Conveyor Belt Market Report

Published Date: 22 January 2026 | Report Code: conveyor-belt

Conveyor Belt Market Size, Share, Industry Trends and Forecast to 2033

This report covers the current landscape and future outlook of the global Conveyor Belt market from 2023 to 2033. It provides key insights into market trends, size, segmentation, and regional analysis, along with forecasts and competitive dynamics.

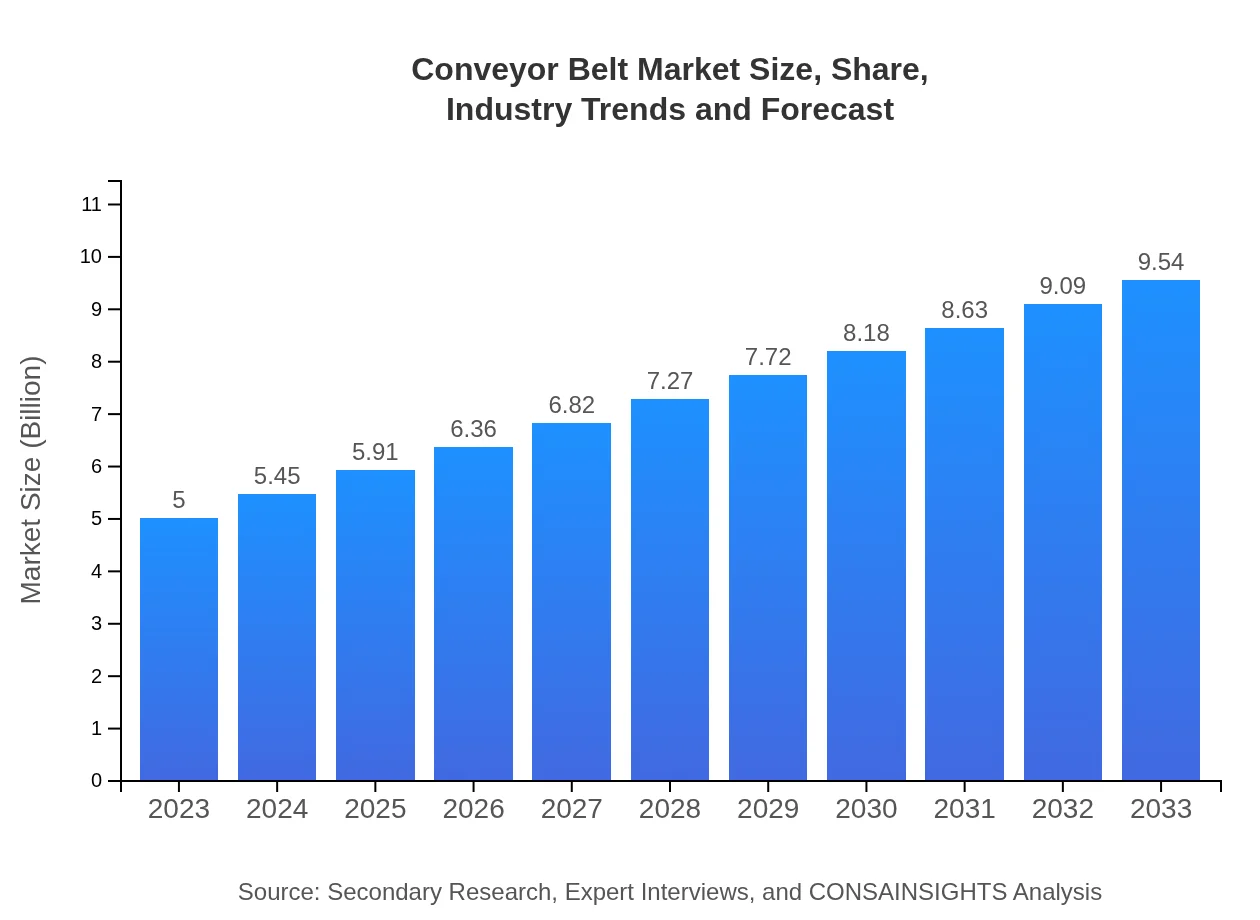

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $5.00 Billion |

| CAGR (2023-2033) | 6.5% |

| 2033 Market Size | $9.54 Billion |

| Top Companies | Continental AG, Fenner PLC, Bridgestone Corporation, Mitsuboshi Belting Ltd. |

| Last Modified Date | 22 January 2026 |

Conveyor Belt Market Overview

Customize Conveyor Belt Market Report market research report

- ✔ Get in-depth analysis of Conveyor Belt market size, growth, and forecasts.

