Long Fiber Thermoplastics Market Report

Published Date: 02 February 2026 | Report Code: long-fiber-thermoplastics

Long Fiber Thermoplastics Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Long Fiber Thermoplastics market, highlighting its current state, future growth prospects, and key trends from 2023 to 2033. It includes insights into market size, segmentation, regional analysis, and profiles of leading companies in the industry.

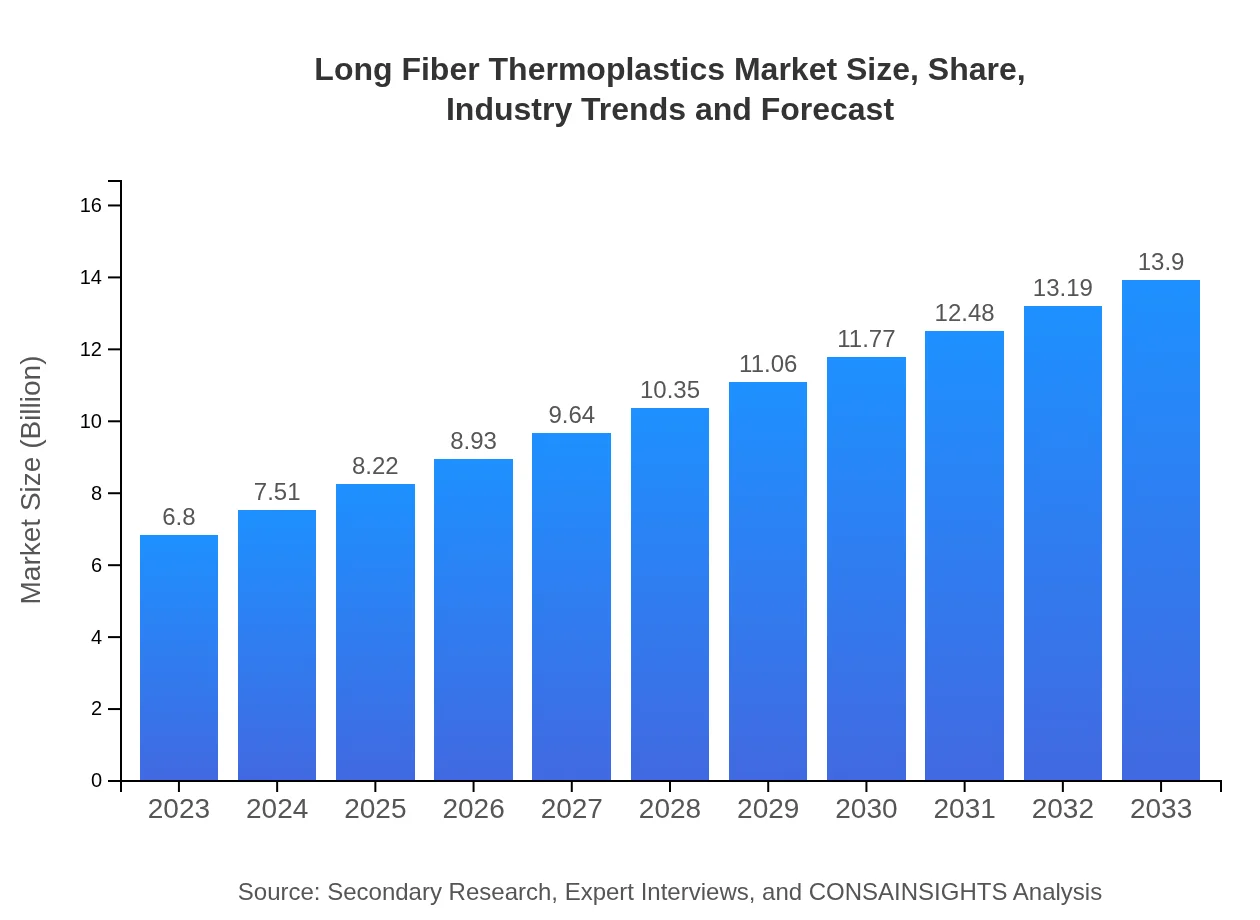

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $6.80 Billion |

| CAGR (2023-2033) | 7.2% |

| 2033 Market Size | $13.90 Billion |

| Top Companies | BASF SE, Toray Industries, Inc., Celanese Corporation, SABIC, DuPont |

| Last Modified Date | 02 February 2026 |

Long Fiber Thermoplastics Market Overview

Customize Long Fiber Thermoplastics Market Report market research report

- ✔ Get in-depth analysis of Long Fiber Thermoplastics market size, growth, and forecasts.

