Epoxy Tooling Board Market Report

Published Date: 22 January 2026 | Report Code: epoxy-tooling-board

Epoxy Tooling Board Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Epoxy Tooling Board market, including insights on its current trends, future forecasts until 2033, and various segments of the industry.

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

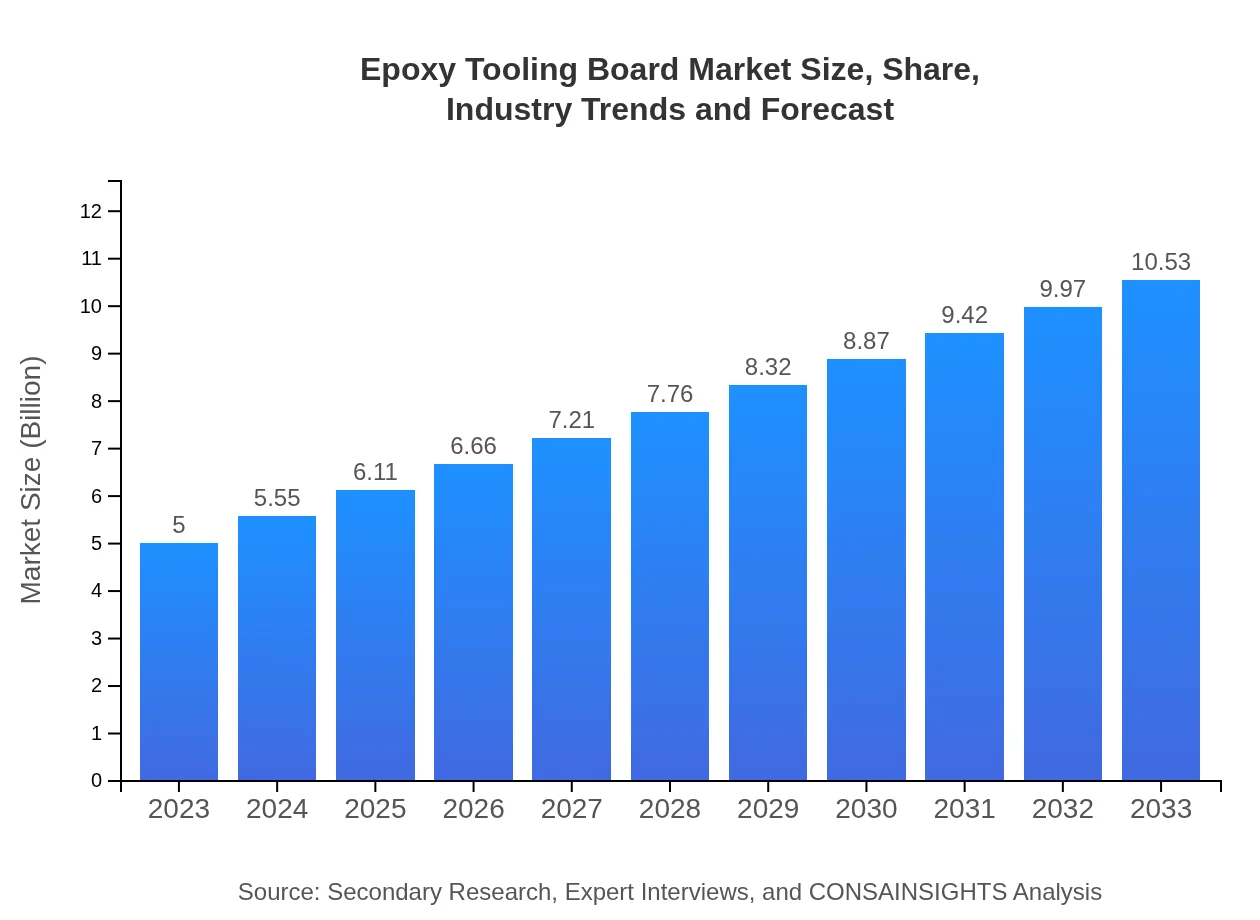

| 2023 Market Size | $5.00 Billion |

| CAGR (2023-2033) | 7.5% |

| 2033 Market Size | $10.53 Billion |

| Top Companies | Gurit Holdings AG, Hexcel Corporation, Boeing , The Dow Chemical Company |

| Last Modified Date | 22 January 2026 |

Epoxy Tooling Board Market Overview

Customize Epoxy Tooling Board Market Report market research report

- ✔ Get in-depth analysis of Epoxy Tooling Board market size, growth, and forecasts.

