Emulsion Coatings Market Report

Published Date: 02 February 2026 | Report Code: emulsion-coatings

Emulsion Coatings Market Size, Share, Industry Trends and Forecast to 2033

This market report provides a comprehensive analysis of the Emulsion Coatings sector, highlighting current market trends, size metrics, regional insights, and future forecasts for the years 2023 to 2033.

| Metric | Value |

|---|---|

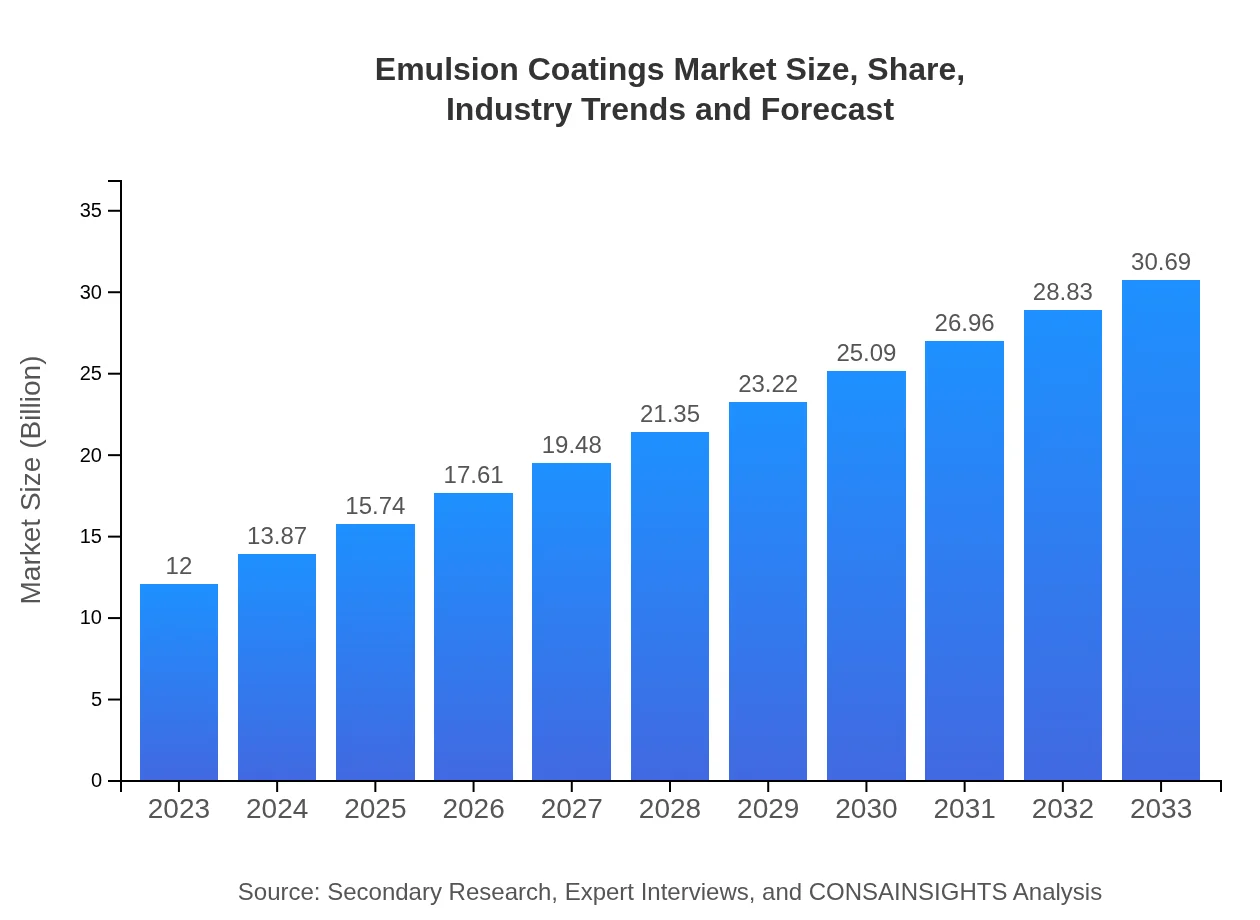

| Study Period | 2023 - 2033 |

| 2023 Market Size | $12.00 Billion |

| CAGR (2023-2033) | 9.5% |

| 2033 Market Size | $30.69 Billion |

| Top Companies | Axalta Coating Systems, PPG Industries, Inc., Sherwin-Williams Company, BASF SE |

| Last Modified Date | 02 February 2026 |

Emulsion Coatings Market Overview

Customize Emulsion Coatings Market Report market research report

- ✔ Get in-depth analysis of Emulsion Coatings market size, growth, and forecasts.

