Tow Prepreg Market Report

Published Date: 02 February 2026 | Report Code: tow-prepreg

Tow Prepreg Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Tow Prepreg market, including market sizing, growth forecasts from 2023 to 2033, and detailed insights into product segments, regional developments, and key players in the industry.

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

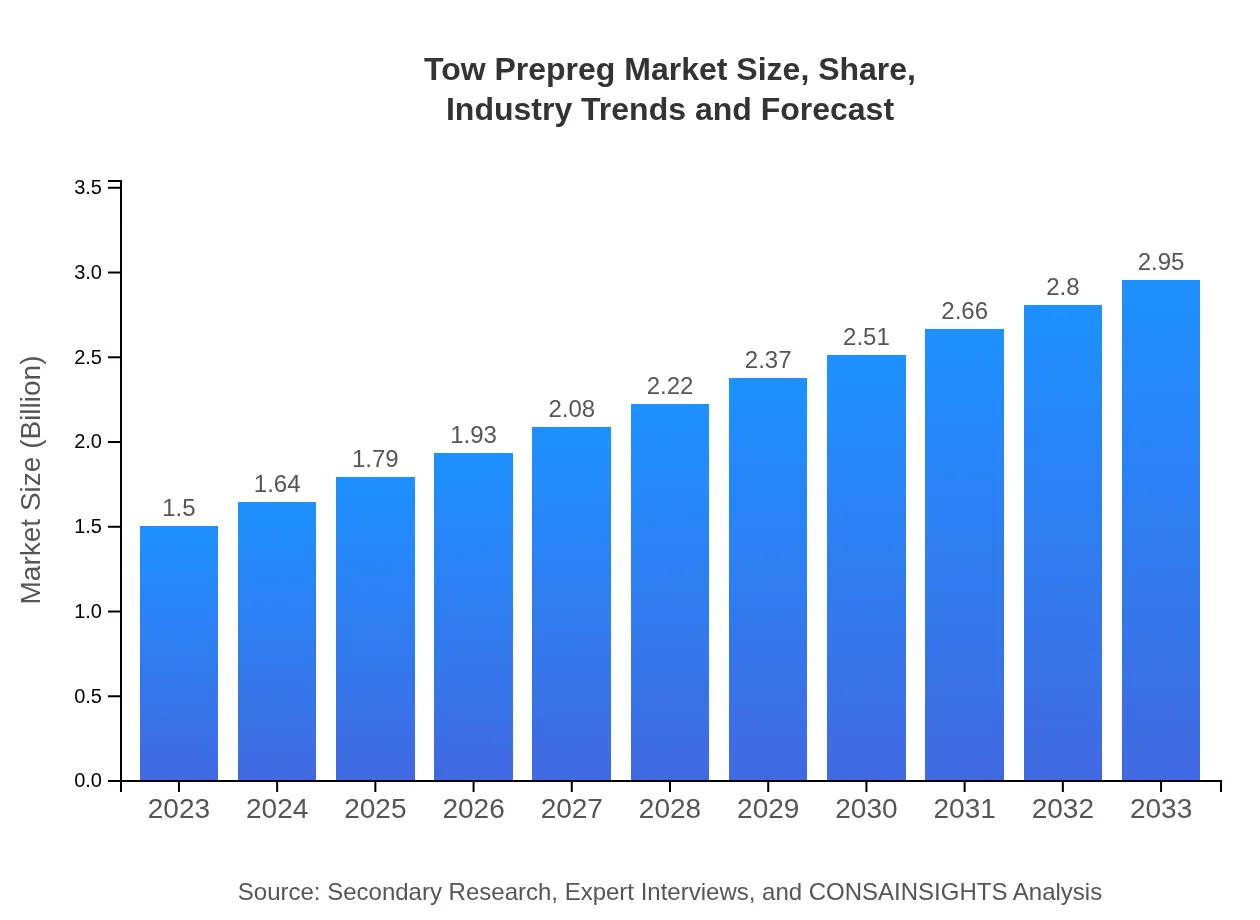

| 2023 Market Size | $1.50 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $2.95 Billion |

| Top Companies | Hexcel Corporation, Toray Industries, Inc., SGL Carbon SE, Mitsubishi Chemical Corporation |

| Last Modified Date | 02 February 2026 |

Tow Prepreg Market Overview

Customize Tow Prepreg Market Report market research report

- ✔ Get in-depth analysis of Tow Prepreg market size, growth, and forecasts.

