Plastic Adhesives Market Report

Published Date: 02 February 2026 | Report Code: plastic-adhesives

Plastic Adhesives Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the Plastic Adhesives market, covering current trends, growth opportunities, and industry dynamics. Insights into market size, segmentation, and forecasts from 2023 to 2033 are included.

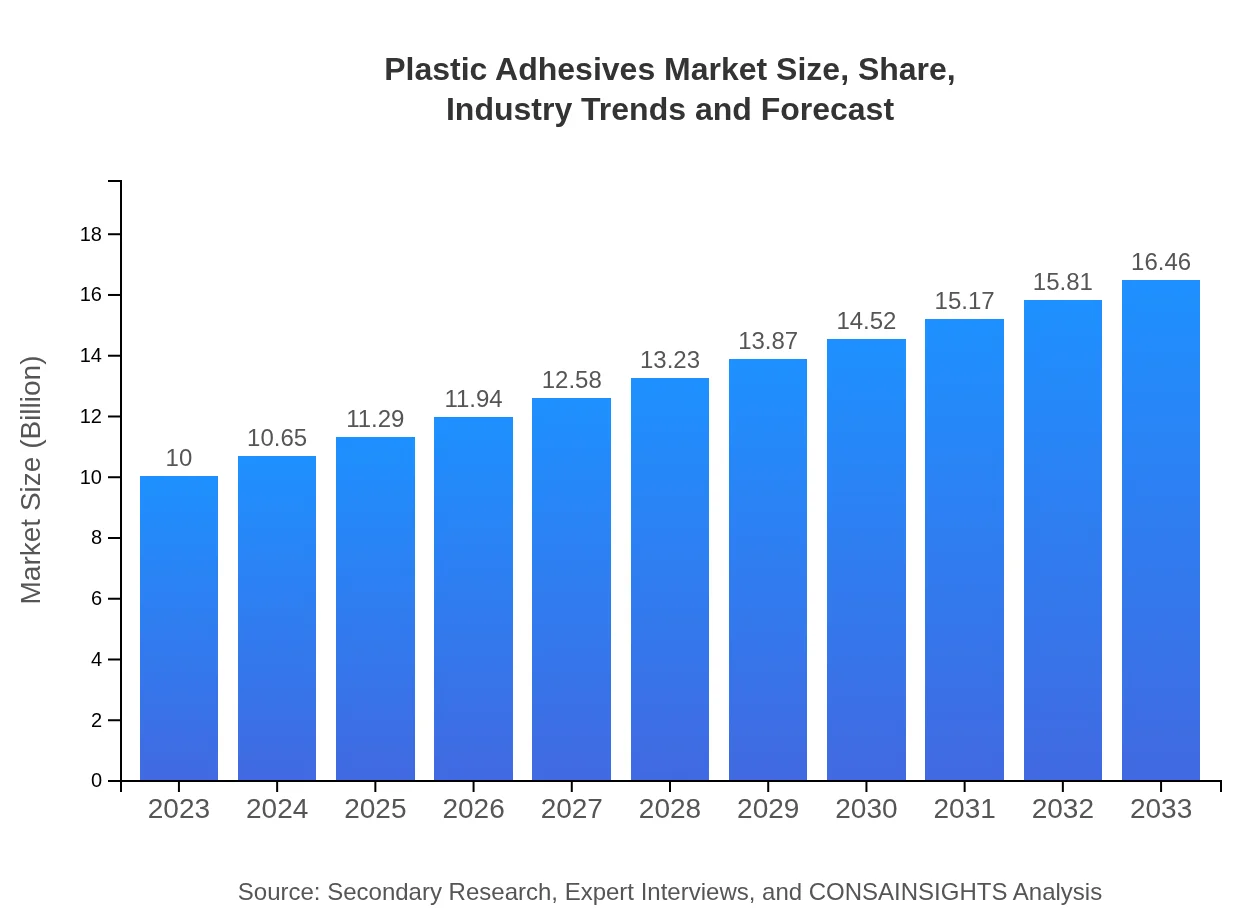

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $10.00 Billion |

| CAGR (2023-2033) | 5% |

| 2033 Market Size | $16.46 Billion |

| Top Companies | Henkel AG, 3M Company, Sika AG, BASF SE |

| Last Modified Date | 02 February 2026 |

Plastic Adhesives Market Overview

Customize Plastic Adhesives Market Report market research report

- ✔ Get in-depth analysis of Plastic Adhesives market size, growth, and forecasts.