- ✔ Understand Long Fiber Thermoplastics's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Long Fiber Thermoplastics

What is the Market Size & CAGR of Long Fiber Thermoplastics market in 2023?

Long Fiber Thermoplastics Industry Analysis

Long Fiber Thermoplastics Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Long Fiber Thermoplastics Market Analysis Report by Region

Europe Long Fiber Thermoplastics Market Report:

The European market for Long Fiber Thermoplastics is expected to increase from USD 2.37 billion in 2023 to USD 4.85 billion by 2033. The region's emphasis on sustainable development and the adoption of electric vehicles significantly influence market growth, as manufacturers seek lightweight, high-performance materials.Asia Pacific Long Fiber Thermoplastics Market Report:

The Asia Pacific region holds substantial market share in the Long Fiber Thermoplastics industry, projected to grow from USD 1.17 billion in 2023 to USD 2.40 billion by 2033. This growth is propelled by the rapid industrialization in countries like China and India, alongside an increased focus on lightweight materials in automotive and construction sectors.North America Long Fiber Thermoplastics Market Report:

North America is poised to remain a lucrative market, with estimates projecting growth from USD 2.35 billion in 2023 to USD 4.81 billion by 2033. The presence of leading automotive manufacturers in the region drives demand for LFTs, supported by stringent regulations aimed at reducing vehicle weight for improved efficiency.South America Long Fiber Thermoplastics Market Report:

In South America, the market is expected to increase from USD 0.64 billion in 2023 to USD 1.31 billion by 2033. The expanding automotive industry in Brazil and Argentina is a significant contributor, fostering investment in advanced materials that enhance fuel efficiency and reduce emissions.Middle East & Africa Long Fiber Thermoplastics Market Report:

The Middle East and Africa market, while smaller, is anticipated to grow from USD 0.26 billion in 2023 to USD 0.53 billion by 2033. The gradual industrial development and investments in infrastructure projects are likely to open new avenues for LFT applications in the region.Tell us your focus area and get a customized research report.

