Thermoplastic Composites Market Report

Published Date: 02 February 2026 | Report Code: thermoplastic-composites

Thermoplastic Composites Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the thermoplastic composites market, exploring market size, trends, and growth forecasts from 2023 to 2033. It includes insights into regional markets, product types, industry leaders, and future opportunities for stakeholders.

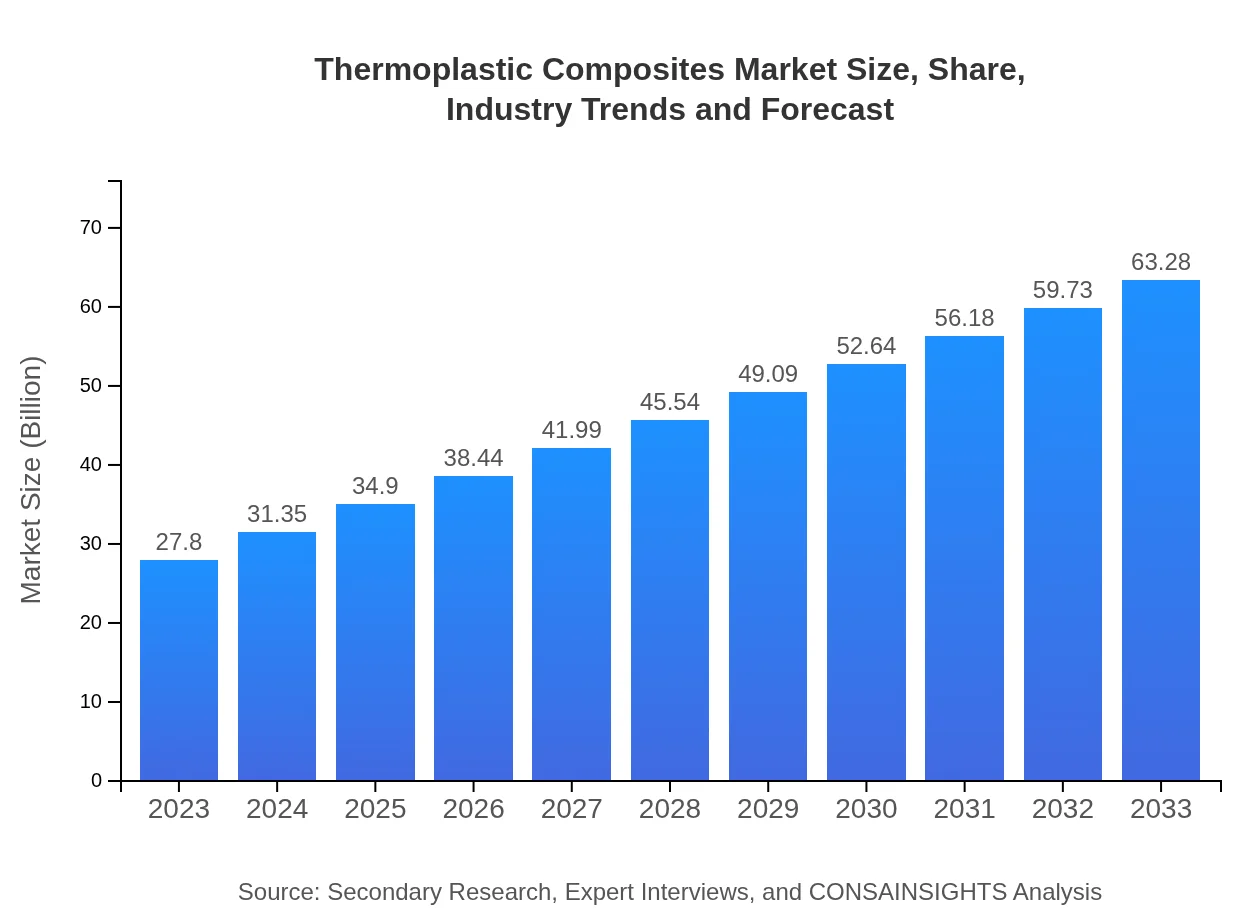

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $27.80 Billion |

| CAGR (2023-2033) | 8.3% |

| 2033 Market Size | $63.28 Billion |

| Top Companies | Hexcel Corporation, Toray Industries, SABIC Innovative Plastics, Basf SE |

| Last Modified Date | 02 February 2026 |

Thermoplastic Composites Market Overview

Customize Thermoplastic Composites Market Report market research report

- ✔ Get in-depth analysis of Thermoplastic Composites market size, growth, and forecasts.

