Surface Vision Inspection Equipment Market Report

Published Date: 31 January 2026 | Report Code: surface-vision-inspection-equipment

Surface Vision Inspection Equipment Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Surface Vision Inspection Equipment market, encompassing market size, trends, and forecasts from 2023 to 2033, along with insights into segmentation, regional dynamics, and major players in the industry.

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

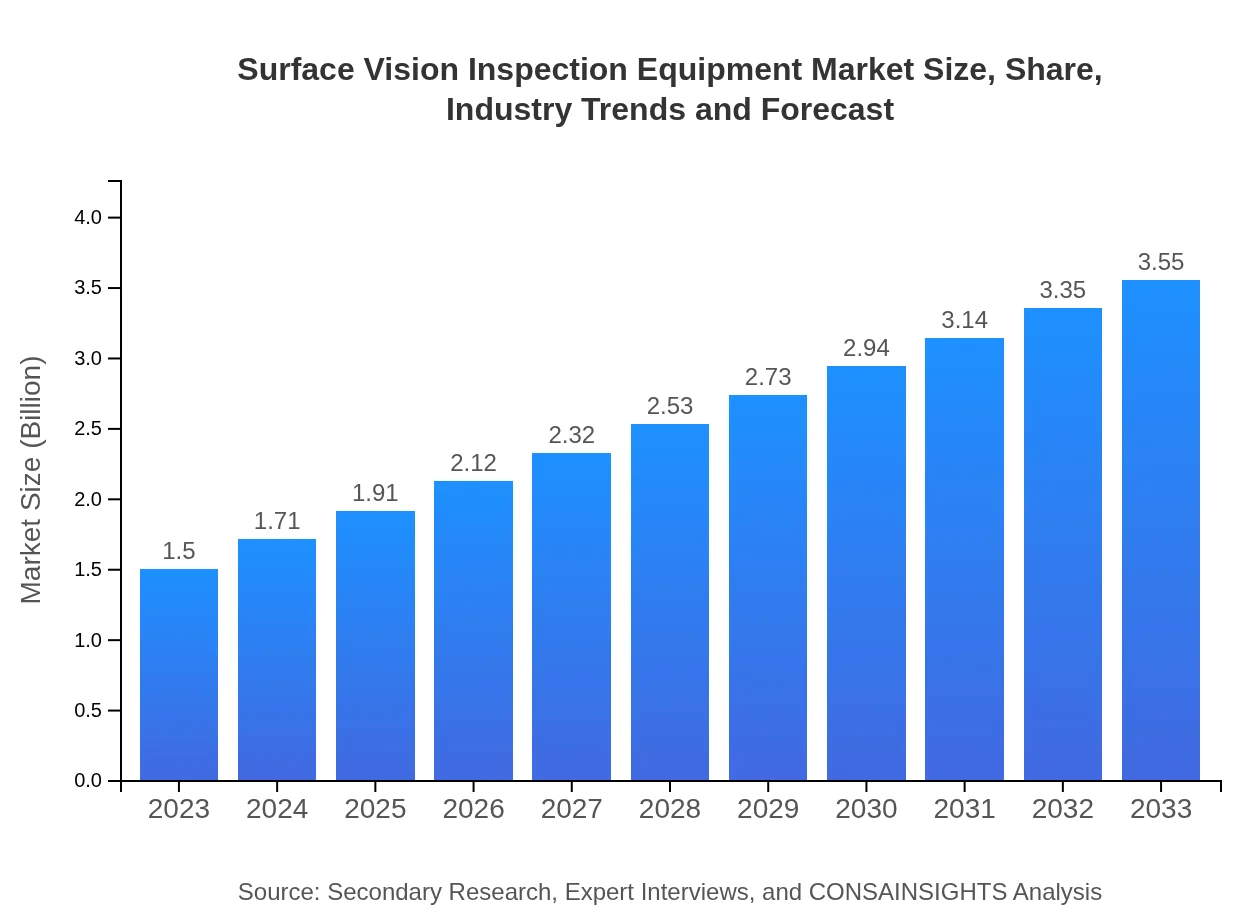

| 2023 Market Size | $1.50 Billion |

| CAGR (2023-2033) | 8.7% |

| 2033 Market Size | $3.55 Billion |

| Top Companies | Cognex Corporation, KEYENCE Corporation, Omron Corporation, Basler AG |

| Last Modified Date | 31 January 2026 |

Surface Vision Inspection Equipment Market Overview

Customize Surface Vision Inspection Equipment Market Report market research report

- ✔ Get in-depth analysis of Surface Vision Inspection Equipment market size, growth, and forecasts.

