Technical Foam Market Report

Published Date: 22 January 2026 | Report Code: technical-foam

Technical Foam Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Technical Foam market from 2023 to 2033, including insights on market size, growth trends, segmentation, regional analysis, and key players impacting the industry.

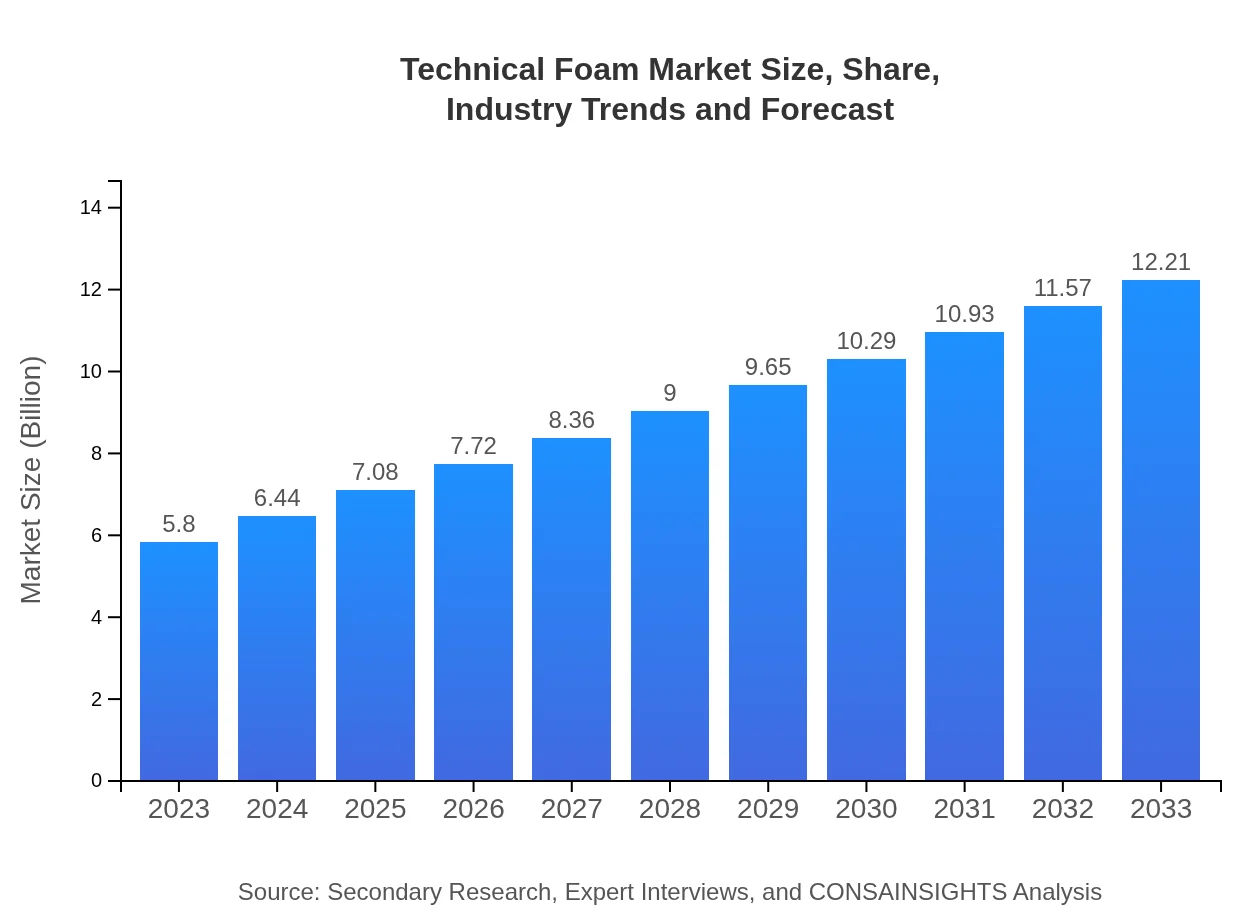

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $5.80 Billion |

| CAGR (2023-2033) | 7.5% |

| 2033 Market Size | $12.21 Billion |

| Top Companies | BASF SE, Huntsman Corporation, 3M Company, Armacell International S.A., Recticel |

| Last Modified Date | 22 January 2026 |

Technical Foam Market Overview

Customize Technical Foam Market Report market research report

- ✔ Get in-depth analysis of Technical Foam market size, growth, and forecasts.