- ✔ Understand Thermoplastic Composites's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Thermoplastic Composites

What is the Market Size & CAGR of Thermoplastic Composites market?

Thermoplastic Composites Industry Analysis

Thermoplastic Composites Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Thermoplastic Composites Market Analysis Report by Region

Europe Thermoplastic Composites Market Report:

The European market is one of the largest, projected at $9.82 billion in 2023 and growing to $22.34 billion by 2033. Strong regulations favoring sustainable development and a significant presence of automotive and aerospace industries are driving the demand for high-performance composites.Asia Pacific Thermoplastic Composites Market Report:

In the Asia Pacific region, the thermoplastic composites market is valued at $5.03 billion in 2023 and is expected to reach $11.44 billion by 2033, driven by robust industrial development and increased consumption in automotive and aerospace sectors. The growing population and rising disposable income in countries like China and India are fostering demand for lightweight materials in various applications.North America Thermoplastic Composites Market Report:

In North America, the market is estimated at $9.60 billion in 2023, with growth to $21.85 billion by 2033. This region is home to several leading aerospace and automotive manufacturers that are adopting advanced materials to maintain competitiveness and compliance with environmental standards.South America Thermoplastic Composites Market Report:

The South American market, valued at $2.52 billion in 2023, is projected to grow to $5.74 billion by 2033. The construction and automotive industries are key drivers of growth as they increasingly turn to thermoplastic composites to improve performance and reduce weight in their products.Middle East & Africa Thermoplastic Composites Market Report:

The Middle East and Africa market is anticipated to grow from $0.84 billion in 2023 to $1.90 billion by 2033. Growth is being spurred by infrastructure developments and a gradual shift towards employing advanced materials in multiple sectors.Tell us your focus area and get a customized research report.