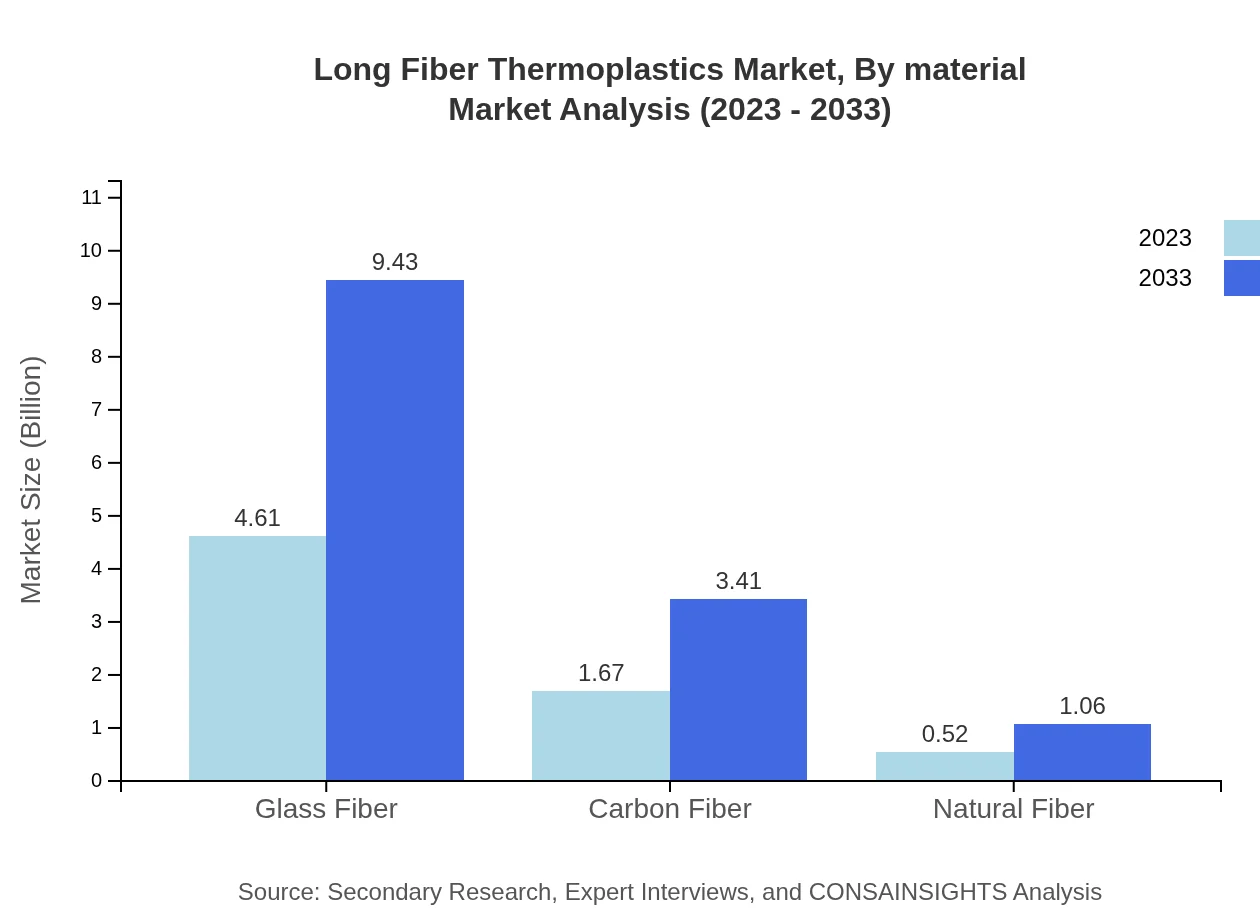

Long Fiber Thermoplastics Market Analysis By Material

The Long Fiber Thermoplastics market is segmented primarily by materials, which include glass fiber, carbon fiber, and natural fiber. Glass fiber dominates the market, representing a size of USD 4.61 billion in 2023 and projected to grow to USD 9.43 billion by 2033, maintaining a consistent market share of 67.81%. Carbon fiber follows, with a size of USD 1.67 billion in 2023 and an expected growth to USD 3.41 billion, holding a 24.53% market share. Natural fiber, while smaller, is anticipated to grow from USD 0.52 billion to USD 1.06 billion, covering 7.66% of the market.

