Automotive Robotics Market Report

Published Date: 31 January 2026 | Report Code: automotive-robotics

Automotive Robotics Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the Automotive Robotics market from 2023 to 2033, highlighting market size, growth prospects, key players, industry trends, regional insights, and future forecasts to deliver valuable insights for stakeholders.

| Metric | Value |

|---|---|

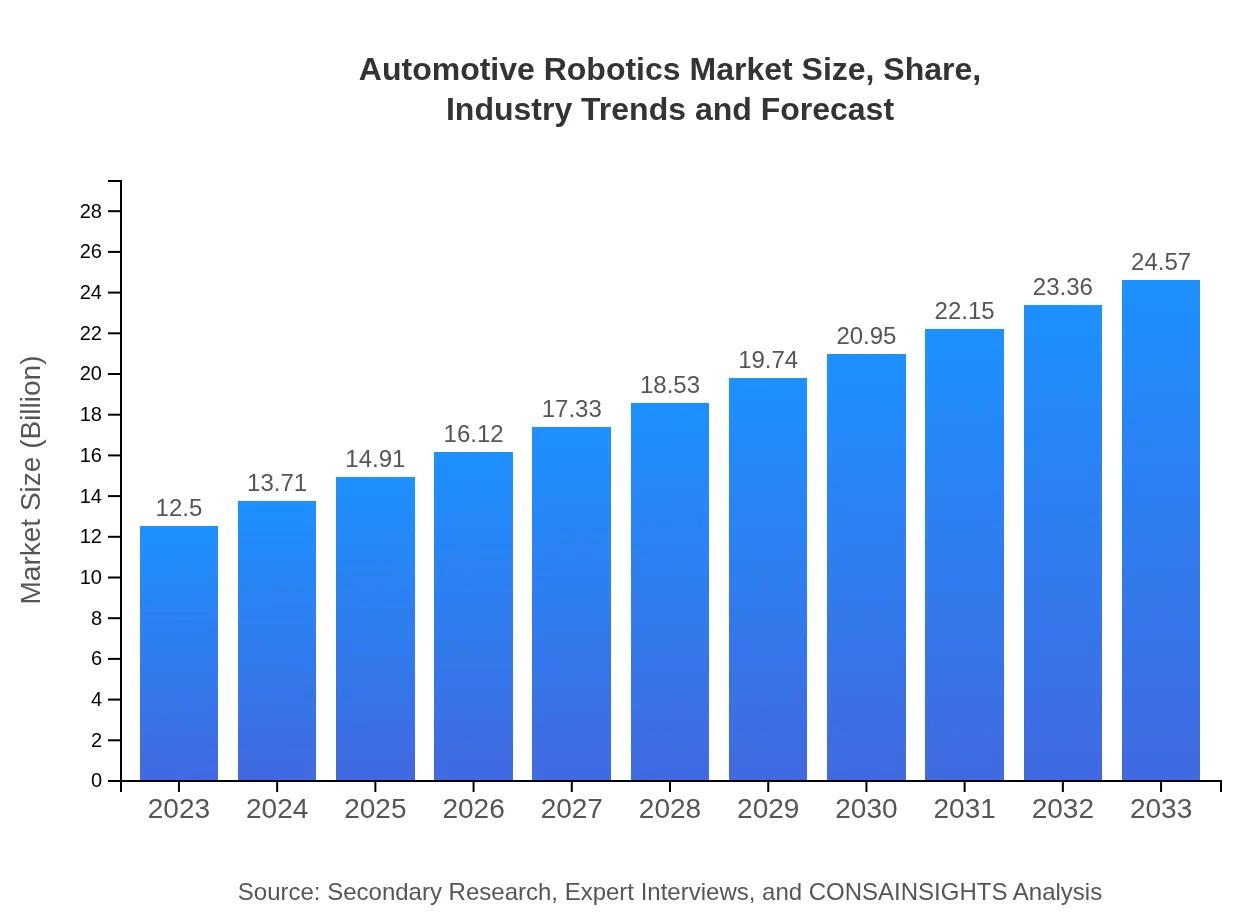

| Study Period | 2023 - 2033 |

| 2023 Market Size | $12.50 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $24.57 Billion |

| Top Companies | ABB Ltd., KUKA Robotics, FANUC Corporation, Yaskawa Electric Corporation |

| Last Modified Date | 31 January 2026 |

Automotive Robotics Market Overview

Customize Automotive Robotics Market Report market research report

- ✔ Get in-depth analysis of Automotive Robotics market size, growth, and forecasts.

