Copper Copper Manufactured Products Market Report

Published Date: 02 February 2026 | Report Code: copper-copper-manufactured-products

Copper Copper Manufactured Products Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Copper Copper Manufactured Products market, examining its size, growth potential, and key trends spanning from 2023 to 2033. Insights into regional variations and leading companies fill the report with crucial data for stakeholders.

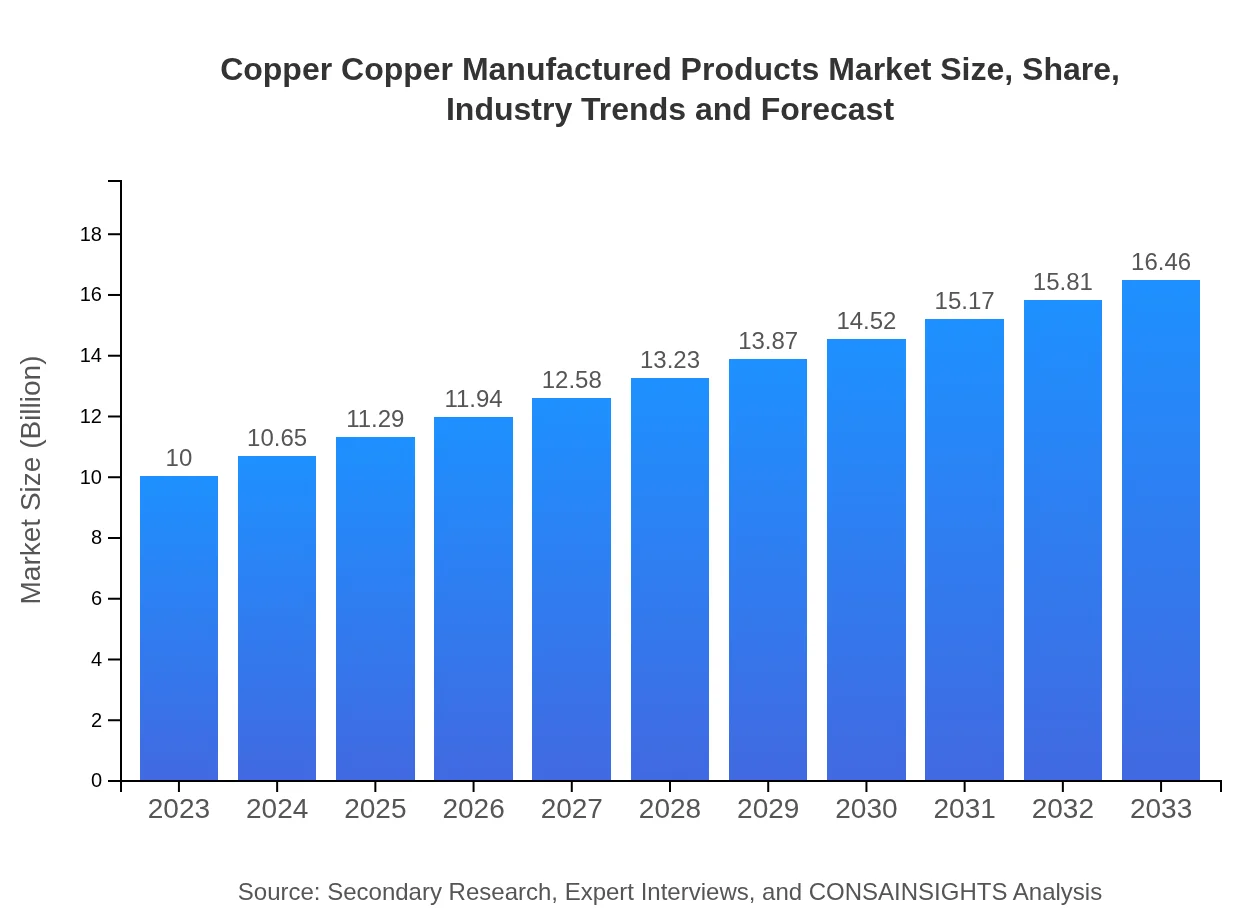

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $10.00 Billion |

| CAGR (2023-2033) | 5% |

| 2033 Market Size | $16.46 Billion |

| Top Companies | KGHM Polska Miedź S.A., Freeport-McMoRan Inc., Southern Copper Corporation, Aurubis AG |

| Last Modified Date | 02 February 2026 |

Copper Copper Manufactured Products Market Overview

Customize Copper Copper Manufactured Products Market Report market research report

- ✔ Get in-depth analysis of Copper Copper Manufactured Products market size, growth, and forecasts.

