Linear Motion System Market Report

Published Date: 22 January 2026 | Report Code: linear-motion-system

Linear Motion System Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the Linear Motion System market from 2023 to 2033, presenting key insights into market size, growth trends, segmentation, regional analysis, and forecasts, helping stakeholders make informed decisions.

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

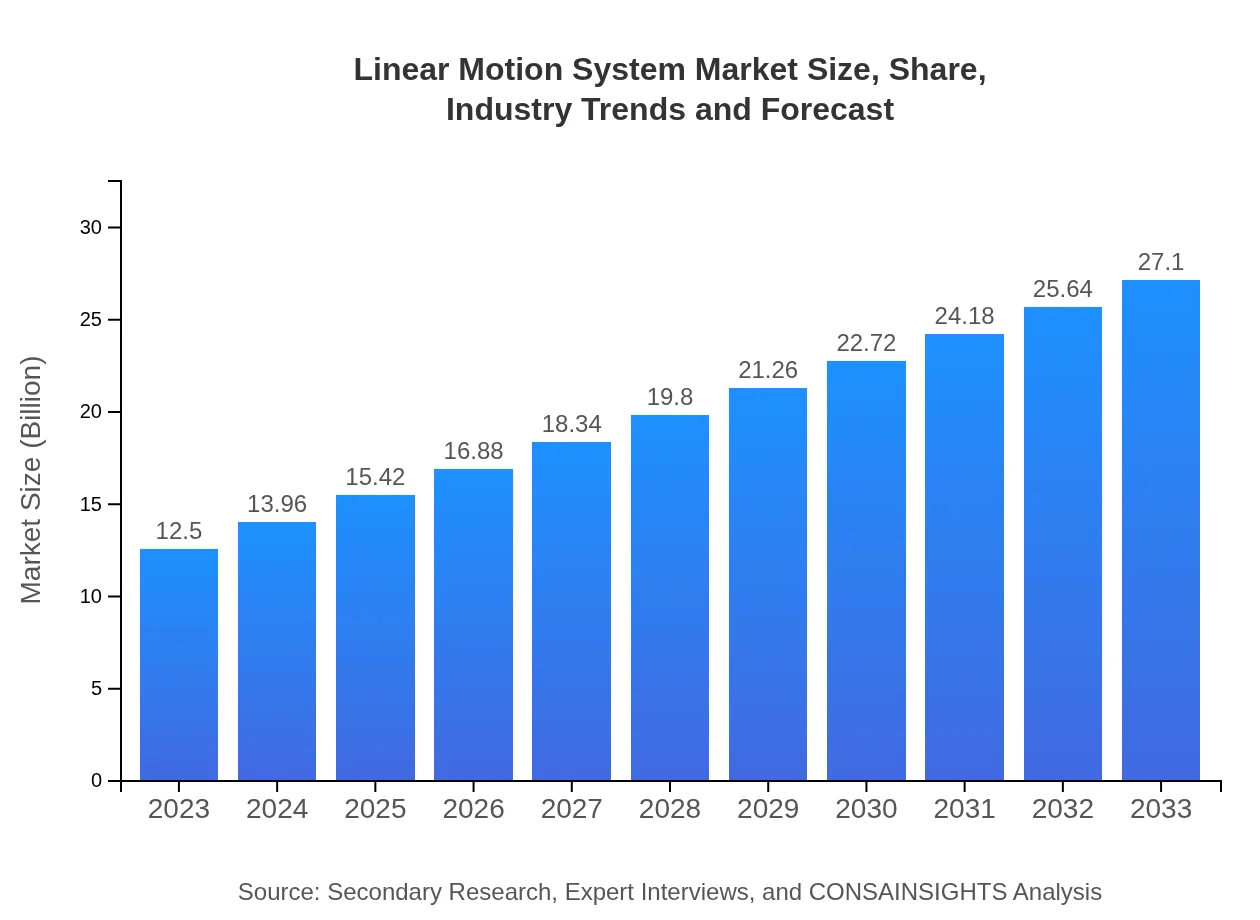

| 2023 Market Size | $12.50 Billion |

| CAGR (2023-2033) | 7.8% |

| 2033 Market Size | $27.10 Billion |

| Top Companies | THK Co., Ltd., Bosch Rexroth AG, Parker Hannifin Corporation, Schaeffler AG |

| Last Modified Date | 22 January 2026 |

Linear Motion System Market Overview

Customize Linear Motion System Market Report market research report

- ✔ Get in-depth analysis of Linear Motion System market size, growth, and forecasts.