- ✔ Understand Conveyor Belt's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Conveyor Belt

What is the Market Size & CAGR of Conveyor Belt market in 2023?

Conveyor Belt Industry Analysis

Conveyor Belt Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Conveyor Belt Market Analysis Report by Region

Europe Conveyor Belt Market Report:

Europe is notable for its strong emphasis on conveyor belt technology research and development. The market in this region is expected to rise significantly from 1.35 billion USD in 2023 to 2.59 billion USD in 2033, with robust demand from food and beverage, automotive, and e-commerce industries.Asia Pacific Conveyor Belt Market Report:

In the Asia-Pacific region, the market is expected to grow from 1.08 billion USD in 2023 to 2.06 billion USD by 2033, driven by increasing industrialization and infrastructure projects, particularly in countries like China and India. The demand for automated systems in manufacturing and logistics is boosting investments in conveyor technologies.North America Conveyor Belt Market Report:

The North American market is projected to expand from 1.78 billion USD in 2023 to 3.40 billion USD by 2033, driven by advancements in automation and technology across manufacturing and logistics sectors, as well as a focus on energy efficiency.South America Conveyor Belt Market Report:

South America is anticipated to see growth from 0.24 billion USD in 2023 to 0.46 billion USD in 2033. This growth is bolstered by an increase in mining activities and expansion in food processing industries, as well as improvements in transport infrastructure.Middle East & Africa Conveyor Belt Market Report:

The Middle East and Africa region is expected to experience growth from 0.55 billion USD in 2023 to 1.04 billion USD by 2033. This growth is attributed to infrastructural developments and local manufacturing investments, especially in countries like South Africa and the UAE.Tell us your focus area and get a customized research report.