- ✔ Understand Copper Copper Manufactured Products's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Copper Copper Manufactured Products

What is the Market Size & CAGR of Copper Copper Manufactured Products market in 2023?

Copper Copper Manufactured Products Industry Analysis

Copper Copper Manufactured Products Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Copper Copper Manufactured Products Market Analysis Report by Region

Europe Copper Copper Manufactured Products Market Report:

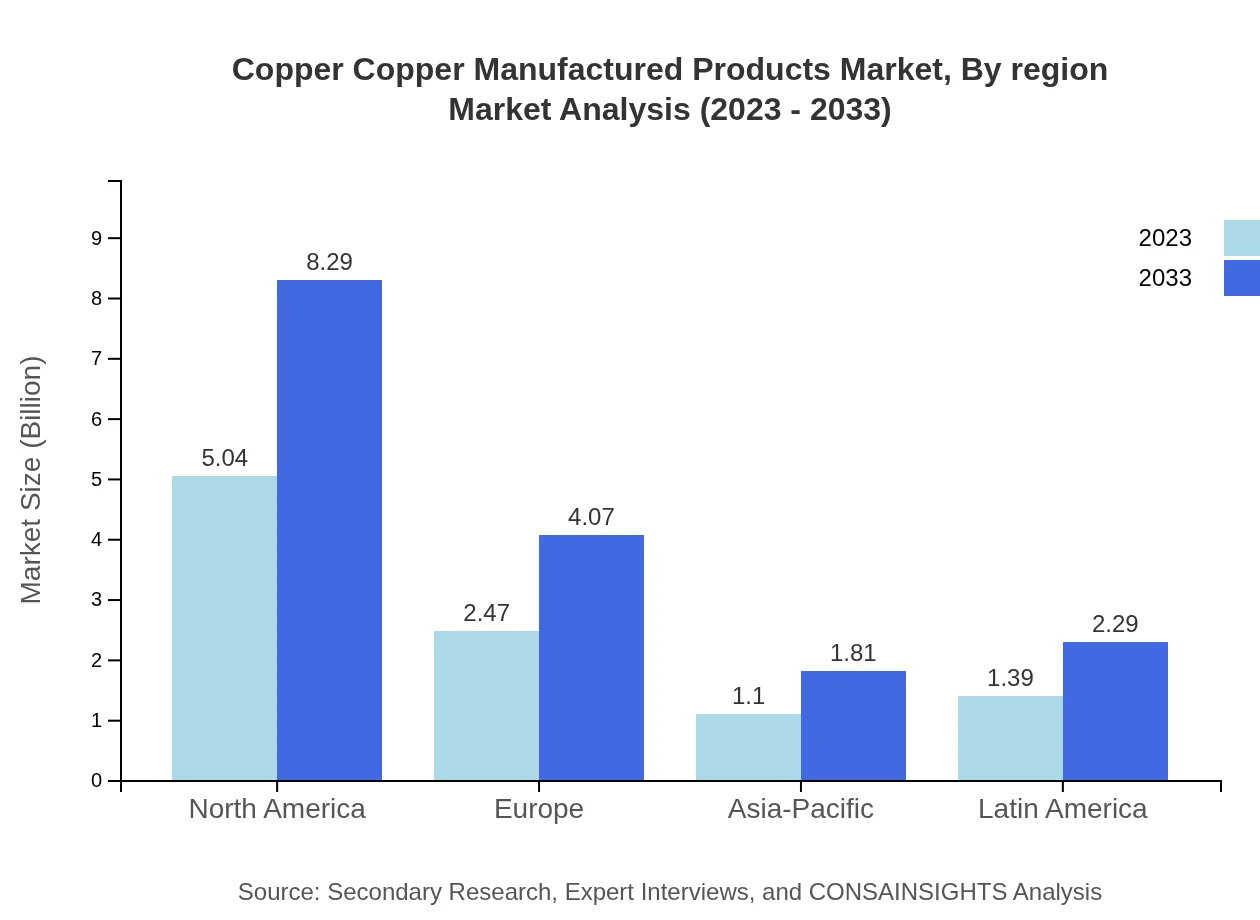

In Europe, the market is anticipated to grow from USD 2.68 billion in 2023 to USD 4.42 billion by 2033. This growth is underpinned by strict regulations promoting energy efficiency and sustainability, driving the demand for copper in electrical applications and renewable energy.Asia Pacific Copper Copper Manufactured Products Market Report:

In Asia Pacific, the market size is projected to grow from USD 1.91 billion in 2023 to USD 3.14 billion by 2033. Rapid industrialization, infrastructure development, and a growing automotive sector are driving demand in this region. With countries like China and India leading in consumption, the market presents considerable growth opportunities fueled by rising investments.North America Copper Copper Manufactured Products Market Report:

North America showcases a strong market landscape, projected to rise from USD 3.83 billion in 2023 to USD 6.30 billion by 2033. This growth is spurred by thriving construction and electrical sectors, coupled with the ongoing transition towards renewable energy technologies, creating a higher demand for copper products.South America Copper Copper Manufactured Products Market Report:

The South American market for Copper Copper Manufactured Products is expected to expand from USD 0.44 billion in 2023 to USD 0.73 billion by 2033. The growth is primarily driven by increased mining activities and infrastructure investments, although political and economic fluctuations may pose challenges to market stability.Middle East & Africa Copper Copper Manufactured Products Market Report:

The Middle East and Africa region is set for growth, increasing from USD 1.14 billion in 2023 to USD 1.88 billion by 2033. Infrastructure development and urbanization, especially in GCC countries, are significant contributing factors to the rising demand for copper products.Tell us your focus area and get a customized research report.