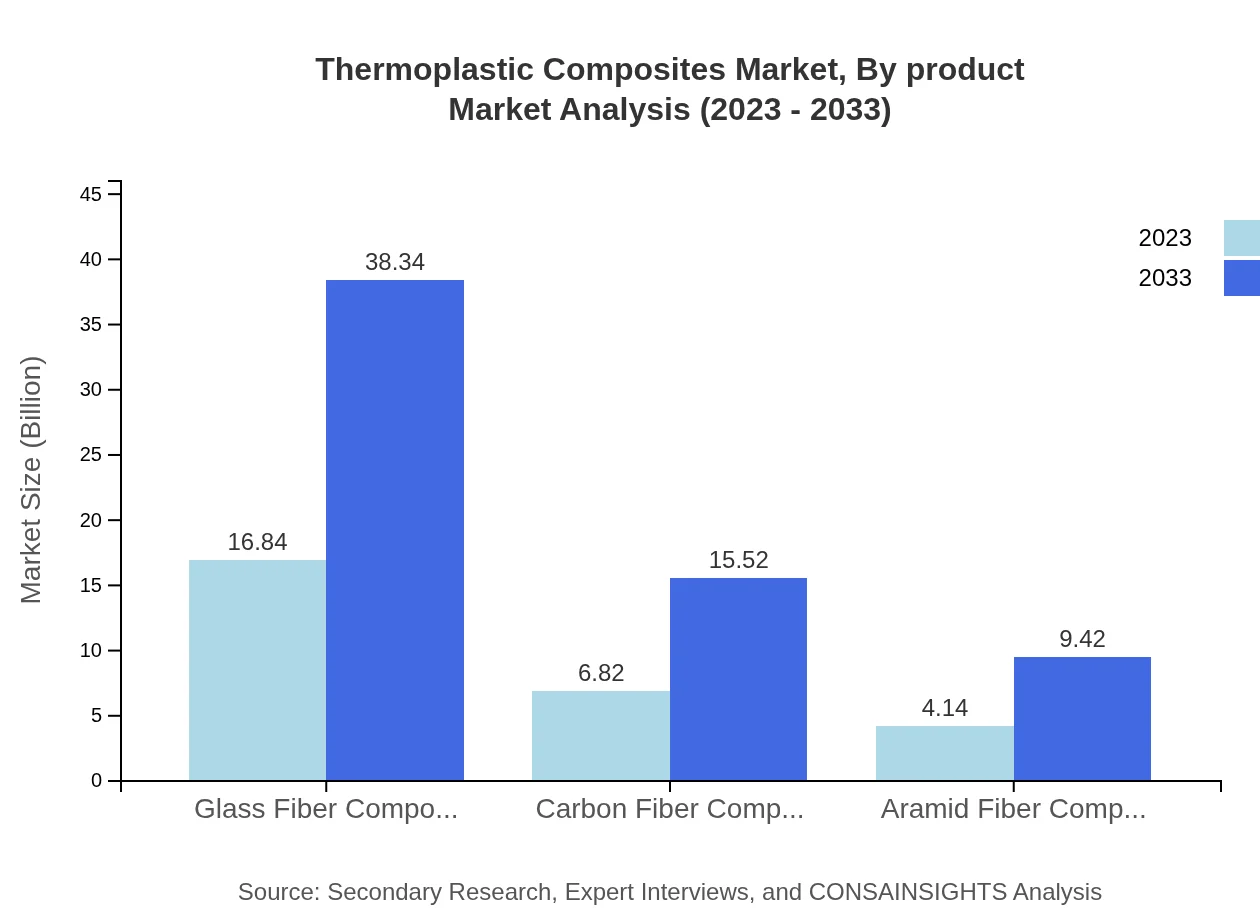

Thermoplastic Composites Market Analysis By Product

The market is significantly influenced by product types like glass fiber composites, which dominate with a market size of $16.84 billion in 2023, expanding to $38.34 billion in 2033, representing 60.59% market share. Carbon fiber composites follow, valued at $6.82 billion in 2023, growing to $15.52 billion by 2033, maintaining a share of 24.52%. Aramid fiber composites, while smaller at $4.14 billion in 2023, are expected to reach $9.42 billion by 2033, reflecting a growing niche in specialized applications.

