Rubber Oil Process Market Report

Published Date: 02 February 2026 | Report Code: rubber-oil-process

Rubber Oil Process Market Size, Share, Industry Trends and Forecast to 2033

This report offers a comprehensive analysis of the Rubber Oil Process market, including trends, forecasts, and insights from 2023 to 2033. It covers market conditions, size, segmentation, regional insights, key players, and industry dynamics.

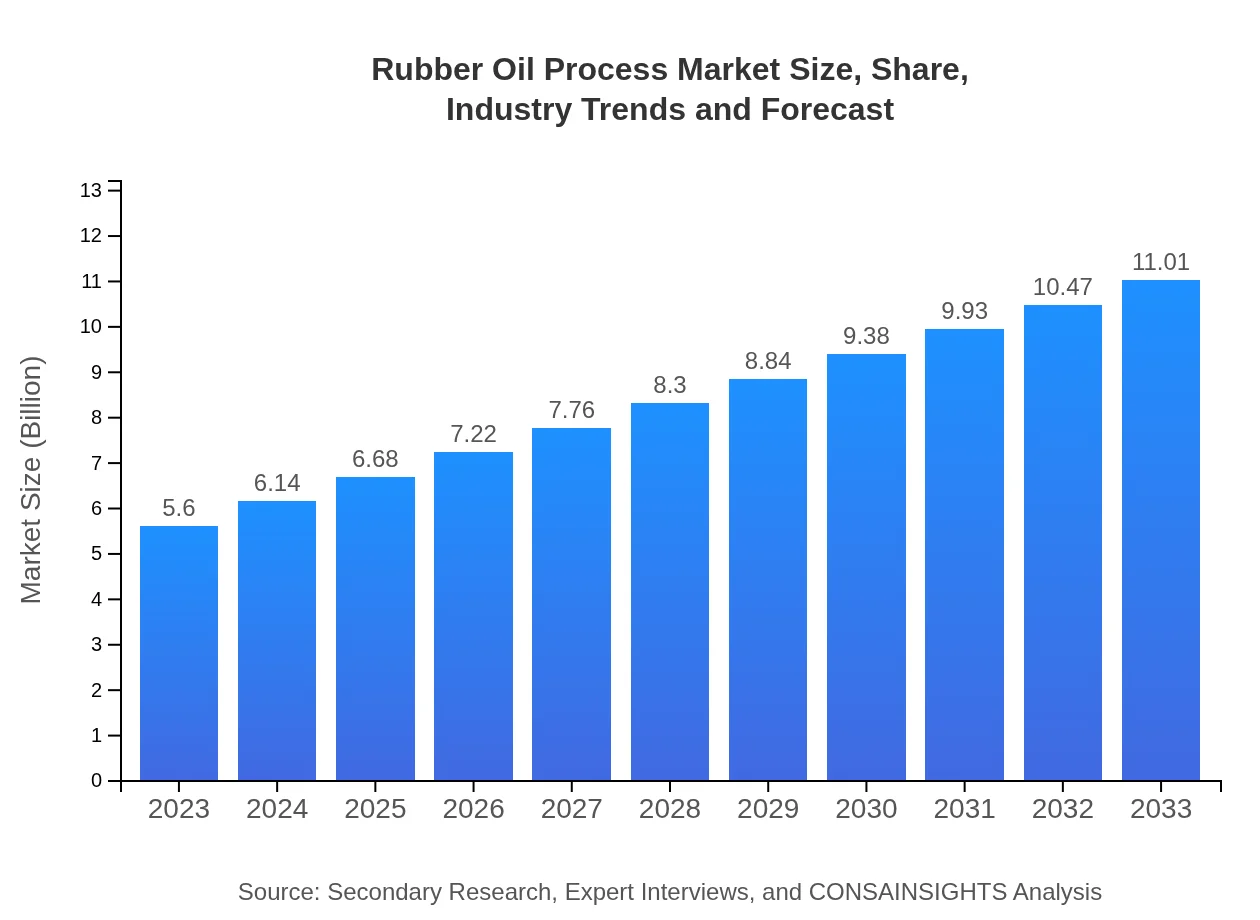

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $5.60 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $11.01 Billion |

| Top Companies | Continental AG, Bridgestone Corporation, Goodyear Tire & Rubber Company, Michelin |

| Last Modified Date | 02 February 2026 |

Rubber Oil Process Market Overview

Customize Rubber Oil Process Market Report market research report

- ✔ Get in-depth analysis of Rubber Oil Process market size, growth, and forecasts.