- ✔ Understand Tow Prepreg's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Tow Prepreg

What is the Market Size & CAGR of Tow Prepreg market in 2023?

Tow Prepreg Industry Analysis

Tow Prepreg Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Tow Prepreg Market Analysis Report by Region

Europe Tow Prepreg Market Report:

Europe's Tow Prepreg market, valued at $0.44 billion in 2023, is expected to double to $0.86 billion by 2033. This growth is predominantly from the aerospace and automotive sectors, where lightweight composites are becoming essential for meeting stringent regulatory requirements.Asia Pacific Tow Prepreg Market Report:

In the Asia-Pacific region, the Tow Prepreg market was valued at $0.29 billion in 2023 and is projected to reach $0.57 billion by 2033. The growth is driven by rapid industrialization, increasing investments in aerospace and automotive sectors, and a growing demand for advanced materials in manufacturing processes.North America Tow Prepreg Market Report:

In North America, the market is projected to grow from $0.49 billion in 2023 to $0.95 billion by 2033. The region is leading in aerospace applications, with major companies investing heavily in Tow Prepreg materials for improved energy efficiency and innovative designs.South America Tow Prepreg Market Report:

The South American Tow Prepreg market size was approximately $0.14 billion in 2023, expected to grow to $0.28 billion by 2033. The rising demand for lightweight materials, particularly in the automotive and construction sectors, is propelling market growth in this region.Middle East & Africa Tow Prepreg Market Report:

The Middle East and Africa Tow Prepreg market, valued at $0.14 billion in 2023, is forecasted to grow to $0.27 billion by 2033. The increasing focus on infrastructure development and technology adoption in various industrial sectors is driving growth in the region.Tell us your focus area and get a customized research report.