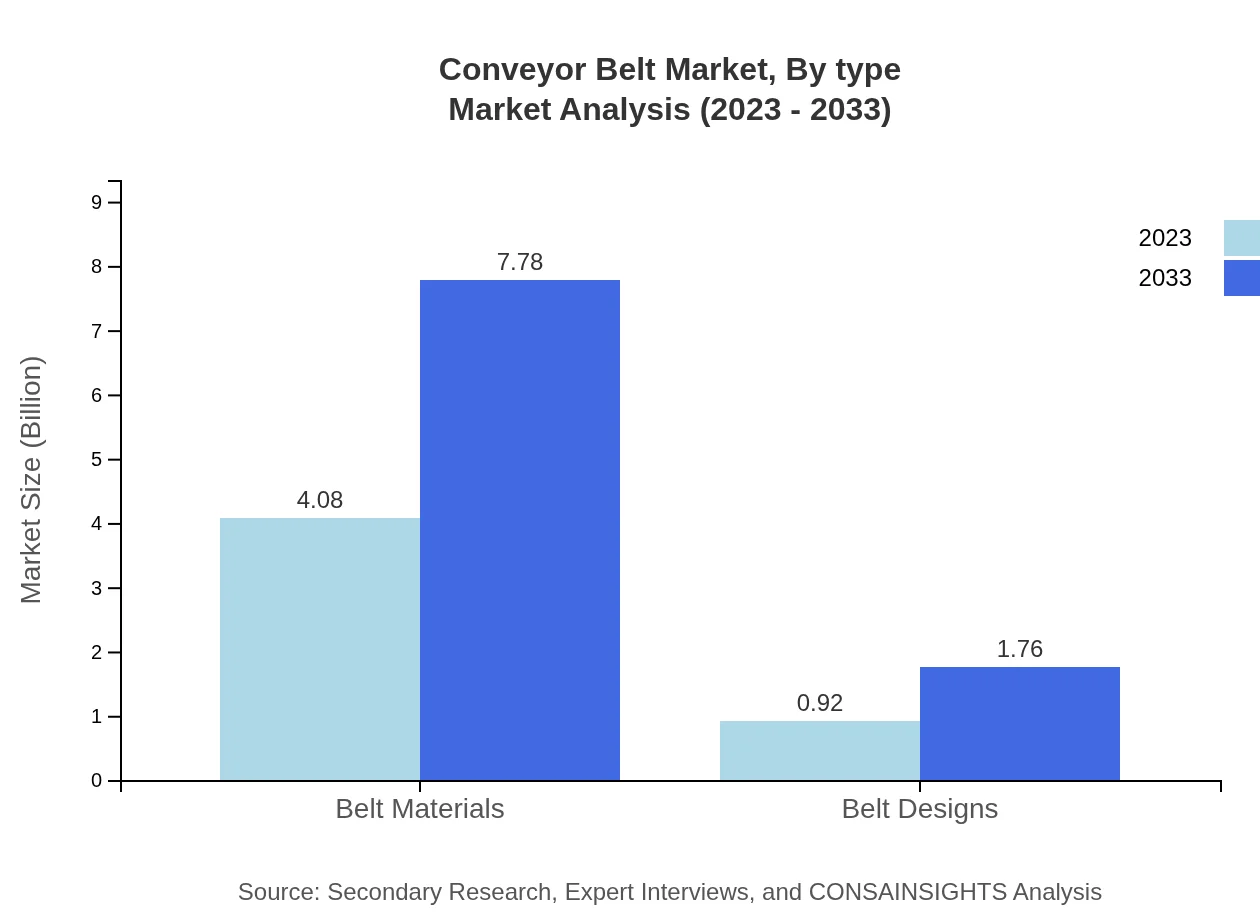

Conveyor Belt Market Analysis By Type

The Conveyor Belt Market by Type includes segments such as Belt Materials, Belt Designs, and others. As of 2023, the size for Belt Materials is 4.08 billion USD, expected to reach 7.78 billion USD by 2033, showcasing its dominance with an 81.55% market share. Belt Designs, on the other hand, account for 0.92 billion USD in 2023, with an anticipated growth to 1.76 billion USD, holding a share of 18.45%. This indicates a strong focus on material quality and customization in designs.