- ✔ Understand Rubber Oil Process's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Rubber Oil Process

What is the Market Size & CAGR of Rubber Oil Process market in 2023?

Rubber Oil Process Industry Analysis

Rubber Oil Process Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Rubber Oil Process Market Analysis Report by Region

Europe Rubber Oil Process Market Report:

The European market size is anticipated to rise from $1.85 billion in 2023 to $3.64 billion by 2033. The emphasis on eco-friendly production methods and high-performance rubber applications will support this growth.Asia Pacific Rubber Oil Process Market Report:

In the Asia Pacific region, the market size for Rubber Oil Process is projected to grow from $1.06 billion in 2023 to $2.08 billion by 2033. This growth is attributed to the booming automotive and manufacturing sectors, coupled with increasing rubber consumption and environmental sustainability efforts.North America Rubber Oil Process Market Report:

In North America, the market is set to grow from $1.92 billion in 2023 to $3.78 billion in 2033, driven by advanced manufacturing capabilities and stringent quality standards in the rubber industry.South America Rubber Oil Process Market Report:

The South American Rubber Oil Process market is expected to reach $0.26 billion in 2023, growing to approximately $0.51 billion by 2033. The expanding agriculture and construction sectors are fueling demand, though potential economic volatility poses challenges.Middle East & Africa Rubber Oil Process Market Report:

The Middle East and Africa market for Rubber Oil Process is currently valued at $0.50 billion in 2023, with projections to grow to $0.99 billion by 2033. The region's expanding construction and automotive industries are significant contributors to this growth.Tell us your focus area and get a customized research report.