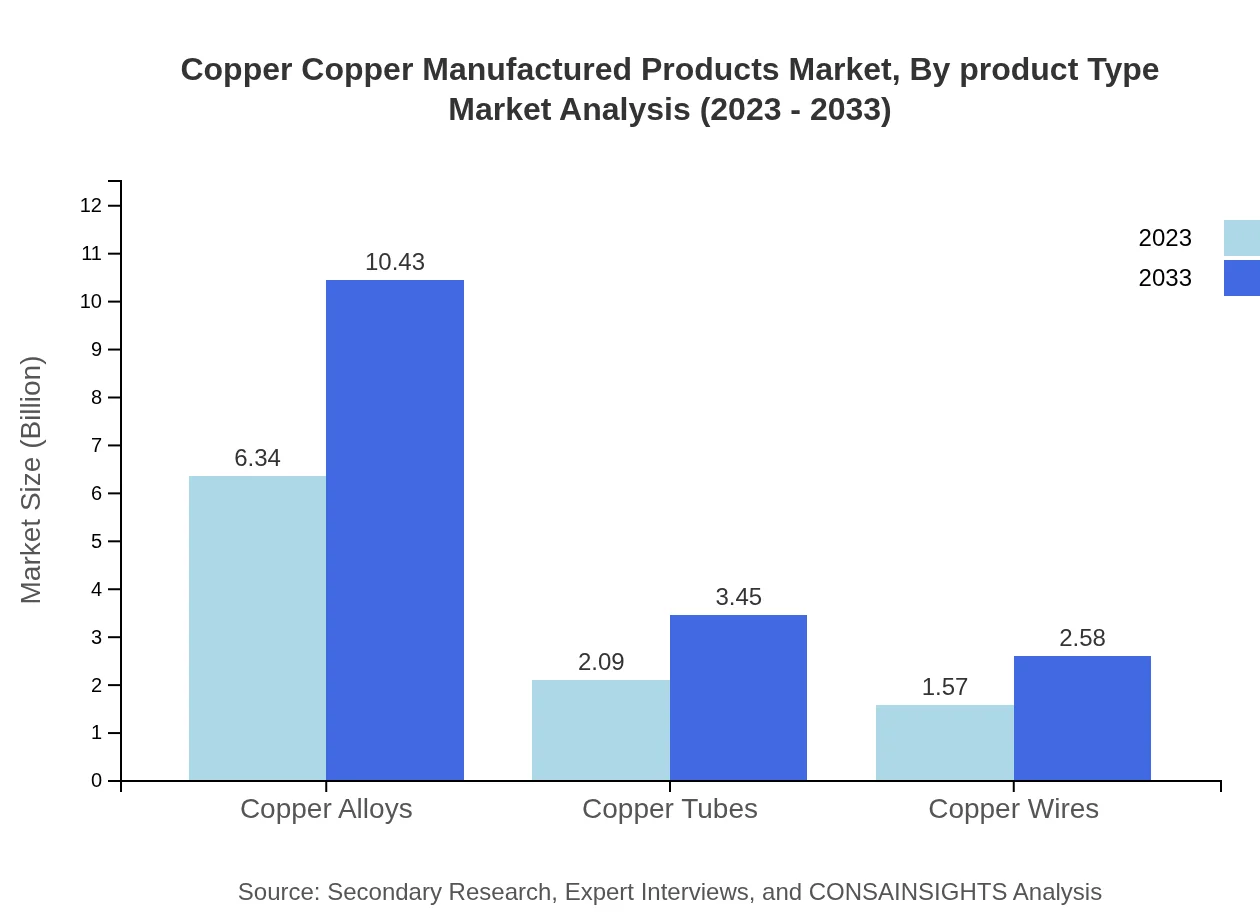

Copper Copper Manufactured Products Market Analysis By Product Type

Copper alloys dominate the market, holding a share of 63.38% in 2023, with a projected size increase from USD 6.34 billion in 2023 to USD 10.43 billion by 2033. Copper tubes and wires also play pivotal roles, representing 20.95% and 15.67% market shares, respectively, showcasing steady growth driven by increasing applications in various industries.