- ✔ Understand Linear Motion System's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Linear Motion System

What is the Market Size & CAGR of Linear Motion System market in 2023?

Linear Motion System Industry Analysis

Linear Motion System Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Linear Motion System Market Analysis Report by Region

Europe Linear Motion System Market Report:

In Europe, the market is estimated at $3.10 billion in 2023 and is anticipated to reach $6.71 billion by 2033, driven by stringent regulations on automation and efficiency in manufacturing processes.Asia Pacific Linear Motion System Market Report:

In 2023, the Asia Pacific region accounts for a market size of $2.60 billion, projected to grow to $5.63 billion by 2033, driven by industrialization and increasing automation in countries like China and India.North America Linear Motion System Market Report:

North America holds a significant share with a market size of $4.58 billion in 2023, set to expand to $9.92 billion by 2033, due to high adoption of advanced technologies and automation in various sectors.South America Linear Motion System Market Report:

The South American market is relatively smaller, with a size of $1.19 billion in 2023, expected to reach $2.58 billion by 2033, primarily fueled by growth in construction and manufacturing industries.Middle East & Africa Linear Motion System Market Report:

The Middle East and Africa market is projected to grow from $1.04 billion in 2023 to $2.25 billion by 2033, with rising investments in infrastructure and technology contributing to market expansion.Tell us your focus area and get a customized research report.