- ✔ Understand Automotive Robotics's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Automotive Robotics

What is the Market Size & CAGR of Automotive Robotics market in 2023?

Automotive Robotics Industry Analysis

Automotive Robotics Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Automotive Robotics Market Analysis Report by Region

Europe Automotive Robotics Market Report:

The European market for automotive robotics was valued at USD 3.13 billion in 2023 and is set to reach USD 6.16 billion by 2033. Innovations in automation to support electric vehicle production, along with stringent regulations pushing for greater safety and efficiency in manufacturing, are key trends driving the robustness of this market.Asia Pacific Automotive Robotics Market Report:

In the Asia Pacific region, the market value was USD 2.48 billion in 2023, expected to grow to USD 4.86 billion by 2033. Countries like China, Japan, and South Korea are leading in automotive production and adopting robotics to enhance manufacturing efficiency. The rapid adoption of electric vehicles and supportive government policies for automation in the automotive sector are substantial growth factors in this region.North America Automotive Robotics Market Report:

North America represented a substantial share of the market with a value of USD 4.30 billion in 2023, anticipated to grow to USD 8.44 billion by 2033. The presence of major automotive manufacturers, significant investments in R&D for robotics, and a heightened focus on automation during supply chain disruptions are pivotal in this region's growth.South America Automotive Robotics Market Report:

The South American automotive robotics market was valued at USD 1.24 billion in 2023, projected to reach USD 2.43 billion by 2033. Despite being a smaller market, Brazil and Argentina are making strides in automotive manufacturing, and robotics adoption is slowly increasing with growing awareness of automation benefits.Middle East & Africa Automotive Robotics Market Report:

In the Middle East and Africa, the market size was USD 1.36 billion in 2023, growing to USD 2.67 billion by 2033. The automotive sector in this region is gradually embracing robotics, driven by the need for modernization and efficiency in production processes amid a challenging economic landscape.Tell us your focus area and get a customized research report.