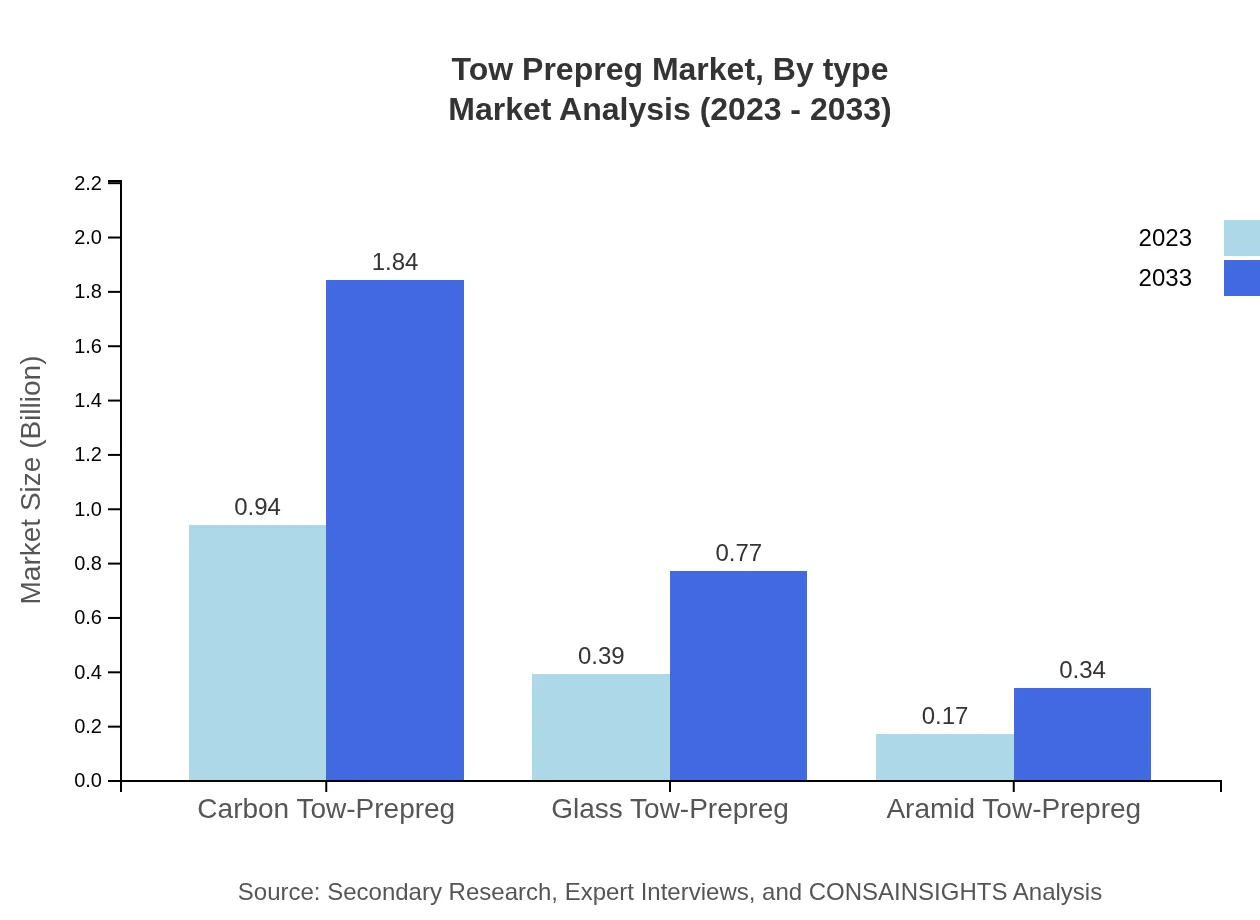

Tow Prepreg Market Analysis By Type

The segment analysis reveals that Carbon Tow-Prepreg holds the largest market share at 62.39% in 2023, growing to 62.39% by 2033, reflecting its importance in high-performance applications such as aerospace and automotive. Glass Tow-Prepreg is valued at $0.39 billion in 2023, expected to reach $0.77 billion by 2033. Aramid Tow-Prepreg, traditionally used in applications requiring durability, maintains a share of 11.4%. Process segmentation indicates that the Autoclave Process remains dominant due to its efficiency in producing high-quality prepregs.