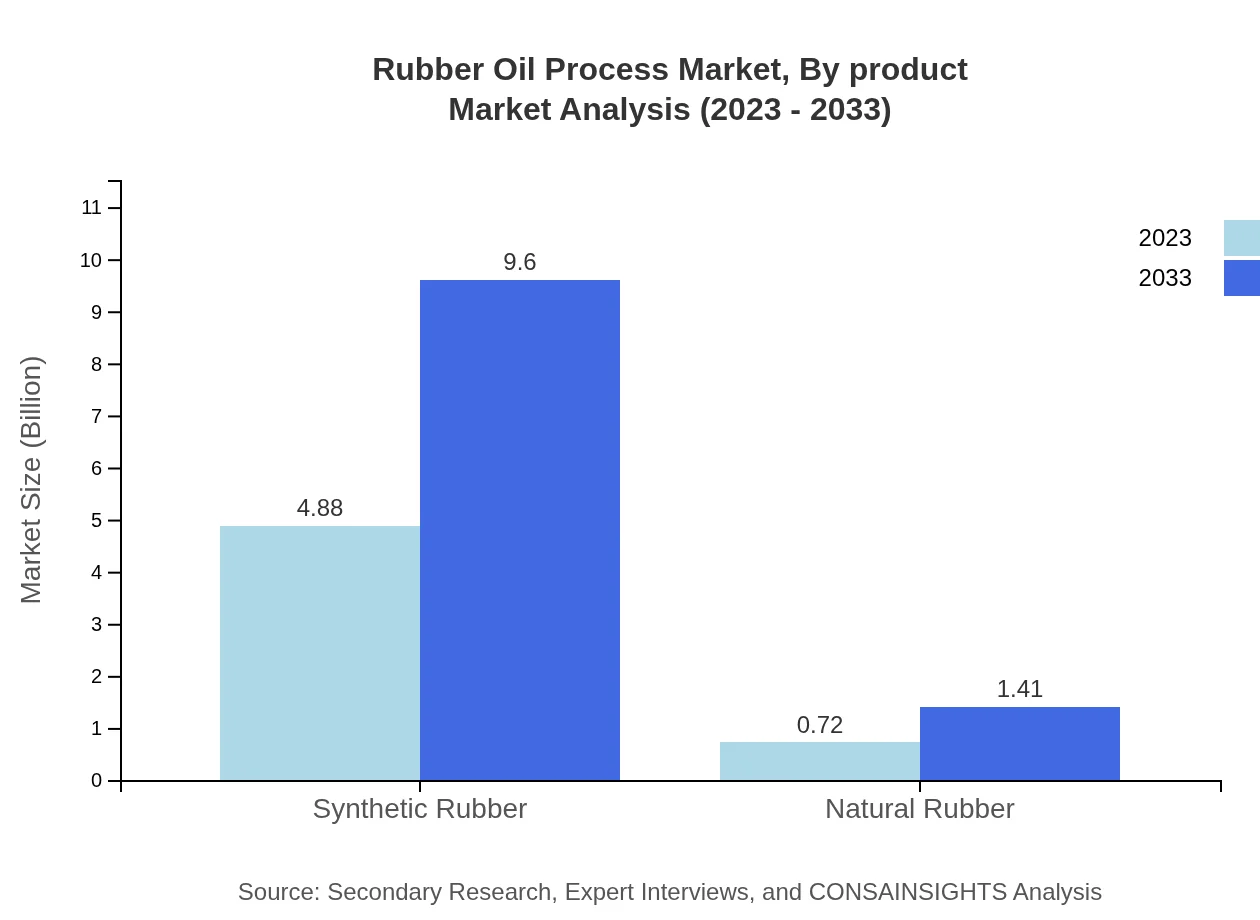

Rubber Oil Process Market Analysis By Product

Micronization remains the leading method in the Rubber Oil Process market, representing a size of approximately $4.88 billion in 2023 and projected to reach $9.60 billion by 2033, maintaining an 87.22% market share. Solvent extraction follows with a size of $0.72 billion in 2023, expected to grow to $1.41 billion in 2033, holding a 12.78% share.