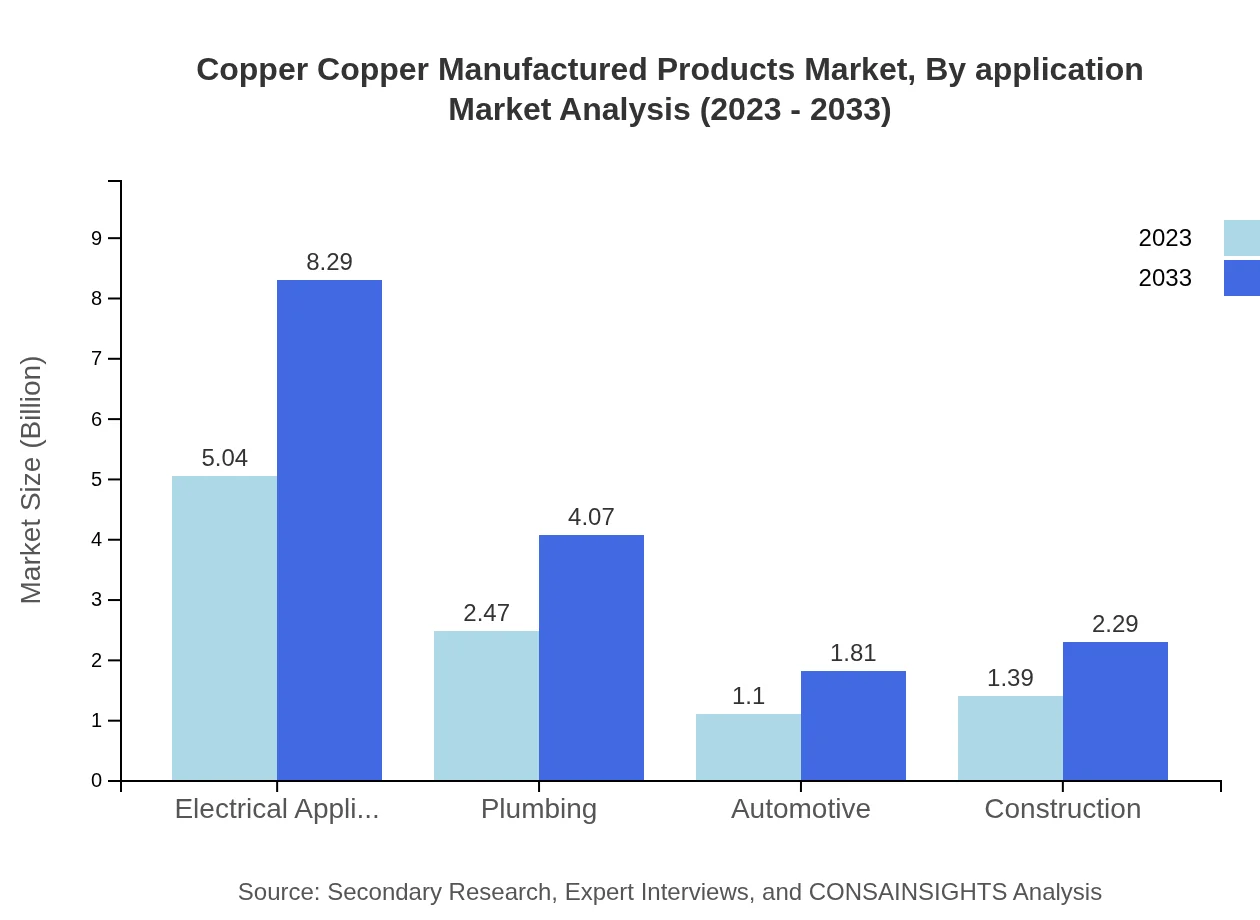

Copper Copper Manufactured Products Market Analysis By Application

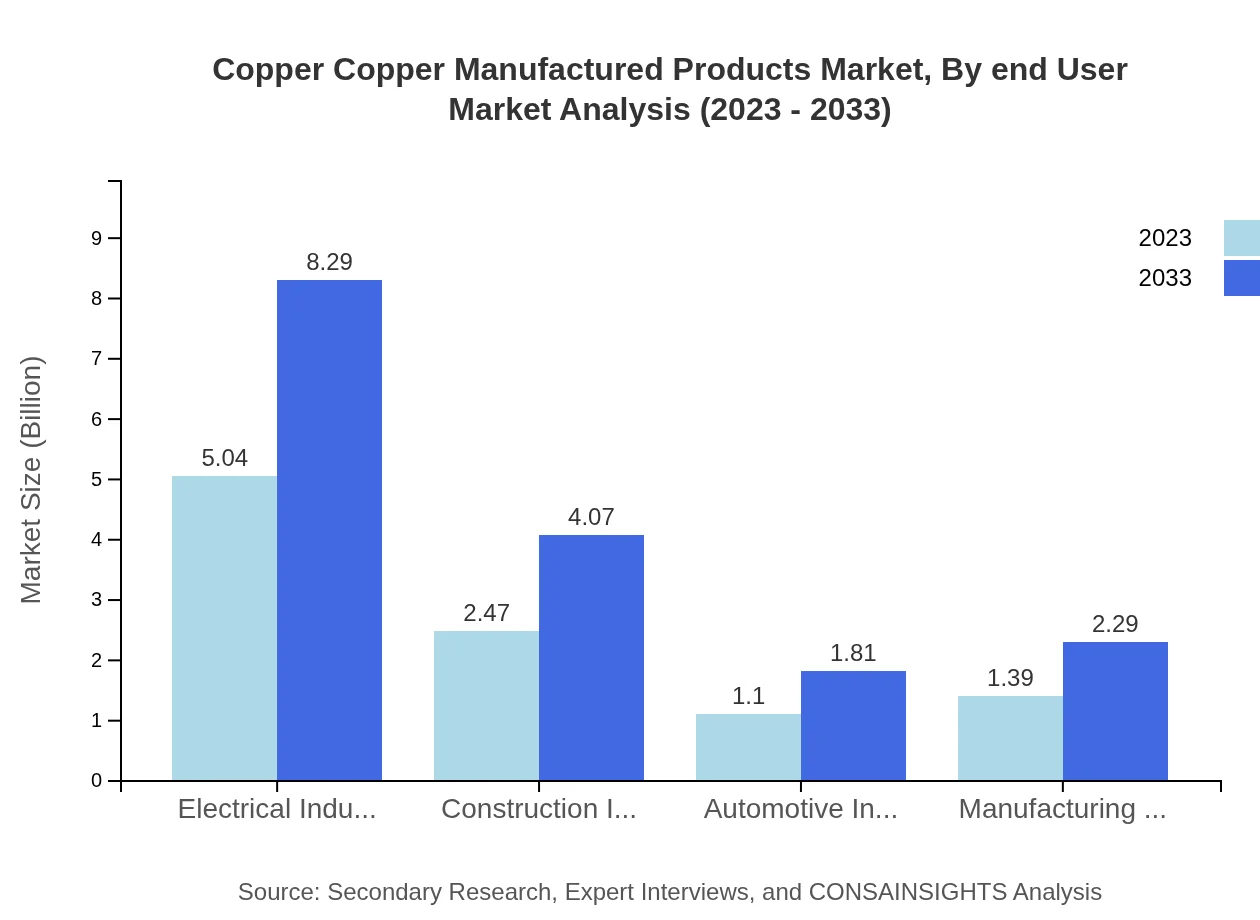

Electrical applications, construction, automotive, plumbing, and manufacturing are key segments in the market. Electrical applications account for the largest share at 50.39%, and their size is expected to grow from USD 5.04 billion to USD 8.29 billion between 2023 and 2033, reflecting the critical role of copper in power transmission and distribution.