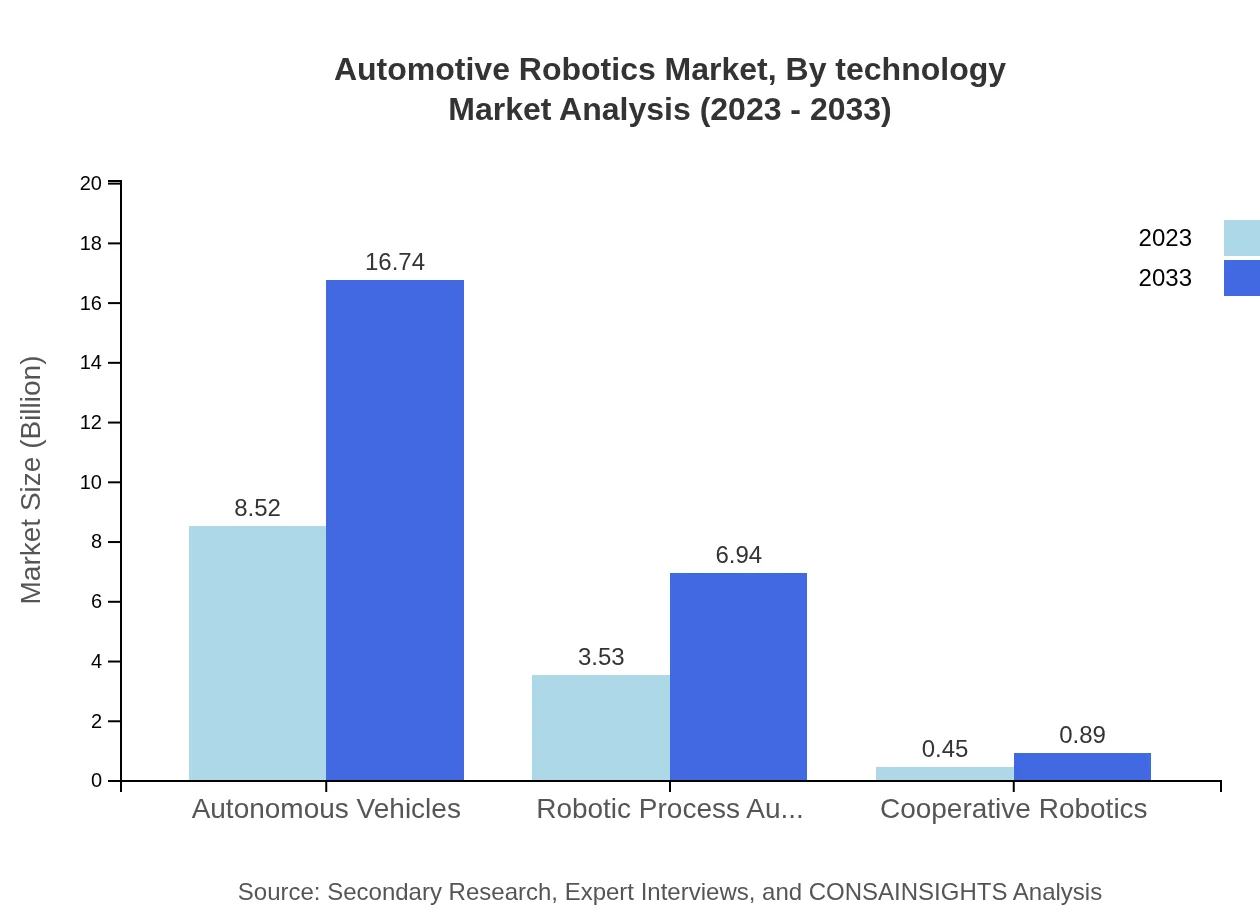

Automotive Robotics Market Analysis By Technology

Robotic arms lead the automotive robotics market, valued at USD 8.52 billion in 2023 and expected to grow to USD 16.74 billion by 2033, dominating the market share at 68.15% throughout this period. AMRs and collaborative robots are also gaining traction, catering to logistics and operational tasks, with respective shares representing 28.23% and 3.62% in the market.