- ✔ Understand Technical Foam's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Technical Foam

What is the Market Size & CAGR of Technical Foam market in 2023?

Technical Foam Industry Analysis

Technical Foam Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Technical Foam Market Analysis Report by Region

Europe Technical Foam Market Report:

The European market is expected to grow from USD 1.62 billion in 2023 to about USD 3.41 billion by 2033. Innovations in sustainable materials and the increasing application of technical foams in healthcare and consumer goods are pivotal factors contributing to this growth.Asia Pacific Technical Foam Market Report:

The Asia Pacific region is witnessing significant growth in the Technical Foam market, projected to reach approximately USD 2.33 billion by 2033 from USD 1.11 billion in 2023. Driven by rapid industrialization and rising demand in automotive and construction sectors, the region is expected to maintain a robust CAGR of around 8.8% during the forecast period.North America Technical Foam Market Report:

North America holds a significant share of the Technical Foam market, with a projected value of USD 4.32 billion by 2033, up from USD 2.05 billion in 2023. The region's demand is backed by substantial automotive and aerospace sectors focusing on lightweight materials for improved fuel efficiency.South America Technical Foam Market Report:

In South America, the Technical Foam market is anticipated to grow from USD 0.24 billion in 2023 to USD 0.51 billion by 2033. Growth in construction and consumer goods applications is driving this market, along with increasing investments in infrastructure development across countries in the region.Middle East & Africa Technical Foam Market Report:

In the Middle East and Africa, the Technical Foam market is projected to grow from USD 0.78 billion in 2023 to USD 1.64 billion by 2033. The region is seeing a rise in construction projects and automotive manufacturing, driving the demand for technical foams in various applications.Tell us your focus area and get a customized research report.