- ✔ Understand Emulsion Coatings's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Emulsion Coatings

What is the Market Size & CAGR of Emulsion Coatings market in 2023?

Emulsion Coatings Industry Analysis

Emulsion Coatings Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Emulsion Coatings Market Analysis Report by Region

Europe Emulsion Coatings Market Report:

In Europe, the Emulsion Coatings market is projected to escalate from $2.95 billion in 2023 to $7.54 billion by 2033. The region's stringent environmental regulations and increasing adoption of low-VOC coatings significantly drive demand.Asia Pacific Emulsion Coatings Market Report:

In the Asia Pacific region, the Emulsion Coatings market was valued at $2.34 billion in 2023 and is projected to reach $5.97 billion by 2033. The driving forces behind this growth include rapid urbanization, increased infrastructure development, and rising consumer preference for eco-friendly products.North America Emulsion Coatings Market Report:

North America presents a significant market for Emulsion Coatings with a valuation of $4.26 billion in 2023, poised to grow to $10.89 billion by 2033. Strong regulatory support for sustainable products and an emphasis on green building practices are major contributors to this growth.South America Emulsion Coatings Market Report:

The South American market, valued at $1.06 billion in 2023, is expected to grow to $2.72 billion by 2033. Factors such as improving economic conditions and increasing investment in residential and commercial infrastructure are propelling market expansion in this region.Middle East & Africa Emulsion Coatings Market Report:

In the Middle East and Africa, the market was valued at $1.40 billion in 2023, with forecasts showing growth to $3.57 billion by 2033. The region's construction boom, coupled with rising awareness of sustainable building practices, is expected to fuel market growth.Tell us your focus area and get a customized research report.

