Level Sensors Market Report

Published Date: 31 January 2026 | Report Code: level-sensors

Level Sensors Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Level Sensors market, including insights on size, trends, technology advancements, and regional performance. The forecast period encompasses 2023 to 2033, offering a valuable perspective for stakeholders.

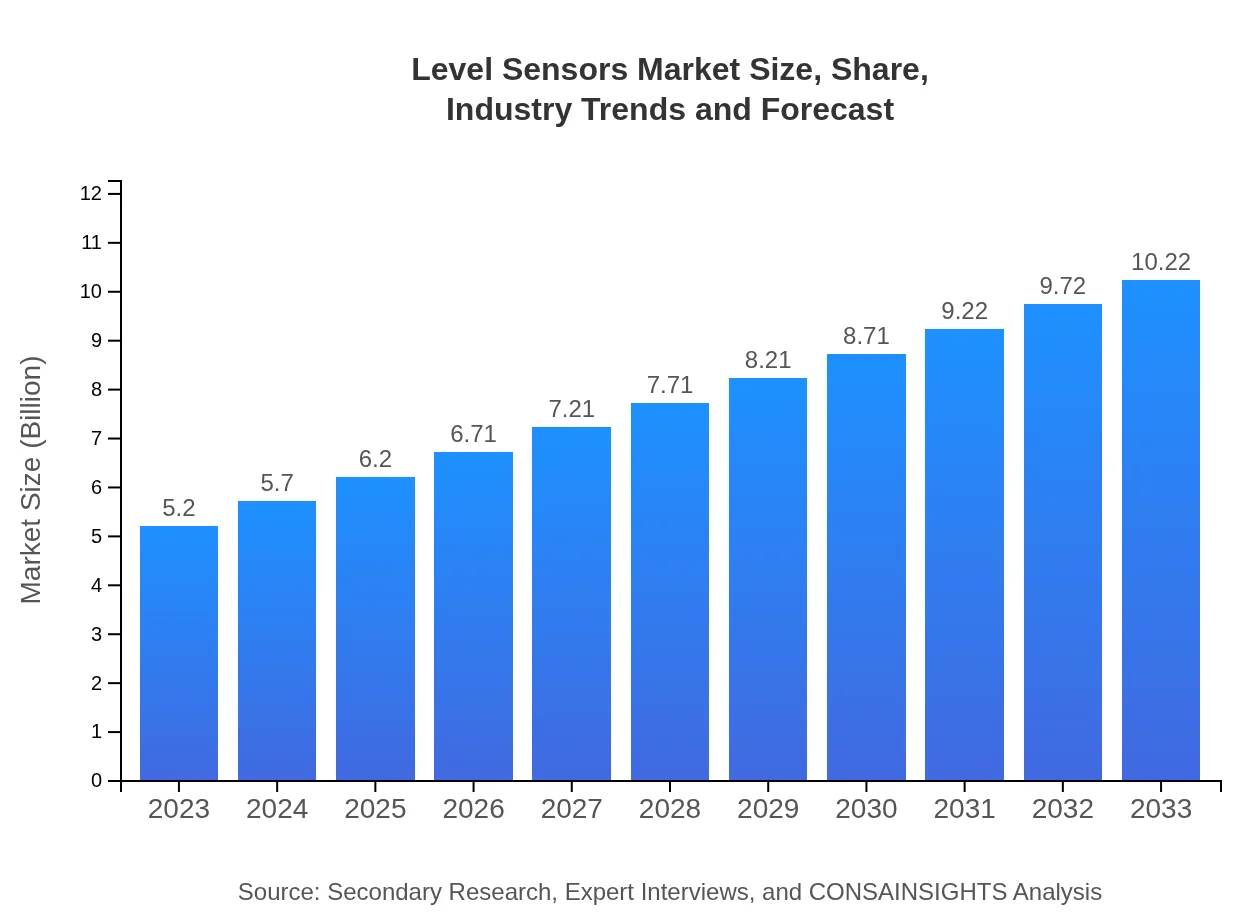

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $5.20 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $10.22 Billion |

| Top Companies | Emerson Electric Co., Honeywell International Inc., Siemens AG, VEGA Grieshaber KG, KROHNE Group |

| Last Modified Date | 31 January 2026 |

Level Sensors Market Overview

Customize Level Sensors Market Report market research report

- ✔ Get in-depth analysis of Level Sensors market size, growth, and forecasts.