- ✔ Understand Surface Vision Inspection Equipment's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Surface Vision Inspection Equipment

What is the Market Size & CAGR of Surface Vision Inspection Equipment market in 2023?

Surface Vision Inspection Equipment Industry Analysis

Surface Vision Inspection Equipment Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Surface Vision Inspection Equipment Market Analysis Report by Region

Europe Surface Vision Inspection Equipment Market Report:

The European market is expected to grow from $0.40 billion in 2023 to $0.95 billion by 2033. Europe is witnessing strong demand for Surface Vision Inspection Equipment due to stringent quality regulations in manufacturing. Countries like Germany and the UK are leading the way in adopting these technologies to ensure product compliance and safety.Asia Pacific Surface Vision Inspection Equipment Market Report:

In Asia Pacific, the market is expected to grow from $0.30 billion in 2023 to $0.71 billion by 2033. The growth is driven by increasing manufacturing activities and the adoption of automation technologies in countries like China and India. Additionally, the region is witnessing substantial investments in smart manufacturing initiatives, which are augmenting the demand for advanced surface vision inspection technologies.North America Surface Vision Inspection Equipment Market Report:

North America, valued at $0.53 billion in 2023, is projected to reach $1.27 billion by 2033. The region's growth is propelled by advancements in machine learning and automation technologies. The presence of established manufacturing hubs and a strong focus on product quality and compliance standards are significant contributors to the market's expansion.South America Surface Vision Inspection Equipment Market Report:

The South American market is anticipated to see growth from $0.13 billion in 2023 to $0.31 billion by 2033. Economic recovery and improvement within the manufacturing sector are key growth factors here. Countries like Brazil and Argentina are focusing on modernizing their production facilities, thereby increasing the demand for inspection solutions.Middle East & Africa Surface Vision Inspection Equipment Market Report:

The Middle East and Africa market is expected to expand from $0.13 billion in 2023 to $0.32 billion by 2033. Growing investments in the manufacturing sector coupled with a rise in consumer goods production are key factors driving this market. The region is gradually adopting advanced technologies to improve operational efficiencies.Tell us your focus area and get a customized research report.