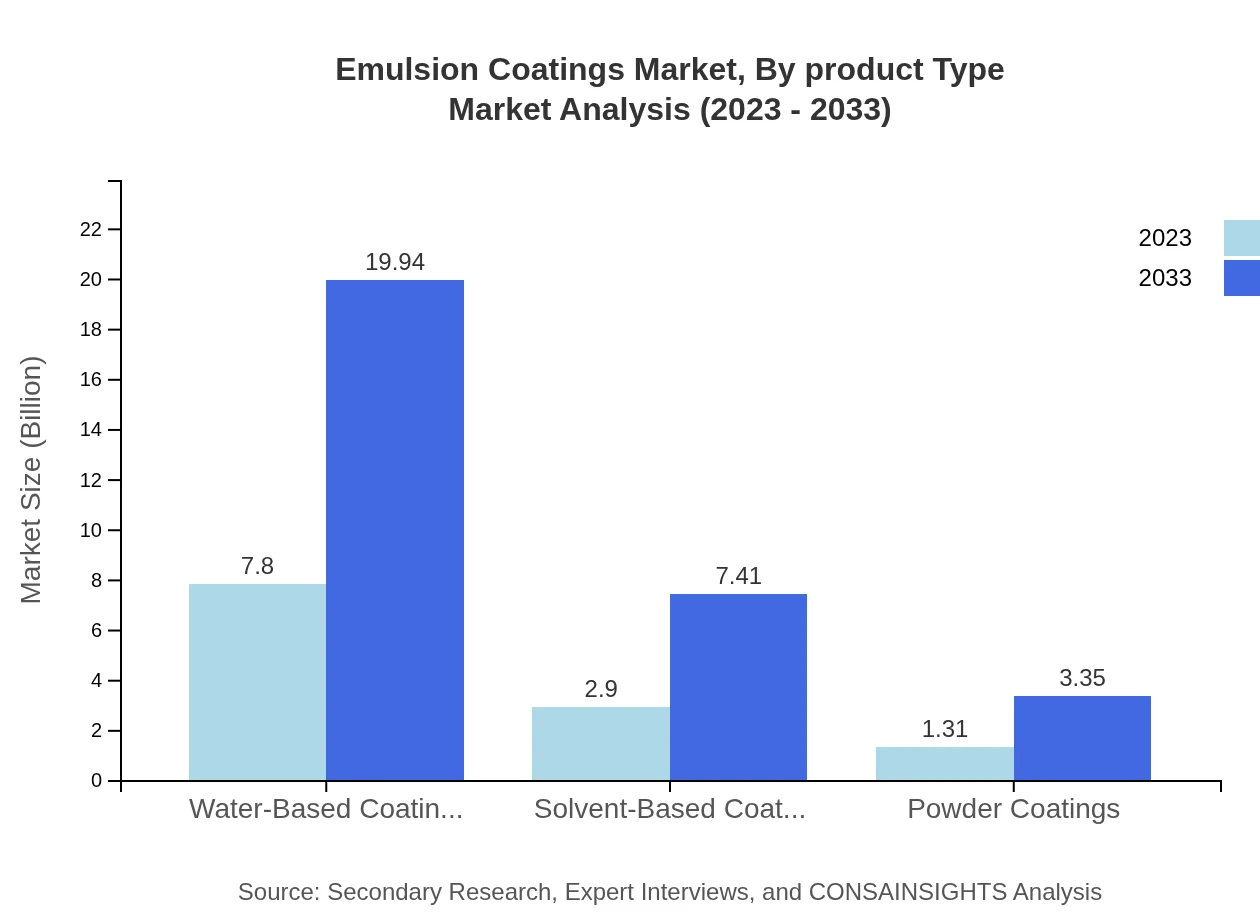

Emulsion Coatings Market Analysis By Product Type

Water-based coatings dominate the Emulsion Coatings market, accounting for 64.96% of the market share in 2023 with a projected growth to 64.96% by 2033. Solvent-based coatings and powder coatings also represent significant segments but are trending downward in market share due to environmental concerns.