- ✔ Understand Level Sensors's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Level Sensors

What is the Market Size & CAGR of Level Sensors market in 2023?

Level Sensors Industry Analysis

Level Sensors Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Level Sensors Market Analysis Report by Region

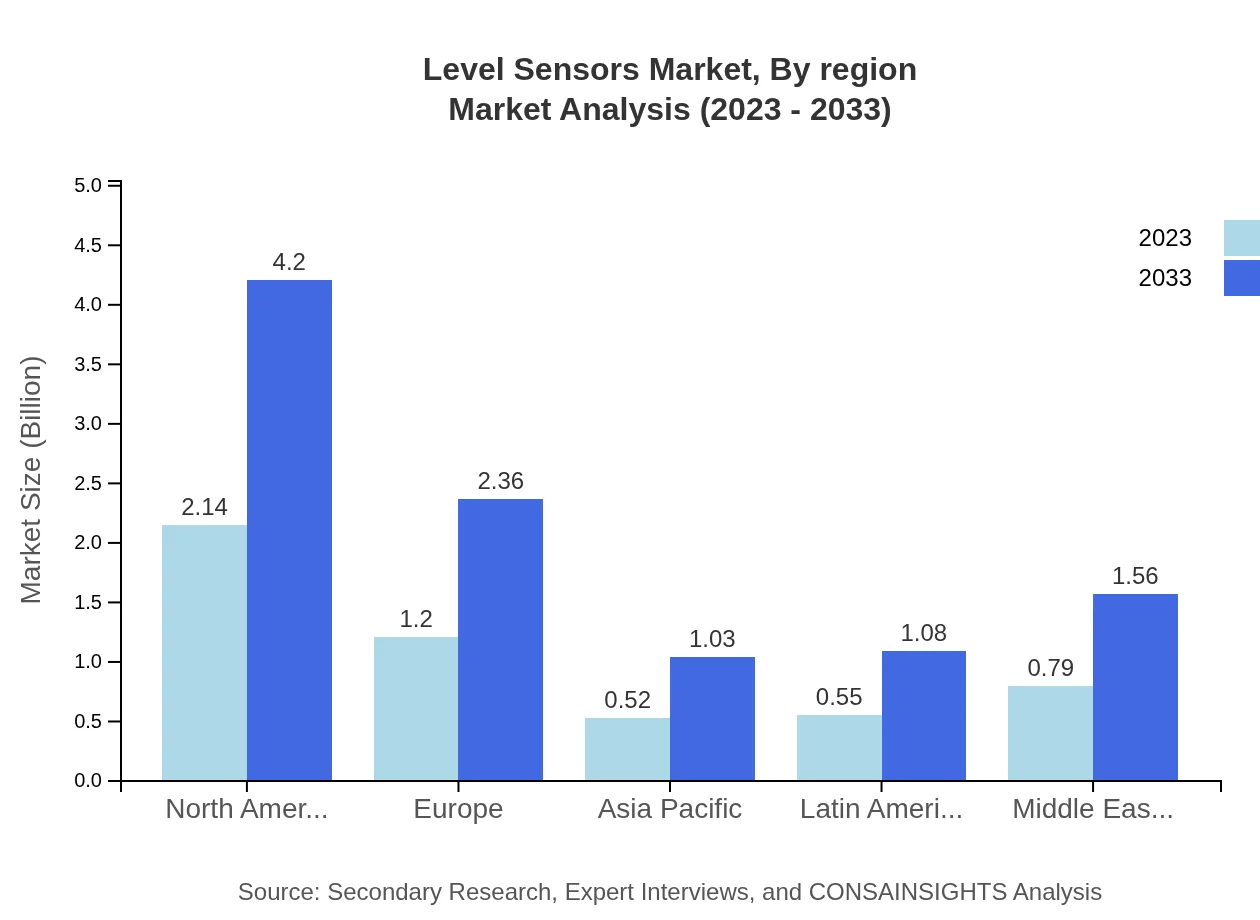

Europe Level Sensors Market Report:

Europe's market is projected to grow from 1.51 billion USD in 2023 to 2.98 billion USD by 2033, fueled by strong regulatory frameworks promoting energy efficiency and sustainability practices across industries.Asia Pacific Level Sensors Market Report:

The Asia Pacific region is expected to witness substantial growth, with the market projected to increase from 1.03 billion USD in 2023 to 2.03 billion USD by 2033. Rapid industrialization and urbanization, coupled with government investments in infrastructure development, contribute to this expansion.North America Level Sensors Market Report:

North America is anticipated to maintain its leadership in the Level Sensors market, with an increase from 1.83 billion USD in 2023 to 3.60 billion USD by 2033. The emphasis on smart manufacturing and automation significantly influences this growth.South America Level Sensors Market Report:

In South America, the Level Sensors market will grow from 0.21 billion USD in 2023 to 0.42 billion USD by 2033, driven by investments in the oil and gas sector, along with improvements in water management systems amidst increasing environmental concerns.Middle East & Africa Level Sensors Market Report:

The Middle East and Africa region is expected to grow from 0.61 billion USD in 2023 to 1.20 billion USD by 2033. Increased oil and gas exploration activities in the region drive the demand for advanced level sensing technologies.Tell us your focus area and get a customized research report.

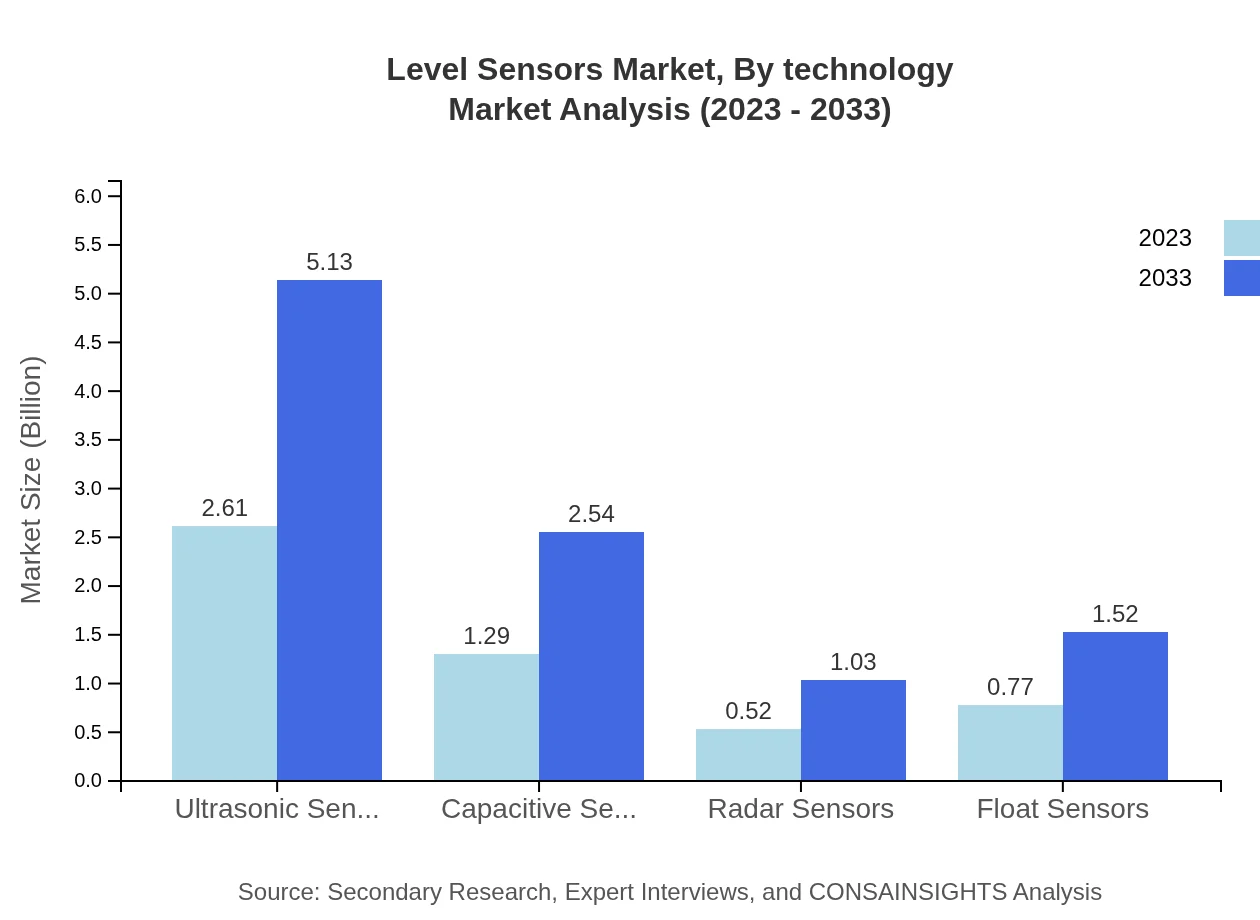

Level Sensors Market Analysis By Technology

The Level Sensors market by technology witnesses significant contributions from ultrasonic sensors, which commanded 50.22% of the market share in 2023. Capacitive sensors are also notable, holding a 24.81% share, while radar and float sensors contribute 10.09% and 14.88%, respectively. These technologies cater to diverse applications, ensuring the market's resilience and adaptability.