- ✔ Understand Plastic Adhesives's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Plastic Adhesives

What is the Market Size & CAGR of Plastic Adhesives market in 2023?

Plastic Adhesives Industry Analysis

Plastic Adhesives Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Plastic Adhesives Market Analysis Report by Region

Europe Plastic Adhesives Market Report:

Europe's market for Plastic Adhesives was valued at $3.50 billion in 2023, projected to rise to $5.77 billion by 2033. The region's stringent regulatory environment is driving innovation in sustainable adhesives, further supported by the growing emphasis on environmentally friendly products.Asia Pacific Plastic Adhesives Market Report:

The Asia Pacific region, with a market size of $1.75 billion in 2023, is projected to grow to $2.88 billion by 2033. This growth is attributed to rising industrial activities, especially in countries like China and India, where manufacturing operations are expanding rapidly. Increased demand for packaging and construction materials further boosts this segment.North America Plastic Adhesives Market Report:

North America holds a significant share of the market with a size of $3.25 billion in 2023, anticipated to grow to $5.36 billion by 2033. The region's strong automotive sector and high demand for durable packaging materials contribute to sustained growth in the market.South America Plastic Adhesives Market Report:

In South America, the Plastic Adhesives market is valued at $0.64 billion in 2023 and is expected to reach $1.05 billion by 2033. Efforts to enhance local manufacturing capabilities and adapt to market needs create growth opportunities for adhesive products in key sectors.Middle East & Africa Plastic Adhesives Market Report:

In the Middle East and Africa, the Plastic Adhesives market is anticipated to grow from $0.86 billion in 2023 to $1.41 billion by 2033. The region is focusing on advancements in construction technology, which along with rising urbanization, creates a burgeoning market for adhesive solutions.Tell us your focus area and get a customized research report.