Conveyor Belt Market Analysis By Industry

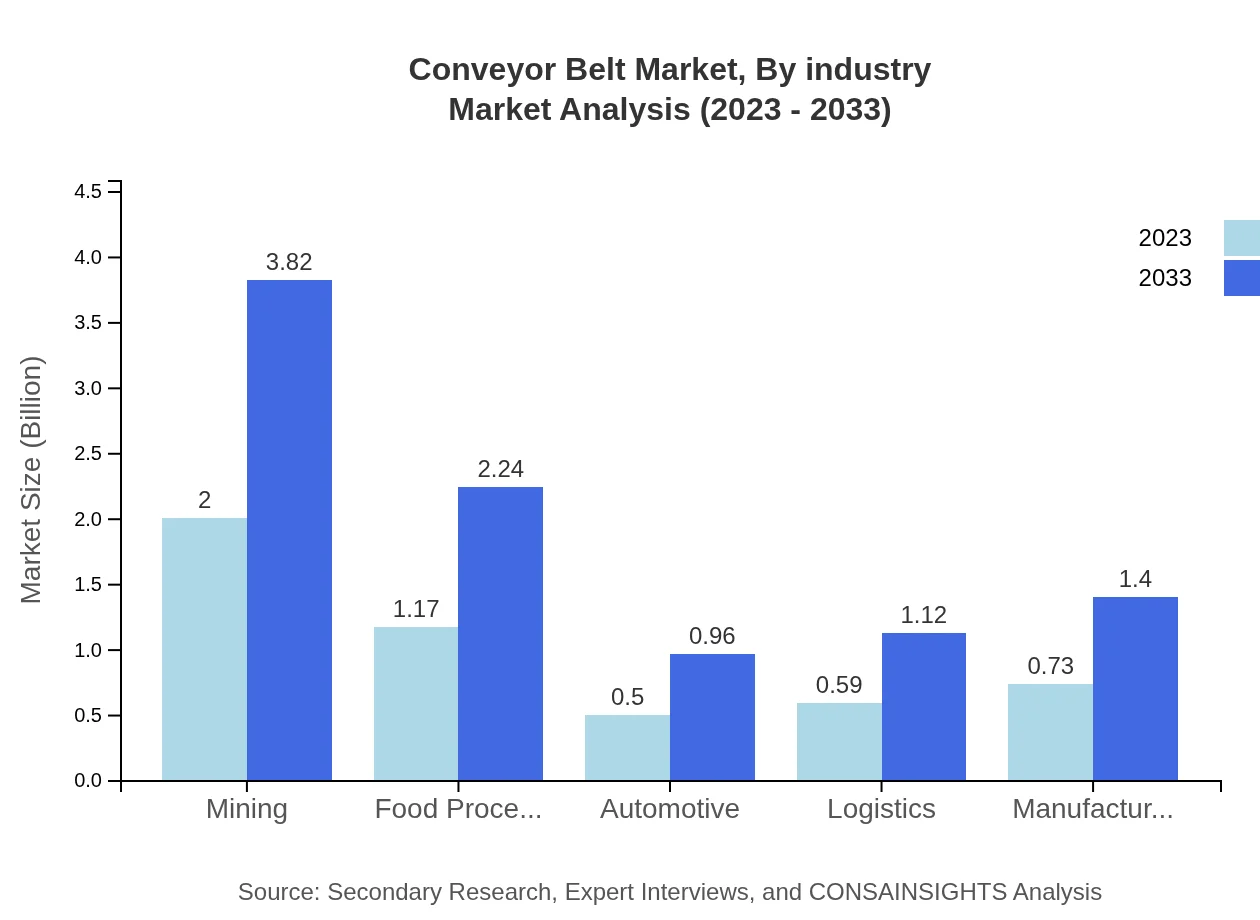

The Conveyor Belt Market by Industry is categorized into key segments such as Mining, Food Processing, Automotive, Logistics, Manufacturing, and more. Mining holds the largest share at 2.00 billion USD in 2023, expected to rise to 3.82 billion USD by 2033, reflecting its 40.01% share. Food Processing and Logistics sectors also contribute significantly, showcasing the versatility of conveyor belts across applications.