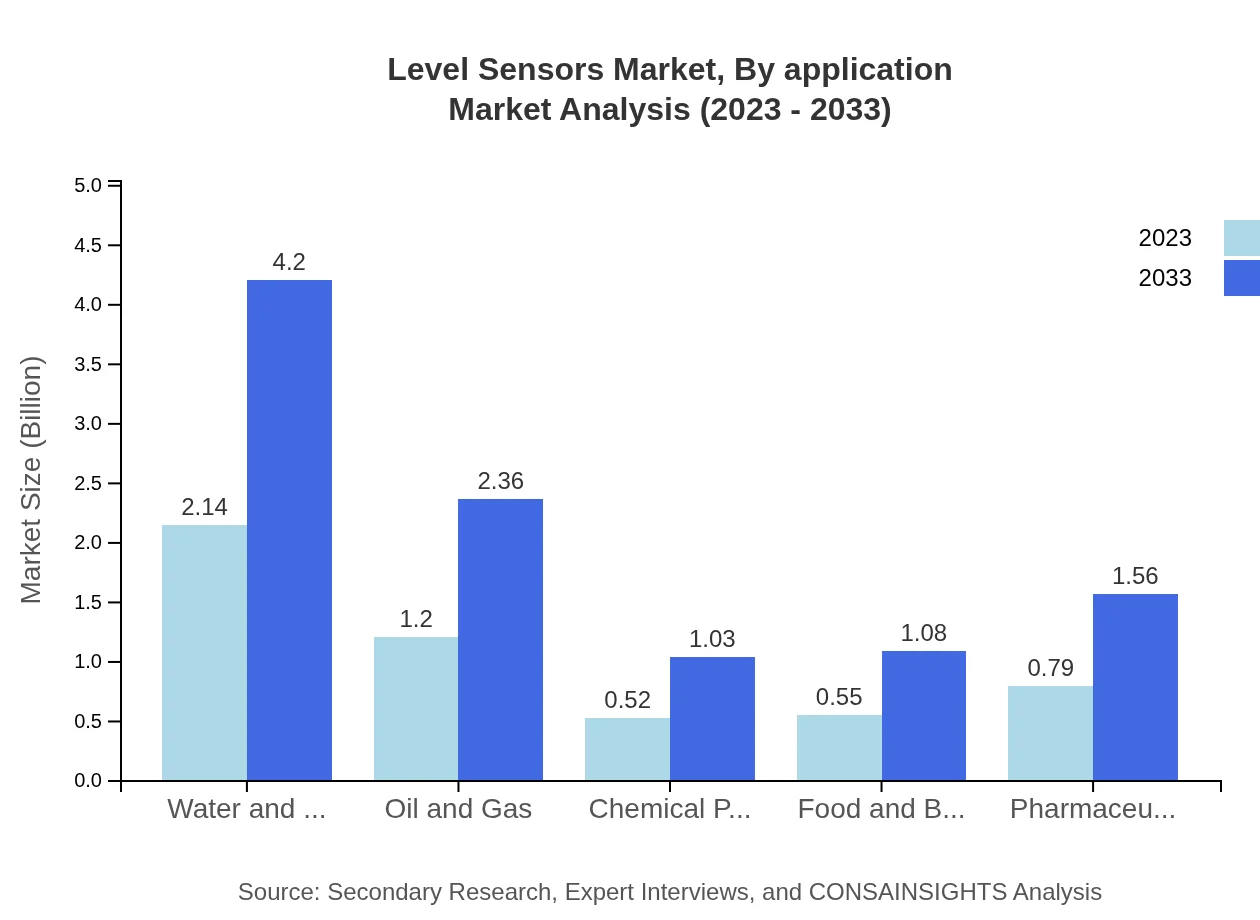

Level Sensors Market Analysis By Application

Applications in the Level Sensors market include water and wastewater management (41.12% share), oil and gas (23.06%), and food and beverage (10.53%). These sectors demand reliable and efficient sensors for monitoring liquids, hence driving innovation and investment in this market.