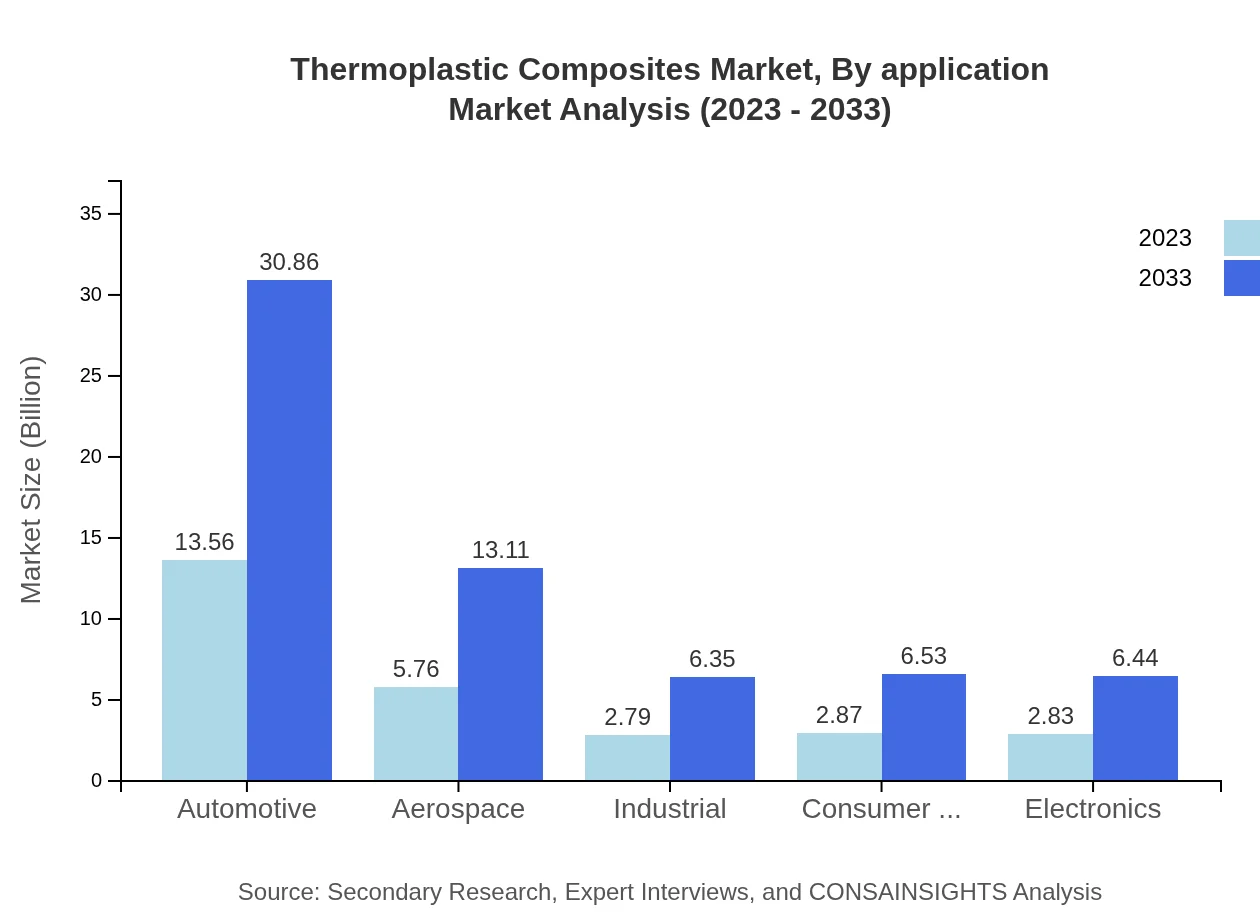

Thermoplastic Composites Market Analysis By Application

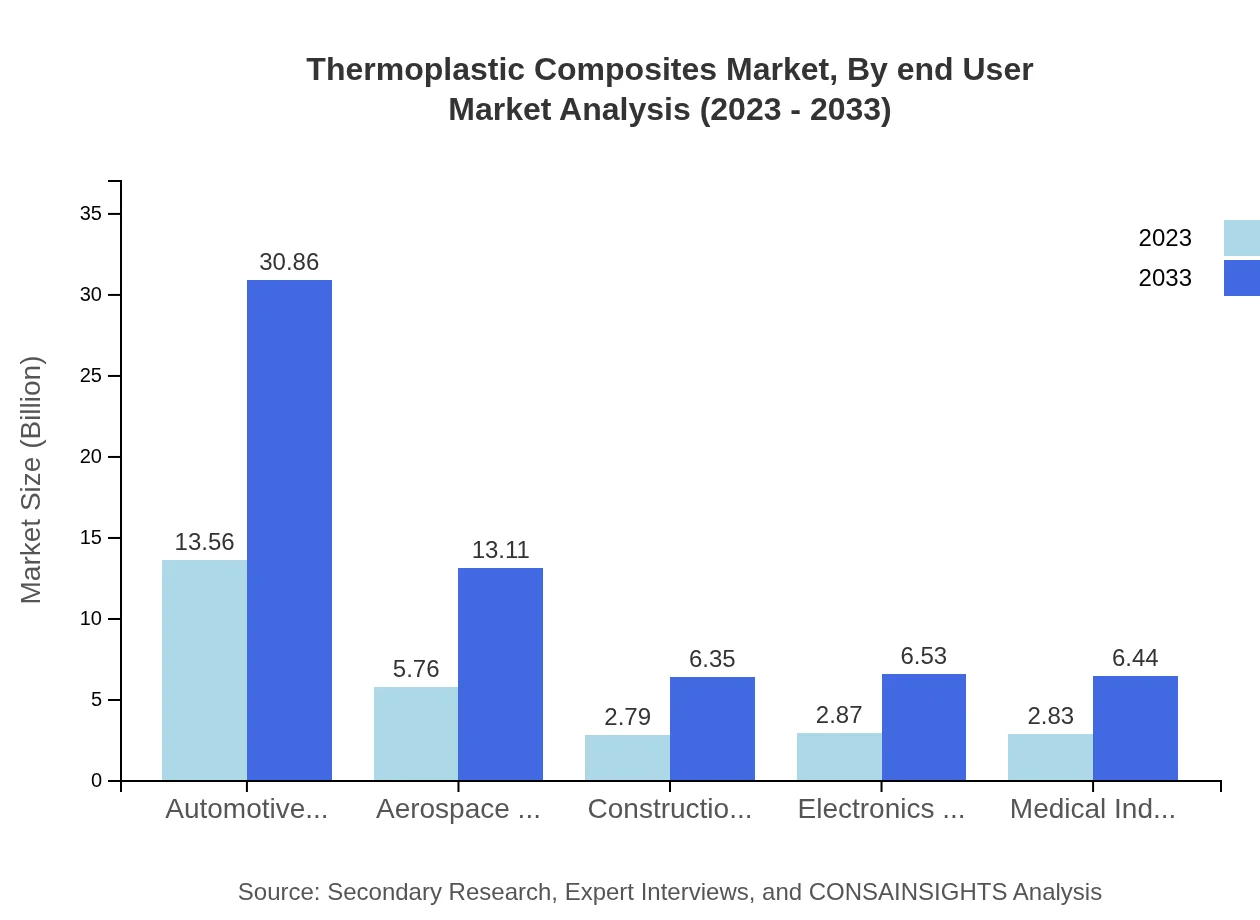

Applications in the automotive sector hold substantial market share at 48.76%, with a growth from $13.56 billion in 2023 to $30.86 billion by 2033. The aerospace industry follows, with significant growth from $5.76 billion to $13.11 billion, driven by innovation in lightweight structures. The construction industry and electronics applications also play critical roles in the overall advancement of thermoplastic composites, with medical and consumer goods sectors emerging as important contributors.