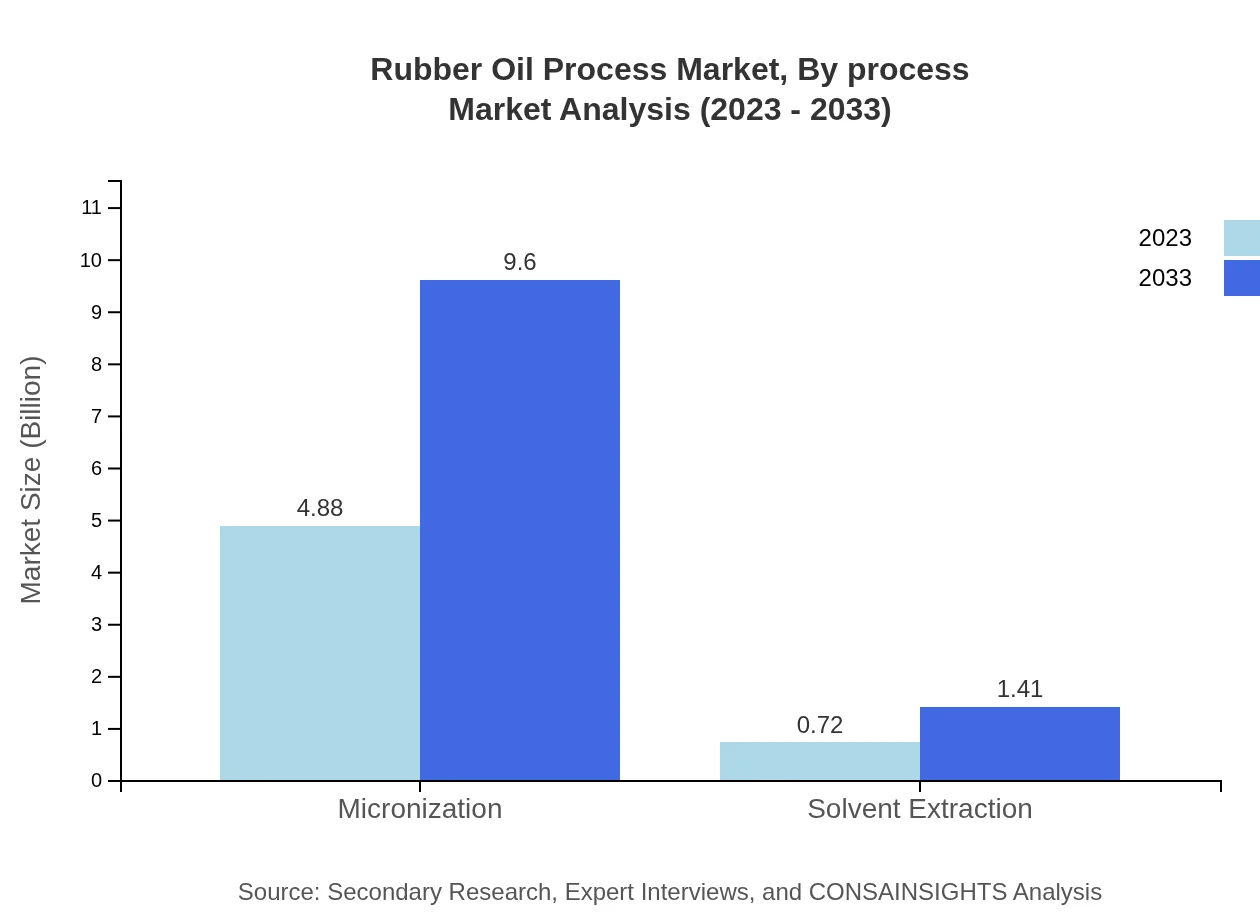

Rubber Oil Process Market Analysis By Process

The market’s major processes encompass both micronization and solvent extraction, with consistent growth in both segments indicating a robust demand for improved rubber quality across industries.