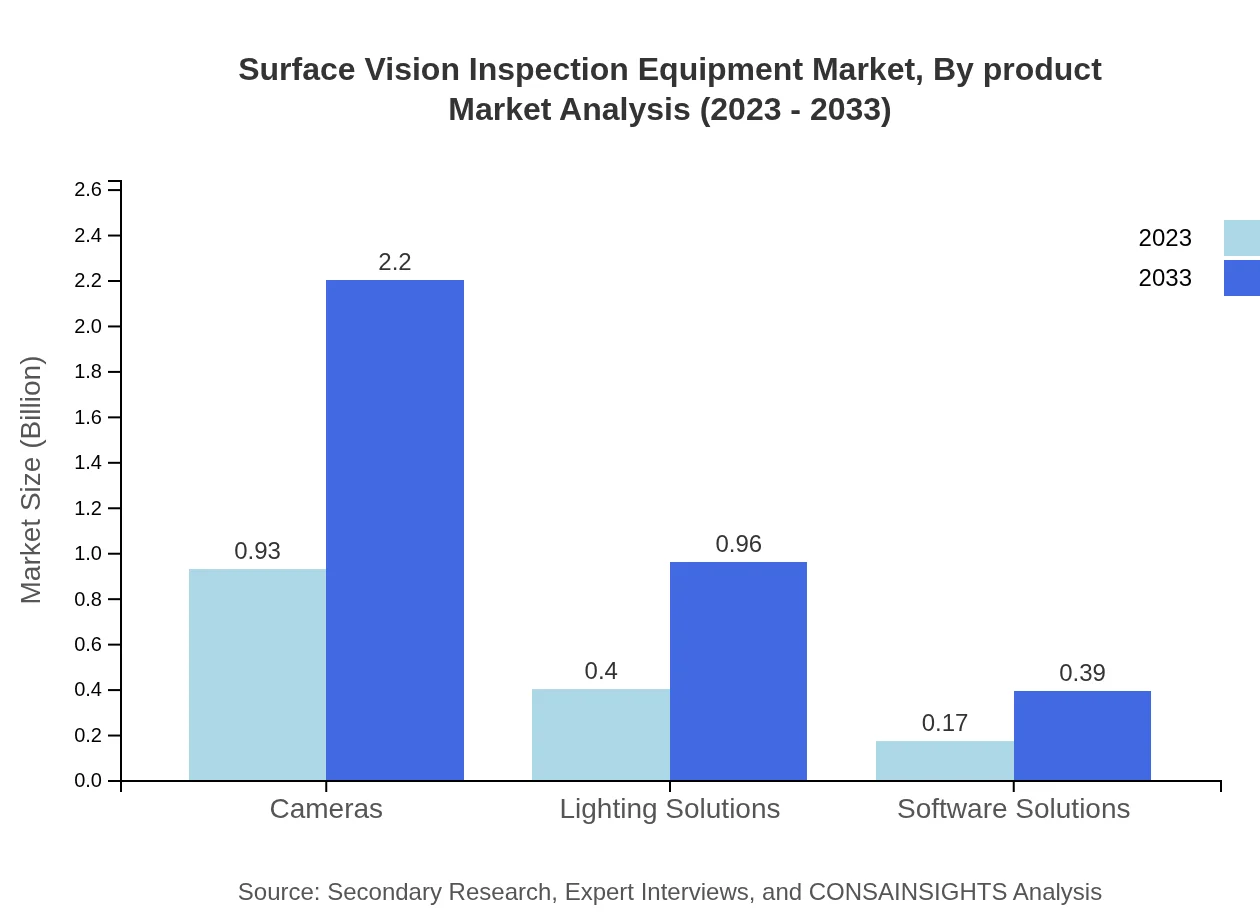

Surface Vision Inspection Equipment Market Analysis By Product

The Surface Vision Inspection Equipment market by product is dominated by Cameras, which accounted for a market size of $0.93 billion in 2023, expected to rise to $2.20 billion by 2033. Lighting Solutions and Software Solutions contribute significantly as well, with respective market sizes growing from $0.40 billion to $0.96 billion, and $0.17 billion to $0.39 billion in the same period.

Surface Vision Inspection Equipment Market Analysis By Application

In terms of application, Manufacturing holds a major share of the market, maintaining a share of 62.02% from $0.93 billion in 2023 to $2.20 billion by 2033. Other applications such as Retail and Pharmaceutical are also significant, with shares of 26.94% and 11.05% respectively, highlighting the diverse usage of vision inspection systems across industries.