- ✔ Understand Epoxy Tooling Board's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Epoxy Tooling Board

What is the Market Size & CAGR of Epoxy Tooling Board market in 2023?

Epoxy Tooling Board Industry Analysis

Epoxy Tooling Board Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Epoxy Tooling Board Market Analysis Report by Region

Europe Epoxy Tooling Board Market Report:

The European market is anticipated to grow from USD 1.31 billion in 2023 to USD 2.76 billion by 2033, driven by stringent regulations in aerospace and automotive applications that require high-performance tooling solutions.Asia Pacific Epoxy Tooling Board Market Report:

In the Asia Pacific region, the Epoxy Tooling Board market size in 2023 is valued at USD 1.03 billion and is projected to reach USD 2.17 billion by 2033. The growth is driven by increasing industrial activities and rising aerospace and automotive manufacturing.North America Epoxy Tooling Board Market Report:

North America holds a significant market share with a value of USD 1.79 billion in 2023, estimated to reach USD 3.77 billion by 2033. The robust demand from aerospace and automotive sectors supports this growth, alongside technological advancements in tooling solutions.South America Epoxy Tooling Board Market Report:

South America's market for Epoxy Tooling Boards is valued at USD 0.33 billion in 2023, expected to increase to USD 0.68 billion by 2033. This region is seeing growth in industrial production capabilities, accelerating the demand for tooling applications.Middle East & Africa Epoxy Tooling Board Market Report:

The Middle East and Africa region reported a market size of USD 0.54 billion in 2023, projected to grow to USD 1.13 billion by 2033, spurred by rising investments in infrastructure and automotive industries.Tell us your focus area and get a customized research report.