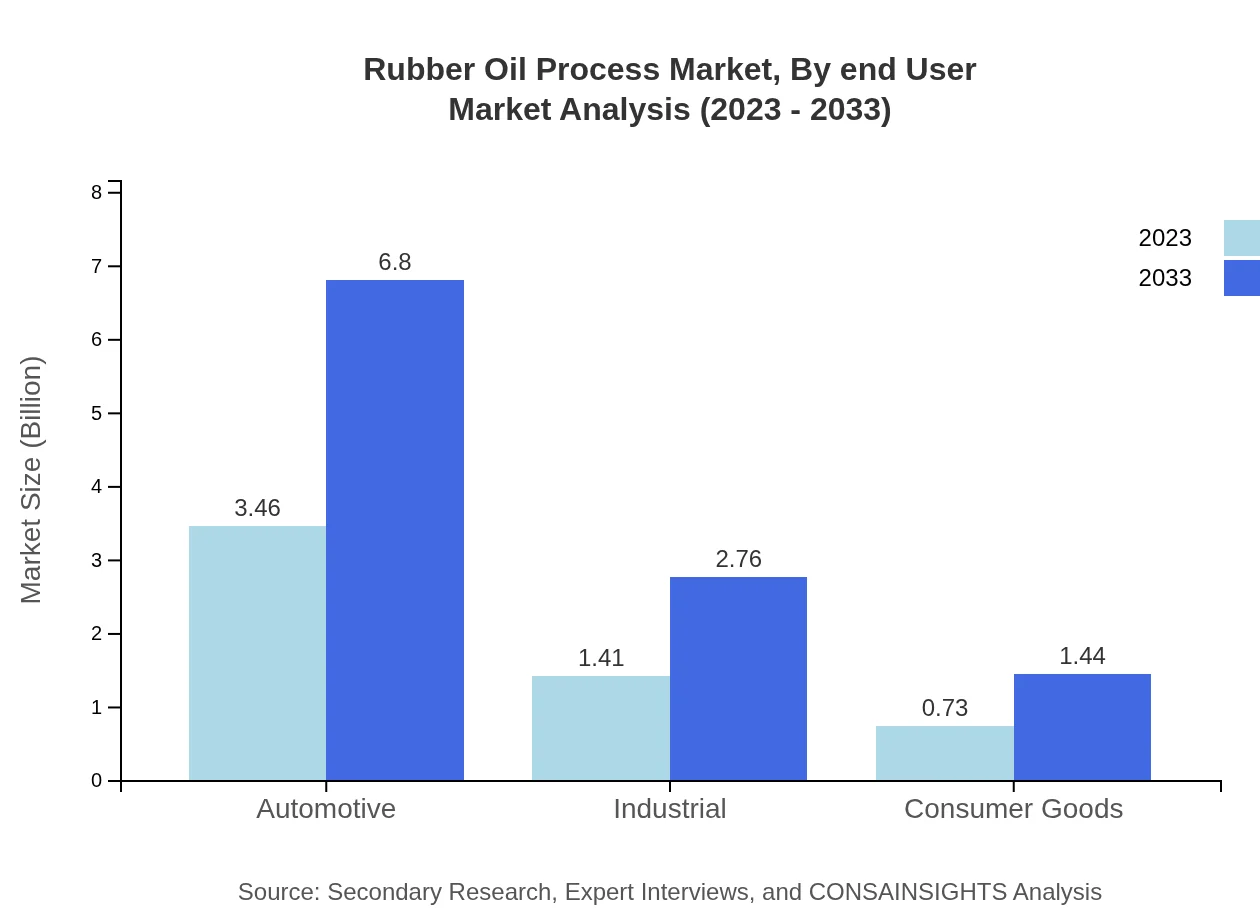

Rubber Oil Process Market Analysis By End User

The automotive sector leads with a market size of $3.46 billion in 2023, projected to increase to $6.80 billion by 2033, accounting for 61.77% of the market share. The industrial sector holds a sizeable share, anticipated to reach $2.76 billion by 2033.