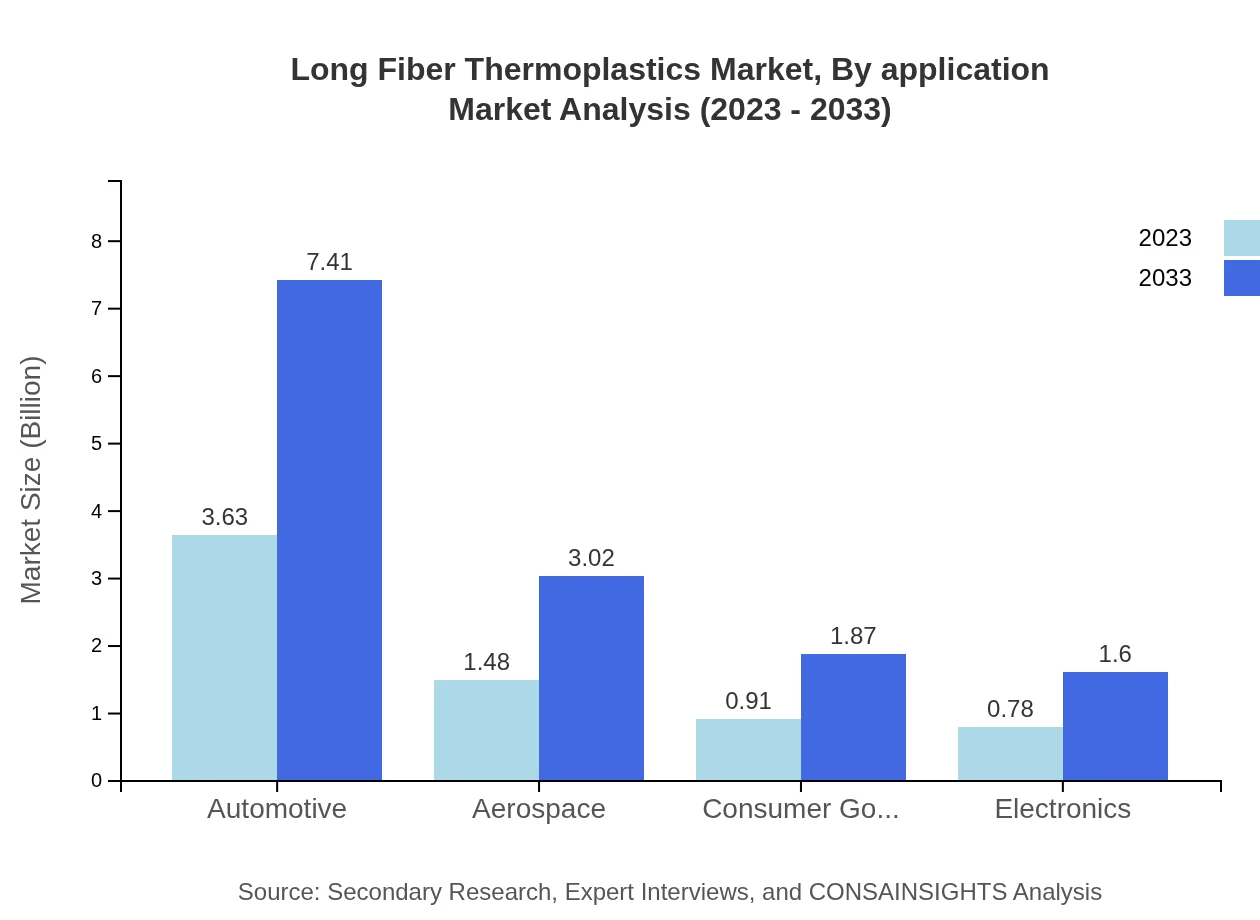

Long Fiber Thermoplastics Market Analysis By Application

Applications for Long Fiber Thermoplastics include automotive, aerospace, consumer goods, electronics, and industrial equipment. The automotive sector is the largest, with a market size of USD 3.63 billion in 2023 and a projected size of USD 7.41 billion by 2033—accounting for 53.33% of the market. Aerospace applications follow, with sizes of USD 1.48 billion and USD 3.02 billion, respectively, holding a 21.71% share. Consumer goods and electronics also play a significant role, with market sizes of USD 0.91 billion and USD 0.78 billion, expanding to USD 1.87 billion and USD 1.60 billion by 2033.