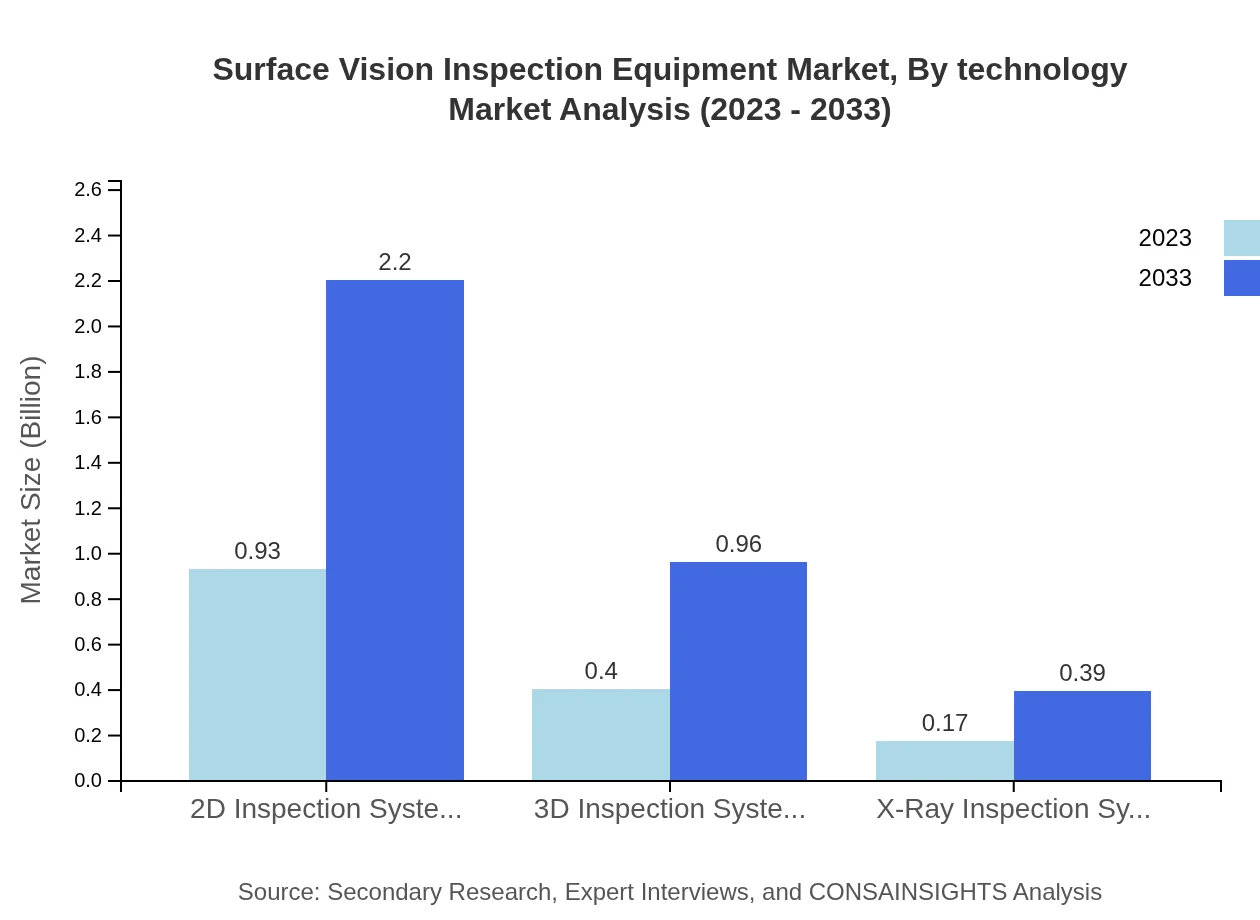

Surface Vision Inspection Equipment Market Analysis By Technology

The technology segment shows a strong inclination towards 2D Inspection Systems, which dominates with a size of $0.93 billion in 2023, growing to $2.20 billion by 2033. 3D Inspection Systems and X-Ray Inspection Systems follow, reflecting a growing trend towards more comprehensive inspection capabilities.