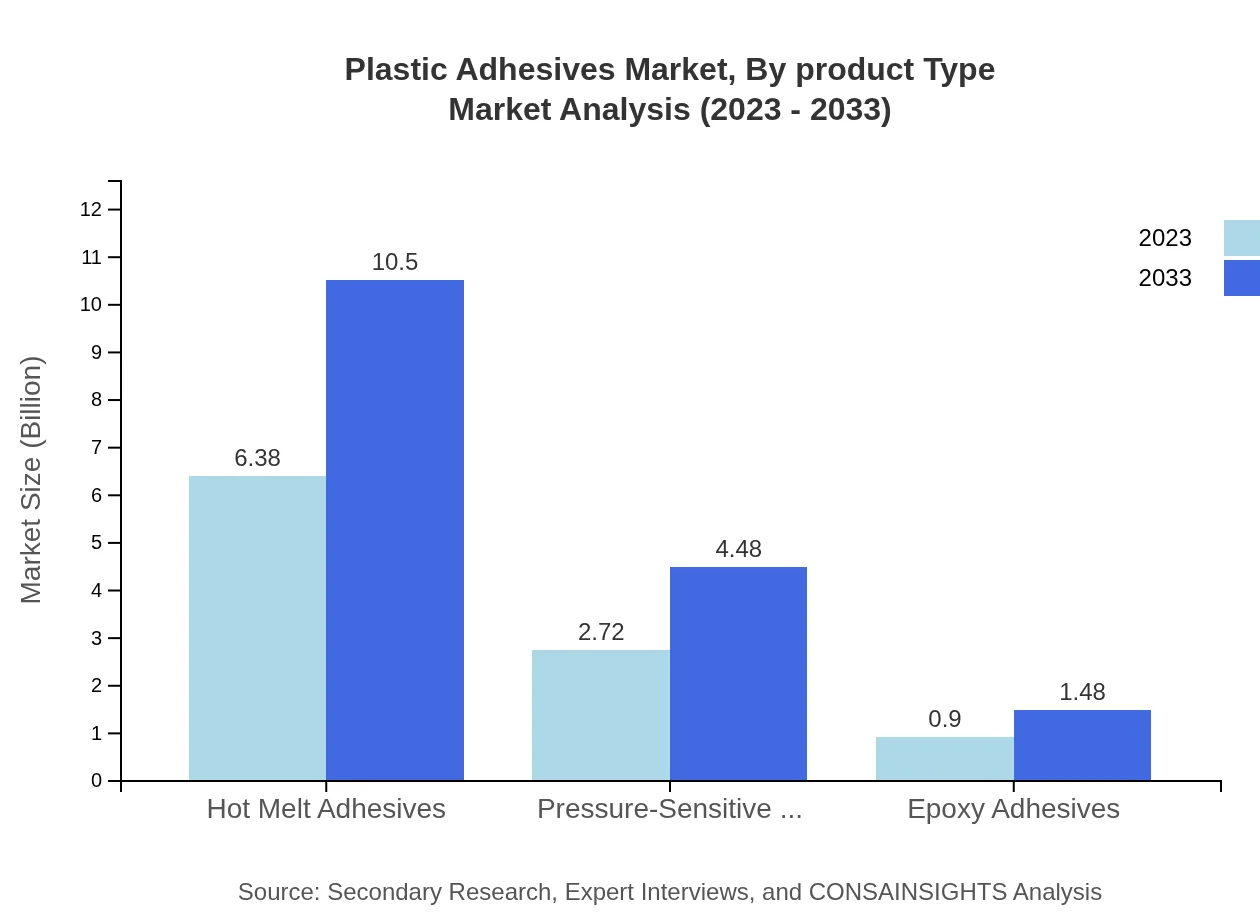

Plastic Adhesives Market Analysis By Product Type

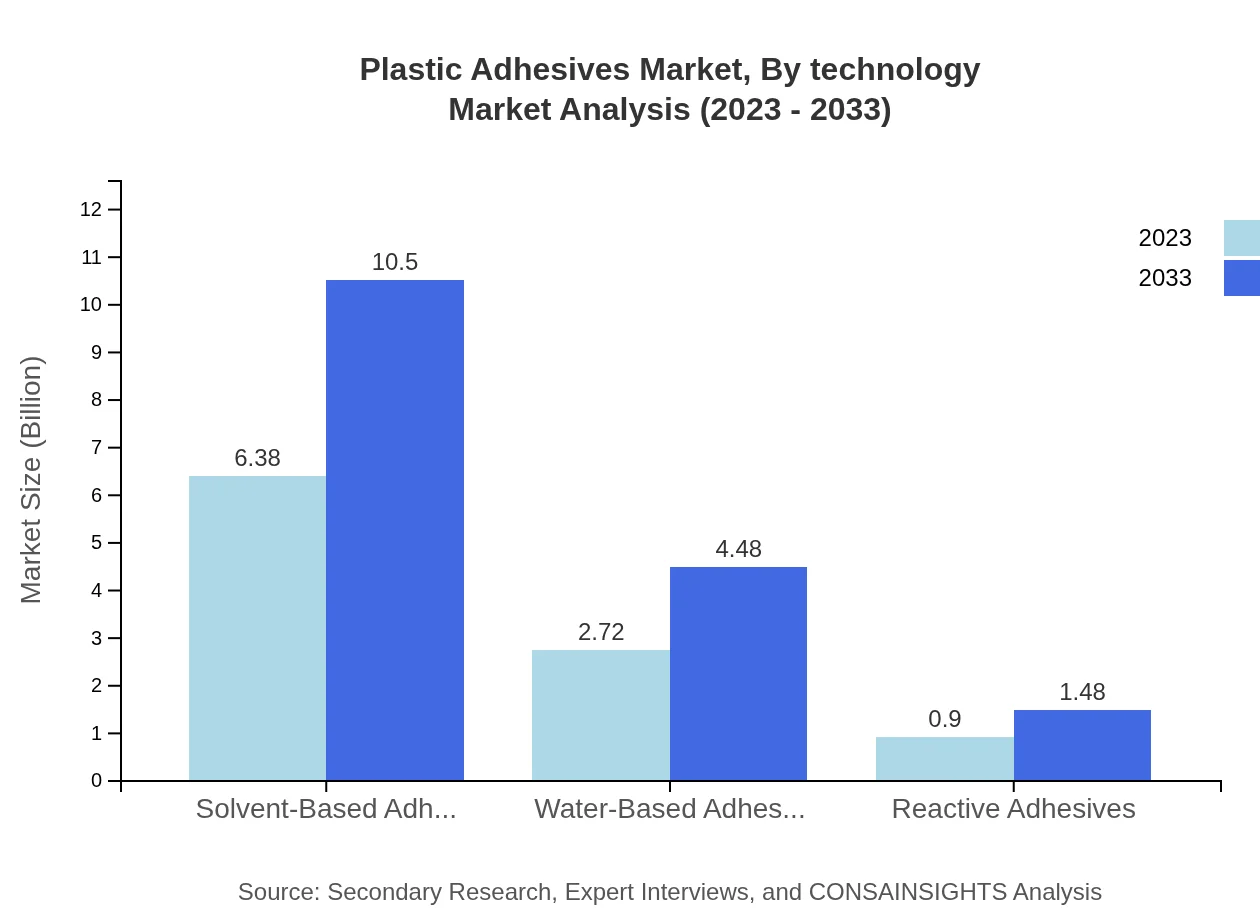

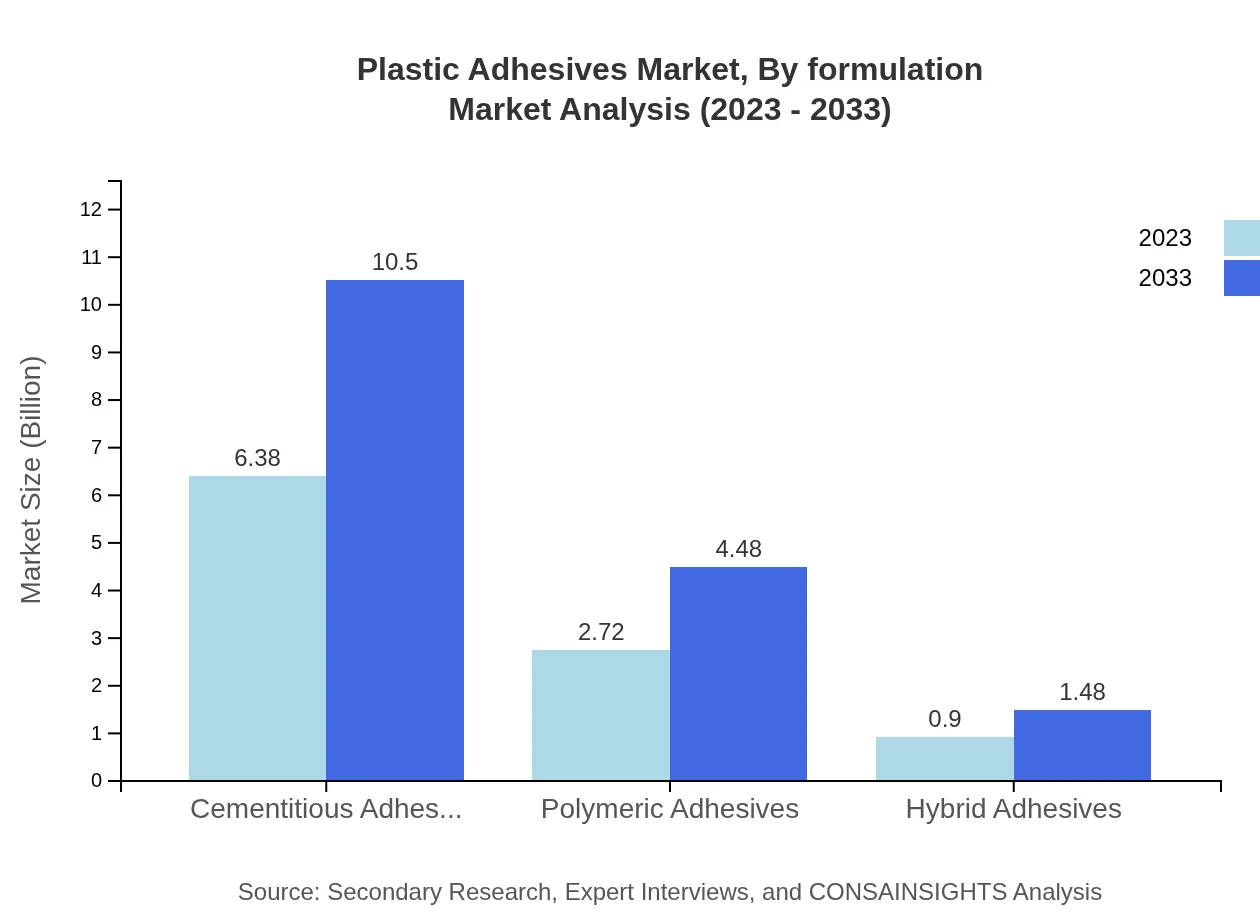

The market is highly segmented by product type, with solvent-based adhesives leading the charge, comprising a market value of $6.38 billion in 2023 and growing to $10.50 billion by 2033. Water-based adhesives hold a market share of $2.72 billion, expanding to $4.48 billion, reflecting a trend toward environmentally friendly options. Reactive adhesives, polymeric adhesives, and hot melt adhesives play significant roles, catering to specialized industrial requirements.