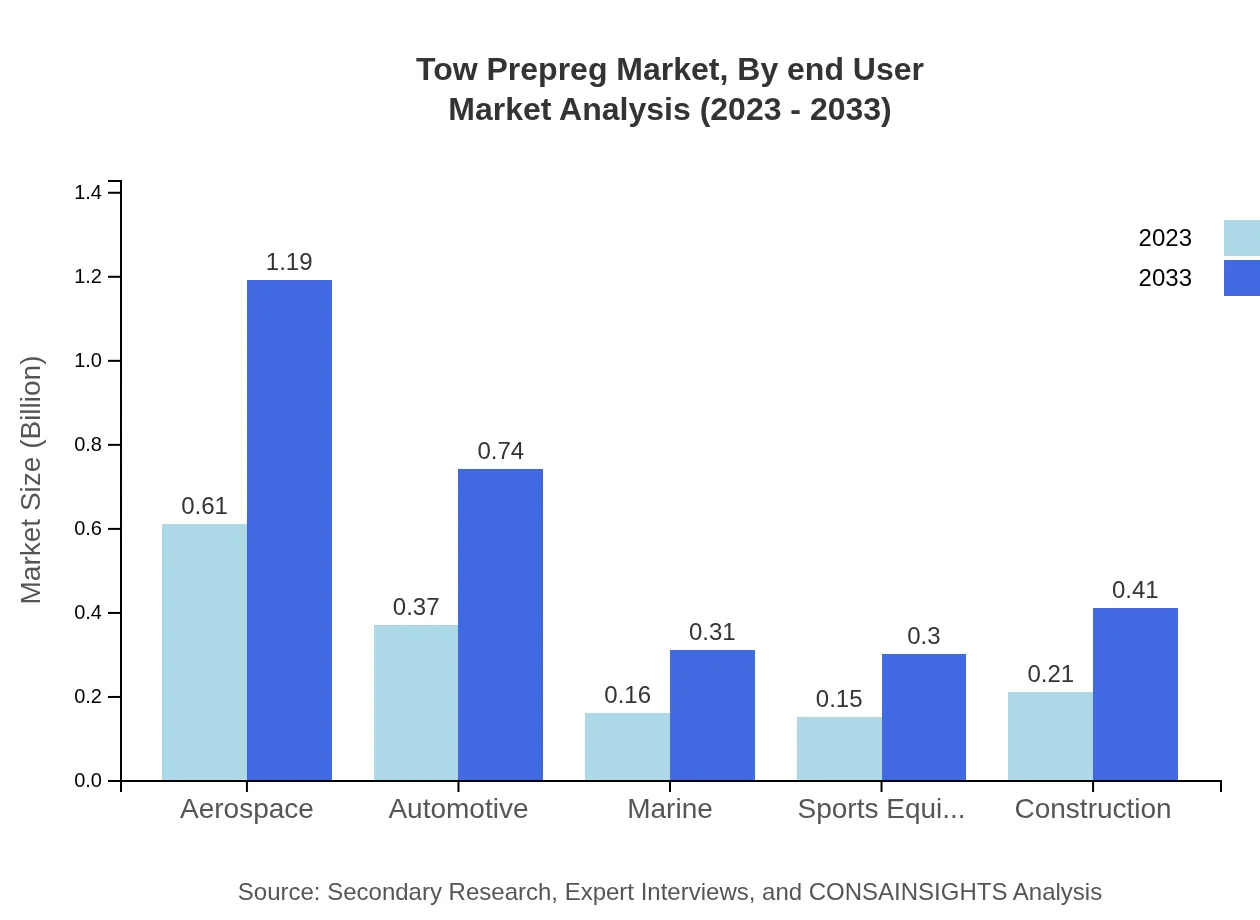

Tow Prepreg Market Analysis By End User

The aerospace industry is the leading end-user for Tow Prepreg, accounting for approximately 40.48% market share in 2023, with forecasts for further growth driven by the demand for lightweight, strong materials. The automotive sector follows, holding a 24.98% share, as manufacturers prioritize fuel efficiency and reduced emissions. Other significant segments include marine and sports equipment, which cumulatively maintain a notable presence in the market.