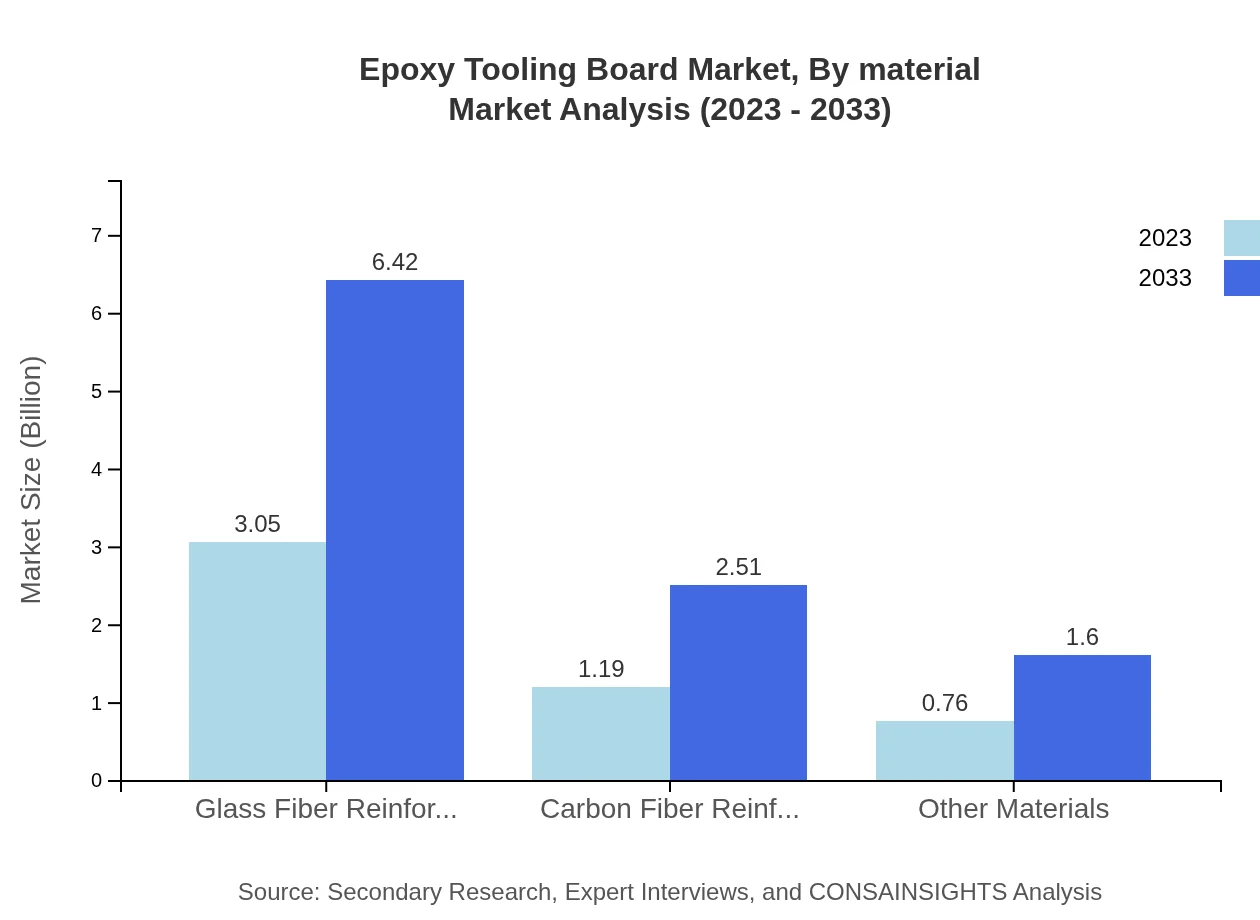

Epoxy Tooling Board Market Analysis By Material

The material types in the Epoxy Tooling Board market include Glass Fiber Reinforced Epoxy, which holds the largest share estimated at 60.99% in 2023, and Carbon Fiber Reinforced Epoxy at 23.81%. The performance characteristics of these materials significantly influence application areas, particularly in high-performance sectors like aerospace and automotive.