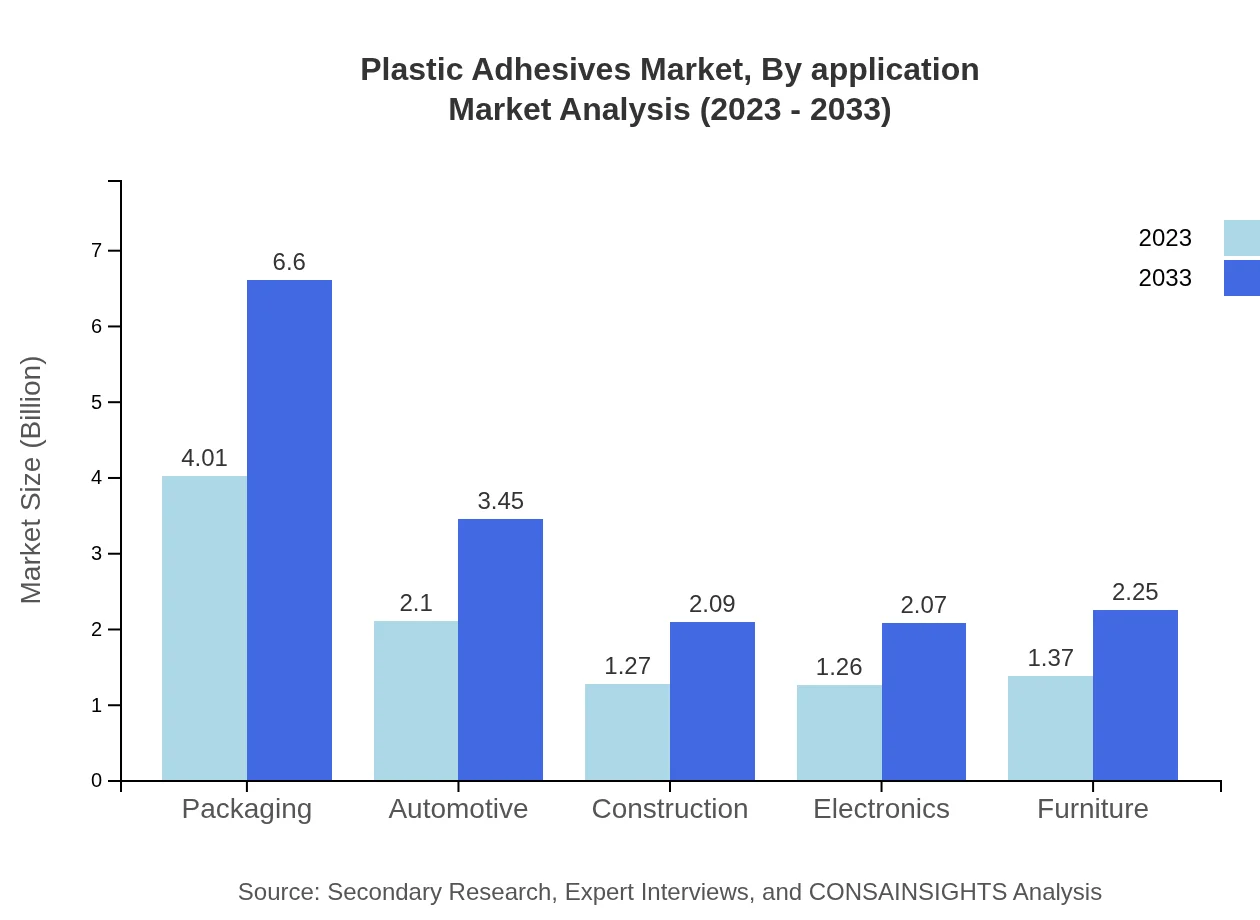

Plastic Adhesives Market Analysis By Application

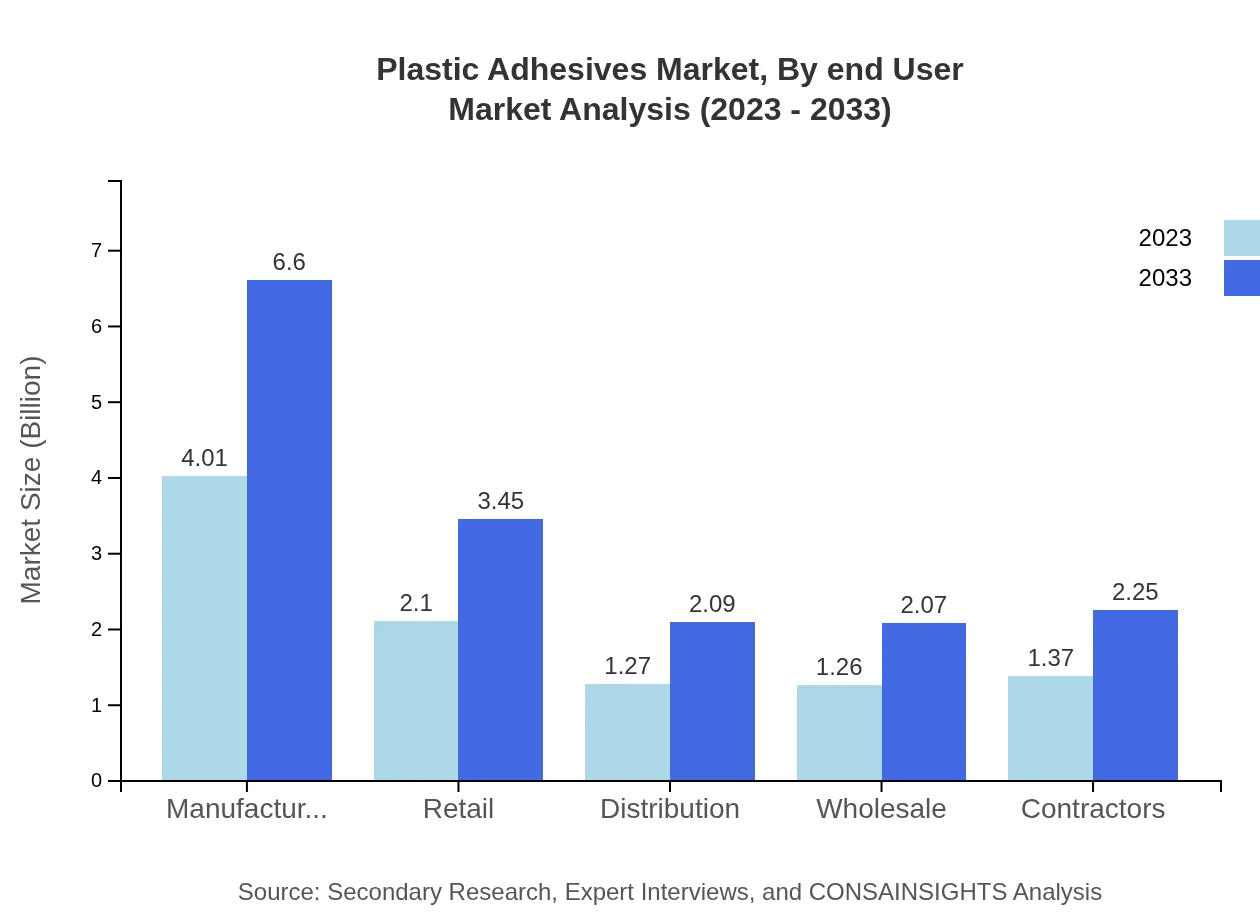

In terms of application, the manufacturing sector dominates with revenues of $4.01 billion in 2023, projected to reach $6.60 billion by 2033. The construction and automotive sectors also contribute significantly, demonstrating steady growth due to rising construction activities and automotive production rates. Packaging and electronics markets are on a fast track, driven by increased consumer demand for packaging solutions.

Plastic Adhesives Market Analysis By Technology

The technology segment sees advancements in application techniques such as pressure-sensitive and hot melt technologies. Hot melt adhesives maintain a dominant position with $6.38 billion in 2023, reflecting a strong growth trajectory. Companies are increasingly investing in R&D to enhance adhesive performance and applicability across various substrates.

Plastic Adhesives Market Analysis By End User

End users of Plastic Adhesives span various sectors, with substantial contributions from the automotive, construction, and electronics industries. The automotive sector alone reaches $2.10 billion in 2023 and is anticipated to grow to $3.45 billion by 2033. The construction industry is also significant, utilizing adhesives for fastening, joining, and sealing applications.

Plastic Adhesives Market Analysis By Formulation

The formulation of adhesives plays a crucial role, with a clear trend toward eco-friendly and less hazardous options. Solvent-based formulations lead the charge but are progressively facing competition from water-based and reactive adhesives that appeal to environmentally conscious consumers and regulations.

Plastic Adhesives Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Plastic Adhesives Industry

Henkel AG:

Henkel AG is a global leader in adhesive technologies, known for its innovative and sustainable solutions for various industries, including automotive and packaging.3M Company:

3M Company specializes in a wide range of adhesives and bonding materials, leveraging advanced technology and a diverse product portfolio to address unique market needs.Sika AG:

Sika AG focuses on construction and industrial applications, providing a vast range of adhesive products with a commitment to sustainability and performance.BASF SE:

