Force Sensors Market Report

Published Date: 31 January 2026 | Report Code: force-sensors

Force Sensors Market Size, Share, Industry Trends and Forecast to 2033

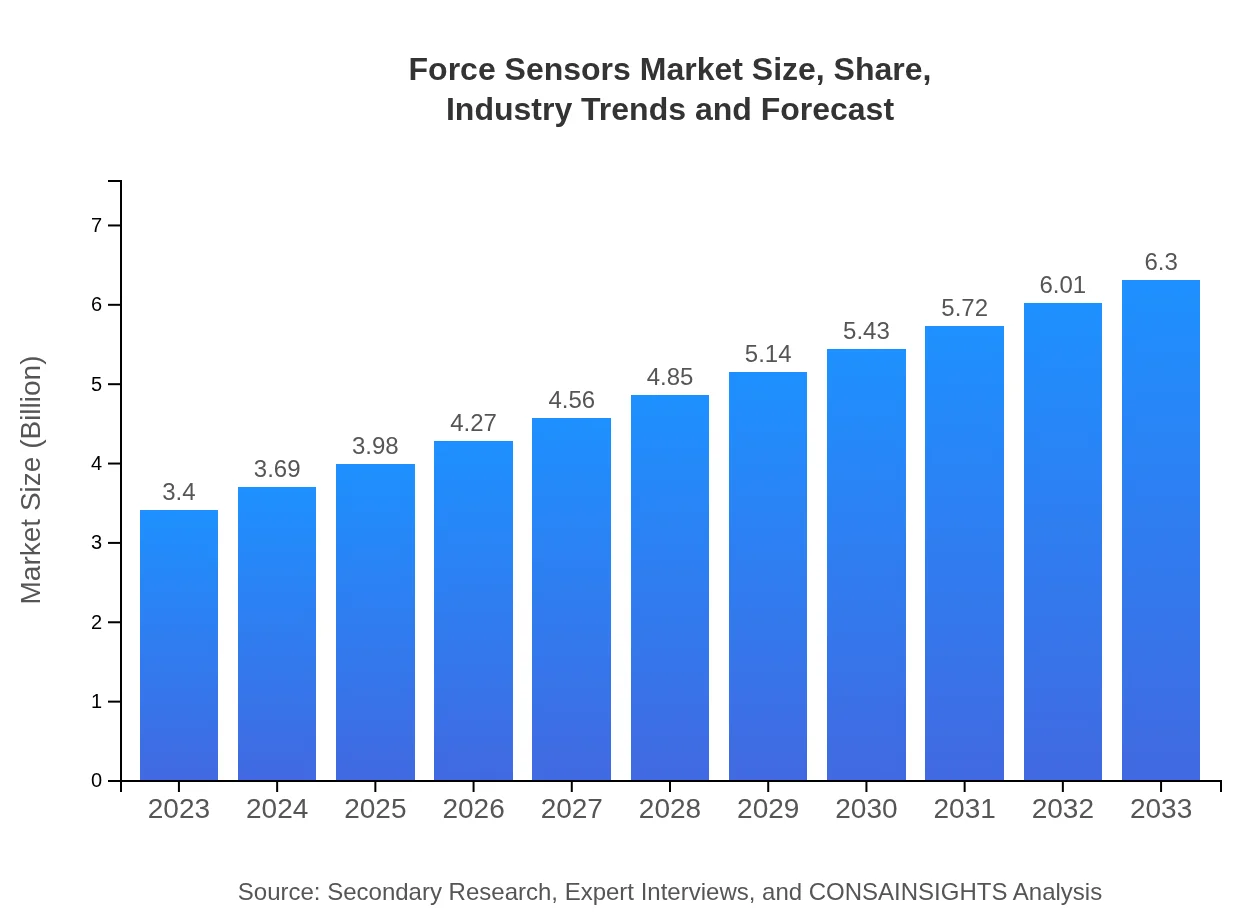

This report provides a comprehensive analysis of the Force Sensors market, detailing current conditions, future forecasts from 2023 to 2033, and insights into market size, trends, and regional performance.