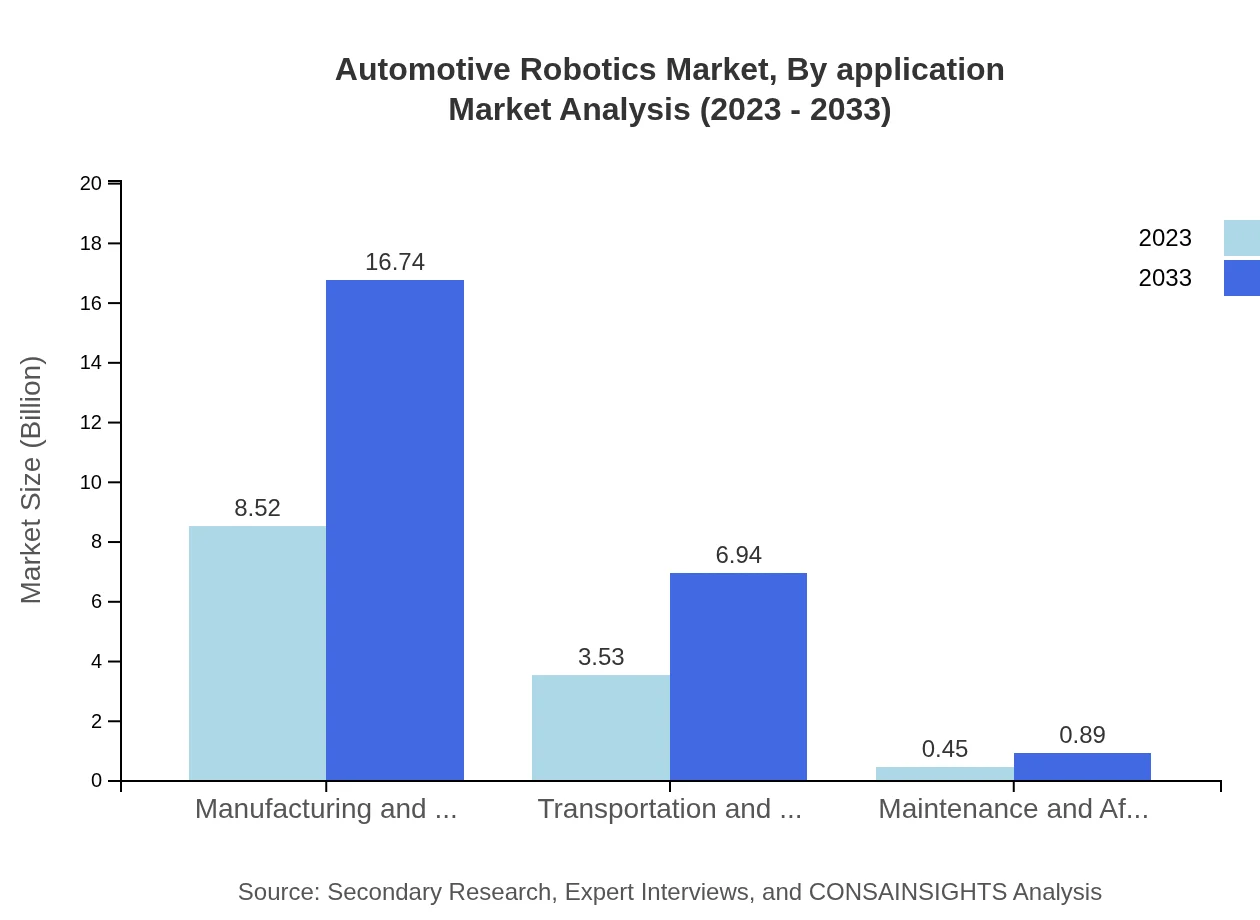

Automotive Robotics Market Analysis By Application

Applications of automotive robotics encompass manufacturing, logistics, and service sectors. Manufacturing accounts for the largest share, driven by robotic assembly lines and automation of production. Logistics and service sectors are gradually increasing their share through the integration of AMRs, showcasing a growing trend towards efficiency in supply chain and operational tasks.