BASF SE is a chemical giant, offering a comprehensive selection of adhesive solutions, with a strong emphasis on innovative and high-quality products.We're grateful to work with incredible clients.

FAQs

What is the market size of plastic Adhesives?

The plastic adhesives market is currently valued at approximately 10 billion USD and is projected to grow at a CAGR of 5% from 2023 to 2033, indicating a strong demand and expansion in diverse applications.

What are the key market players or companies in this plastic Adhesives industry?

Key market players in the plastic adhesives industry include prominent manufacturers and suppliers focused on innovation and quality, addressing various sectors such as packaging, automotive, construction, and electronics to enhance their market presence.

What are the primary factors driving the growth in the plastic Adhesives industry?

The growth of the plastic adhesives industry is driven by increasing demand from end-use sectors such as automotive and construction, technological advancements in adhesive formulations, and a growing emphasis on sustainability and eco-friendly products.

Which region is the fastest Growing in the plastic Adhesives market?

The fastest-growing region in the plastic adhesives market is Europe, expected to grow from 3.50 billion USD in 2023 to 5.77 billion USD by 2033, indicating robust expansion driven by industrial advancements and increasing demand.

Does ConsaInsights provide customized market report data for the plastic Adhesives industry?

Yes, ConsaInsights offers customized market report data tailored to specific requirements in the plastic adhesives industry, enabling clients to gain comprehensive insights and strategic advantages in their business planning.

What deliverables can I expect from this plastic Adhesives market research project?

From this plastic adhesives market research project, expect detailed reports, data analysis, market forecasts, competition landscape overviews, and strategic recommendations tailored to enhance decision-making and market positioning.

What are the market trends of plastic Adhesives?

Key market trends in the plastic adhesives industry include increased adoption of bio-based adhesives, innovations in technology for improved performance, growing demand for versatile bonding solutions, and heightened focus on regulatory compliance for safety.