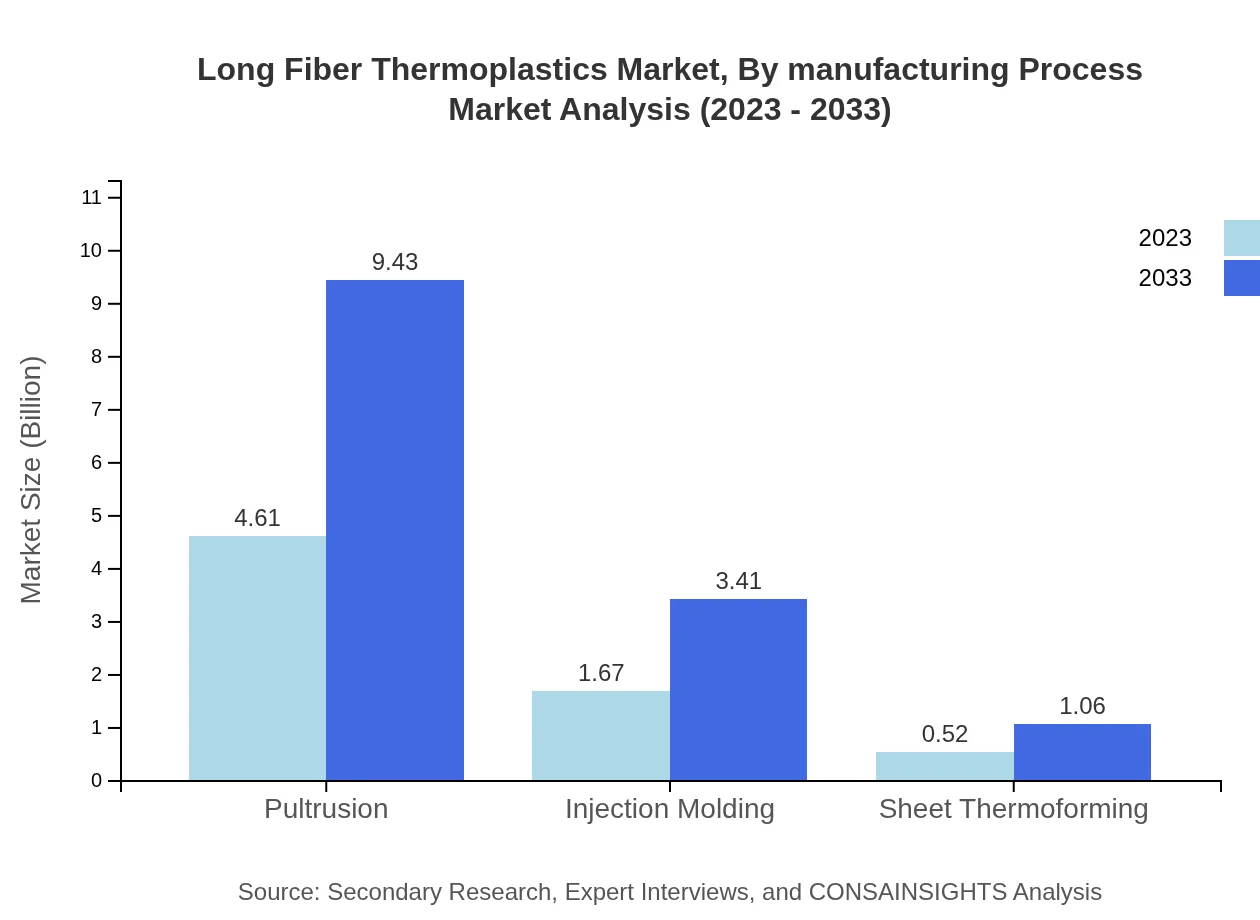

Long Fiber Thermoplastics Market Analysis By Manufacturing Process

Manufacturing processes such as pultrusion and injection molding significantly affect the performance and quality of Long Fiber Thermoplastics. Pultrusion is the predominant process, accounting for USD 4.61 billion in 2023 and projected to rise to USD 9.43 billion by 2033, maintaining a share of 67.81%. Injection molding also contributes significantly, with market sizes of USD 1.67 billion in 2023 and expected growth to USD 3.41 billion, capturing a 24.53% share.