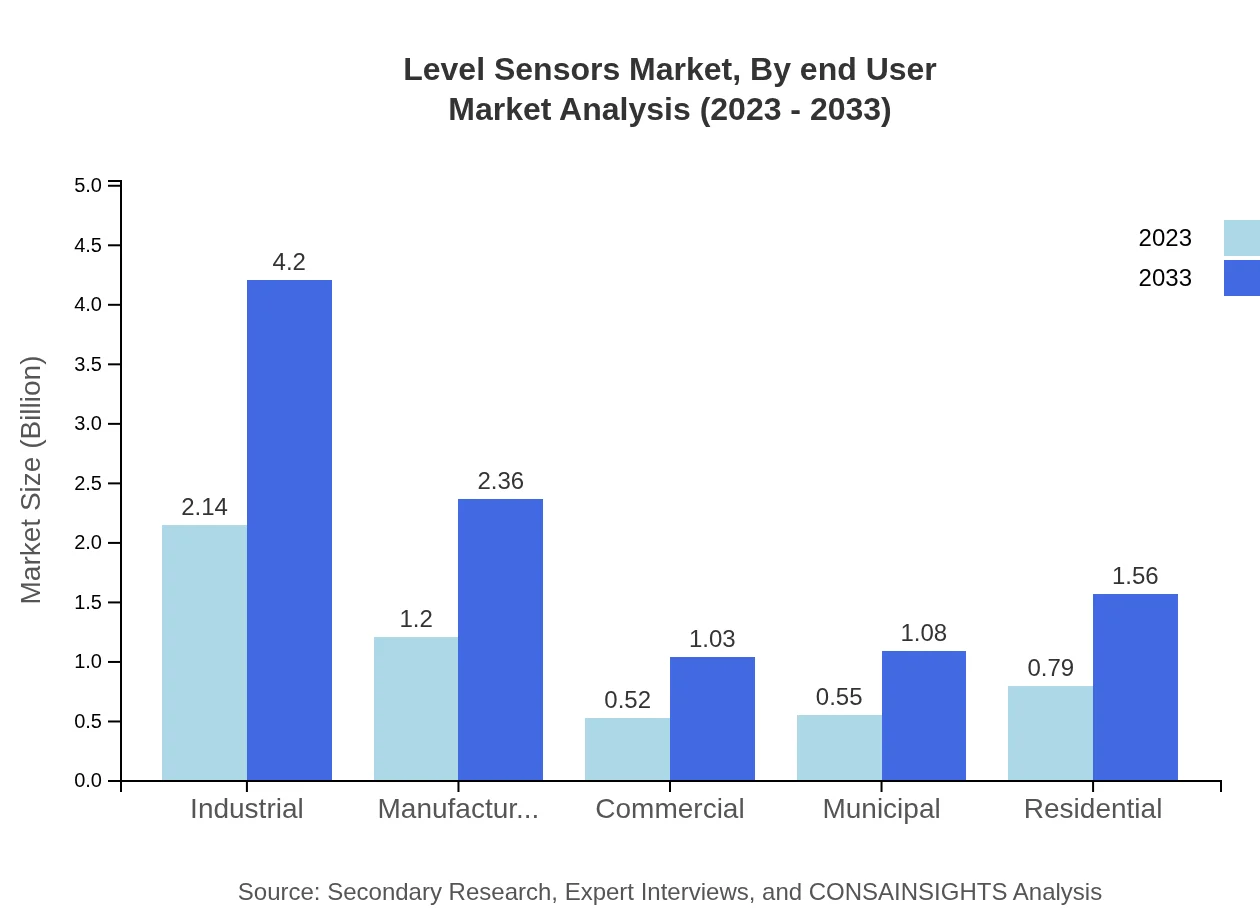

Level Sensors Market Analysis By End User

End-user industries for Level Sensors market are primarily industrial (41.12% share) and manufacturing (23.06%). These sectors emphasize accuracy in level measurement, propelling technological advancements and increased demand for various sensor types.