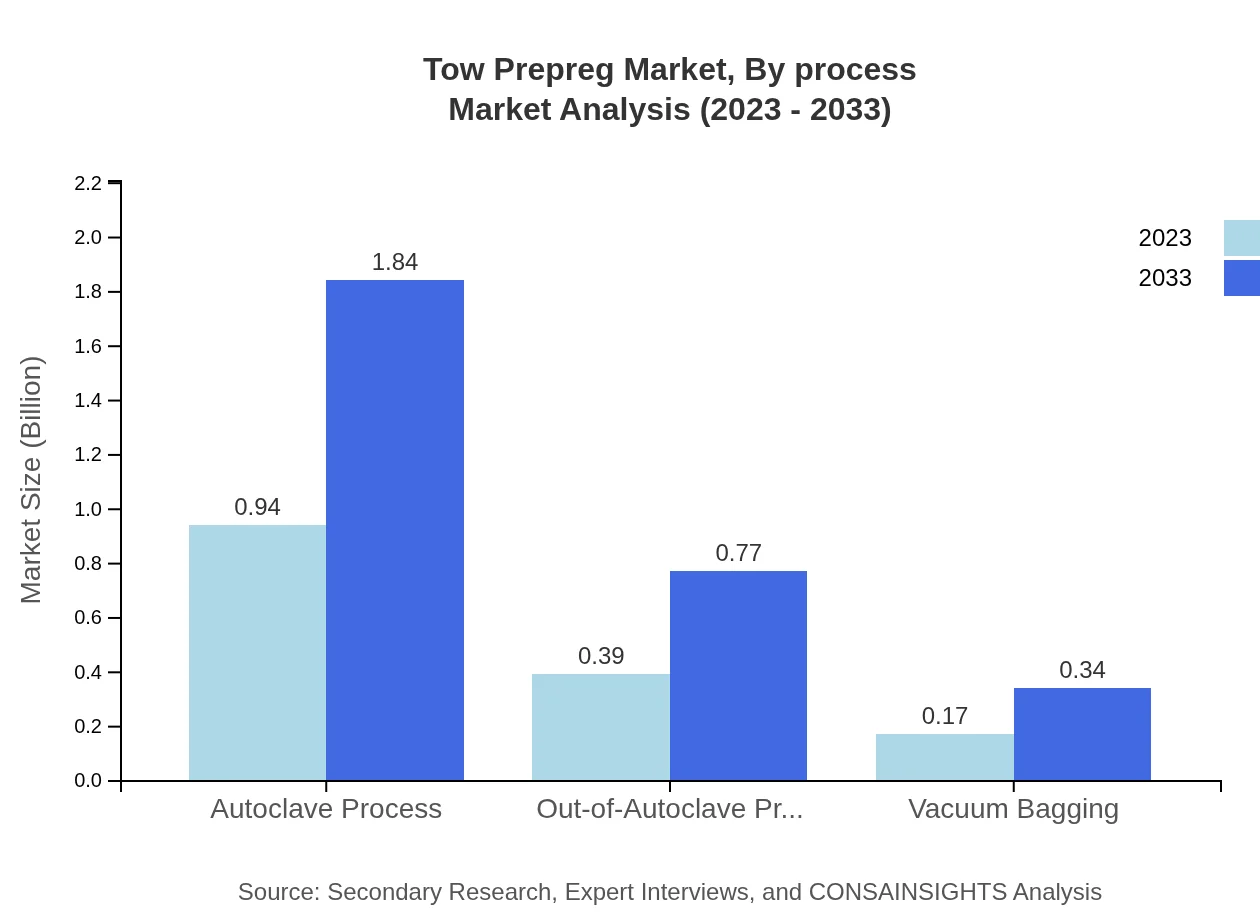

Tow Prepreg Market Analysis By Process

In terms of processing, the Autoclave Process leads the Tow Prepreg market with 62.39% market share in 2023, owing to its ability to deliver superior quality. The Out-of-Autoclave Process captures 26.21% of market share, with increasing adoption due to lower costs and suitability for pressure-sensitive components. The Vacuum Bagging process, though smaller at 11.4%, is gaining traction for specific applications in the industry.