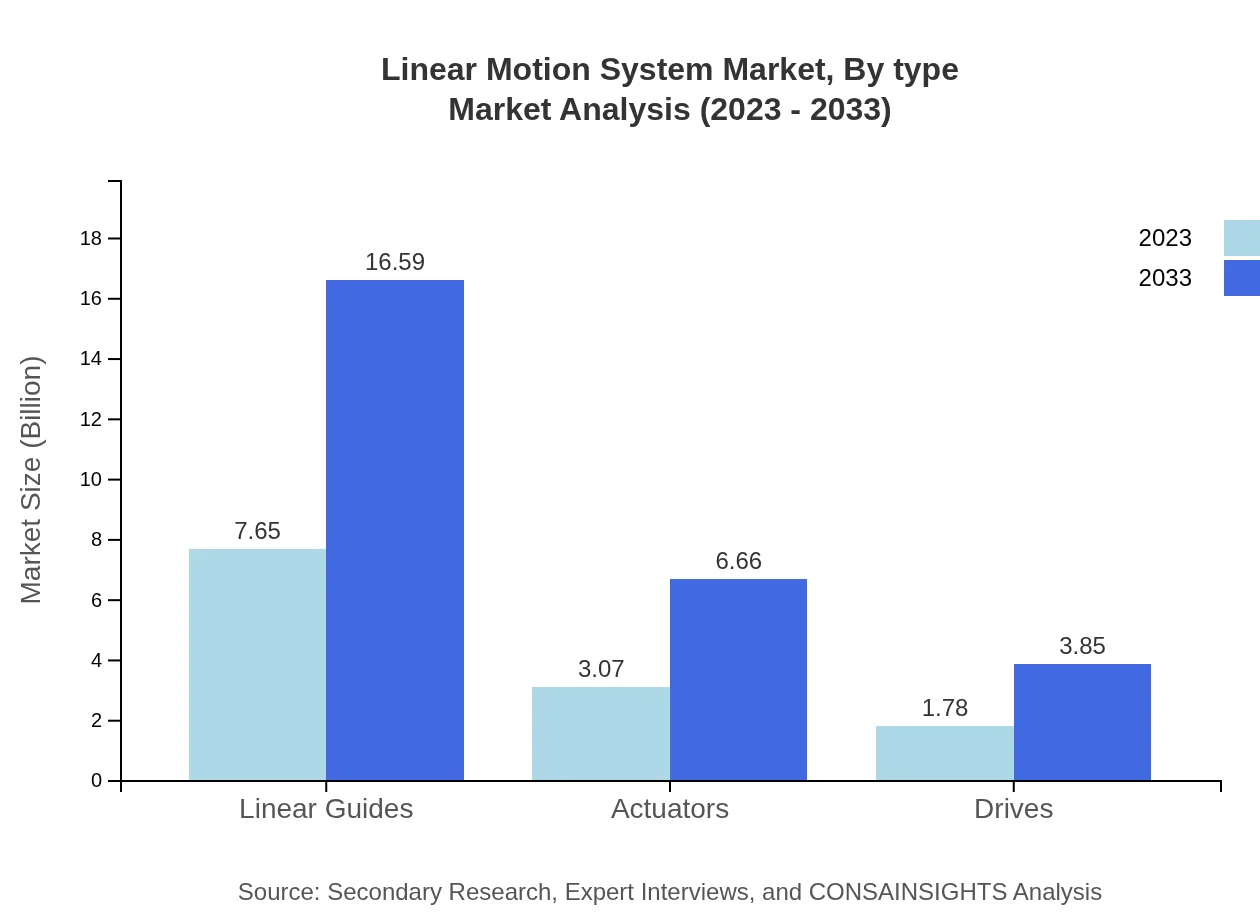

Linear Motion System Market Analysis By Type

The primary segments in this market include Linear Guides, Actuators, and Drives, with linear guides expected to continue dominating the market. In 2023, Linear Guides hold a market size of $7.65 billion, growing to $16.59 billion by 2033. Actuators and Drives follow with significant market shares, reflecting the importance of various motion systems in industrial applications.