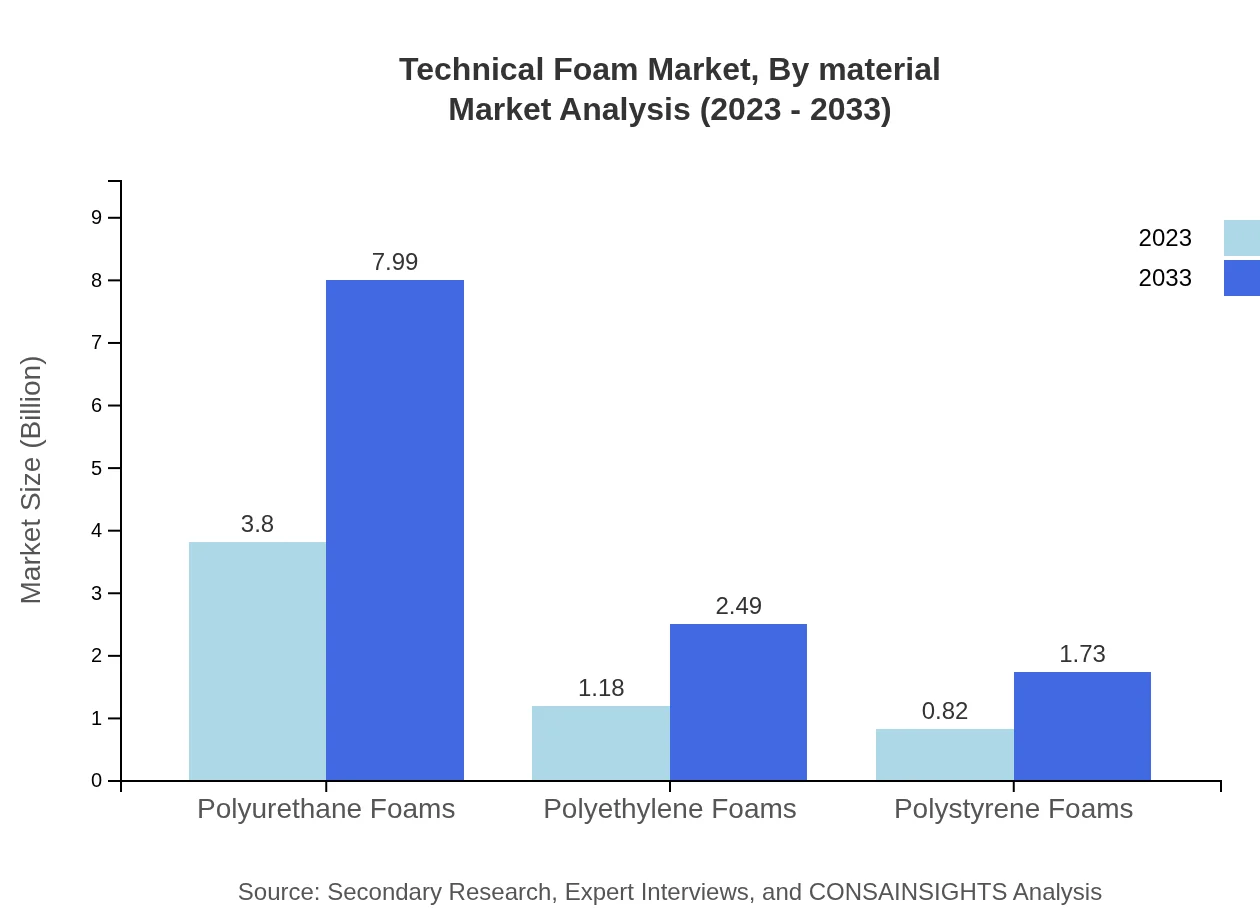

Technical Foam Market Analysis By Material

In terms of materials, polyurethane foams dominate the market, accounting for approximately 65.46% of the total share as of 2023, with a projected growth rate reaching USD 7.99 billion by 2033. Polyethylene and polystyrene foams follow, catering to various applications due to their specific properties such as insulation and soundproofing.