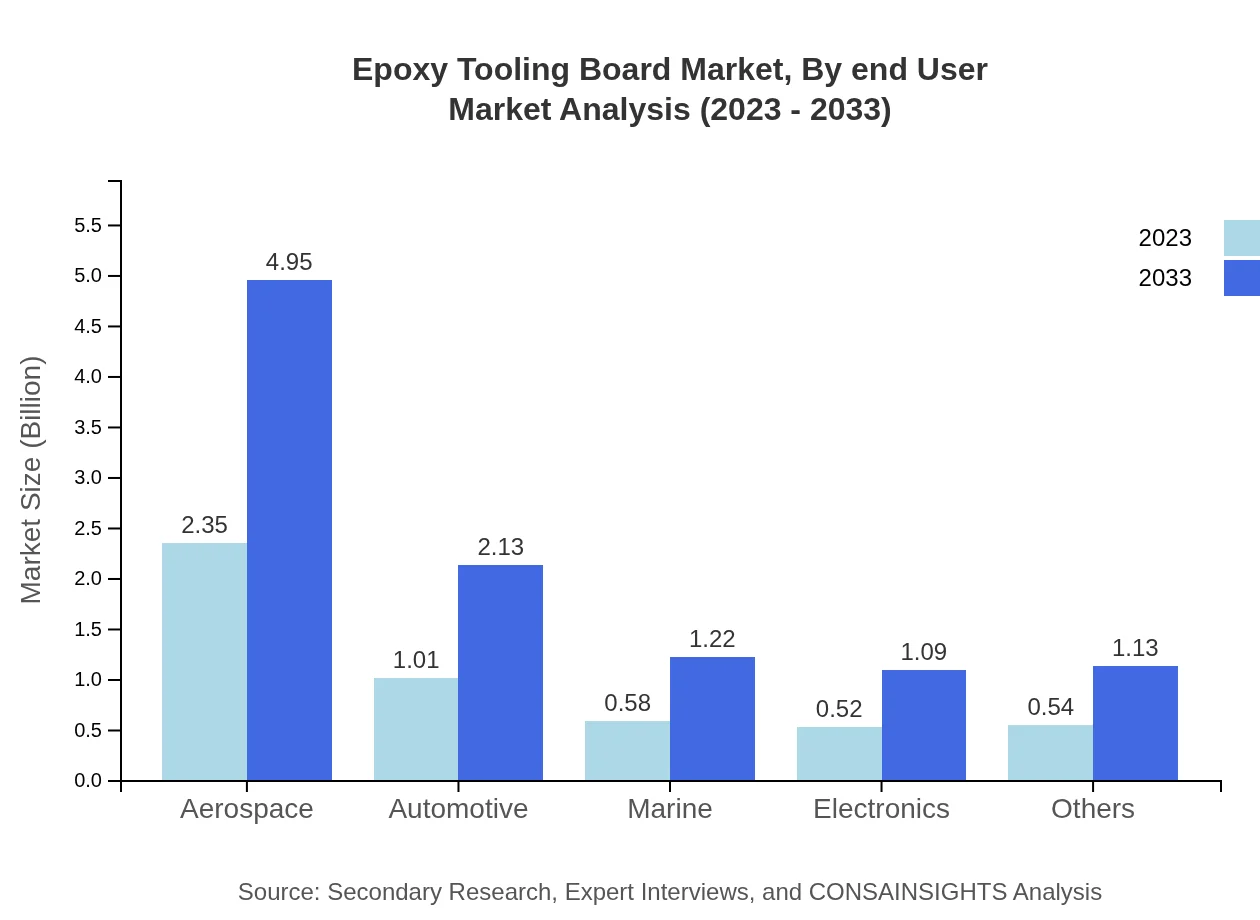

Epoxy Tooling Board Market Analysis By End User

In 2023, the Aerospace sector accounted for 47.06% of the market share, reflecting its reliance on high-quality tooling for composite materials. The automotive industry follows with 20.28%, driven by the push for lightweight designs. Electronics and marine sectors also constitute significant portions, showcasing the versatility of epoxy tooling.