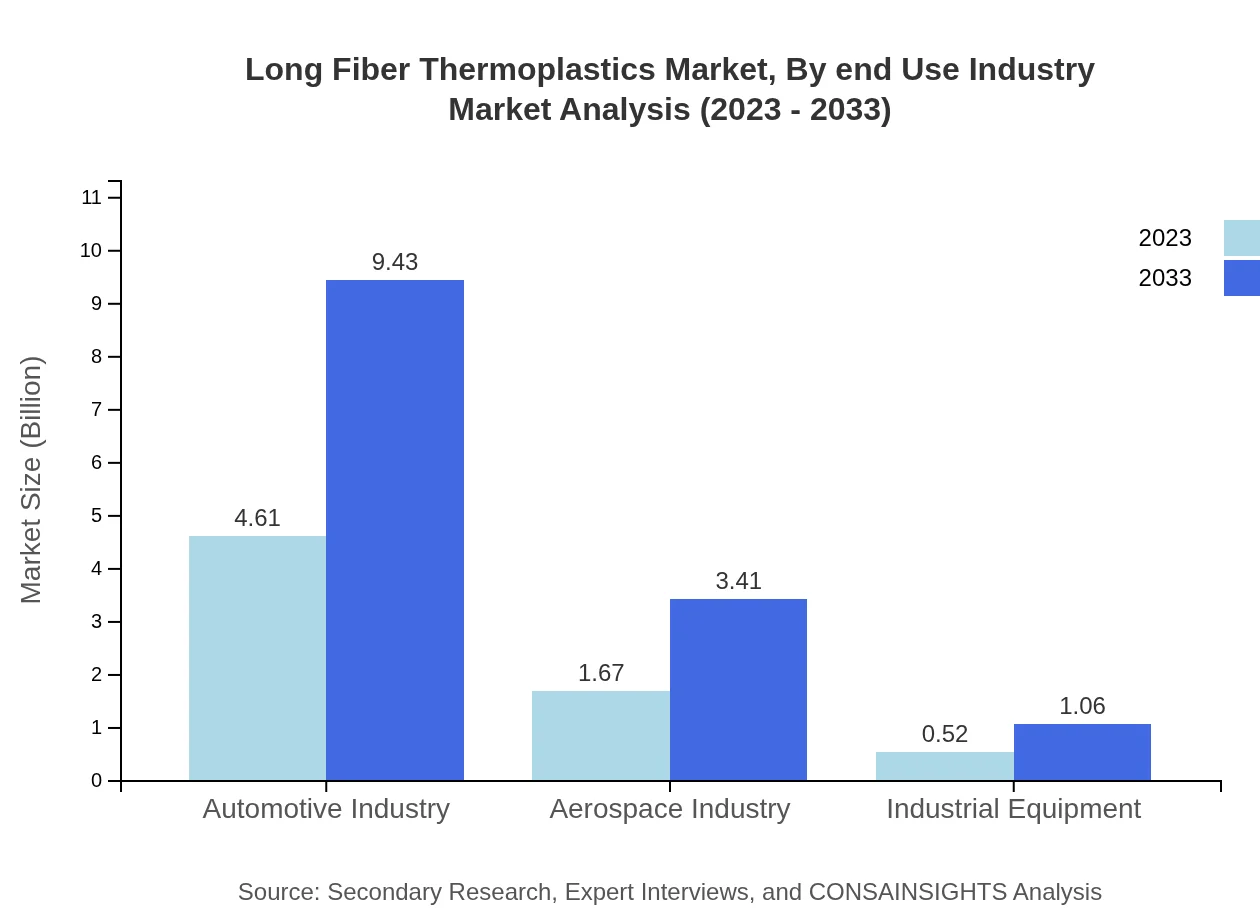

Long Fiber Thermoplastics Market Analysis By End Use Industry

The Long Fiber Thermoplastics market is also analyzed by end-use industries, where automotive dominates with sizes of USD 4.61 billion and USD 9.43 billion from 2023 to 2033, ensuring a 67.81% market share. Aerospace and industrial equipment also have notable sizes, with aerospace growing from USD 1.67 billion to USD 3.41 billion, representing 24.53% of the market. Other sectors like consumer goods and electronics remain relevant, with sizes of USD 0.91 billion and USD 0.78 billion, growing to USD 1.87 billion and USD 1.60 billion respectively.

Long Fiber Thermoplastics Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Long Fiber Thermoplastics Industry

BASF SE:

A leading global chemical company, BASF specializes in producing high-performance thermoplastics, including Long Fiber Thermoplastics, with a strong focus on innovation and sustainability.Toray Industries, Inc.:

Toray is a prominent manufacturer of carbon and composite materials, providing advanced Long Fiber Thermoplastics solutions primarily for the aerospace and automotive sectors.Celanese Corporation:

Celanese is known for its innovative material solutions, actively involved in the development of Long Fiber Thermoplastics aimed at improving the performance of automotive and consumer applications.SABIC:

SABIC is a global leader in diversified chemicals and has developed a range of LFT products for different applications, focusing on enhancing performance and lightweight characteristics.DuPont:

DuPont provides advanced LFT materials with properties tailored to meet the demanding requirements of automotive and industrial applications, driven by extensive research and development efforts.We're grateful to work with incredible clients.

FAQs

What is the market size of long Fiber Thermoplastics?

The global long-fiber thermoplastics market is projected to reach $6.8 billion by 2033, growing at a CAGR of 7.2% from 2023. This indicates significant demand across various applications, driven by the need for lightweight and strong materials.

What are the key market players or companies in this long Fiber Thermoplastics industry?

Key players in the long-fiber thermoplastics market include major manufacturers and suppliers who specialize in composite materials, including companies known for advanced polymers and thermoplastic technologies, ensuring competitive innovations in the industry.

What are the primary factors driving the growth in the long Fiber Thermoplastics industry?

The growth of the long-fiber thermoplastics market is driven by increasing demand in the automotive and aerospace industries, advancements in recycling technologies, and the emphasis on reducing vehicle weight to improve fuel efficiency and lower emissions.

Which region is the fastest Growing in the long Fiber Thermoplastics?

The fastest-growing region in the long-fiber thermoplastics market is Europe, projected to rise from $2.37 billion in 2023 to $4.85 billion by 2033. The region shows robust demand for high-performance materials across various industries.

Does ConsaInsights provide customized market report data for the long Fiber Thermoplastics industry?

Yes, Consainsights offers customized market report data tailored to specific needs within the long-fiber thermoplastics industry, assisting clients in gaining deeper insights into market trends, forecasts, and competitive analysis tailored to their business.

What deliverables can I expect from this long Fiber Thermoplastics market research project?

Deliverables from the market research project include in-depth reports, analysis of market segments, competitive landscape evaluations, and forecasts, providing a comprehensive understanding of market dynamics and strategic opportunities.

What are the market trends of long Fiber Thermoplastics?

Current trends in the long-fiber thermoplastics market include increasing adoption in automotive applications, a shift towards sustainable manufacturing practices, and innovations in composite material technologies, reflecting a growing emphasis on performance and sustainability.