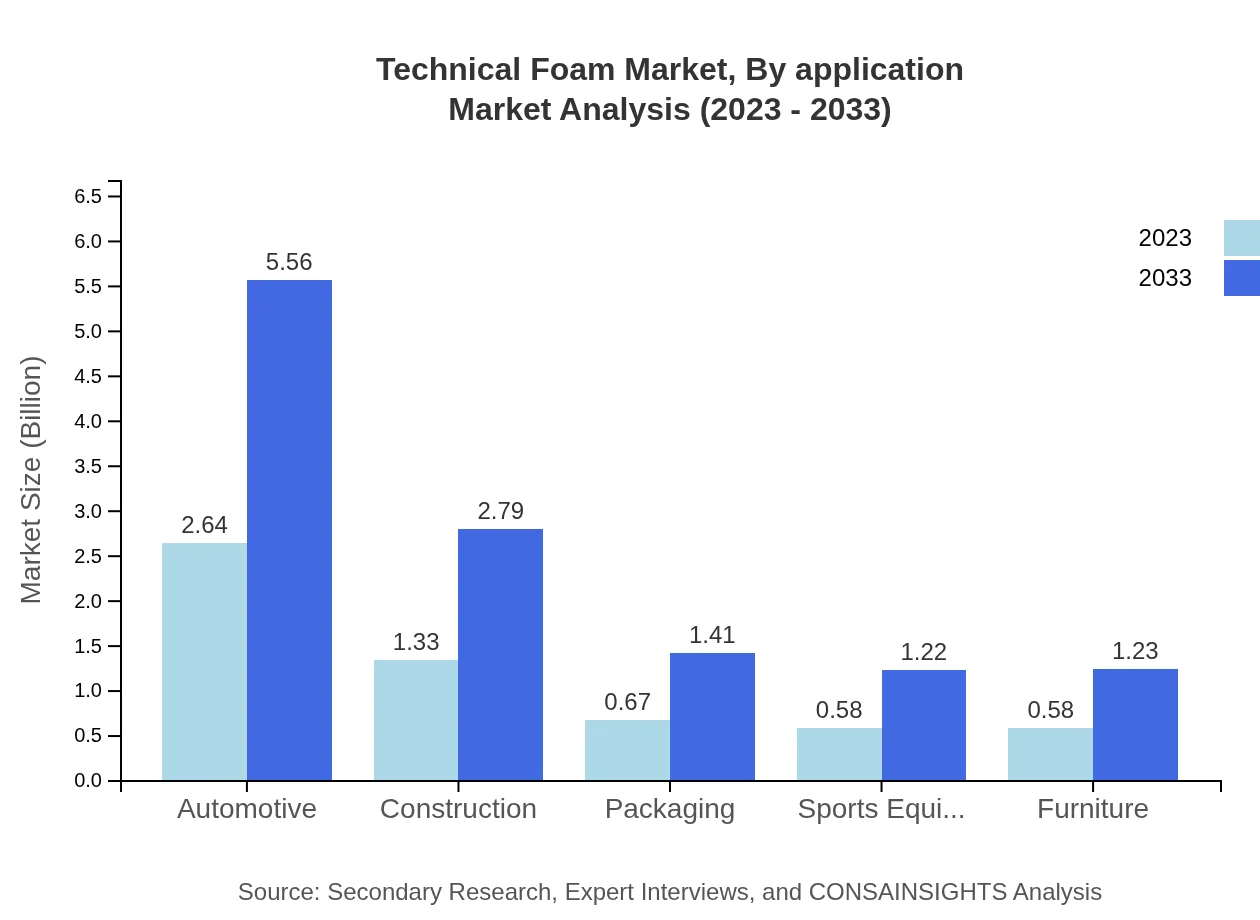

Technical Foam Market Analysis By Application

The automotive sector remains a key application area, consuming around 45.53% of the market share in 2023. Other significant applications include aerospace and construction, reflecting the versatile nature of technical foams in enhancing product performance and durability.