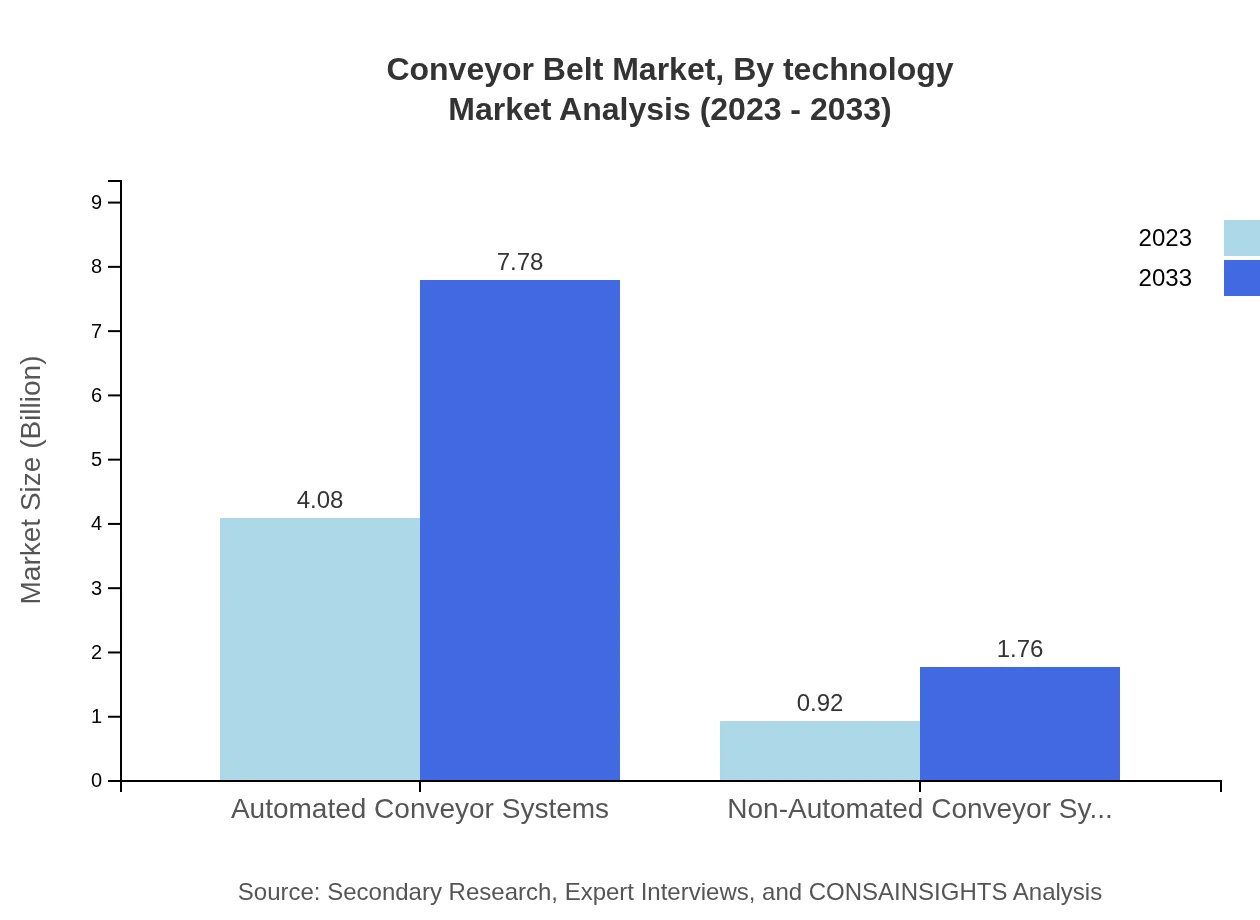

Conveyor Belt Market Analysis By Functionality

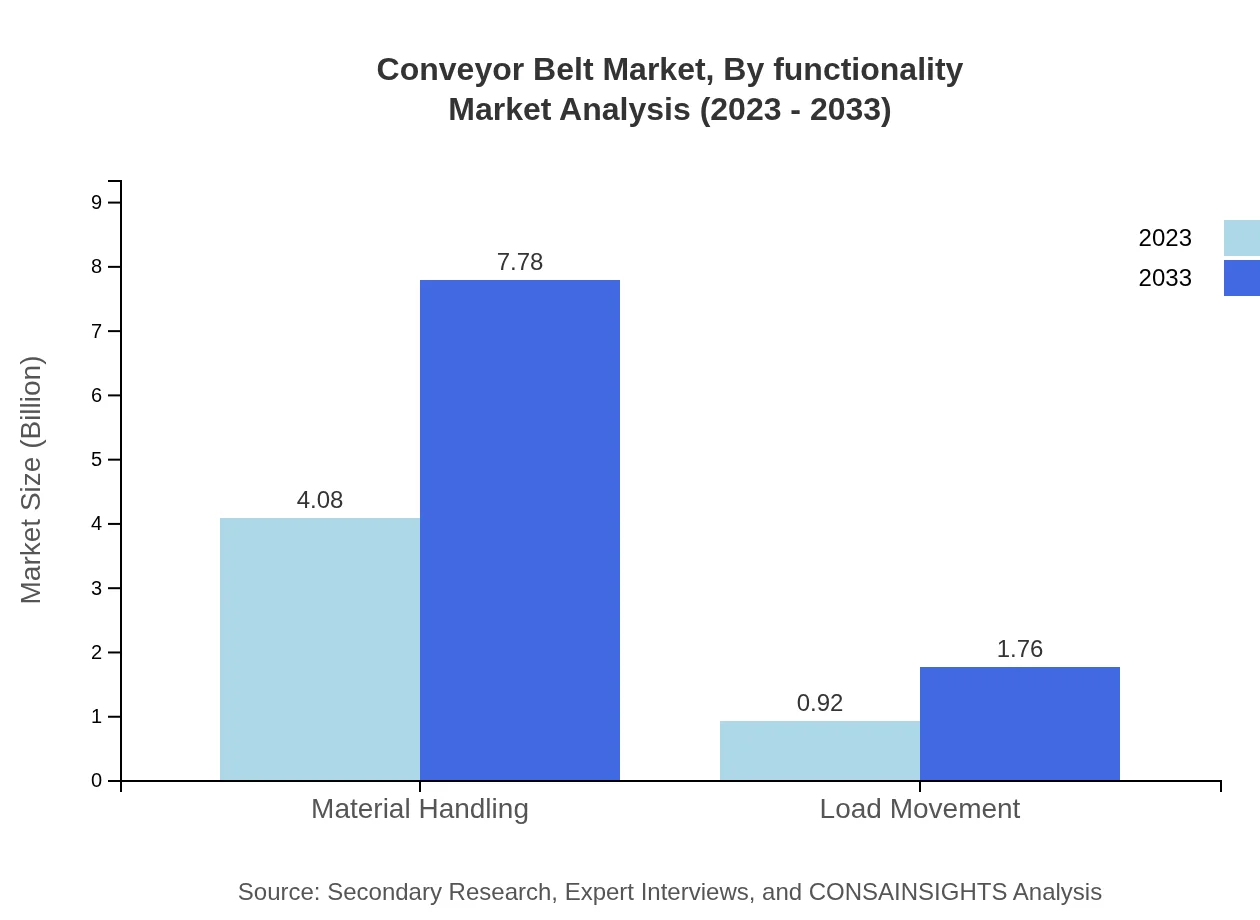

In terms of functionality, the Conveyor Belt market includes Automated and Non-Automated Systems. Automated Conveyor Systems dominate the market, accounting for a size of 4.08 billion USD in 2023 and expected to reach 7.78 billion USD by 2033, with an 81.55% market share. Non-Automated systems follow, valued at 0.92 billion USD in 2023 and anticipating growth to 1.76 billion USD, holding a share of 18.45%.

Conveyor Belt Market Analysis By Technology

The market analysis by Technology reflects the use of traditional and advanced conveyor systems. The demand for smart conveyor systems integrating IoT technology is growing rapidly, with existing systems progressing towards more intelligent and efficient configurations, enhancing operational capabilities through real-time data processing.