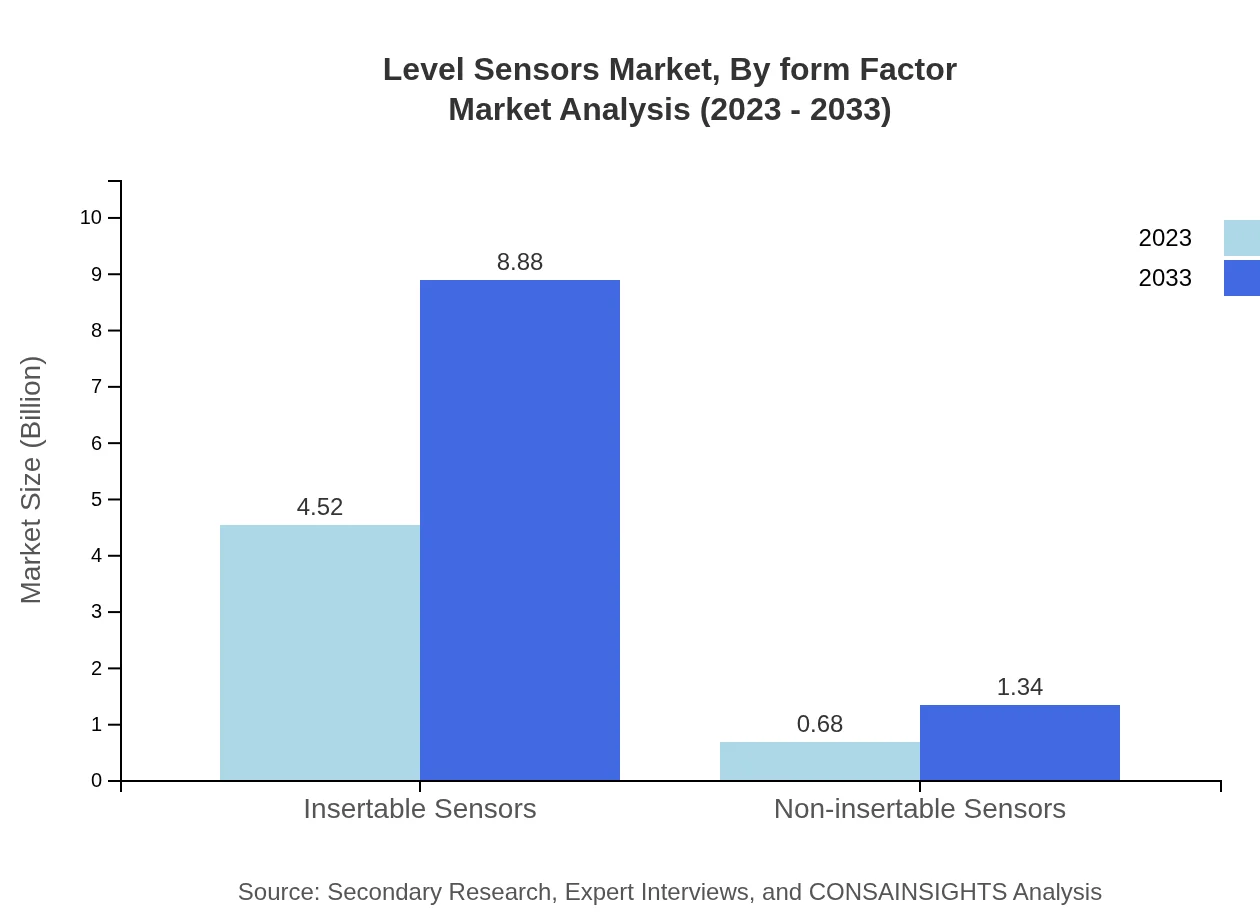

Level Sensors Market Analysis By Form Factor

The market is characterized by both insertable sensors, which dominate with an 86.85% market share due to their efficiency and effectiveness in many applications, alongside non-insertable sensors, which comprise the remaining 13.15%. This division of form factors illustrates the broad deployment of sensor technology.

Level Sensors Market Analysis By Region

Regionally, North America leads with a 41.12% market share, followed by Europe at 23.06%. Asia Pacific is growing steadily, representing 10.06% of the market share. This segmentation reinforces the varying demands and opportunities across different geographical areas.

Level Sensors Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Level Sensors Industry

Emerson Electric Co.:

Emerson is a global leader in automation technology, providing innovative solutions including level measuring devices that enhance efficiency and ensure compliance across various industries.Honeywell International Inc.:

Honeywell is a frontrunner in sensor technology providing a range of level sensors that cater to diverse sectors, prioritizing accuracy and regulatory compliance.Siemens AG:

Siemens is renowned for its comprehensive range of level sensors that integrate seamlessly with automation technologies, facilitating smart manufacturing practices.VEGA Grieshaber KG:

VEGA specializes in level and pressure measurement technologies and has pioneered various sensors that are widely used in water management and industrial applications.KROHNE Group:

KROHNE offers advanced level measurement solutions tailored for numerous industries, from chemical processing to food and beverage, focusing on innovation and reliability.We're grateful to work with incredible clients.

FAQs

What is the market size of Level Sensors?

The global level sensors market is projected to reach $5.2 billion by 2033, growing at a CAGR of 6.8% from its current value in 2023. This growth reflects the increasing demand for automation in various industries.