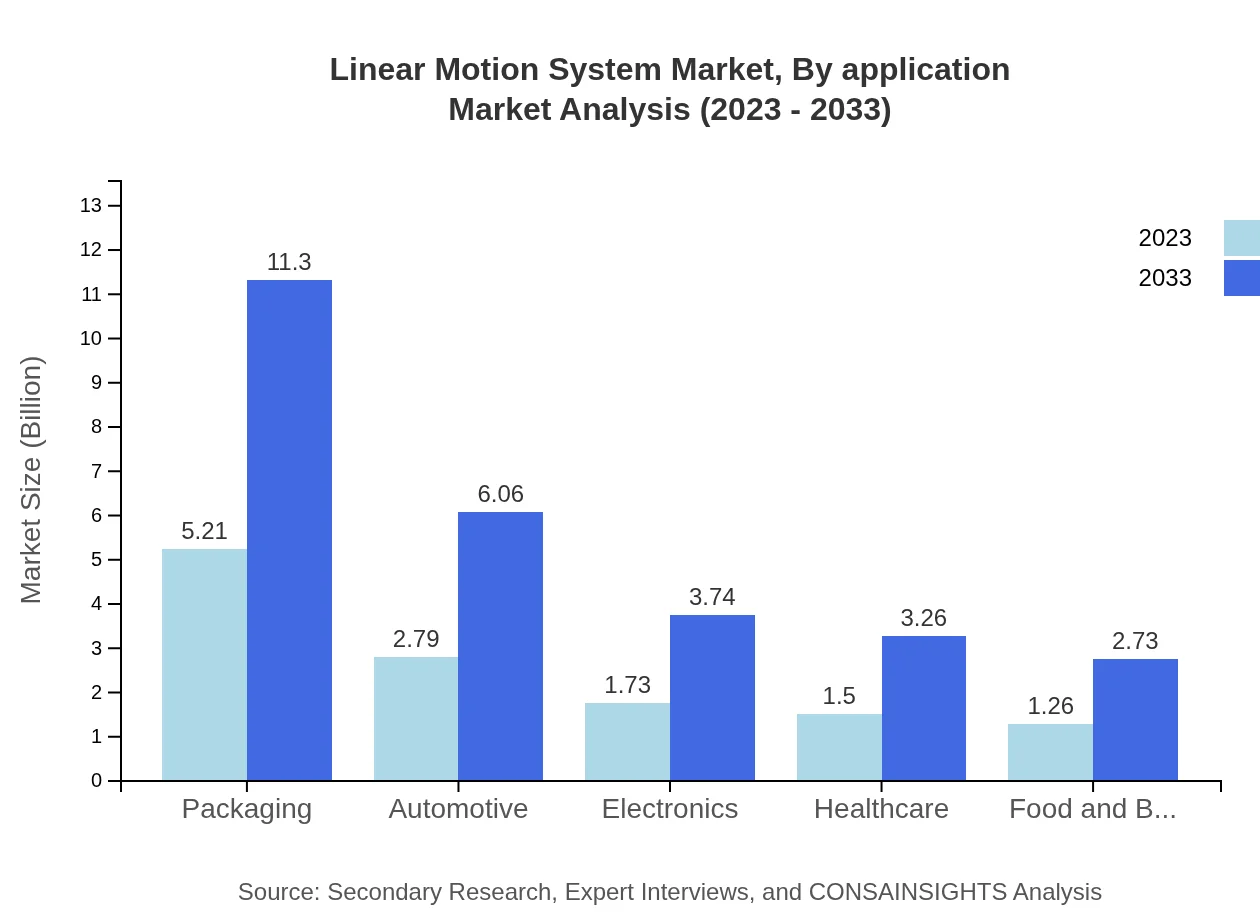

Linear Motion System Market Analysis By Application

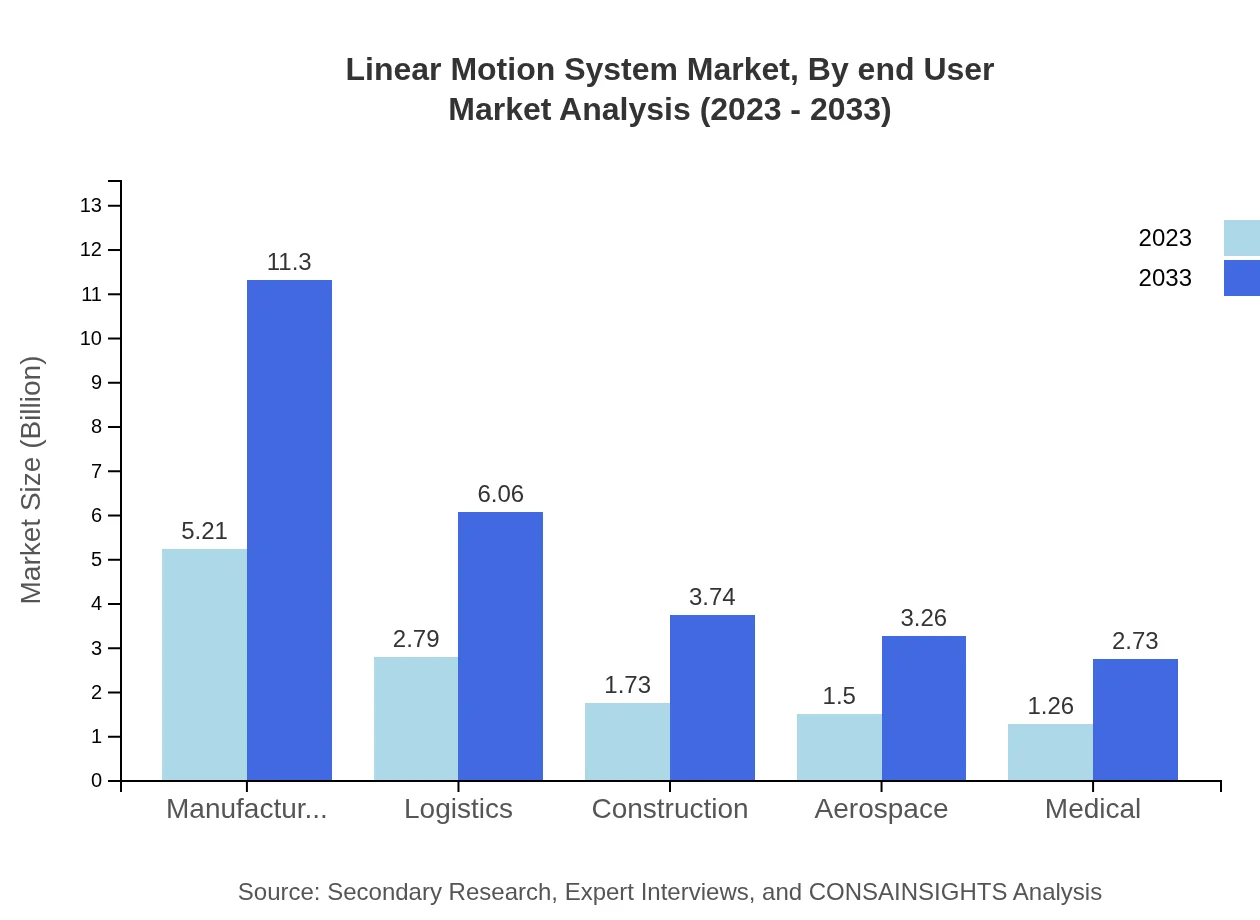

The market is applied across various sectors, including Manufacturing ($5.21 billion in 2023), Automotive ($2.79 billion), and Aerospace ($1.50 billion). Manufacturing leads due to high demand for precision machinery and automation technologies, while the aerospace industry is growing due to increasing reliance on efficient motion systems.