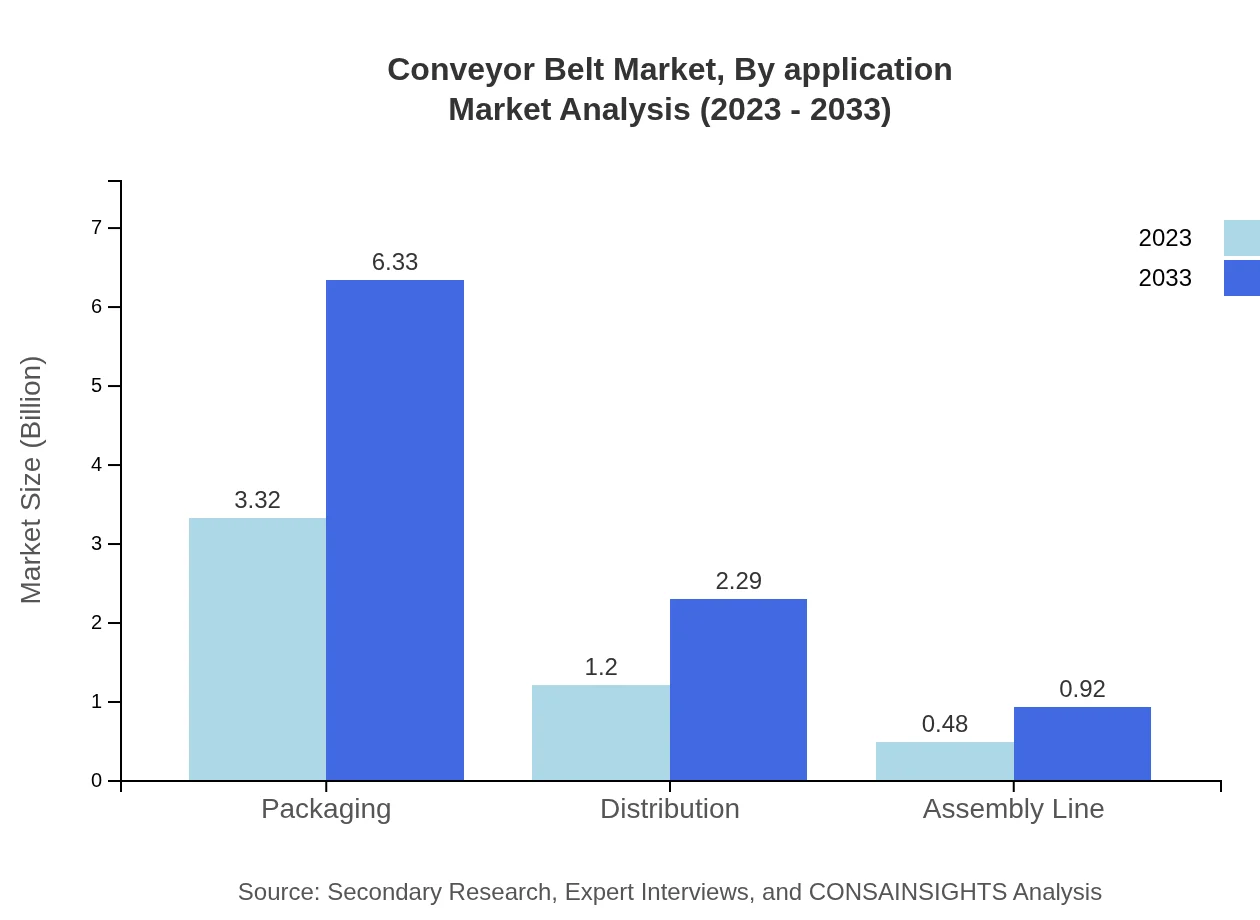

Conveyor Belt Market Analysis By Application

The Conveyor Belt Market by Application examines critical areas such as Packaging, Distribution, and Assembly Line operations. Packaging leads with a size of 3.32 billion USD in 2023, projected to grow to 6.33 billion USD by 2033, while Distribution holds significant potential, growing from 1.20 billion USD to 2.29 billion USD, reflecting the crucial role of conveyor systems in logistics and packaging operations.

Conveyor Belt Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Conveyor Belt Industry

Continental AG:

A leading manufacturer of conveyor belt solutions, Continental AG specializes in production innovation and sustainable engineering. They cater to various industries, including mining, automotive, and logistics, providing quality and reliability.Fenner PLC:

Fenner PLC is a significant player in the Conveyor Belt market, known for its durable products in heavy industries. Their commitment to research and development ensures they remain competitive through advanced material technology.Bridgestone Corporation:

Bridgestone, widely recognized for its tire manufacturing, also has a significant market presence in conveyor belt manufacturing. They focus on high-performance and customized solutions for diverse applications.Mitsuboshi Belting Ltd.:

Mitsuboshi Belting offers a wide range of conveyor belts known for their strength and longevity. They are recognized for their integrated approach to manufacturing and innovative solutions tailored to customer specifications.We're grateful to work with incredible clients.

FAQs

What is the market size of conveyor belts?

The global conveyor belt market is valued at $5 billion in 2023, with a projected CAGR of 6.5% between 2023 and 2033. This growth indicates significant demand across various industries over the next decade.

What are the key market players or companies in the conveyor belt industry?

Key players in the conveyor belt market include companies like Continental AG, Bridgestone Corporation, and Schenck Process AG. These companies dominate through innovation, quality, and expanding global footprints.

What are the primary factors driving growth in the conveyor belt industry?

Growth in the conveyor belt industry is driven by technological advancements, rising automation, and increasing demand from mining, food processing, and logistics sectors. Additionally, expansion in e-commerce is fueling conveyor system needs.

Which region is the fastest growing in the conveyor belt market?

The North American region is projected to be the fastest growing, with a market increase from $1.78 billion in 2023 to $3.40 billion in 2033. Europe and Asia Pacific also show strong growth, contributing significantly to market expansion.

Does ConsaInsights provide customized market report data for the conveyor belt industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs within the conveyor belt industry. This includes in-depth insights and analysis, ensuring relevance to client requirements.

What deliverables can I expect from this conveyor belt market research project?

Deliverables from the conveyor belt market research project typically include detailed reports, statistical analysis, regional insights, and segmentation data. Clients can expect actionable insights and market forecasts.

What are the market trends of conveyor belts?

Key trends in the conveyor belt market include the rise of automated systems, green technologies, and customization trends catering to specific industrial needs. Increased efficiency and sustainability are also major focal points.