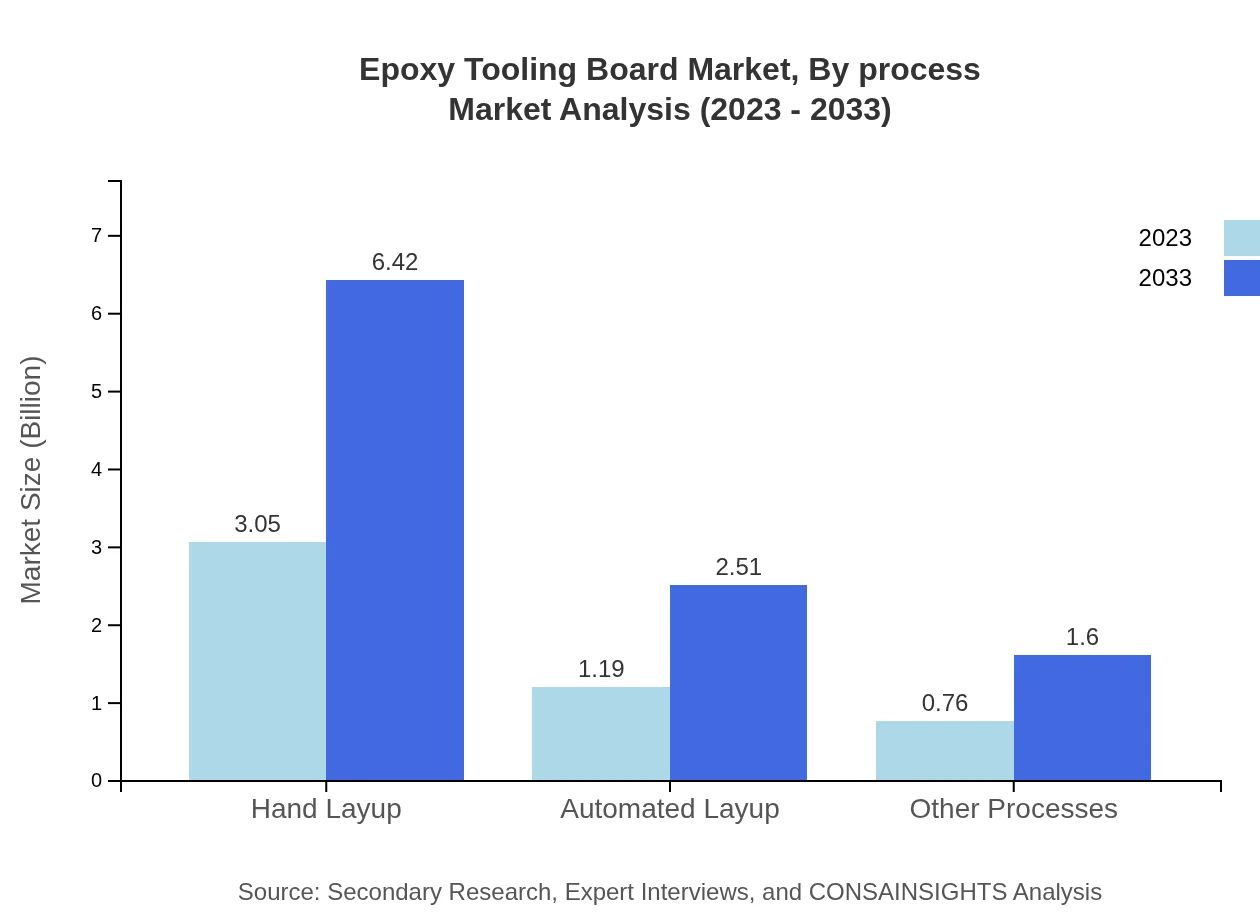

Epoxy Tooling Board Market Analysis By Process

The Hand Layup process dominated the market with a size of USD 3.05 billion in 2023, showcasing traditional manufacturing’s resilience. Automated Layup, with a size of USD 1.19 billion, is increasingly gaining traction for improved efficiency and accuracy.