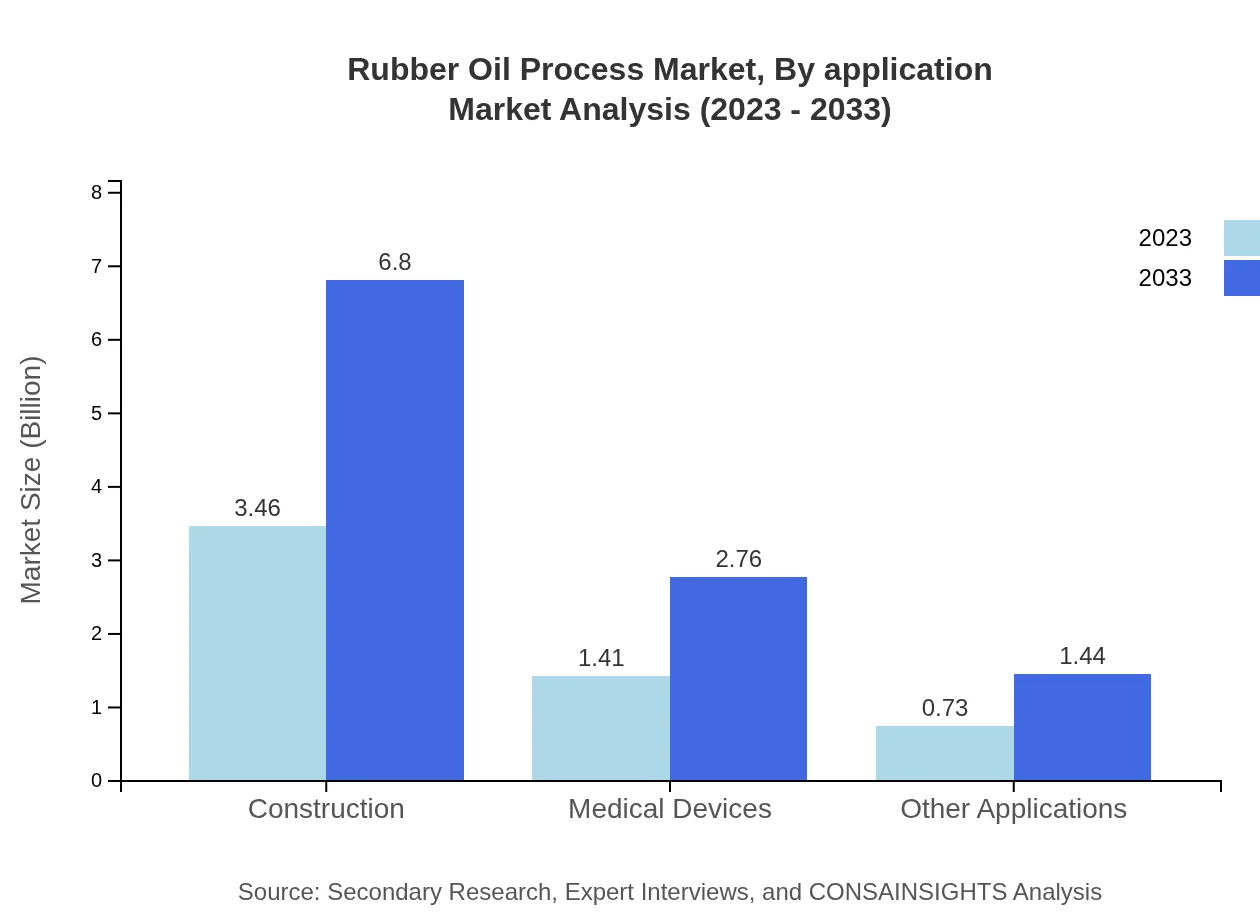

Rubber Oil Process Market Analysis By Application

Key applications include automotive, construction, and consumer goods, with automotive applications dominant in the market. The construction segment is also significant, mirroring growth patterns seen in infrastructure and construction projects globally.

Rubber Oil Process Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Rubber Oil Process Industry

Continental AG:

A leading manufacturer of tires and rubber products, Continental AG invests heavily in R&D for sustainable rubber processing solutions.Bridgestone Corporation:

Bridgestone is a major player in the rubber products market, continually advancing its processes to enhance efficacy and reduce environmental impact.Goodyear Tire & Rubber Company:

Goodyear focuses on innovation in rubber processing, developing new types of rubber oils to enhance performance across diverse applications.Michelin:

Michelin is known for its commitment to sustainability and innovation, leveraging advanced technologies in rubber processing to enhance product offerings.We're grateful to work with incredible clients.

FAQs

What is the market size of rubber Oil Process?

The global rubber oil process market is projected to reach approximately $5.6 billion by 2033, growing at a CAGR of 6.8%. This growth reflects increased demand and advancements in processing technologies across various industries.

What are the key market players or companies in the rubber Oil Process industry?

Key players in the rubber oil process industry include major rubber manufacturers, chemical processing companies, and technology firms specializing in rubber processing solutions. These companies are instrumental in driving innovation and meeting market demands.

What are the primary factors driving the growth in the rubber Oil Process industry?

Growth in the rubber oil process industry is driven by rising demand for rubber products in automotive and consumer goods, advancements in processing technologies, and stringent regulations promoting the use of sustainable materials.

Which region is the fastest Growing in the rubber Oil Process?

The fastest-growing region in the rubber oil process market is expected to be Europe, projected to grow from $1.85 billion in 2023 to $3.64 billion by 2033. Other notable regions include North America and Asia-Pacific.

Does ConsaInsights provide customized market report data for the rubber Oil Process industry?

Yes, ConsaInsights offers customized market report data tailored to the specific needs of stakeholders in the rubber oil process industry, ensuring insights are relevant and actionable for strategic decision-making.

What deliverables can I expect from this rubber Oil Process market research project?

Deliverables from the rubber oil process market research project typically include detailed market analysis reports, segment insights, competitive landscape profiles, and growth forecasts, providing comprehensive information for informed decision-making.

What are the market trends of rubber Oil Process?

Current market trends include increased investment in sustainable manufacturing processes, rising demand for high-performance rubber materials, and a shift towards innovative processing methods to enhance product quality and reduce environmental impact.