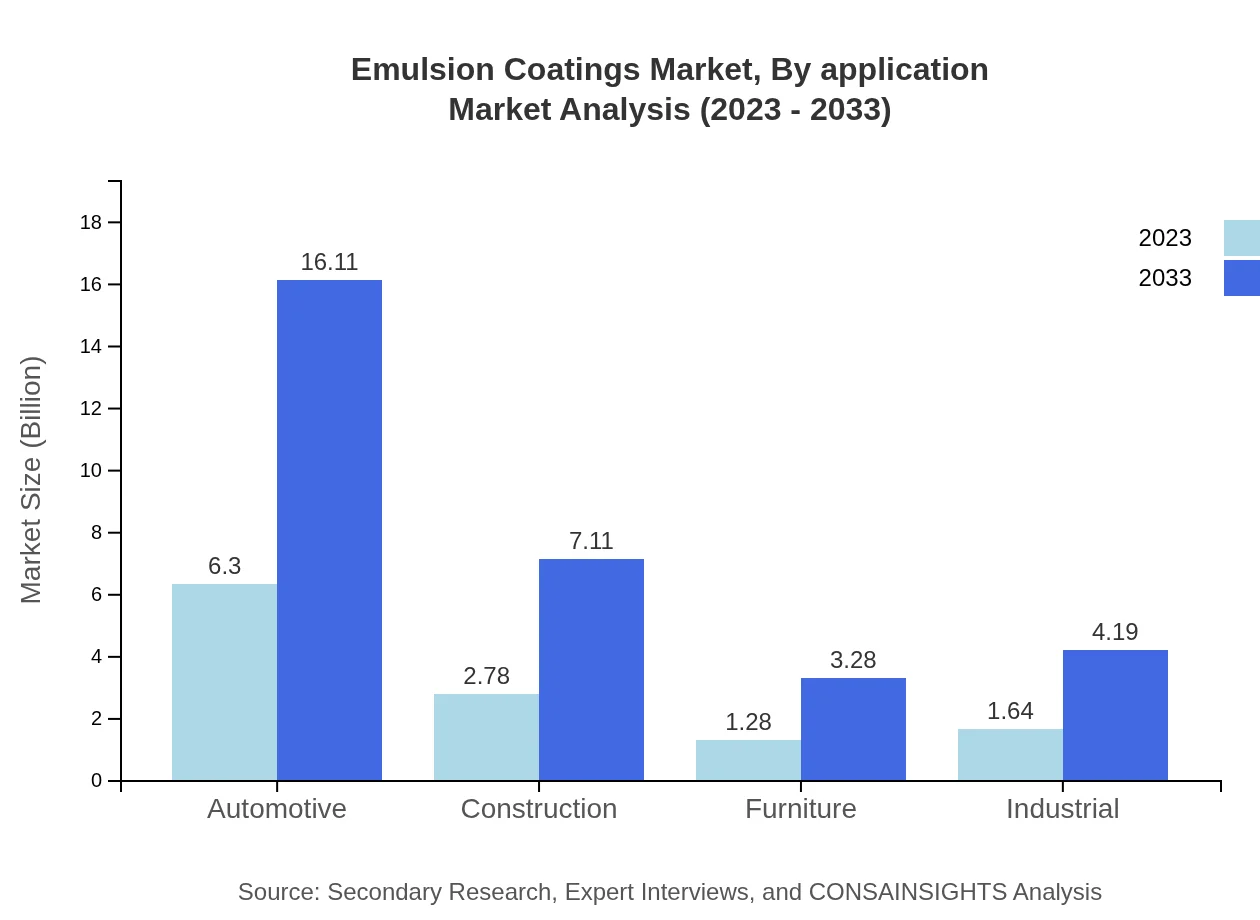

Emulsion Coatings Market Analysis By Application

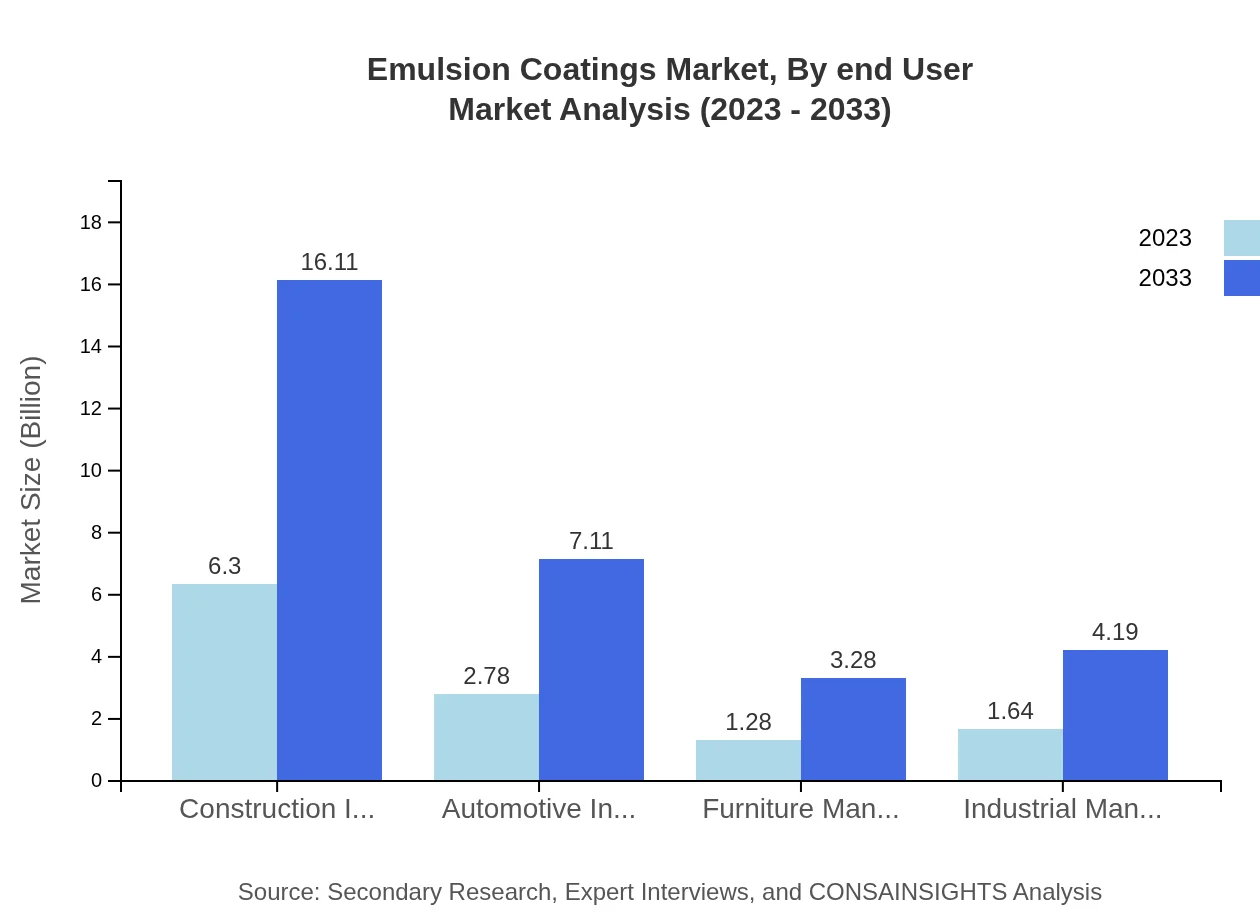

The construction industry heavily utilizes Emulsion Coatings, holding a market size of $6.30 billion in 2023 and expected to increase to $16.11 billion by 2033, maintaining a constant share of 52.49%. Other applications, such as automotive and furniture manufacturing, also show strong growth trajectories.