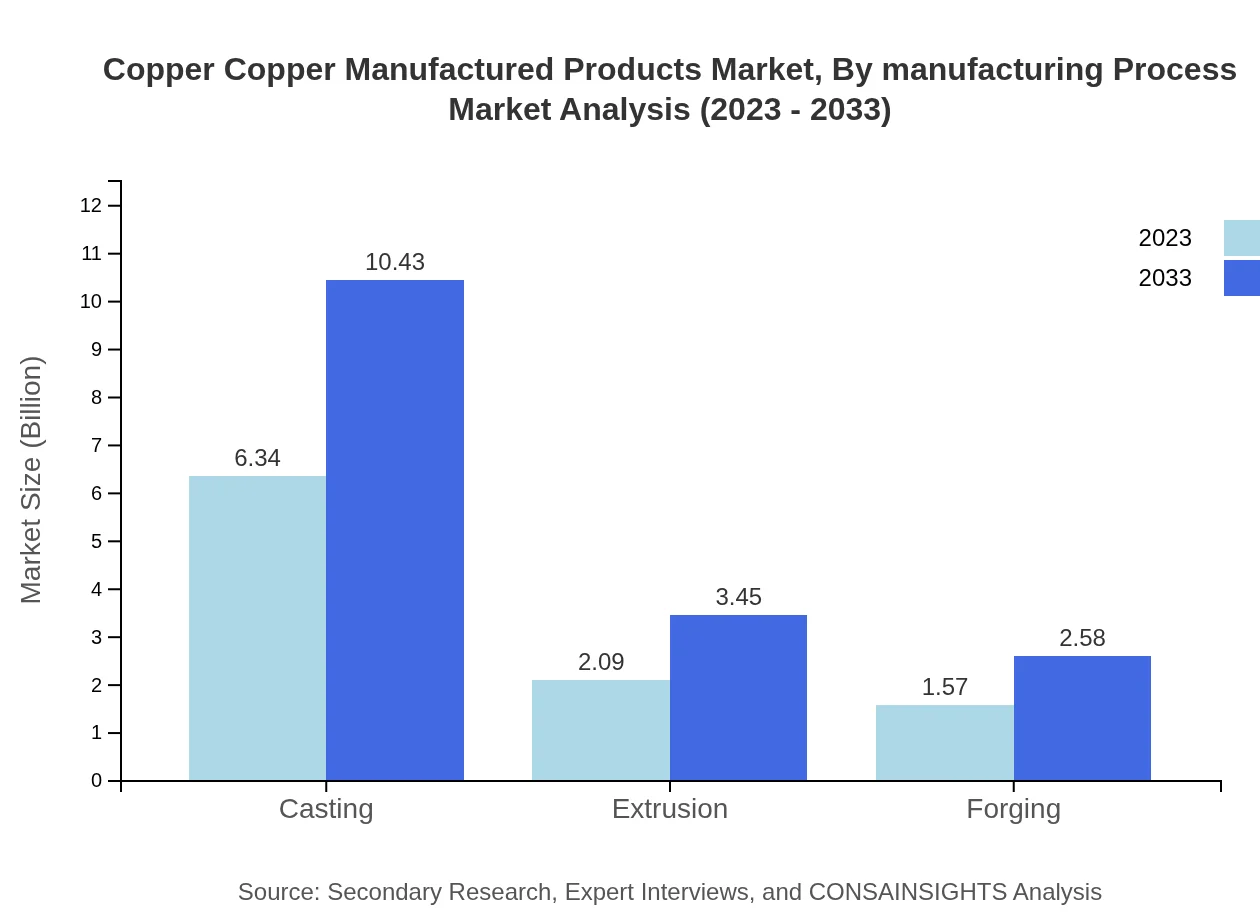

Copper Copper Manufactured Products Market Analysis By Manufacturing Process

The manufacturing processes of casting, extrusion, and forging significantly influence production efficiencies. Casting commands a sizeable share with 63.38%, while extrusion and forging represent 20.95% and 15.67% shares, respectively, demonstrating the diverse methods through which copper products are produced to meet industry standards.

Copper Copper Manufactured Products Market Analysis By End User

The electrical industry remains the dominant end-user of copper products with a share of 50.39%, showcasing its essential role in electrical wiring systems. Other notable segments include the construction industry with a 24.7% share and automotive with 11.01%, indicating diverse usage across various sectors.

Copper Copper Manufactured Products Market Analysis By Region

Regional dynamics play a significant role in shaping market trends. North America leads with USD 5.04 billion in 2023, while Asia Pacific and Europe follow closely with notable growth. The segmentation by region reflects diverse growth factors, including regulatory frameworks, economic stability, and technological advancements unique to each area.

Copper Copper Manufactured Products Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Copper Copper Manufactured Products Industry

KGHM Polska Miedź S.A.:

One of the world's largest producers of copper and silver, KGHM has a significant market presence, focusing on sustainable mining practices and innovation in copper manufacturing.Freeport-McMoRan Inc.:

A leading international mining company, Freeport-McMoRan is heavily involved in the exploration and production of copper, with extensive operations across the globe.Southern Copper Corporation:

As one of the largest integrated copper producers, Southern Copper Corporation operates significant mining facilities and generates considerable copper and molybdenum output.Aurubis AG:

Europe's largest copper producer, Aurubis is a leader in recycling and copper production, focusing on sustainable and responsible processing.We're grateful to work with incredible clients.