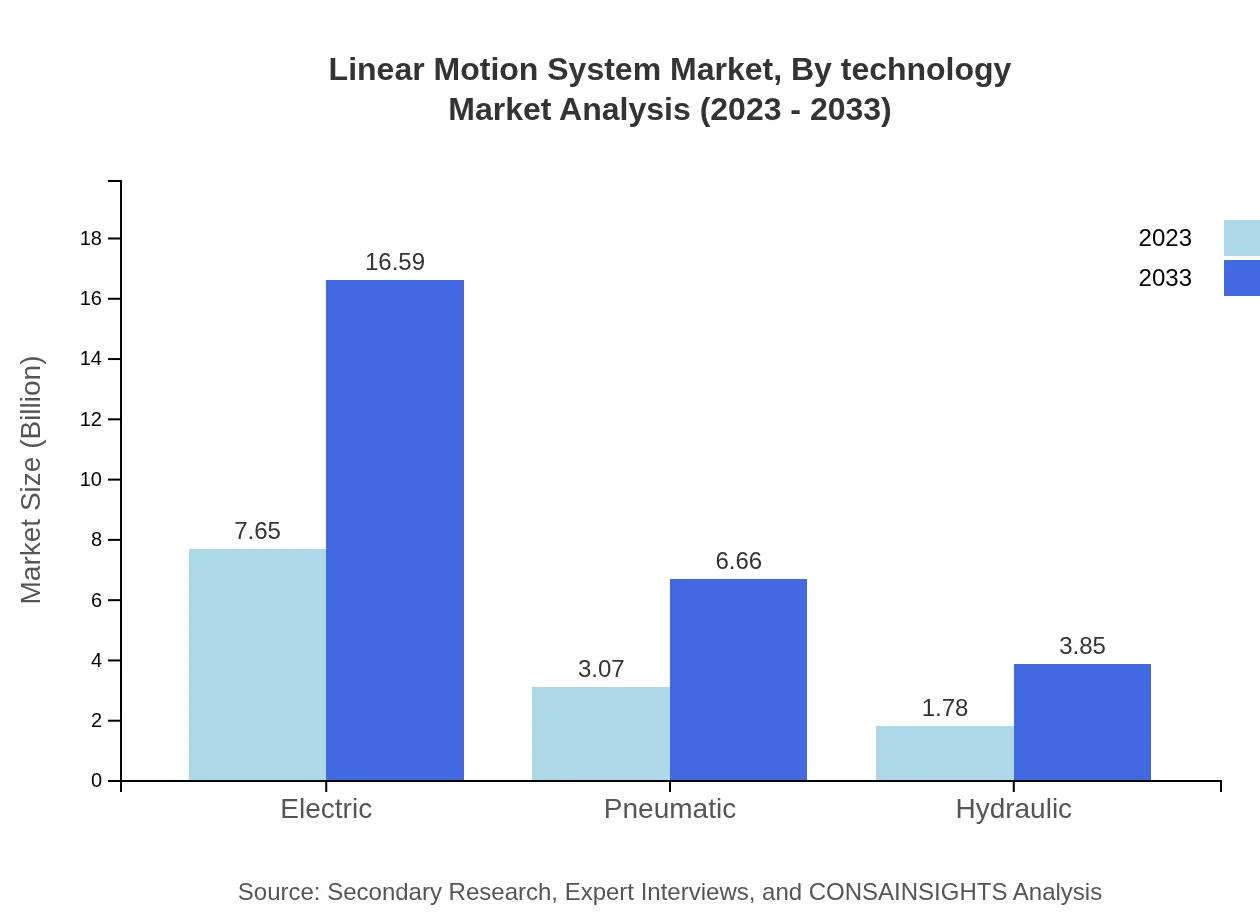

Linear Motion System Market Analysis By Technology

Technology plays a critical role in this market, with trends towards electric, pneumatic, and hydraulic systems. Electric systems dominate in terms of market size and share (61.23%), driven by energy efficiency and precision requirements. Pneumatic systems capture 24.56%, while hydraulic systems hold around 14.21%.

Linear Motion System Market Analysis By End User

The key end-users include industries like Healthcare, Food and Beverage, and Electronics. Each sector exhibits unique requirements, with healthcare utilizing precise automation, and food and beverage focusing on efficient production lines. The Electronics industry, leveraging innovative motion control, is anticipated to grow fast in the forecast period.