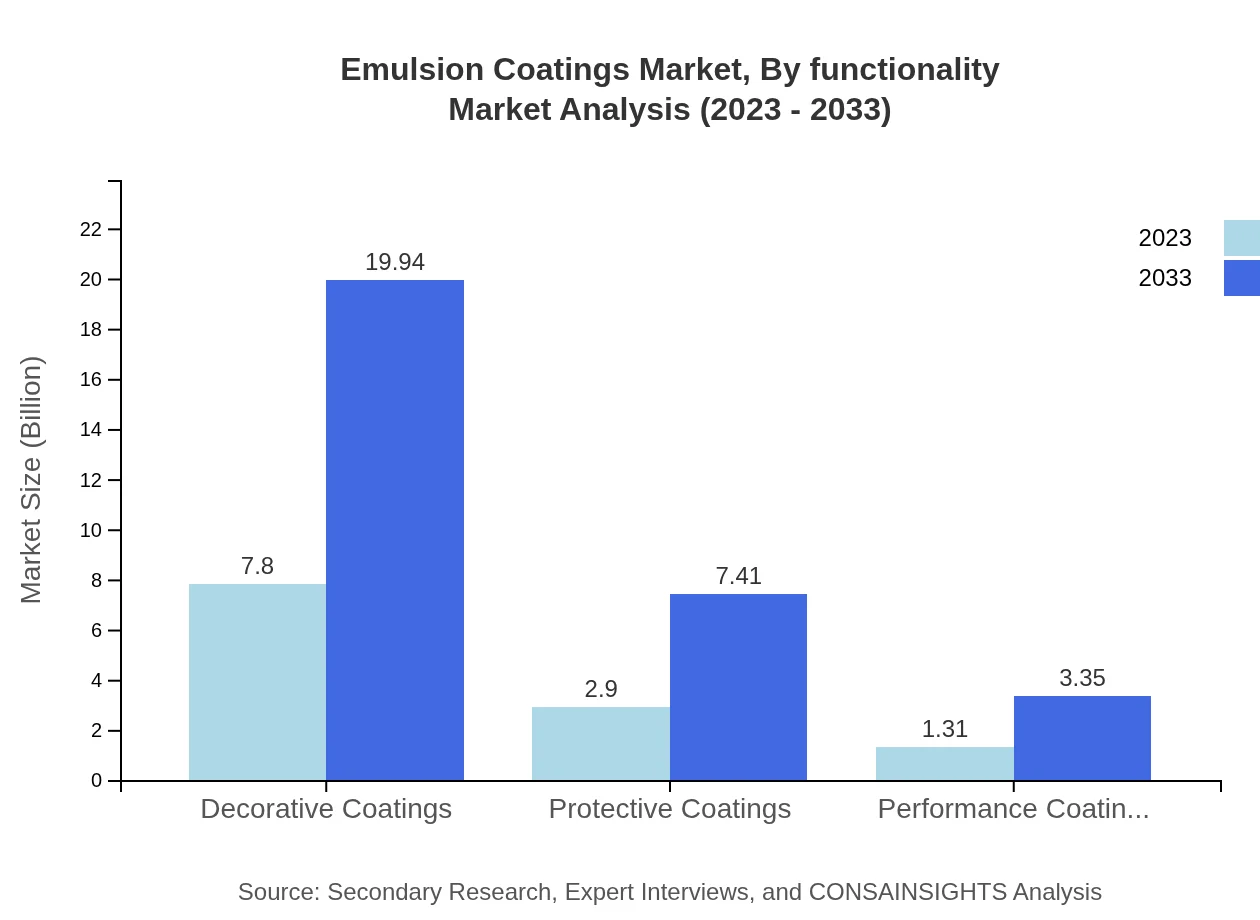

Emulsion Coatings Market Analysis By Functionality

The demand for functional coatings in the Emulsion Coatings sector is growing, particularly for protective and decorative purposes. Protective coatings are worth $2.90 billion in 2023 and expected to grow to $7.41 billion by 2033. Decorative coatings, essential in the residential and commercial sectors, are seeing similar growth patterns.

Emulsion Coatings Market Analysis By End User

Key end-users of Emulsion Coatings include the construction, automotive, and furniture manufacturing sectors. The construction industry heavily influences market trends, with projected growth rates reflecting continuous investment in infrastructure and housing projects.

Emulsion Coatings Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Emulsion Coatings Industry

Axalta Coating Systems:

A leader in world-class advanced coatings, Axalta specializes in high-performance coating solutions across various industries including automotive and general industrial.PPG Industries, Inc.:

PPG is a global supplier of paints, coatings, and specialty materials, committed to innovative solutions and sustainability in the coatings sector.Sherwin-Williams Company:

Sherwin-Williams provides a wide range of protective and decorative coatings, with a focus on high-quality, sustainable products for multiple applications.BASF SE:

As one of the largest chemical producers globally, BASF provides innovative emulsion coatings and is at the forefront of research and development in coating technology.We're grateful to work with incredible clients.

FAQs

What is the market size of emulsion coatings?

The global emulsion coatings market is projected to reach $12 billion by 2033, growing at a CAGR of 9.5%. This growth indicates a robust demand across various sectors due to the evolving demand for eco-friendly coating solutions.

What are the key market players or companies in the emulsion coatings industry?

Key players in the emulsion coatings market include BASF, AkzoNobel, Sherwin-Williams, Dow, and PPG Industries. These companies lead through product innovation, sustainability initiatives, and expanding applications, catering to construction, automotive, and industrial sectors.

What are the primary factors driving the growth in the emulsion coatings industry?

The growth of the emulsion coatings industry is driven by the increasing demand for eco-friendly coatings, growth in the construction and automotive sectors, and technological advancements in formulation techniques. Rising environmental regulations also play a significant role in this growth.

Which region is the fastest Growing in the emulsion coatings?

North America is the fastest-growing region in the emulsion coatings market, expected to grow from $4.26 billion in 2023 to $10.89 billion by 2033. This growth is spurred by increasing construction activities and consumer demand for durable, sustainable coatings.

Does ConsaInsights provide customized market report data for the emulsion coatings industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs in the emulsion coatings industry. Our bespoke reports include detailed insights and analysis on market trends, competitive landscape, and growth forecasts.

What deliverables can I expect from this emulsion coatings market research project?

From the emulsion coatings market research project, you can expect comprehensive reports detailing market size, trends, growth projections, competitive analysis, and segment-specific data, including regional insights and key players overview.

What are the market trends of emulsion coatings?

Current trends in the emulsion coatings market include a shift towards water-based formulations, increased adoption of sustainable products, and growing investments in R&D for innovative coating solutions that meet regulatory standards.