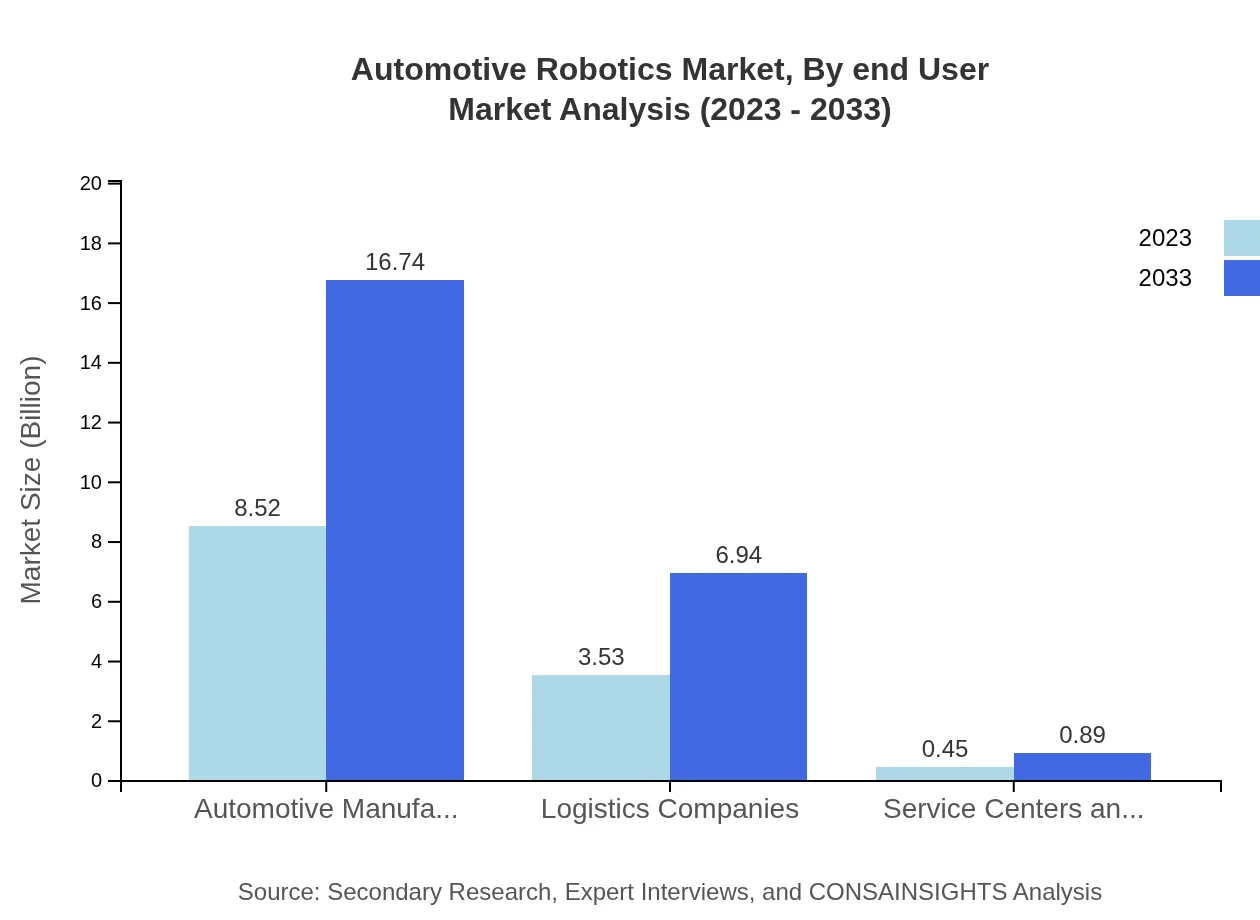

Automotive Robotics Market Analysis By End User

The automotive manufacturers are the largest segment, contributing USD 8.52 billion to the market in 2023, growing to USD 16.74 billion by 2033, holding a share of 68.15%. Logistics companies also play a vital role, with increasing robotics adoption to optimize distribution processes.