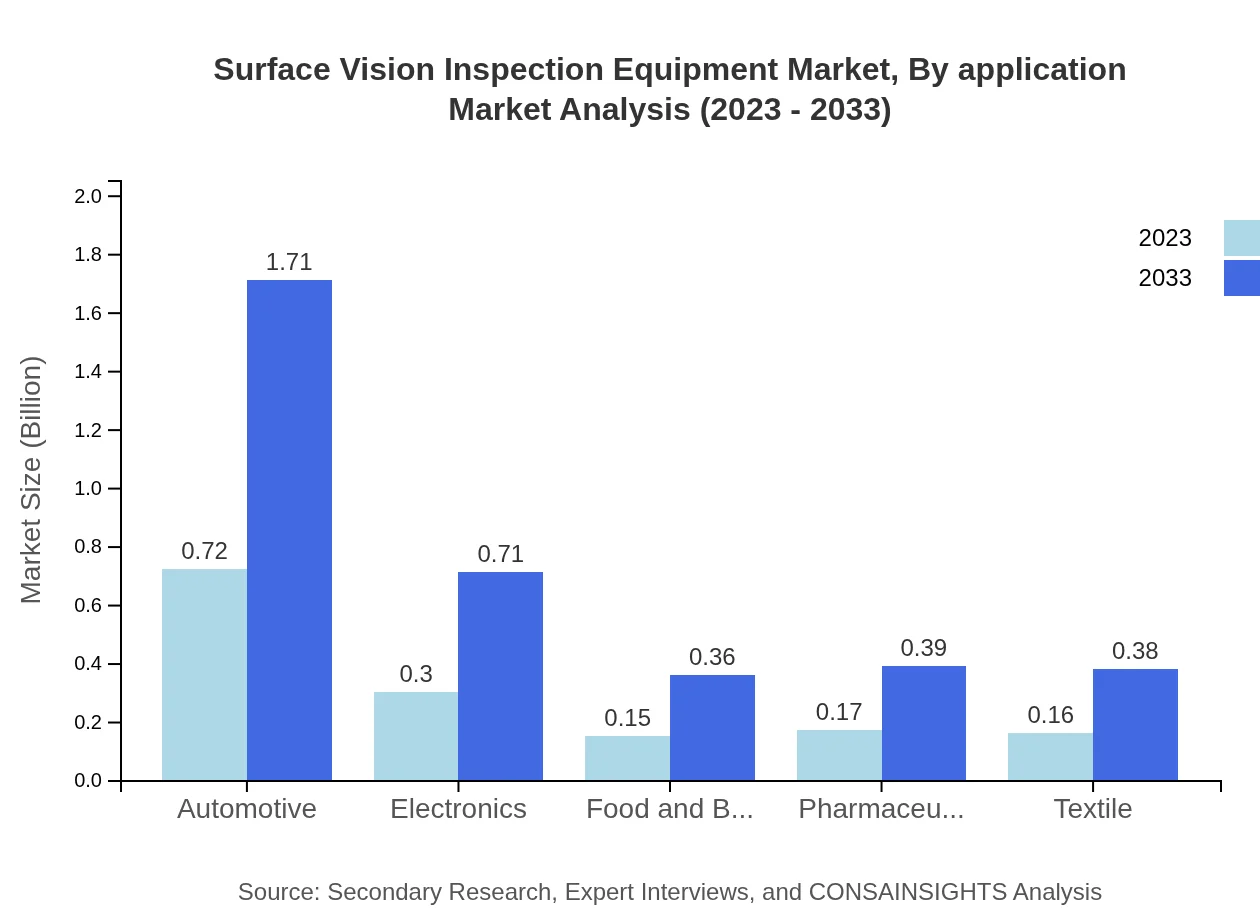

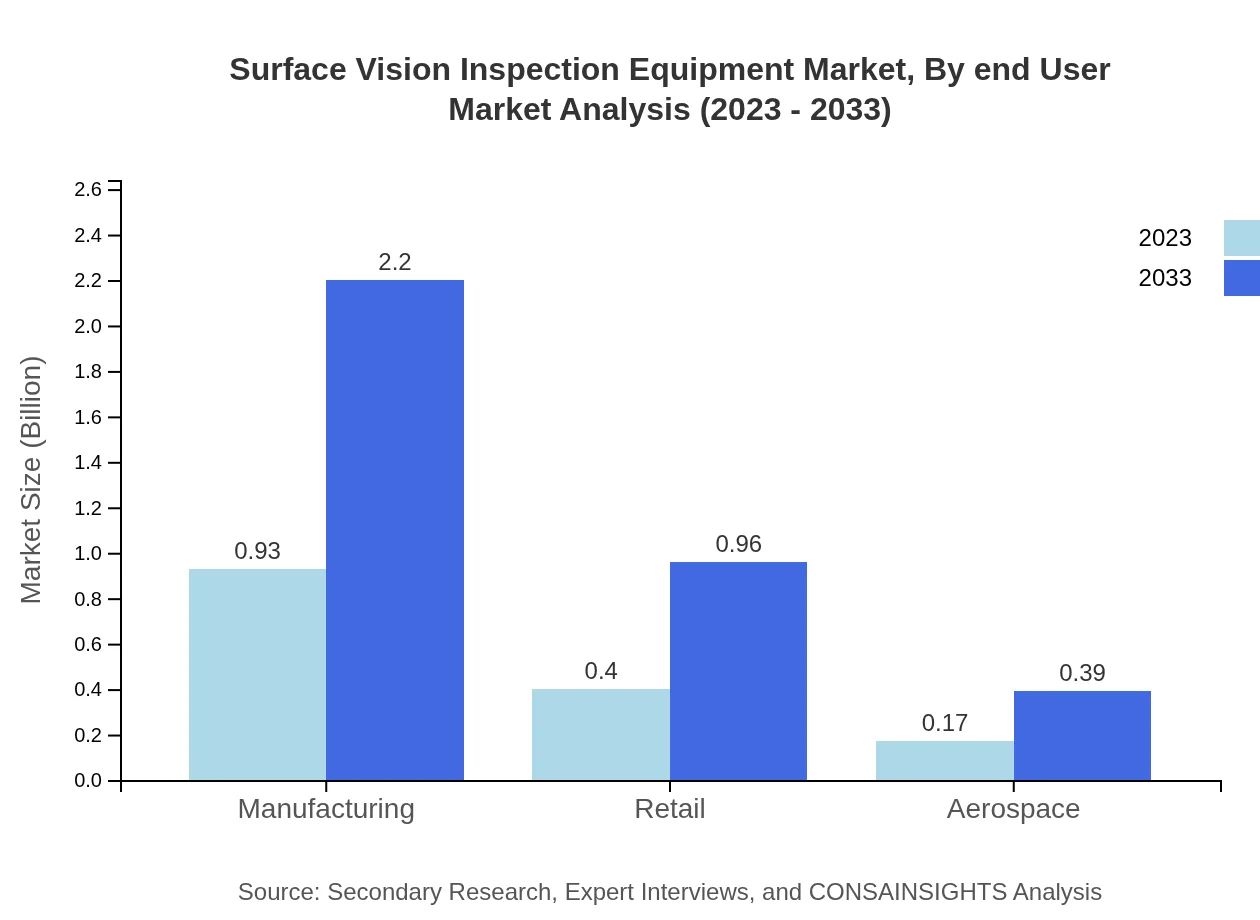

Surface Vision Inspection Equipment Market Analysis By End User

The Automotive industry is a key end-user of Surface Vision Inspection Equipment, expected to grow from $0.72 billion in 2023 to $1.71 billion by 2033, holding a significant share of 48.1%. Other notable sectors include Electronics and Food & Beverage, which are poised for growth in the upcoming years.

Surface Vision Inspection Equipment Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Surface Vision Inspection Equipment Industry

Cognex Corporation:

Cognex is a leading provider of machine vision and industrial barcode readers. Their expertise in vision systems and software offers innovative solutions that cater to diverse industries' inspection needs.KEYENCE Corporation:

KEYENCE is renowned for its advanced sensors and vision systems that enhance manufacturing processes. They focus on providing comprehensive inspection solutions that maximize efficiency and minimize errors.Omron Corporation:

Omron specializes in automation technology and offers a robust lineup of vision inspection systems aimed at improving quality and accelerating production workflows across various sectors.Basler AG:

Basler provides high-quality network and USB cameras, paired with software solutions that facilitate effective image processing and quality inspection in different applications.We're grateful to work with incredible clients.

FAQs

What is the market size of surface vision inspection equipment?

The surface vision inspection equipment market is currently valued at approximately $1.5 billion in 2023. It is projected to grow at a CAGR of 8.7%, reaching significant growth by the year 2033.

What are the key market players or companies in the surface vision inspection equipment industry?