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $3.40 Billion |

| CAGR (2023-2033) | 6.2% |

| 2033 Market Size | $6.30 Billion |

| Top Companies | TE Connectivity, Honeywell International Inc., Futek Advanced Sensor Technology, Inc., Omega Engineering |

| Last Modified Date | 31 January 2026 |

Force Sensors Market Overview

Customize Force Sensors Market Report market research report

- ✔ Get in-depth analysis of Force Sensors market size, growth, and forecasts.

- ✔ Understand Force Sensors's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Force Sensors

What is the Market Size & CAGR of Force Sensors market in 2023?

Force Sensors Industry Analysis

Force Sensors Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Force Sensors Market Analysis Report by Region

Europe Force Sensors Market Report:

Europe's Force Sensors market, valued at 0.94 billion in 2023, is expected to rise to 1.75 billion by 2033. An emphasis on accuracy and safety in automotive and manufacturing processes contributes to the steady demand for force sensors in this region.Asia Pacific Force Sensors Market Report:

The Asia Pacific region is forecasted to experience substantial growth, with the market size expanding from 0.70 billion in 2023 to 1.30 billion by 2033. This growth is driven primarily by rapid industrialization, increased adoption of automation in manufacturing, and technological advancements particularly in countries like China and Japan.North America Force Sensors Market Report:

North America is predicted to showcase a significant market increase from 1.19 billion in 2023 to 2.20 billion by 2033, fueled by advancements in industrial automation, automotive sectors, and a growing focus on research and technology development.South America Force Sensors Market Report:

The South American market for Force Sensors, estimated at 0.31 billion in 2023, is projected to grow to 0.57 billion by 2033. Factors contributing to this growth include expanding sectors like agriculture and manufacturing, driving the demand for precision measurement tools.Middle East & Africa Force Sensors Market Report:

The Middle East and Africa region's market for Force Sensors is relatively smaller, starting at 0.26 billion in 2023 and growing to 0.48 billion by 2033. Growth is primarily due to increasing industrial activities and the need for modernized measurement technologies.Tell us your focus area and get a customized research report.