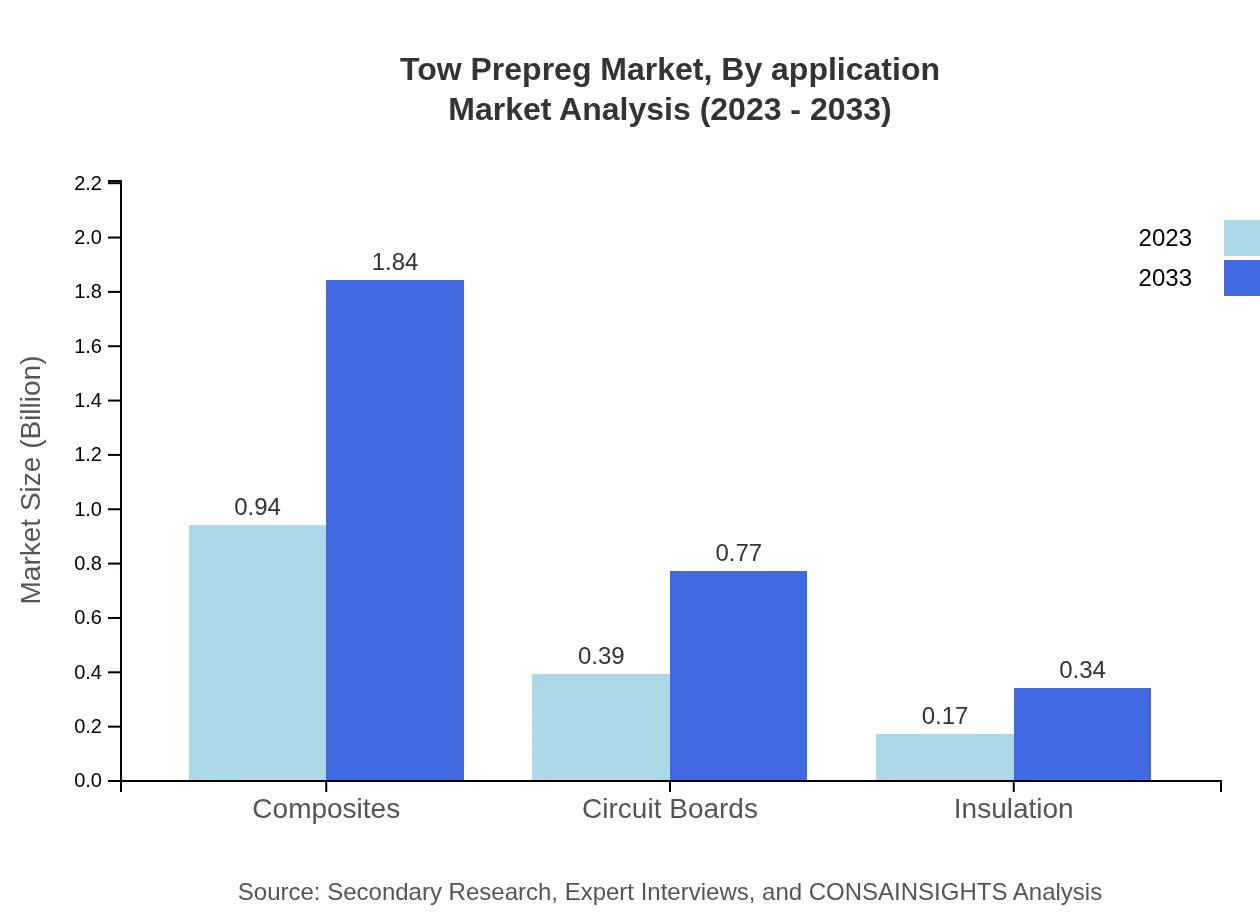

Tow Prepreg Market Analysis By Application

For applications, Composites dominate with a market share of 62.39%, driven by the rise in demand for high-performance composite materials. Circuit boards represent a growing application segment with a 26.21% share, fuelled by technological advancements in electronics. Insulation applications account for the remaining 11.4%, where thermal resistance is critically needed.