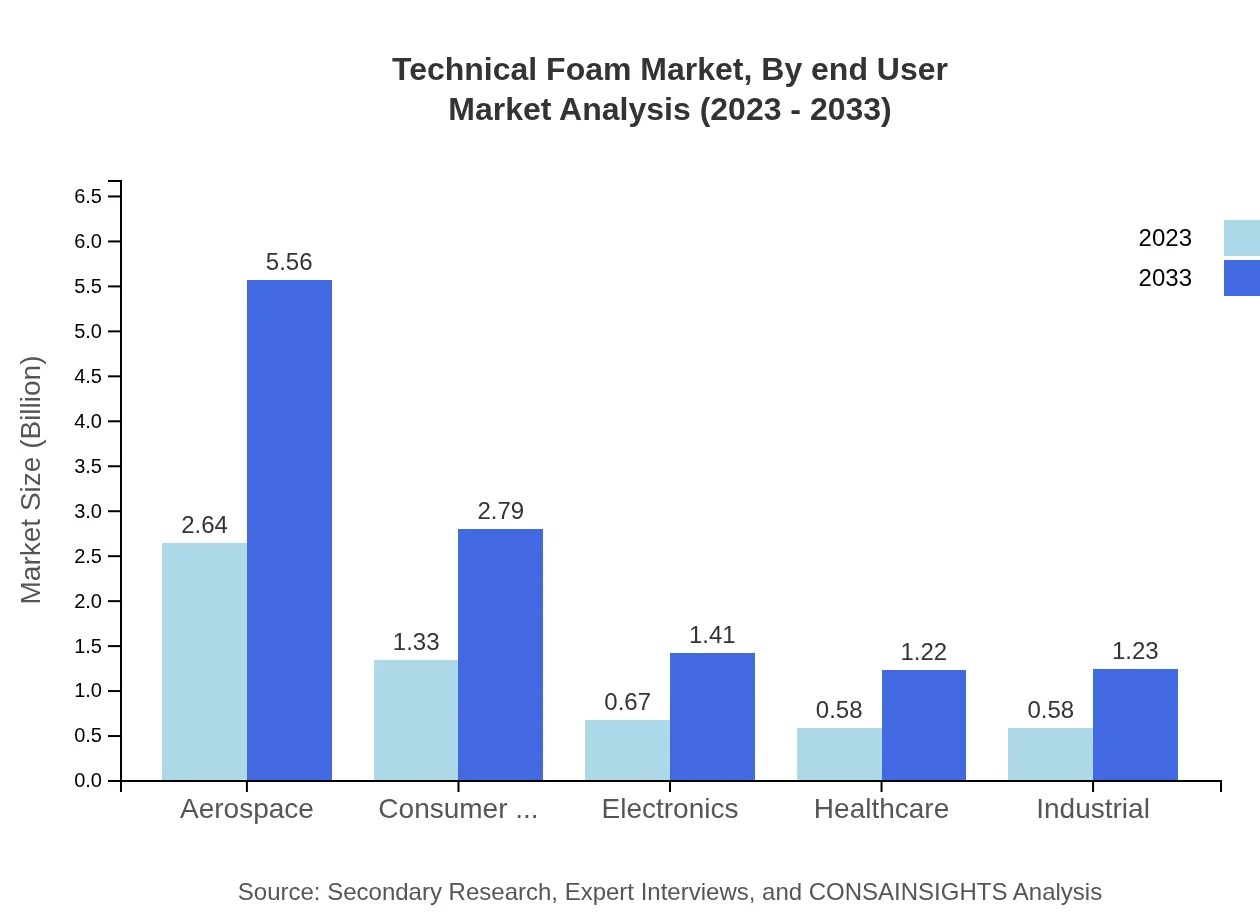

Technical Foam Market Analysis By End User

The healthcare industry presents substantial growth opportunities, driven by advancements in medical devices and patient care products. Industrial applications also contribute significantly to market volume, thanks to their use in machinery and protective equipment.

