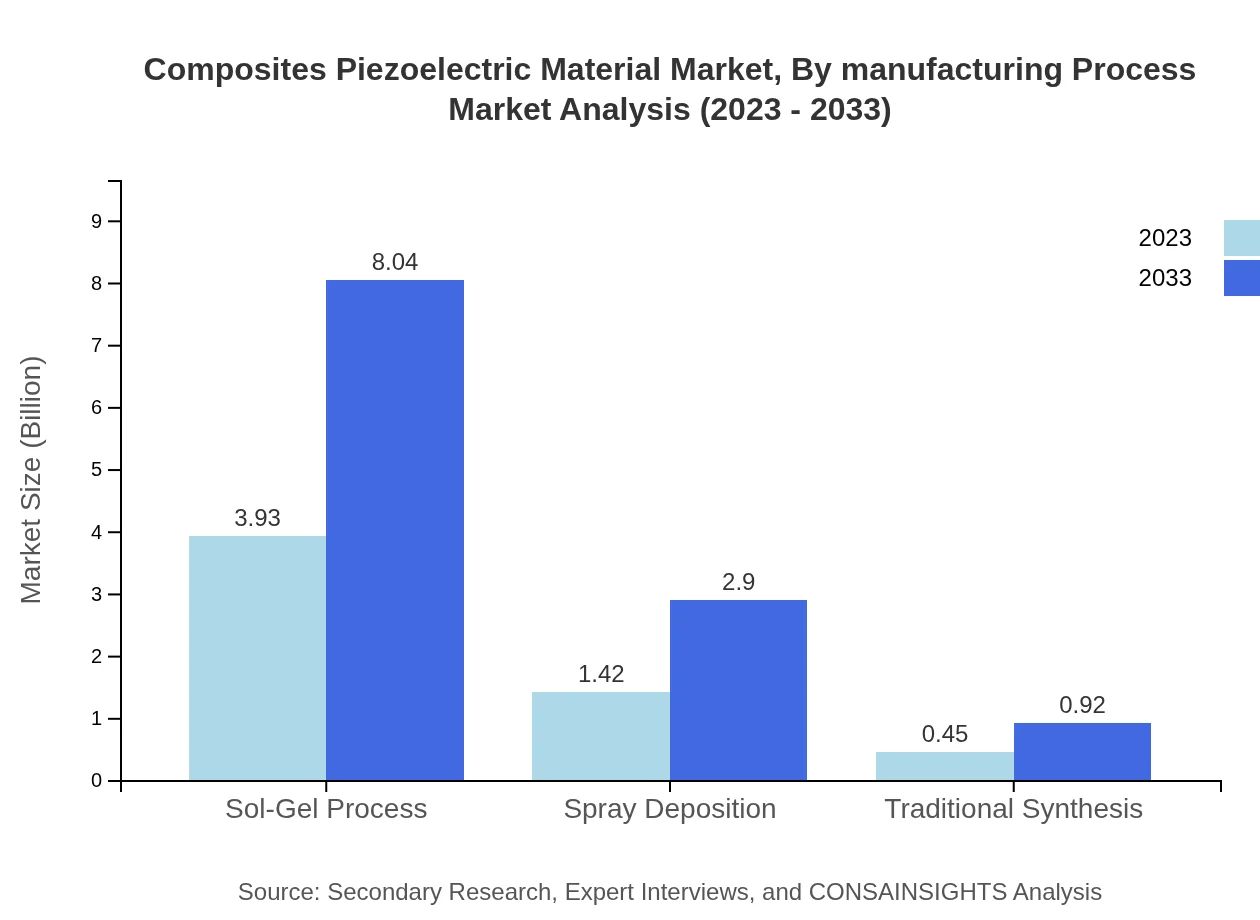

Composites Piezoelectric Material Market Analysis By Manufacturing Process

The manufacturing processes for piezoelectric materials include sol-gel processes, spray deposition, and traditional synthesis. The sol-gel process currently holds the largest market share at 67.79%, with significant future growth expected in spray deposition technologies due to their efficiency and effectiveness in producing high-quality materials.

Composites Piezoelectric Material Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Composites Piezoelectric Material Industry

TRS Technologies, Inc.:

A leader in the manufacturing of piezoelectric materials and products, specializing in customized solutions for various applications across multiple industries.PI Ceramics:

Renowned for its innovative piezoelectric products, PI Ceramics focuses on high-quality and precise manufacturing for complex sensor and actuator systems.American Piezo Ceramics, Inc.:

A pioneer in piezoelectric technology, offering a wide range of piezoelectric ceramic products for diverse applications in medical and industrial sectors.We're grateful to work with incredible clients.

FAQs

What is the market size of composites Piezoelectric Material?

The global composites piezoelectric material market is projected to reach $5.8 billion by 2033, growing at a CAGR of 7.2% from its current valuation.

What are the key market players or companies in this composites Piezoelectric Material industry?

Key players include leading manufacturers and innovators in materials and electronics who are expanding their portfolios to include piezoelectric solutions for various applications such as aerospace, healthcare, automotive, and consumer electronics.

What are the primary factors driving the growth in the composites Piezoelectric Material industry?

Factors driving growth include the increasing demand for lightweight materials in aerospace and automotive sectors, advancements in technology, and the rising need for efficient energy conversion in various industrial applications.

Which region is the fastest Growing in the composites Piezoelectric Material?

The Asia Pacific region is the fastest-growing market, expected to reach $2.29 billion by 2033, indicating strong demand particularly in electronics and automotive applications.

Does ConsInsights provide customized market report data for the composites Piezoelectric Material industry?

Yes, ConsInsights offers customized market report data tailored to specific requirements, allowing clients to obtain insights relevant to their unique business contexts and strategic needs.

What deliverables can I expect from this composites Piezoelectric Material market research project?

Deliverables typically include comprehensive market analysis reports, insights on market trends, detailed segmentation data, competitive landscape analysis, and customized recommendations for strategic planning.

What are the market trends of composites Piezoelectric Material?

Current trends involve increased investment in R&D for innovative materials, a shift towards sustainable production methods, and the growing utilization of piezoelectric materials in smart technologies and consumer electronics.