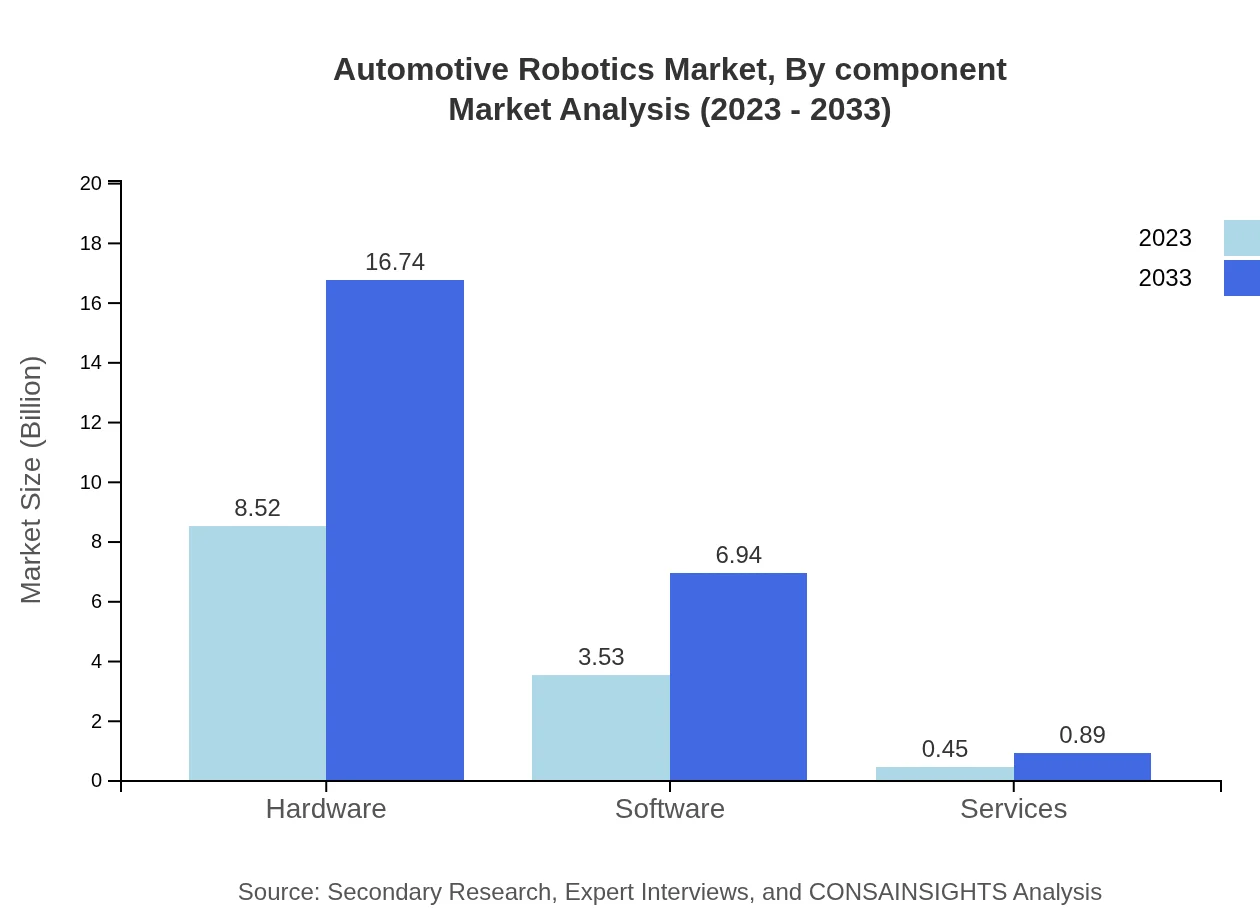

Automotive Robotics Market Analysis By Component

Market components include hardware, software, and services. Hardware dominates with a share of 68.15% in both years, indicating a consistent need for advanced robotics systems. Software solutions are essential for operational efficiency in automation, while services are on the rise with increased maintenance and support requirements.

Automotive Robotics Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Automotive Robotics Industry

ABB Ltd.:

ABB is a leader in robotics and automation technology, providing innovative solutions for industries including automotive, driven by its advanced R&D capabilities.KUKA Robotics:

KUKA Robotics specializes in industrial robots and automation systems, offering flexible robotic solutions tailored for automotive manufacturing to enhance productivity.FANUC Corporation:

FANUC Corporation is recognized for its wide range of industrial robots, including collaborative robots, promoting exponential growth in the automotive industry.Yaskawa Electric Corporation:

Yaskawa Electric Corporation is leading automation and robotics development, focusing on optimized solutions for automotive production lines.We're grateful to work with incredible clients.

FAQs

What is the market size of automotive Robotics?

The automotive robotics market is valued at approximately $12.5 billion in 2023, with a projected compound annual growth rate (CAGR) of 6.8%, indicating substantial growth opportunities over the next decade.

What are the key market players or companies in the automotive Robotics industry?

Key players in the automotive robotics industry include major manufacturers such as ABB, Fanuc, KUKA, Yaskawa Electric, and Honda Robotics, participating in advanced robotic solutions for manufacturing automotive systems.

What are the primary factors driving the growth in the automotive Robotics industry?

The growth of the automotive robotics industry is driven by increased demand for automation, need for cost reduction, improvement in quality control, the rise of electric vehicles, and advancements in technology such as AI and machine learning.

Which region is the fastest Growing in the automotive Robotics?

North America is the fastest-growing region in the automotive robotics market, projected to grow from $4.30 billion in 2023 to $8.44 billion by 2033, supported by technological advancements and manufacturing expansions.

Does ConsaInsights provide customized market report data for the automotive Robotics industry?

Yes, ConsaInsights offers customized market report data tailored to client needs within the automotive robotics industry, providing detailed insights and analysis tailored to specific segments and regional markets.

What deliverables can I expect from this automotive Robotics market research project?

Clients can expect deliverables including comprehensive market reports, detailed segment analysis, competitive landscape insights, growth forecasts, and tailored recommendations based on specific objectives within the automotive robotics space.

What are the market trends of automotive Robotics?

Market trends in automotive robotics include the integration of AI and IoT in manufacturing, increased adoption of collaborative robots, rising safety standards, and the growing role of robotics in electric vehicle production and supply chain optimization.