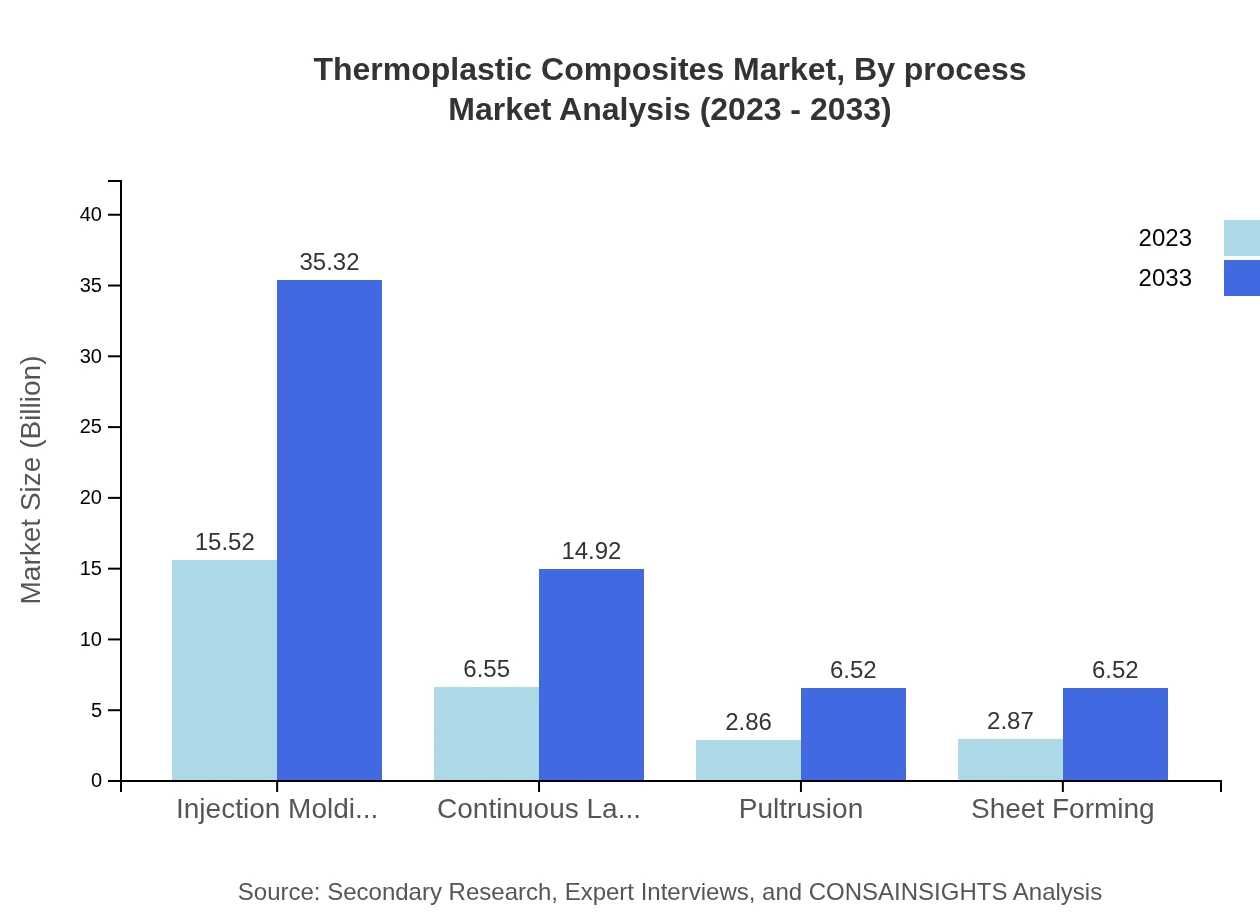

Thermoplastic Composites Market Analysis By Process

Injection molding remains the leading manufacturing process, with a market size of $15.52 billion in 2023, growing to $35.32 billion by 2033. Continuous laminating and sheet forming processes also show robust growth, with respective market sizes of $6.55 billion and $2.87 billion in 2023, indicating the diverse applications of thermoplastic composites.

Thermoplastic Composites Market Analysis By End User

End-user industries such as automotive, aerospace, construction, electronics, and medical exhibit continued growth. Automotive leads at 48.76% share, followed closely by aerospace at 20.71%. Emerging industries like electronics and medical also present considerable opportunities for thermoplastic composite manufacturers.

Thermoplastic Composites Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Thermoplastic Composites Industry

Hexcel Corporation:

Hexcel is a leading advanced composites company that specializes in high-performance carbon fiber composites for aerospace and industrial applications.Toray Industries:

Toray is a global leader in advanced materials, focusing on high-performance thermoplastic composites for a variety of applications including automotive and aerospace.SABIC Innovative Plastics:

SABIC offers a comprehensive range of thermoplastic composites, known for their innovation in lightweight solutions for automotive and industrial applications.Basf SE:

BASF is a prominent player in the chemicals industry, providing extensive thermoplastic composite materials tailored for automotive and consumer goods.We're grateful to work with incredible clients.

FAQs

What is the market size of thermoplastic Composites?

The thermoplastic composites market is valued at approximately $27.8 billion in 2023, with a projected CAGR of 8.3% leading up to 2033, showcasing significant growth opportunities in various sectors.

What are the key market players or companies in the thermoplastic Composites industry?

Key players in the thermoplastic composites industry include major companies such as BASF, Toray Industries, Solvay, and Teijin, who are pivotal in driving innovation and production within this expanding market.

What are the primary factors driving the growth in the thermoplastic Composites industry?

The growth of the thermoplastic composites industry is primarily driven by increasing demand in aerospace and automotive sectors, advancements in manufacturing technologies, and the push for lightweight materials to improve fuel efficiency and reduce emissions.

Which region is the fastest Growing in the thermoplastic Composites?

The Asia Pacific region is the fastest-growing market for thermoplastic composites, expected to grow from $5.03 billion in 2023 to $11.44 billion in 2033, reflecting a robust demand trajectory driven by industrial advancements.

Does ConsaInsights provide customized market report data for the thermoplastic Composites industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs in the thermoplastic-composites industry, ensuring clients receive the most relevant insights and analyses for their business objectives.

What deliverables can I expect from this thermoplastic Composites market research project?

Deliverables from the thermoplastic-composites market research project typically include comprehensive market analysis reports, forecasts, competitive landscape evaluations, and insights into key market trends and drivers.

What are the market trends of thermoplastic Composites?

Market trends in thermoplastic composites indicate a shift towards sustainable materials, increased adoption in automotive and aerospace sectors, and rising investment in innovative manufacturing processes that enhance product performance and reduce costs.