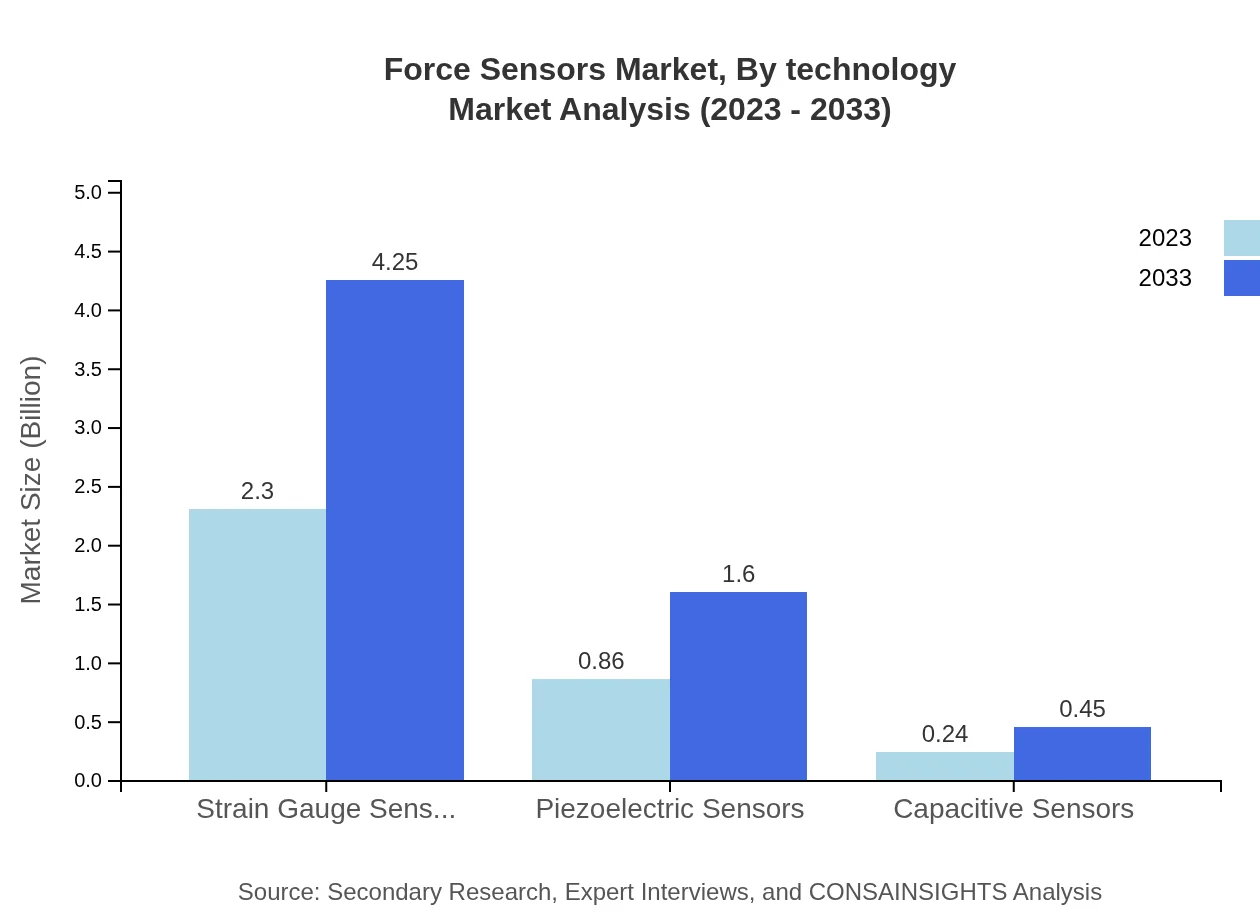

Force Sensors Market Analysis By Technology

The Force Sensors market by technology is led by metal-based sensors, which hold a dominant share of 67.51% as of 2023 and are projected to continue leading through to 2033. Strain gauge sensors also represent a significant segment, showcasing robust growth due to their extensive applications in industrial settings. Piezoelectric and capacitive sensors, while smaller in market size (representing shares of 25.34% and 7.15% respectively in 2023), are gradually increasing in importance, particularly in applications requiring compact and lightweight solutions.