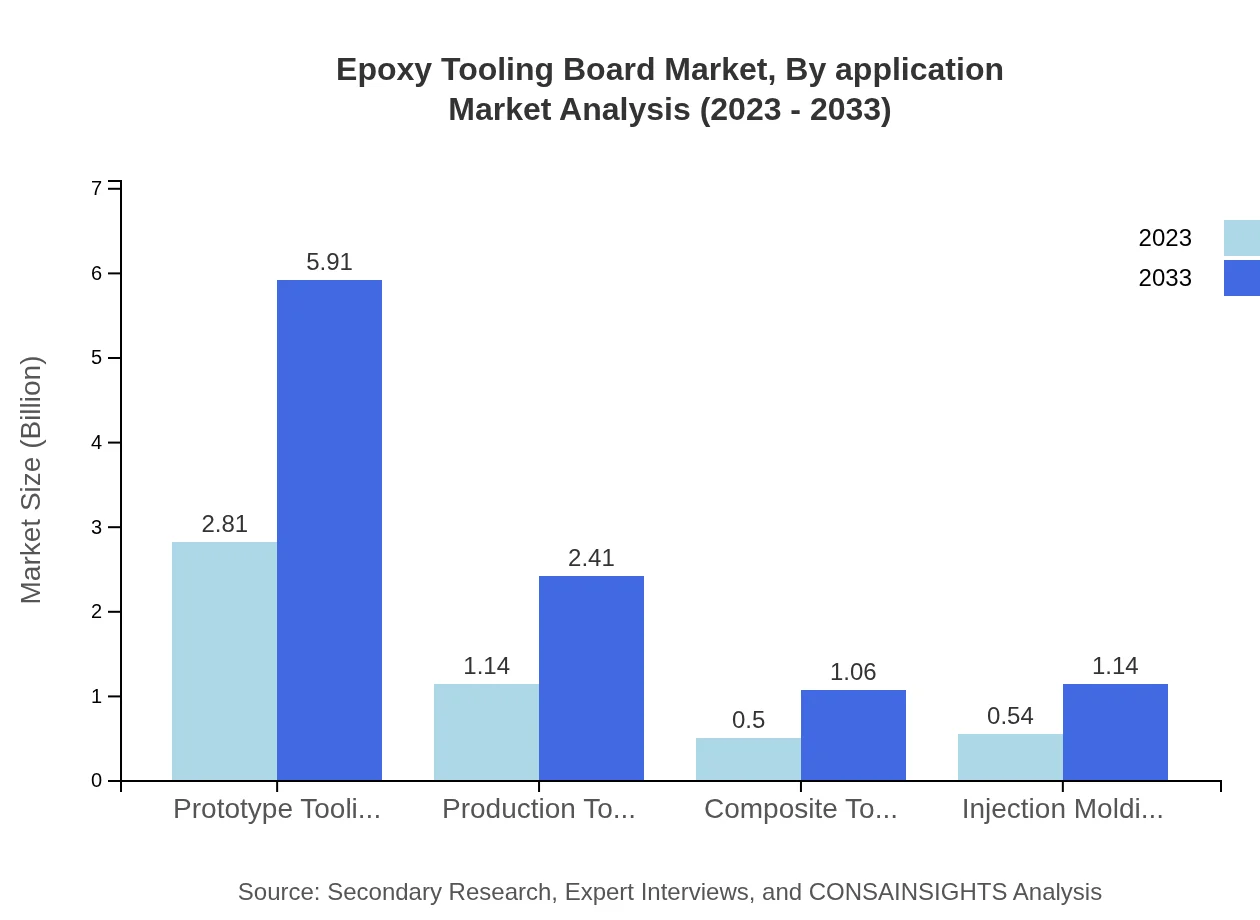

Epoxy Tooling Board Market Analysis By Application

Prototype Tooling leads the applications with a size of USD 2.81 billion, highlighting its importance in new product development. Production tooling and composite tooling follow, showcasing the essential role of epoxy boards in various manufacturing processes.

Epoxy Tooling Board Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Epoxy Tooling Board Industry

Gurit Holdings AG:

A leader in composite materials, Gurit offers a wide range of epoxy tooling solutions tailored for various industries, particularly aerospace and automotive.Hexcel Corporation:

Hexcel is known for its innovative composite materials and epoxy solutions, emphasizing product performance in high-stress applications like aerospace.Boeing :

As a major player in the aerospace sector, Boeing utilizes epoxy tooling boards for its manufacturing processes, contributing to advancements and research in tooling solutions.The Dow Chemical Company:

Dow offers a variety of epoxy products and technologies that cater to the tooling industry, focusing on sustainability and high performance.We're grateful to work with incredible clients.

FAQs

What is the market size of epoxy Tooling Board?

The epoxy-tooling-board market is projected to reach approximately $5 billion by 2033 with a CAGR of 7.5%, indicating robust growth in demand across various manufacturing sectors from 2023 onwards.

What are the key market players or companies in this epoxy Tooling Board industry?

Key players in the epoxy-tooling-board industry include major manufacturers like Hexcel, Gurit, and Scott Bader, who dominate the market with their innovative products and extensive distribution networks.

What are the primary factors driving the growth in the epoxy Tooling Board industry?

Growth in the epoxy-tooling-board market is driven by increasing demand in aerospace and automotive sectors, advancements in composite materials, and rising production capacities to meet evolving manufacturing requirements.

Which region is the fastest Growing in the epoxy Tooling Board?

The fastest-growing region in the epoxy-tooling-board market is North America, with the market projected to expand from $1.79 billion in 2023 to $3.77 billion by 2033, reflecting significant investment in technology and manufacturing.

Does ConsaInsights provide customized market report data for the epoxy Tooling Board industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs within the epoxy-tooling-board industry, providing insights that are crucial for strategic planning and decision-making.

What deliverables can I expect from this epoxy Tooling Board market research project?

Deliverables include comprehensive reports detailing market size, trends, regional breakdowns, competitive analysis, and future growth opportunities, all designed to support informed investment decisions.

What are the market trends of epoxy Tooling Board?

Current market trends for epoxy-tooling-boards include a shift towards sustainable materials, increased adoption of automation in production processes, and a focus on lightweight, high-performance composites in manufacturing.