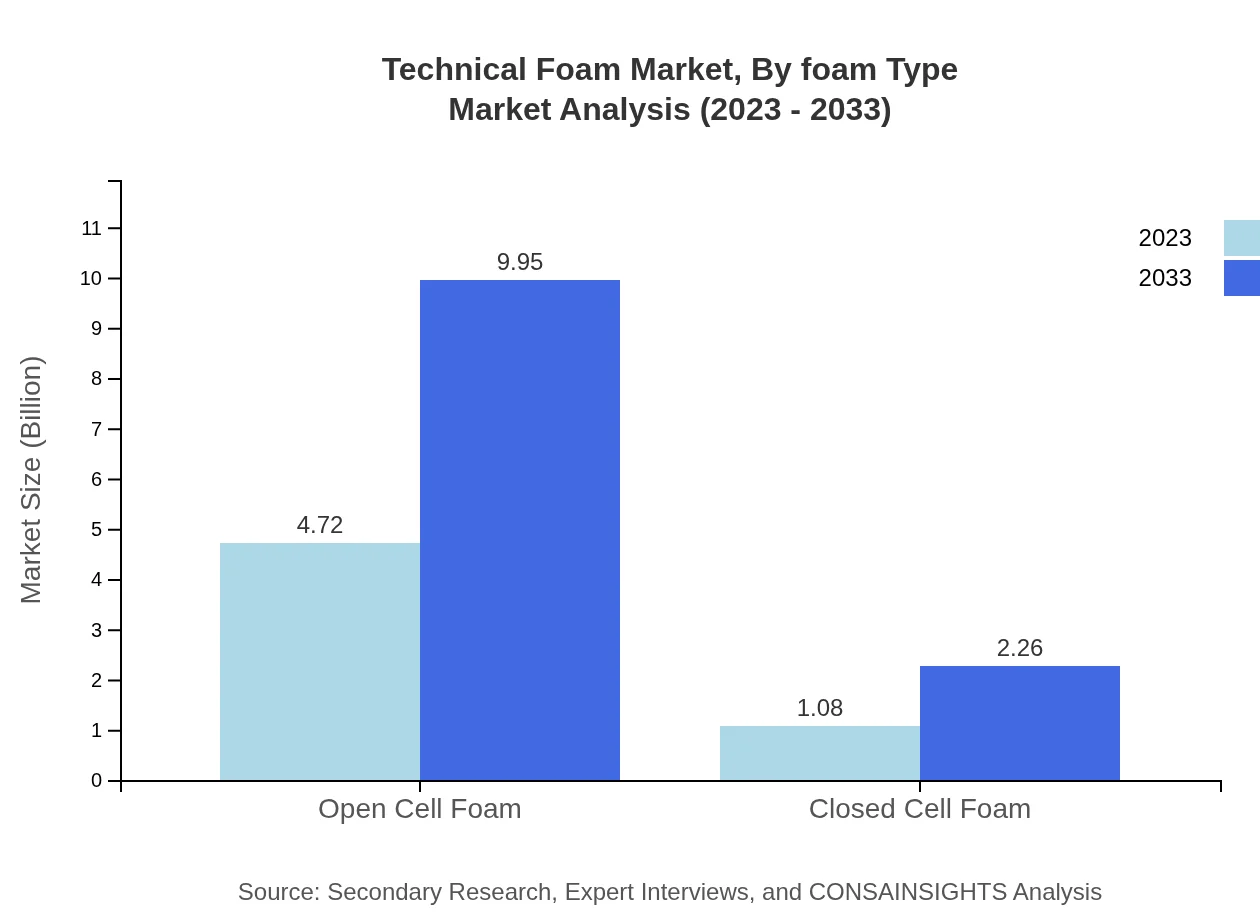

Technical Foam Market Analysis By Foam Type

Open cell foams lead the foam type segment, representing 81.46% of the market share. Closed cell foams are also vital in applications requiring moisture resistance. The differing foam characteristics influence their preferential use in various applications, including insulation and cushioning.