Key players in the surface vision inspection equipment industry include leading technology firms that specialize in inspection systems, software solutions, and imaging technologies, driving innovation and market share.

What are the primary factors driving the growth in the surface vision inspection equipment industry?

The growth in the surface vision inspection equipment market is primarily driven by advancements in automation, increasing demand for quality assurance in manufacturing, and the adoption of machine vision technologies across industries.

Which region is the fastest Growing in the surface vision inspection equipment market?

North America is the fastest-growing region in the surface vision inspection equipment market, expected to surge from $0.53 billion in 2023 to $1.27 billion by 2033, showcasing significant investment and technological advancements.

Does ConsaInsights provide customized market report data for the surface vision inspection equipment industry?

Yes, ConsaInsights offers customized market report data tailored to the unique needs of clients in the surface vision inspection equipment industry, ensuring actionable insights and strategic decision-making.

What deliverables can I expect from this surface vision inspection equipment market research project?

Deliverables from the surface vision inspection equipment market research project include comprehensive market analysis reports, regional insights, competitive landscape assessments, and future growth forecasts, aiding business strategies and planning.

What are the market trends of surface vision inspection equipment?

Emerging trends in the surface vision inspection equipment market include increased integration of AI technologies, growth in automation processes, enhanced imaging techniques, and a shift towards sustainability in manufacturing operations.