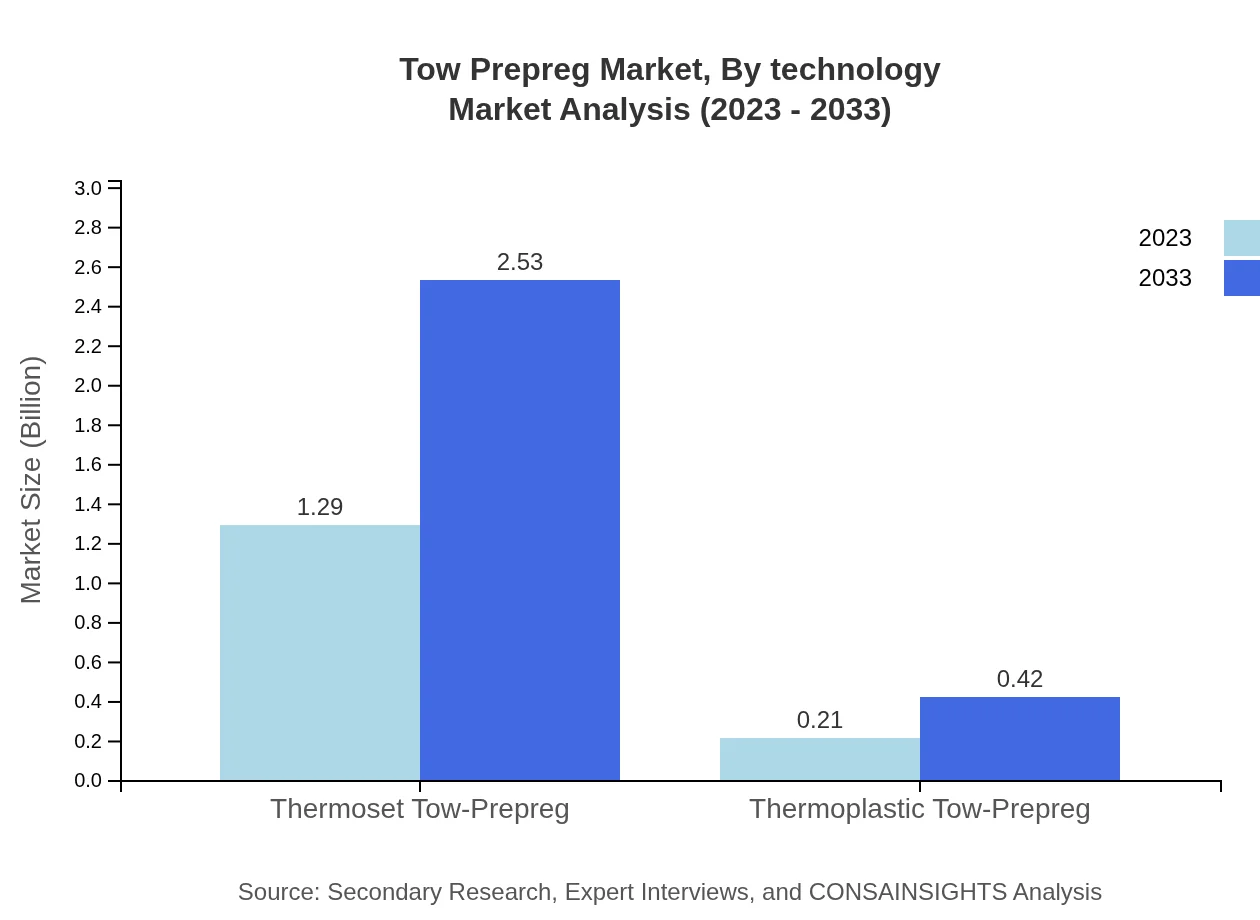

Tow Prepreg Market Analysis By Technology

Technological advances significantly impact the Tow Prepreg market, with increased investments in automation and advanced manufacturing processes that improve production efficiency and lower costs. The integration of machine learning and Internet of Things (IoT) technologies is helping manufacturers optimize prepreg designs and processing techniques.

Tow Prepreg Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Tow Prepreg Industry

Hexcel Corporation:

Hexcel is a leading manufacturer of advanced composites, dedicated to providing innovative solutions for aerospace, automotive, and industrial applications. Their commitment to research and development makes them a leader in the Tow Prepreg market.Toray Industries, Inc.:

Toray is a global leader in synthetic fibers and textiles, with a significant presence in the carbon fiber prepreg market. Their advanced technology and diverse product offerings cater to various industries, including aerospace and automotive.SGL Carbon SE:

SGL Carbon is a prominent player in carbon-based products, specializing in innovative Tow Prepreg solutions that meet demanding performance standards in aerospace and industrial applications.Mitsubishi Chemical Corporation:

Mitsubishi Chemical focuses on providing high-quality composite materials, including Tow Prepreg, optimizing their performance for various sectors, most notably in the aerospace industry.We're grateful to work with incredible clients.

FAQs

What is the market size of tow Prepreg?

The global tow prepreg market size was valued at approximately $1.5 billion in 2023 and is projected to exhibit a compound annual growth rate (CAGR) of 6.8%, reaching a market size of over $2.9 billion by 2033.

What are the key market players or companies in the tow Prepreg industry?

Key players in the tow-prepreg market include leading companies specialized in advanced composites and materials engineering. These may include prominent names such as Hexcel Corporation, Toray Industries, and Mitsubishi Chemical, which are known for innovation and quality.

What are the primary factors driving the growth in the tow Prepreg industry?

Factors driving growth in the tow-prepreg industry include increasing demand for lightweight and high-strength materials in aerospace and automotive sectors, technological advancements in composite manufacturing, and a rising focus on sustainable materials.

Which region is the fastest Growing in the tow Prepreg market?

The Asia Pacific region is expected to be the fastest-growing market for tow prepreg, with growth driven by rising manufacturing activities and demand in countries like China and India, projected to expand from $0.29 billion in 2023 to $0.57 billion by 2033.

Does ConsaInsights provide customized market report data for the tow Prepreg industry?

Yes, ConsaInsights offers customized market reports tailored to specific client needs in the tow-prepreg industry, providing data-driven insights to support strategic decisions and achieve business goals.

What deliverables can I expect from this tow Prepreg market research project?

Expect detailed market analysis reports, trends forecasts, competitive landscape assessments, and segment-wise breakdowns, including regional and application-specific insights, enabling informed decisions in the tow-prepreg market.

What are the market trends of tow Prepreg?

Current market trends in tow prepreg include the increasing adoption of thermoplastic materials, growing use in aerospace and automotive applications, advancements in manufacturing techniques like out-of-autoclave processes, and heightened emphasis on sustainability.