What are the key market players or companies in the Level Sensors industry?

Key players in the level sensors market include industry leaders such as Honeywell, Siemens, and Endress+Hauser. These companies are recognized for their innovative technologies and commitment to quality, driving industry standards and competition.

What are the primary factors driving the growth in the Level Sensors industry?

Major drivers of growth in the level sensors market include advancements in automation technology, increasing industrialization, and the rising demand for precise measurement solutions in sectors such as oil and gas, water treatment, and manufacturing.

Which region is the fastest Growing in the Level Sensors market?

The Asia Pacific region is the fastest-growing market for level sensors, expected to grow from $1.03 billion in 2023 to $2.03 billion by 2033. The increasing industrial sector in countries like China and India fuels this expansion.

Does ConsaInsights provide customized market report data for the Level Sensors industry?

Yes, ConsaInsights offers customized market report data tailored to the specific needs of clients in the level sensors industry. This includes detailed analytics, regional insights, and forecasts to support informed decision-making.

What deliverables can I expect from this Level Sensors market research project?

Deliverables from the level sensors market research project include comprehensive reports, market analysis, trend forecasts, segment data, and regional insights that provide stakeholders with actionable intelligence for strategic planning.

What are the market trends of Level Sensors?

Key market trends in level sensors include the shift towards smart sensors, increased adoption in IoT applications, and a growing emphasis on environmentally sustainable technologies, driving innovation and development in the sector.