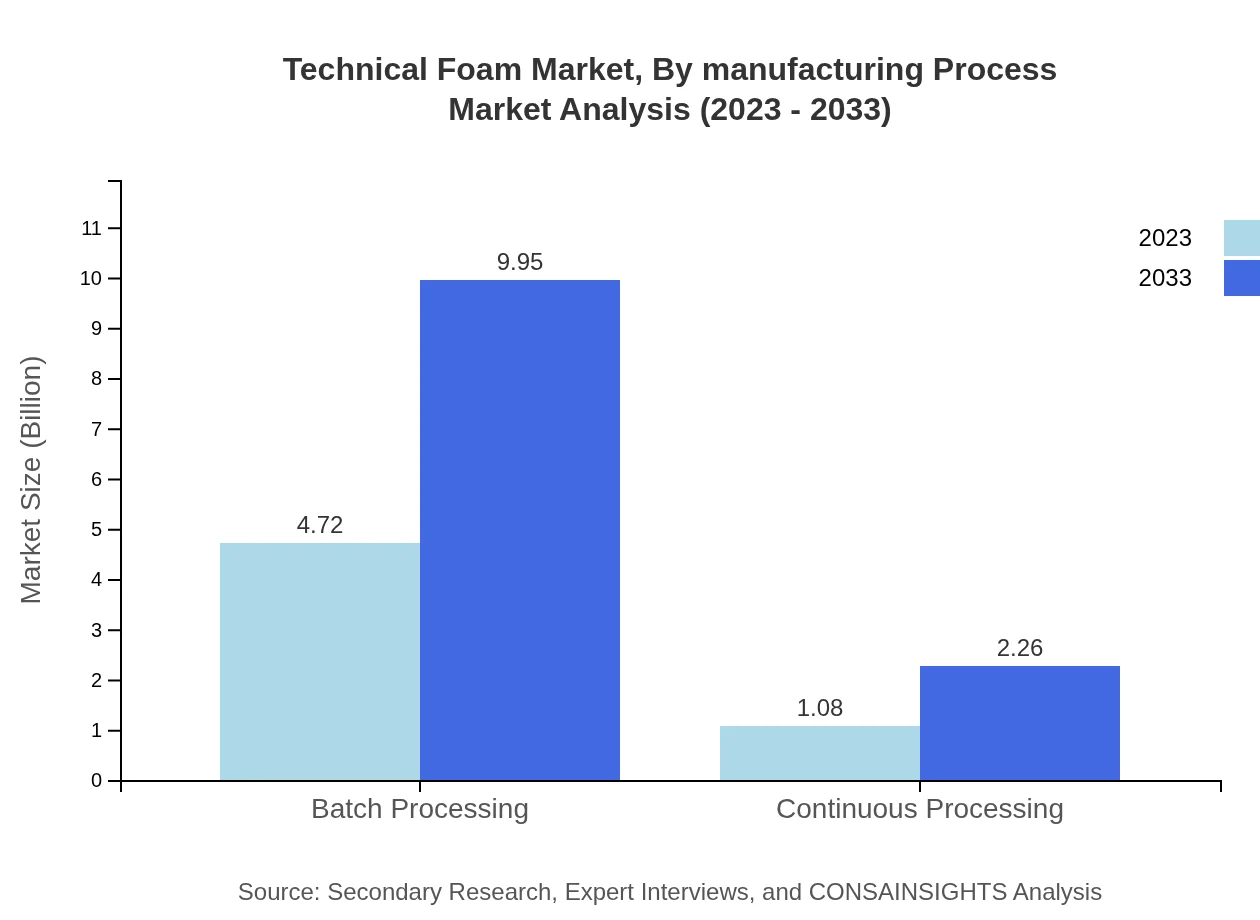

Technical Foam Market Analysis By Manufacturing Process

Batch processing dominates the manufacturing processes of Technical Foam due to its efficiency and flexibility in production. Continuous processing is crucial for larger-scale production where uniformity and quality consistency are required across products.

Technical Foam Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Technical Foam Industry

BASF SE:

BASF SE is a leading chemical company that produces high-performance foams for various applications, specializing in sustainability and innovative solutions.Huntsman Corporation:

Huntsman Corporation manufactures a broad range of polyurethane and technical foams, focusing on advanced materials for automotive and industrial applications.3M Company:

3M Company is a global technology company that offers a wide variety of foam solutions emphasizing high-quality performance in consumer and industrial markets.Armacell International S.A.:

Armacell specializes in flexible foam solutions for insulation and technical applications, playing a vital role in energy efficiency industries.Recticel:

Recticel is known for its high-quality insulation and technical foam products, servicing multiple sectors including aerospace, automotive, and construction.We're grateful to work with incredible clients.

FAQs

What is the market size of technical Foam?

The global technical foam market is valued at approximately $5.8 billion in 2023, with a projected CAGR of 7.5%. By 2033, it is expected to reach around $12.9 billion, showcasing robust growth in this sector.

What are the key market players or companies in the technical Foam industry?

Key players in the technical foam industry include global manufacturers and suppliers who dominate this market. Companies like BASF, Huntsman International, and Recticel lead with diverse products across various applications, driving innovation and competition.

What are the primary factors driving the growth in the technical foam industry?

Growth in the technical foam industry is propelled by increased demand from sectors such as automotive, construction, and aerospace. Innovations in materials technology and rising consumer preferences for lightweight materials also contribute significantly to market expansion.

Which region is the fastest Growing in the technical foam market?

Asia-Pacific is the fastest-growing region in the technical foam market. With a market size increasing from $1.11 billion in 2023 to $2.33 billion by 2033, it reflects significant industrial growth, particularly in manufacturing and automotive sectors.

Does ConsaInsights provide customized market report data for the technical foam industry?

Yes, ConsaInsights offers customized market report data tailored to specific requirements in the technical foam industry. Clients can request focused insights based on geographical locations, market segments, or emerging trends.

What deliverables can I expect from this technical foam market research project?

Deliverables from the technical foam market research include comprehensive reports, data analytics, market segmentation insights, competitive landscape analysis, and forecasts, providing actionable intelligence for strategic planning.

What are the market trends of technical foam?

Current trends in the technical foam market include a growing preference for eco-friendly materials, advancements in manufacturing processes, and innovations for better performance. Market segments like aerospace and automotive show increased investment in technical foam applications.