FAQs

What is the market size of copper Copper Manufactured Products?

The copper-copper manufactured products market is projected to reach around $10 billion by 2033, growing at a CAGR of 5%. This growth is driven by increasing demand in various industries such as electrical and construction.

What are the key market players or companies in the copper Copper Manufactured Products industry?

Key players include major manufacturers and suppliers in the copper industry, particularly those involved in electrical components, construction materials, automotive parts, and plumbing solutions. Their innovations drive the market forward.

What are the primary factors driving the growth in the copper Copper Manufactured Products industry?

Growth drivers include increased use in electrical and construction sectors, expanding automotive applications, and sustainable practices favoring copper's recyclability. Also, construction activities and infrastructure projects boost demand significantly.

Which region is the fastest Growing in the copper Copper Manufactured Products?

North America is expected to be the fastest-growing region, with market size increasing from $3.83 billion in 2023 to $6.30 billion by 2033, driven by industrial growth and technological advancements.

Does ConsaInsights provide customized market report data for the copper Copper Manufactured Products industry?

Yes, ConsaInsights offers customized market report data tailored to clients' specific needs in the copper-copper manufactured products industry, ensuring insights are relevant and actionable.

What deliverables can I expect from this copper Copper Manufactured Products market research project?

Deliverables include comprehensive market analysis reports, regional breakdowns, segment insights, competitive analysis, and growth forecasts to aid strategic decision-making for businesses in the industry.

What are the market trends of copper Copper Manufactured Products?

Trends include rising demand for copper alloys and eco-friendly manufacturing processes. Innovations in product applications and a shift towards smart technologies are shaping the market's future direction.