Linear Motion System Market Analysis By Design

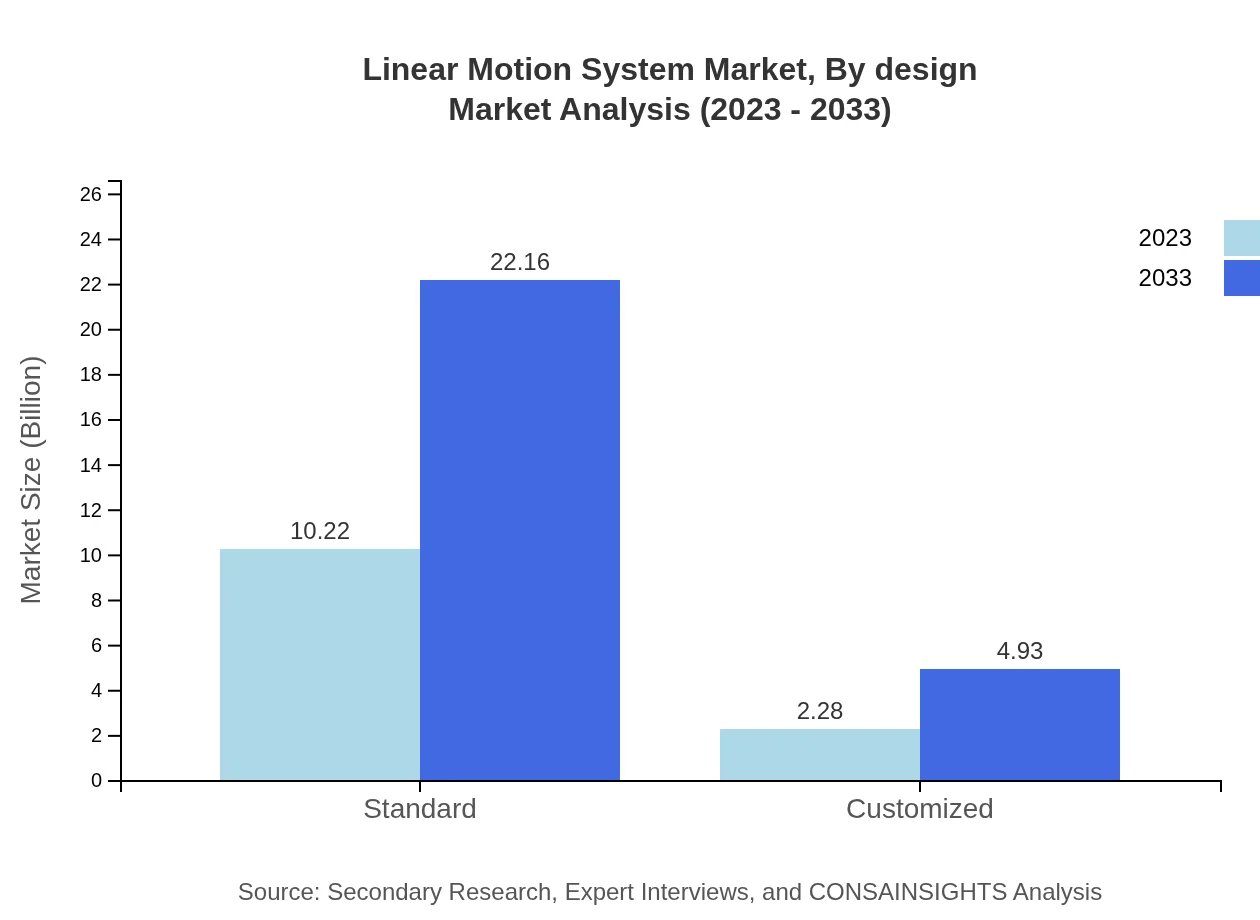

The design aspect focuses on customized versus standardized solutions. Standard designs dominate with an 81.79% market share, reflecting widespread adoption. Nonetheless, customized solutions are growing due to specific industrial requirements, contributing significantly to market dynamics.

Linear Motion System Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Linear Motion System Industry

THK Co., Ltd.:

Leading provider of linear motion systems, THK is renowned for its innovative products that enhance precision and efficiency in various industrial applications.Bosch Rexroth AG:

A key player in automation and motion control, Bosch Rexroth offers a wide range of linear motion systems designed to meet complex customer needs in diverse sectors.Parker Hannifin Corporation:

Parker is recognized for its extensive portfolio in motion control, offering advanced linear actuators and guides that cater to a variety of industries.Schaeffler AG:

Specializing in rolling bearings and linear motion systems, Schaeffler provides high-quality solutions to improve functionality in many applications.We're grateful to work with incredible clients.

FAQs

What is the market size of Linear Motion Systems?

The global Linear Motion System market is projected to grow from $12.5 billion in 2023 to a significant size by 2033, with a Compound Annual Growth Rate (CAGR) of 7.8%. This growth reflects the increasing demand across various industries for precision motion control.

What are the key market players or companies in the Linear Motion Systems industry?

Key players in the Linear Motion Systems industry include major companies such as THK Co. Ltd., Bosch Rexroth AG, and Hiwin Technologies Corp. These companies drive innovation and enhance market competition through advanced technologies and strategic partnerships.

What are the primary factors driving the growth in the Linear Motion Systems industry?

Growth in the Linear Motion Systems industry is driven by technological advancements, increasing automation in manufacturing processes, and rising demand from sectors like aerospace, automotive, and packaging for precise and efficient motion solutions.

Which region is the fastest Growing in the Linear Motion Systems market?

The Asia Pacific region is experiencing rapid growth in the Linear Motion Systems market, expanding from $2.60 billion in 2023 to $5.63 billion by 2033, influenced by increasing industrialization and automation activities in countries like China and India.

Does ConsaInsights provide customized market report data for the Linear Motion Systems industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs in the Linear Motion Systems industry, allowing clients to gain insights that are relevant to their unique market and business requirements.

What deliverables can I expect from this Linear Motion Systems market research project?

From this research project, you can expect detailed reports, market analyses, and forecasts on regional dynamics, competitive landscape, and segment insights, which collectively inform strategic decision-making in the Linear Motion Systems market.

What are the market trends of Linear Motion Systems?

Current trends in the Linear Motion Systems market include increased adoption of electric linear guides due to their efficiency and environmental benefits, as well as innovations in manufacturing processes aimed at enhancing productivity and reducing operational costs.