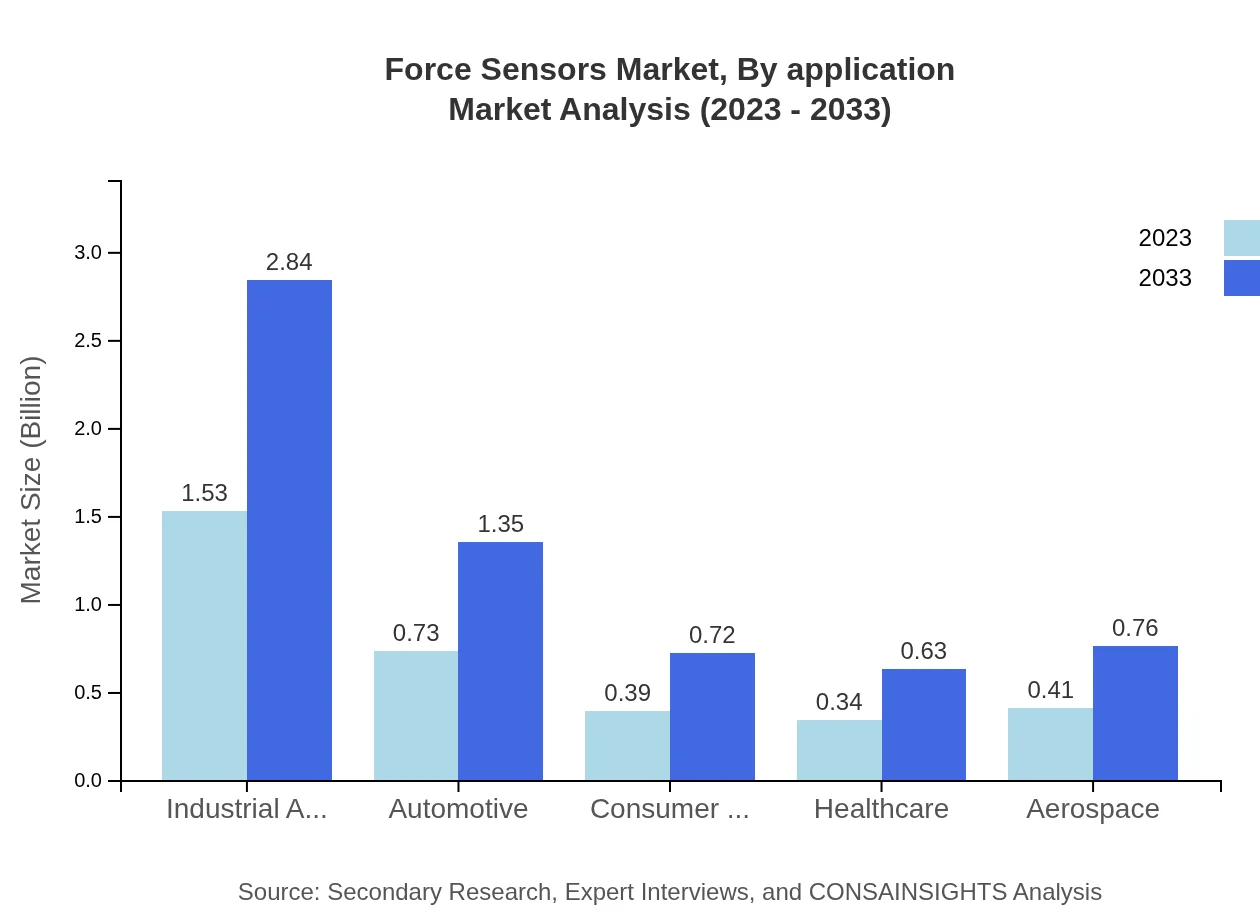

Force Sensors Market Analysis By Application

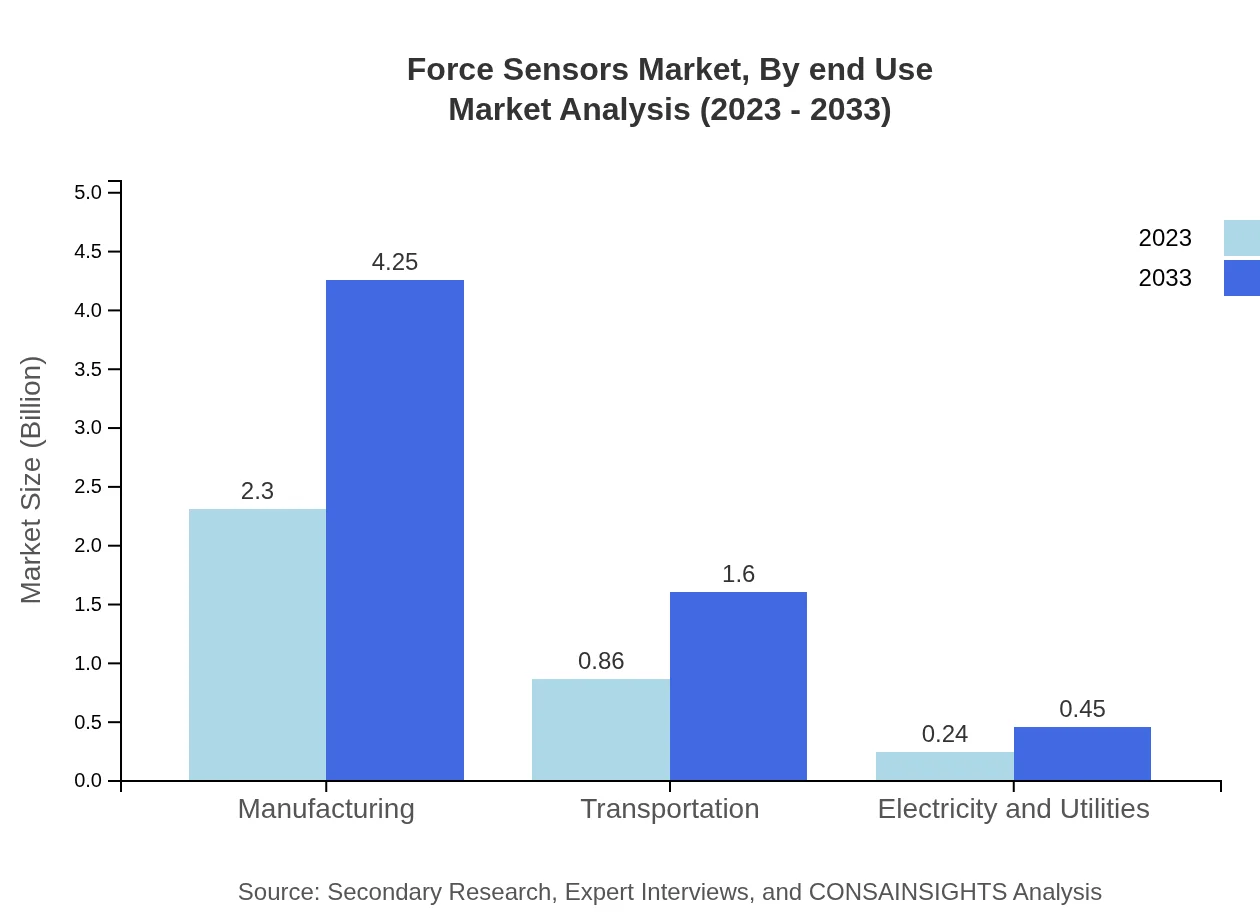

In the application segment of the Force Sensors market, manufacturing leads with a market size of 2.30 billion in 2023, expected to reach 4.25 billion by 2033. The transportation sector follows, reflecting a growing need for sensors in vehicle safety and automation, with market sizes projected at 0.86 billion in 2023 and 1.60 billion in 2033. Other notable segments include industrial automation and healthcare, which continue to expand their applications in precision measurement.

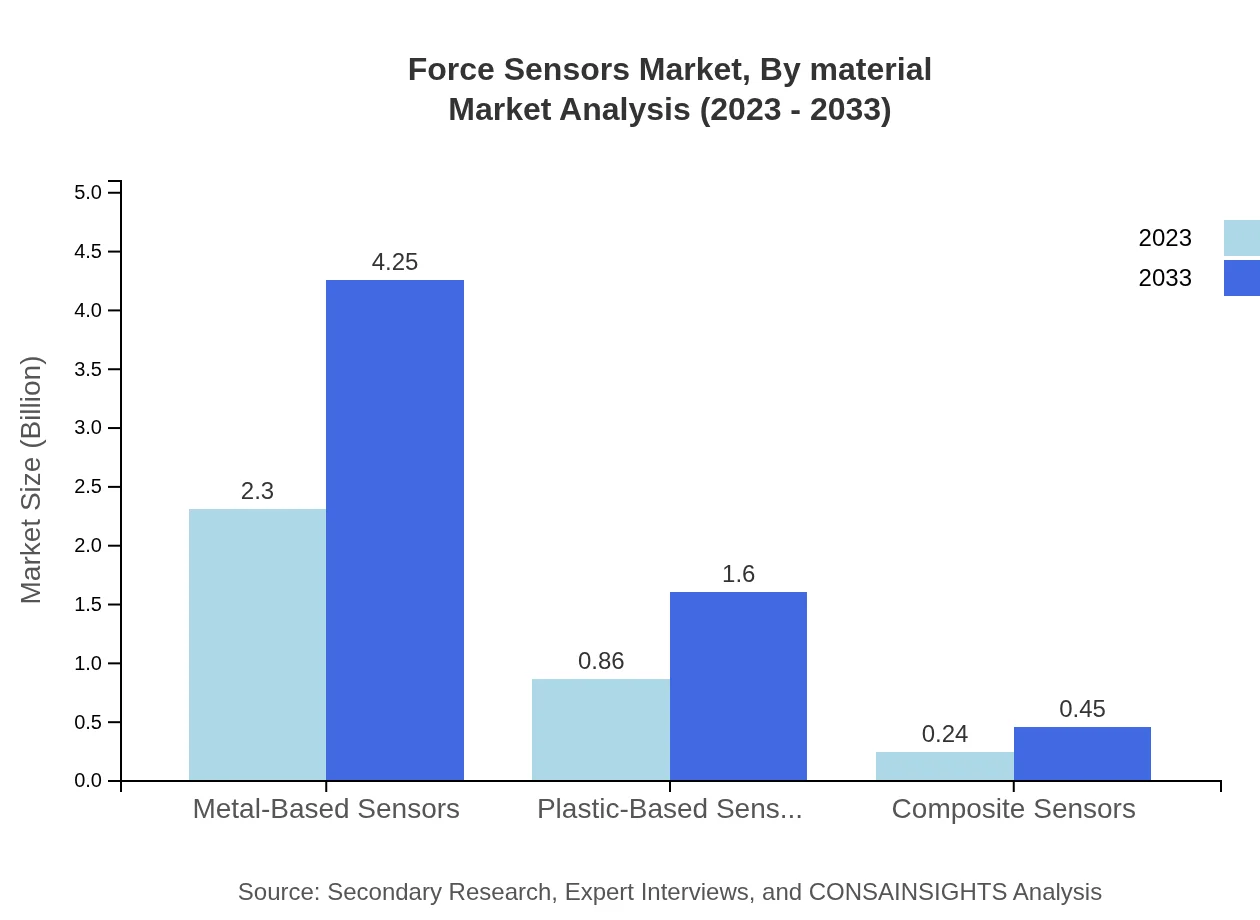

Force Sensors Market Analysis By Material

The material segmentation shows that metal-based sensors dominate the market, projected to remain significant due to their durability and applicability across various sectors. In 2023, metal-based sensors are valued at 2.30 billion, maintaining a share of 67.51%. Plastic-based sensors are also a key segment representing 25.34% of the market share, while composite materials play a niche role, valued at 0.24 billion with a share of 7.15%.

Force Sensors Market Analysis By End Use

The market analysis by end-use industry highlights that industrial automation is a significant driver, with a market size of 1.53 billion in 2023 expected to grow to 2.84 billion by 2033. The automotive sector shows promising growth potential, with forecasted increases in sensor application for vehicle safety systems. The healthcare and aerospace sectors also contribute appreciably, although they represent smaller market sizes comparatively.

Force Sensors Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Force Sensors Industry

TE Connectivity:

TE Connectivity is a leading provider of electronic components and sensors, offering a broad range of Force Sensors used in diverse applications across automotive and industrial automation sectors.Honeywell International Inc.:

Honeywell is a key player in sensor technologies, developing advanced force sensors that are essential in applications like robotics, aerospace, and medical devices.Futek Advanced Sensor Technology, Inc.:

Futek specializes in providing high-quality force and load sensors ideal for industrial and OEM applications, renowned for precision and reliability.Omega Engineering:

Omega offers a wide array of Force Sensors, known for their accuracy and robustness, serving various industries including manufacturing and healthcare.We're grateful to work with incredible clients.

FAQs

What is the market size of force Sensors?

The global force sensors market is projected to reach $3.4 billion by 2033, growing at a CAGR of 6.2%. This growth reflects significant advances in technology and increasing applications across various industries.

What are the key market players or companies in the force Sensors industry?

Key players in the force sensors market include major corporations like Honeywell,TE Connectivity, and Flintec. These companies lead in innovation and hold substantial market shares, contributing to the industry's overall growth and technological advancements.

What are the primary factors driving the growth in the force sensors industry?

Key growth drivers include increased adoption in industrial automation, demand for enhanced safety in transportation, and the rising need for precision in healthcare applications. Additionally, advances in sensor technology are boosting market expansion.

Which region is the fastest Growing in the force sensors market?

The Asia-Pacific region is the fastest-growing market for force sensors, expected to reach $1.30 billion by 2033, up from $0.70 billion in 2023. This growth is driven by rapid industrialization and increasing investments in automation.

Does ConsaInsights provide customized market report data for the force Sensors industry?

Yes, ConsaInsights offers tailored market report data for the force sensors industry. Custom reports can focus on specific segments or regions, addressing unique requirements and providing comprehensive insights.

What deliverables can I expect from this force Sensors market research project?

Deliverables include a detailed report with market size, segment analysis, competitive landscape, and key trends. The report will also provide forecasts and actionable insights tailored to the client's needs.

What are the market trends of the force sensors industry?

Current trends include the increasing integration of force sensors in IoT applications, growing demand for miniaturized sensors, and advancements in wireless technology, enhancing the capabilities and applications of force sensors.